specifications NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3163 of 3745

MA-28

< SERVICE INFORMATION >

ENGINE MAINTENANCE (MR18DE)

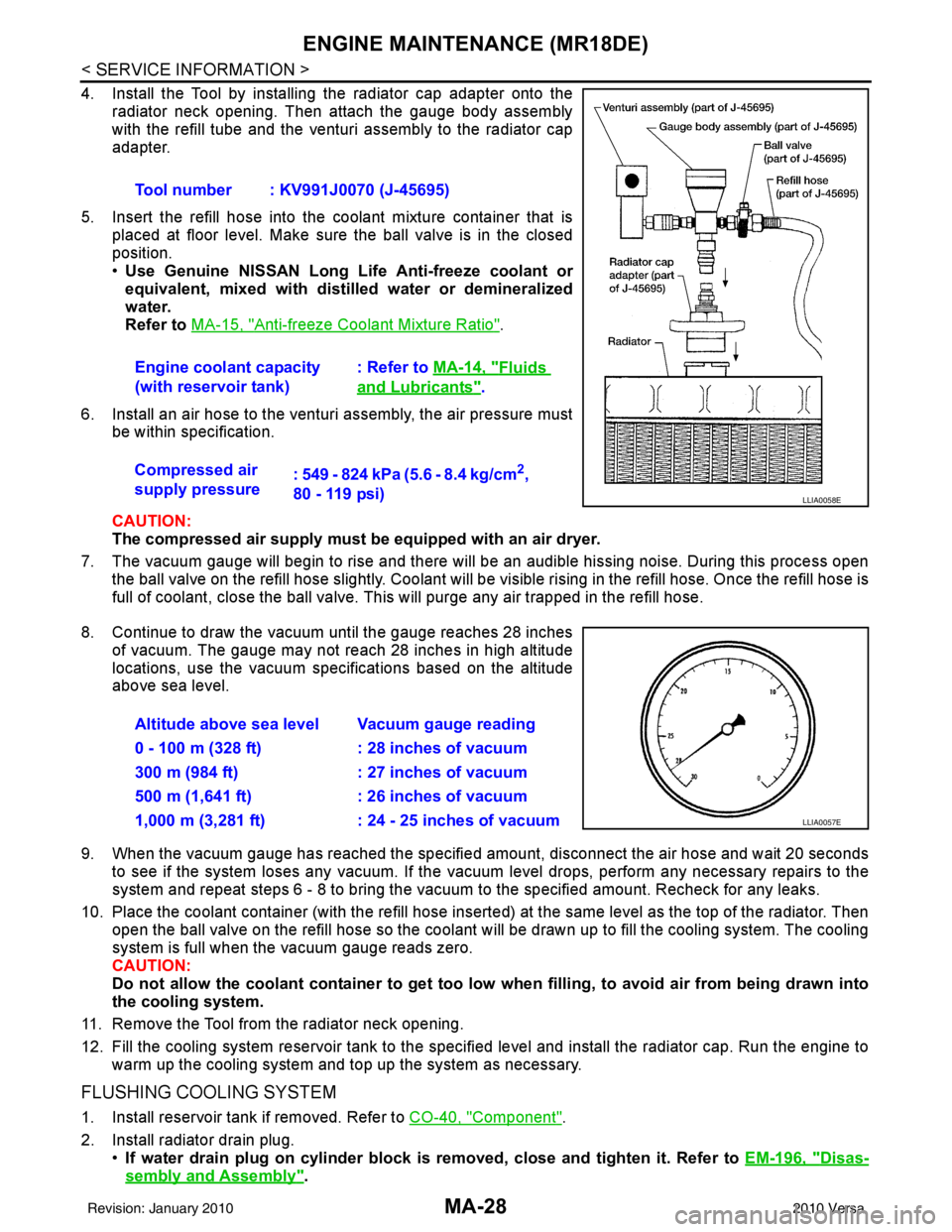

4. Install the Tool by installing the radiator cap adapter onto theradiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

•Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, "

Anti-freeze Coolant Mixture Ratio".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

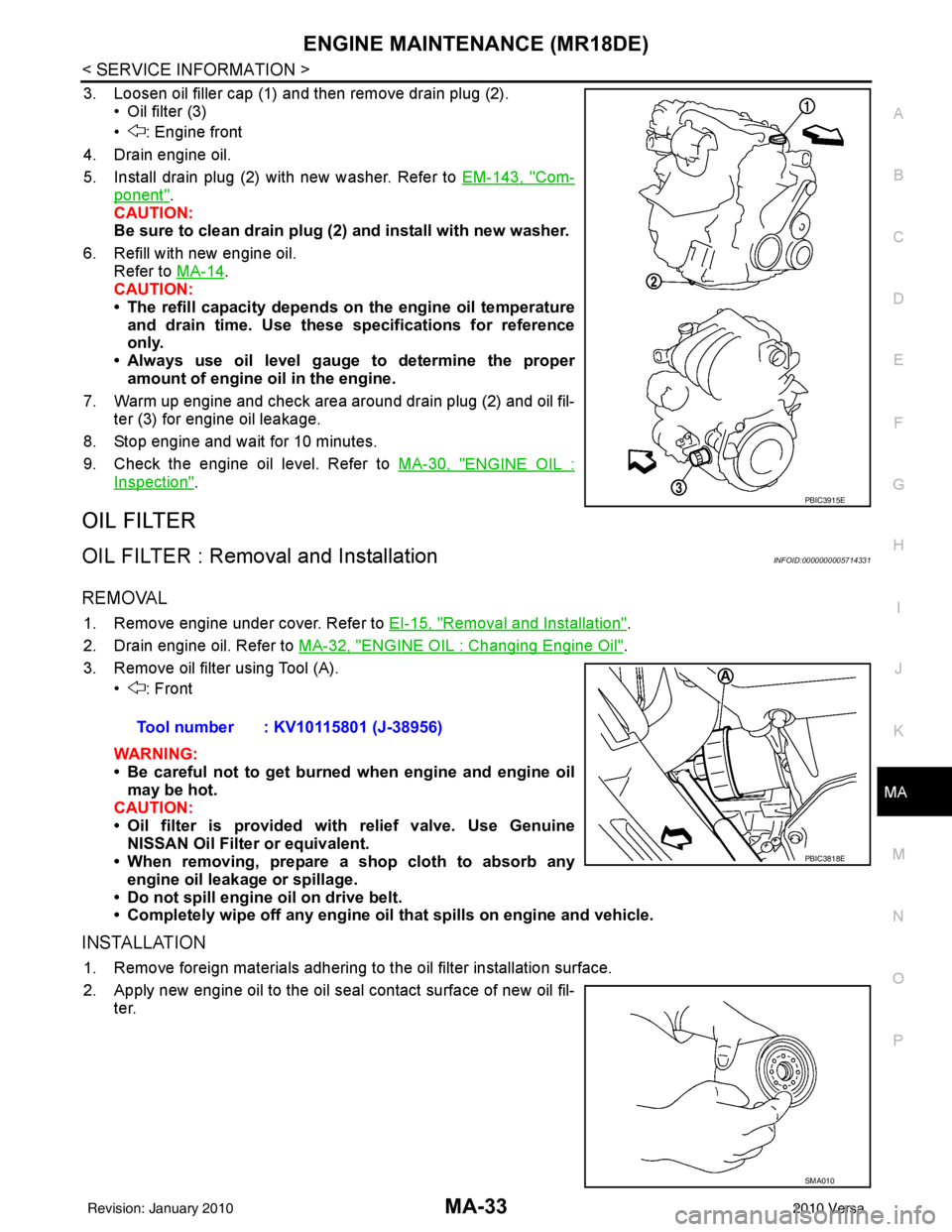

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose insert ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-40, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-196, "

Disas-

sembly and Assembly".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to

MA-14, "

Fluids

and Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: January 20102010 Versa

Page 3168 of 3745

ENGINE MAINTENANCE (MR18DE)MA-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

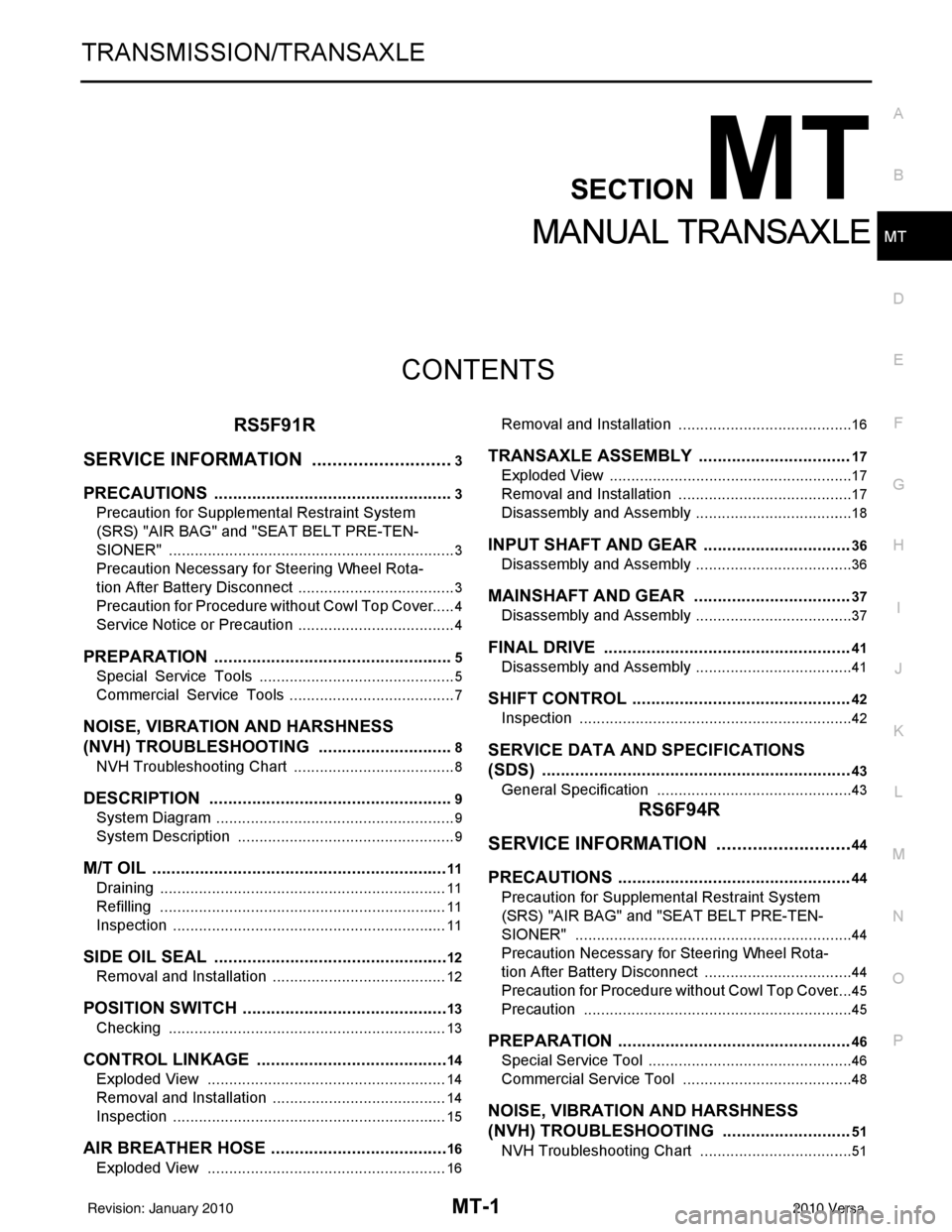

3. Loosen oil filler cap (1) and then remove drain plug (2). • Oil filter (3)

• : Engine front

4. Drain engine oil.

5. Install drain plug (2) with new washer. Refer to EM-143, "

Com-

ponent".

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14

.

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to MA-30, "

ENGINE OIL :

Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000005714331

REMOVAL

1. Remove engine under cover. Refer to EI-15, "Removal and Installation".

2. Drain engine oil. Refer to MA-32, "

ENGINE OIL : Changing Engine Oil".

3. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine

NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

PBIC3915E

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Revision: January 20102010 Versa

Page 3185 of 3745

MT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

SECTION MT

A

B

MT

N

O P

CONTENTS

MANUAL TRANSAXLE

RS5F91R

SERVICE INFORMATION .. ..........................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Service Notice or Precaution .....................................4

PREPARATION ...................................................5

Special Service Tools ........................................ ......5

Commercial Service Tools .......................................7

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

8

NVH Troubleshooting Chart ................................ ......8

DESCRIPTION ....................................................9

System Diagram .................................................. ......9

System Description ...................................................9

M/T OIL ...............................................................11

Draining ...................................................................11

Refilling ...................................................................11

Inspection ................................................................11

SIDE OIL SEAL ..................................................12

Removal and Installation .........................................12

POSITION SWITCH ........................................ ....13

Checking ............................................................. ....13

CONTROL LINKAGE .........................................14

Exploded View .................................................... ....14

Removal and Installation .........................................14

Inspection ............................................................ ....15

AIR BREATHER HOSE ......................................16

Exploded View .................................................... ....16

Removal and Installation ..................................... ....16

TRANSAXLE ASSEMBLY ................................17

Exploded View .........................................................17

Removal and Installation .........................................17

Disassembly and Assembly .....................................18

INPUT SHAFT AND GEAR ...............................36

Disassembly and Assembly .....................................36

MAINSHAFT AND GEAR .................................37

Disassembly and Assembly .....................................37

FINAL DRIVE ....................................................41

Disassembly and Assembly .....................................41

SHIFT CONTROL ..............................................42

Inspection ................................................................42

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

43

General Specification ..............................................43

RS6F94R

SERVICE INFORMATION .. .........................

44

PRECAUTIONS .................................................44

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

44

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

44

Precaution for Procedure without Cowl Top Cover ....45

Precaution ...............................................................45

PREPARATION .................................................46

Special Service Tool ................................................46

Commercial Service Tool ........................................48

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

51

NVH Troubleshooting Chart ....................................51

Revision: January 20102010 Versa

Page 3186 of 3745

MT-2

DESCRIPTION ...................................................52

Cross-Sectional View .......................................... ...52

M/T OIL ..............................................................54

Changing M/T Oil ................................................. ...54

Checking M/T Oil ....................................................54

VEHICLE SPEED SENSOR ..............................55

Removal and Installation ..................................... ...55

SIDE OIL SEAL .................................................56

Removal and Installation ..................................... ...56

POSITION SWITCH ...........................................57

Checking .............................................................. ...57

CONTROL LINKAGE ........................................58

Component of Control Device and Cable ............ ...58

Removal and Installation ........................................58

AIR BREATHER HOSE .....................................60

Removal and Installation ..................................... ...60

TRANSAXLE ASSEMBLY ................................61

Component .......................................................... ...61

Removal and Installation .........................................61

Disassembly and Assembly ................................. ...62

INPUT SHAFT AND GEARS .............................80

Disassembly and Assembly ................................. ...80

MAINSHAFT AND GEARS ...............................85

Disassembly and Assembly ................................. ...85

REVERSE IDLER SHAFT AND GEARS ...........90

Disassembly and Assembly ................................. ...90

FINAL DRIVE .....................................................92

Disassembly and Assembly ....................................92

SHIFT CONTROL ..............................................94

Inspection ............................................................. ...94

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

95

General Specification ........................................... ...95

Revision: January 20102010 Versa

Page 3227 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAX NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAX](/img/5/57397/w960_57397-3226.png)

SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAXLE

Transaxle type RS5F91R

Engine type HR16DE

Number of speed 5

Synchromesh type Warner

Shift pattern

Gear ratio 1st 3.7272

2nd 2.0476

3rd 1.3928

4th 1.0294

5th 0.8205

Reverse 3.5454

Final gear 4.0666

Number of teeth Input gear 1st 11

2nd 21

3rd 28

4th 34

5th 39

Reverse 11

Main gear 1st 41

2nd 43

3rd 39

4th 35

5th 32

Reverse 39

Reverse idler gear 26

Final gear Final gear/Pinion 61/15

Side gear/Pinion

mate gear 13/9

Oil capacity (Reference) (US pt, Imp pt)Approx. 2.6 (5-1/2, 4-5/8)

Remarks Reverse synchronizer Installed

Double-cone synchronizer 1st and 2nd

SCIA0821E

Revision: January 20102010 Versa

Page 3279 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax](/img/5/57397/w960_57397-3278.png)

SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transaxle type RS6F94R

Engine type MR18DE

Number of speed 6

Synchromesh type Warner

Shift pattern

Gear ratio 1st 3.727

2nd 2.105

3rd 1.452

4th 1.171

5th 0.971

6th 0.811

Reverse 3.687

Final gear 3.933

Number of teeth Input gear 1st 11

2nd 19

3rd 31

4th 35

5th 35

6th 37

Reverse 11

Main gear 1st 41

2nd 40

3rd 45

4th 41

5th 34

6th 30

Reverse 42

Reverse idler gear Input/Output 28/29

Final gear Final gear/Pinion 59/15

Side gear/Pinion

mate gear 21/18

Oil capacity (Reference) (US pt, Imp pt)Approx. 2.0 (4-1/4, 3-1/2)

Remarks Reverse synchronizer Installed

Triple-cone synchronizer 1st and 2nd

PCIB1769E

Revision: January 20102010 Versa

Page 3281 of 3745

MTC-2

DUCTS AND GRILLES ......................................70

Removal and Installation ..................................... ...70

REFRIGERANT LINES ......................................75

HFC-134a (R-134a) Service Procedure .............. ...75

Component .............................................................77

Removal and Installation of Compressor -

HR16DE .................................................................

79

Removal and Installation of Compressor -

MR18DE .................................................................

81

Removal and Installation for Compressor Clutch -

Type 1 .................................................................. ...

82

Removal and Installation for Compressor Clutch -

Type 2 .................................................................. ...

84

Removal and Installation of Low-Pressure Flexi-

ble Hose .................................................................

87

Removal and Installation of High-Pressure Flexi-

ble Hose .................................................................

88

Removal and Installation of High-Pressure Pipe . ...89

Removal and Installation of Refrigerant Pressure

Sensor .....................................................................

89

Removal and Installation of Condenser ..................90

Removal and Installation of Liquid Tank .................90

Removal and Installation of Evaporator ............... ...91

Removal and Installation of Expansion Valve .........92

Checking of Refrigerant Leaks ................................92

Checking System for Leaks Using the Fluorescent

Leak Detector ..........................................................

93

Dye Injection ...........................................................93

Electronic Refrigerant Leak Detector ......................93

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

96

Compressor ......................................................... ...96

Oil ............................................................................96

Refrigerant ..............................................................96

Revision: January 20102010 Versa

Page 3286 of 3745

PRECAUTIONSMTC-7

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

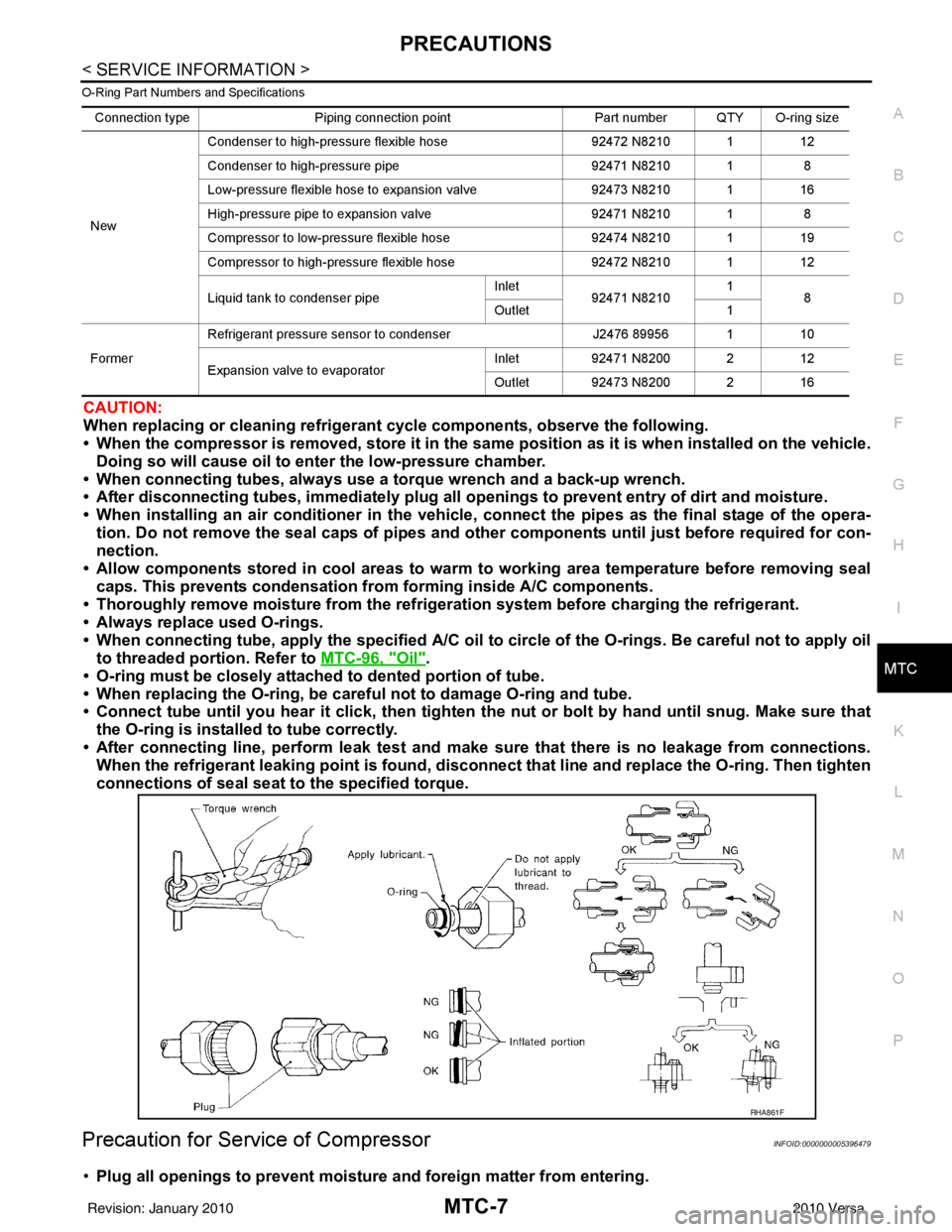

O-Ring Part Numbers and Specifications

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the sam e position as it is when installed on the vehicle.

Doing so will cause oil to en ter the low-pressure chamber.

• When connecting tubes, always use a to rque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all op enings to prevent entry of dirt and moisture.

• When installing an air conditione r in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply the speci fied A/C oil to circle of the O-rings. Be careful not to apply oil

to threaded portion. Refer to MTC-96, "

Oil".

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Precaution for Service of CompressorINFOID:0000000005396479

•Plug all openings to prevent moisture and foreign matter from entering.

Connection typePiping connection point Part number QTY O-ring size

New Condenser to high-pressure flexible hose

92472 N8210 112

Condenser to high-pressure pipe 92471 N8210 18

Low-pressure flexible hose to expansion valve 92473 N8210 116

High-pressure pipe to expansion valve 92471 N8210 18

Compressor to low-pressure flexible hose 92474 N8210 119

Compressor to high-pressure flexible hose 92472 N8210 112

Liquid tank to condenser pipe Inlet

92471 N8210 1

8

Outlet 1

Former Refrigerant pressure sensor to condenser

J2476 89956 110

Expansion valve to evaporator Inlet

92471 N8200 2 12

Outlet 92473 N8200 2 16

RHA861F

Revision: January 20102010 Versa

Page 3294 of 3745

REFRIGERATION SYSTEMMTC-15

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

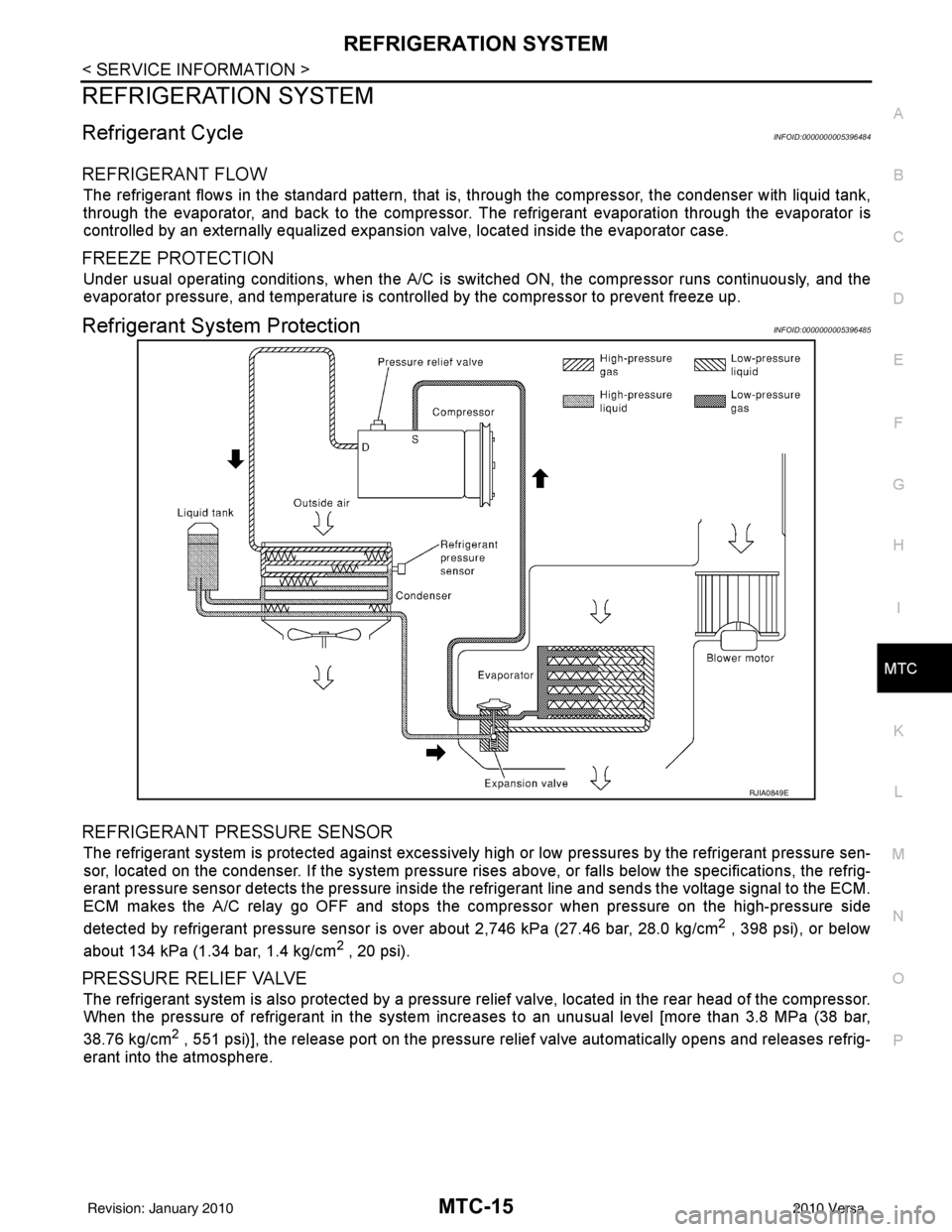

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000005396484

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. T he refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is s witched ON, the compressor runs continuously, and the

evaporator pressure, and temperature is controlled by the compressor to prevent freeze up.

Refrigerant System ProtectionINFOID:0000000005396485

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above, or falls below the specifications, the refrig-

erant pressure sensor detects the pressure inside t he refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high-pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (27.46 bar, 28.0 kg/cm

2 , 398 psi), or below

about 134 kPa (1.34 bar, 1.4 kg/cm

2 , 20 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system in creases to an unusual level [more than 3.8 MPa (38 bar,

38.76 kg/cm

2 , 551 psi)], the release port on the pressure relief valve automatically opens and releases refrig-

erant into the atmosphere.

RJIA0849E

Revision: January 20102010 Versa

Page 3375 of 3745

MTC-96

< SERVICE INFORMATION >

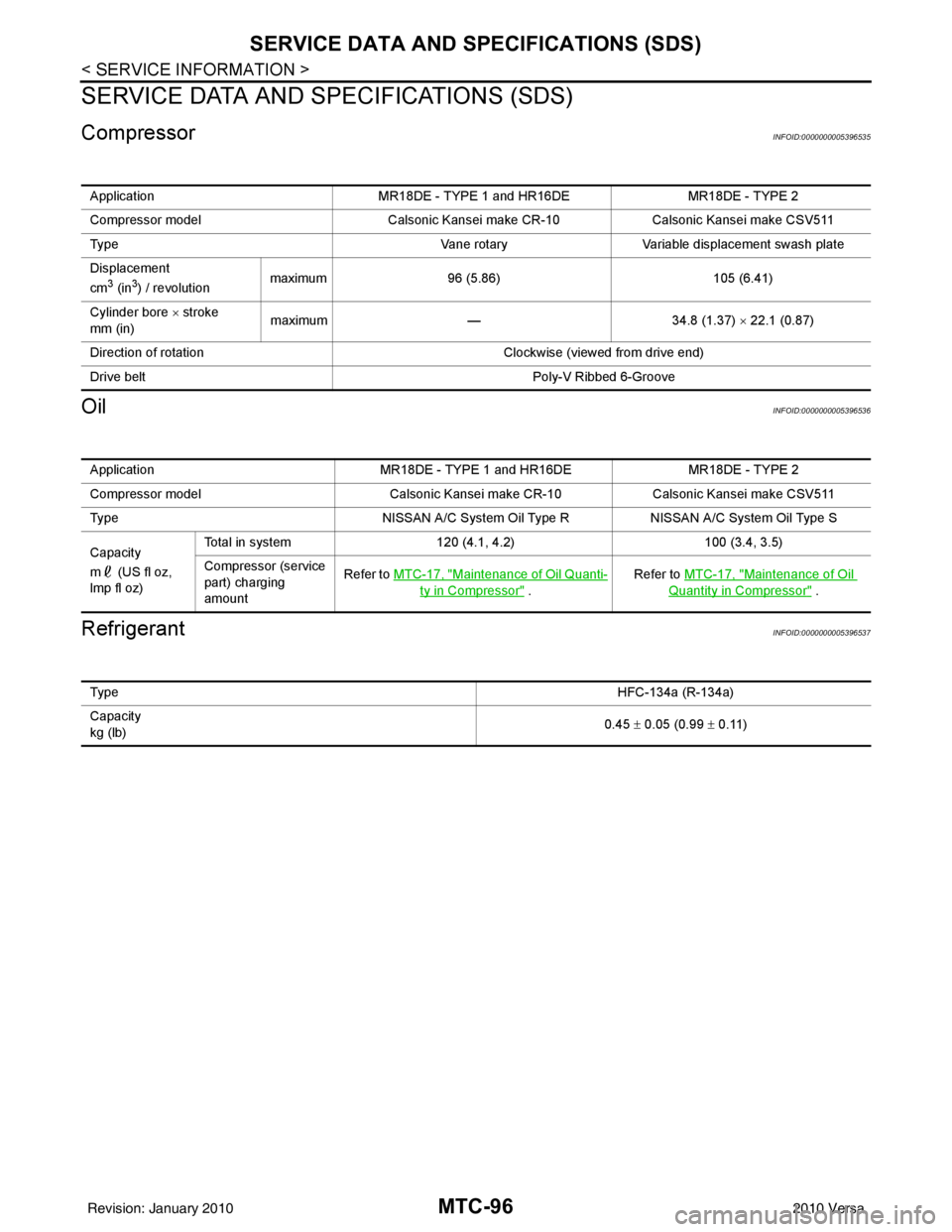

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

CompressorINFOID:0000000005396535

OilINFOID:0000000005396536

RefrigerantINFOID:0000000005396537

ApplicationMR18DE - TYPE 1 and HR16DE MR18DE - TYPE 2

Compressor model Calsonic Kansei make CR-10Calsonic Kansei make CSV511

Type Vane rotaryVariable displacement swash plate

Displacement

cm

3 (in3) / revolution maximum

96 (5.86) 105 (6.41)

Cylinder bore × stroke

mm (in) maximum

— 34.8 (1.37) × 22.1 (0.87)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly-V Ribbed 6-Groove

ApplicationMR18DE - TYPE 1 and HR16DE MR18DE - TYPE 2

Compressor model Calsonic Kansei make CR-10Calsonic Kansei make CSV511

Type NISSAN A/C System Oil Type RNISSAN A/C System Oil Type S

Capacity

m (US fl oz,

lmp fl oz) Total in system

120 (4.1, 4.2) 100 (3.4, 3.5)

Compressor (service

part) charging

amount Refer to

MTC-17, "

Maintenance of Oil Quanti-

ty in Compressor" . Refer to MTC-17, "

Maintenance of Oil

Quantity in Compressor" .

Ty p e

HFC-134a (R-134a)

Capacity

kg (lb) 0.45

± 0.05 (0.99 ± 0.11)

Revision: January 20102010 Versa