specifications NISSAN TIIDA 2010 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2666 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-19

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

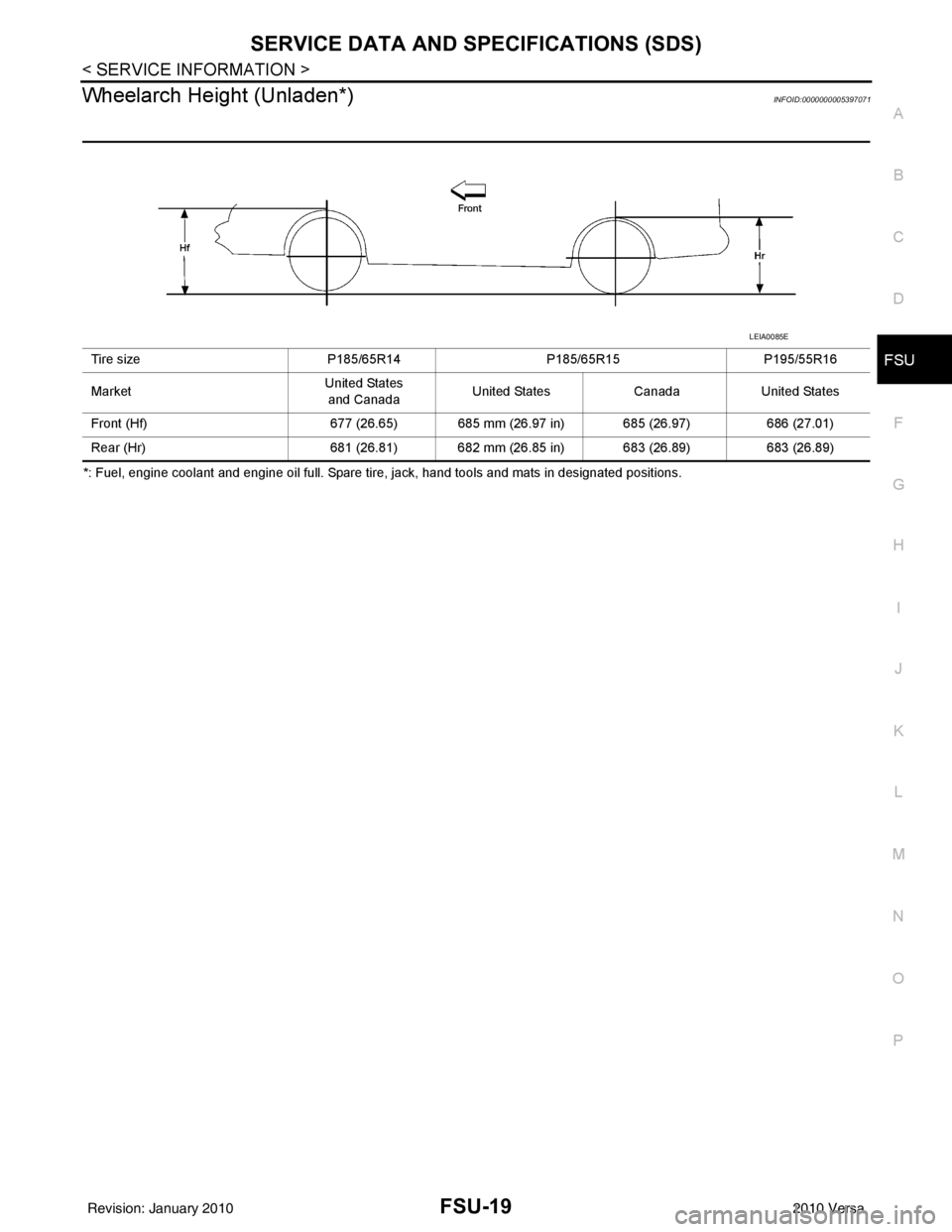

Wheelarch Height (Unladen*)INFOID:0000000005397071

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Tire size

P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65) 685 mm (26.97 in) 685 (26.97) 686 (27.01)

Rear (Hr) 681 (26.81) 682 mm (26.85 in) 683 (26.89) 683 (26.89)

LEIA0085E

Revision: January 20102010 Versa

Page 2687 of 3745

HOW TO USE THIS MANUALGI-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PFR, RR Front, RearLH, RH Left-Hand, Right-Hand M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range Second [Gear (2GR)]

2

12nd range First [Gear (1GR)]

1

21st range Second [Gear (2GR)]

1

11st range First [Gear (1GR)]

ABBREVIATION

DESCRIPTION

Revision: January 20102010 Versa

Page 2690 of 3745

GI-24

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

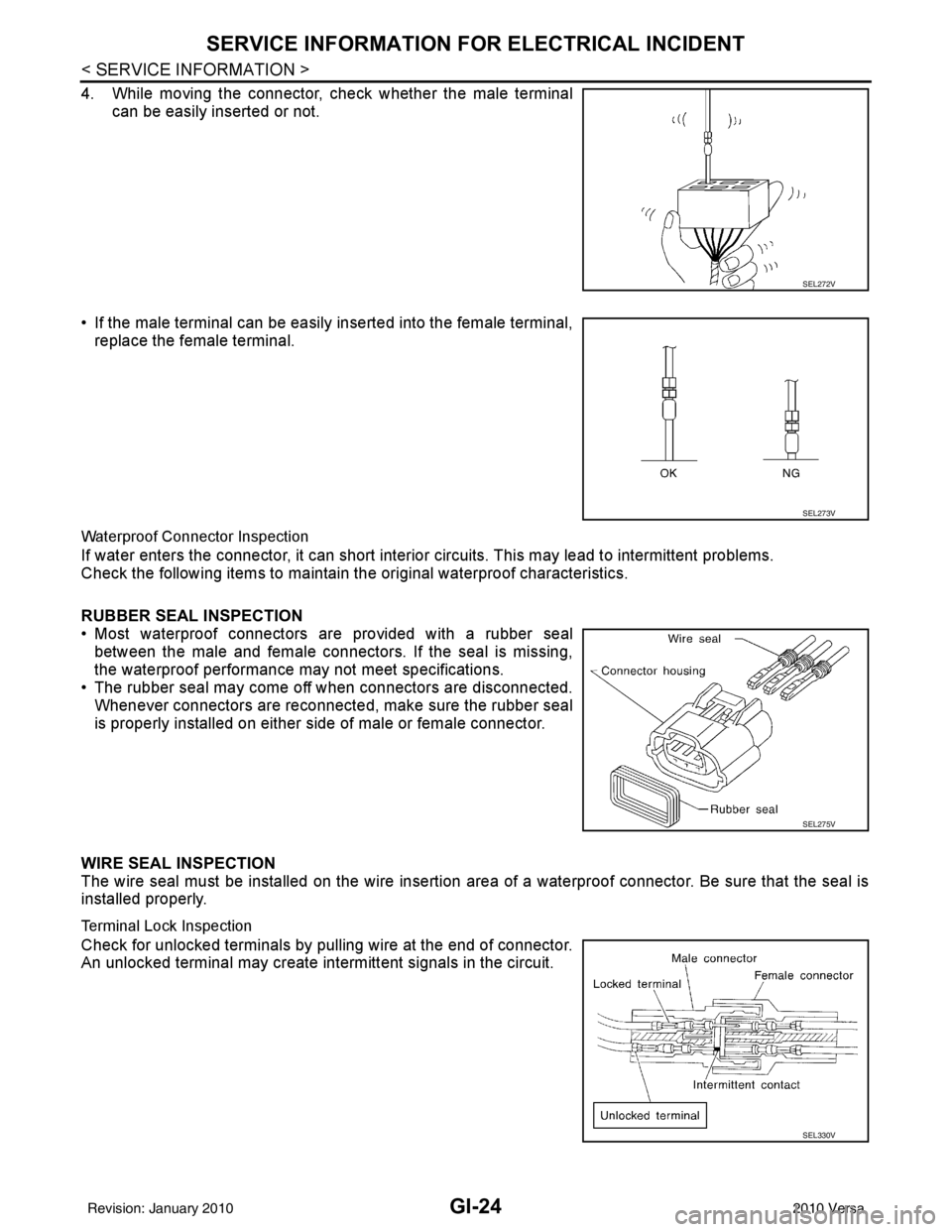

4. While moving the connector, check whether the male terminalcan be easily inserted or not.

• If the male terminal can be easily inserted into the female terminal, replace the female terminal.

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION

• Most waterproof connectors are provided with a rubber seal between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

The wire seal must be installed on the wire insertion area of a waterproof connector. Be sure that the seal is

installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

SEL272V

SEL273V

SEL275V

SEL330V

Revision: January 20102010 Versa

Page 2997 of 3745

LT-2

Component Parts and Harness Connector Loca-

tion ..........................................................................

51

System Description .................................................51

CAN Communication System Description ..............53

Schematic ............................................................ ...54

Wiring Diagram - TURN - ........................................55

Terminal and Reference Value for BCM .................58

How to Proceed with Trouble Diagnosis .................58

Preliminary Check ..................................................59

CONSULT-III Function (BCM) ................................59

Turn Signals Do Not Operate .................................59

Front Turn Signal Lamp Does Not Operate ............59

Rear Turn Signal Lamp Does Not Operate ............60

Hazard Warning Lamp Does Not Operate But

Turn Signal Lamp Operates ...................................

61

Turn Signal Indicator Lamp Does Not Operate ......62

Bulb Replacement for Front Turn Signal Lamp ......62

Bulb Replacement for Rear Turn Signal Lamp .......62

Removal and Installation of Front Turn Signal

Lamp .......................................................................

62

Removal and Installation of Rear Turn Signal

Lamp .......................................................................

62

LIGHTING AND TURN SIGNAL SWITCH .........63

Removal and Installation ..................................... ...63

HAZARD SWITCH .............................................64

Removal and Installation ..................................... ...64

COMBINATION SWITCH ..................................65

Wiring Diagram - COMBSW - .............................. ...65

Combination Switch Reading Function ...................65

Terminal and Reference Value for BCM .................66

CONSULT-III Function (BCM) ................................66

Combination Switch Inspection ..............................66

Removal and Installation ..................................... ...68

STOP LAMP ......................................................69

Wiring Diagram - STOP/L .................................... ...69

Wiring Diagram - STOP/L .......................................70

Bulb Replacement for High-Mounted Stop Lamp ...70

Bulb Replacement for Rear Combination Lamp for

Stop Lamp ..............................................................

71

Removal and Installation of High-Mounted Stop

Lamp .......................................................................

71

Removal and Installation of Rear Combination

Lamp for Stop Lamp ...............................................

72

BACK-UP LAMP ................................................73

Wiring Diagram - BACK/L - .................................. ...73

Bulb Replacement ..................................................73

Removal and Installation ........................................74

PARKING, LICENSE PLATE AND TAIL

LAMPS ...............................................................

75

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

75

System Description .............................................. ...75

CAN Communication System Description ..............76

Schematic ...............................................................77

Wiring Diagram - TAIL/L - .......................................78

Terminal and Reference Value for BCM .............. ...81

Terminal and Reference Value for IPDM E/R .........81

How to Proceed with Trouble Diagnosis .................82

Preliminary Check ...................................................82

CONSULT-III Function (BCM) ............................. ...82

CONSULT-III Function (IPDM E/R) ........................82

Parking, License Plate and Tail Lamps Do Not Il-

luminate ..................................................................

82

Parking, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) .....................

85

Bulb Replacement ................................................ ...85

Removal and Installation .........................................86

REAR COMBINATION LAMP ........................ ...88

Component .......................................................... ...88

Bulb Replacement ...................................................88

Removal and Installation .........................................89

Disassembly and Assembly ................................. ...89

INTERIOR LAMP ...............................................91

Map Lamp ............................................................ ...91

Luggage Room Lamp, Hatch Back .........................91

Trunk Room Lamp, Sedan ......................................92

Vanity Mirror Lamp ..................................................92

INTERIOR ROOM LAMP ...................................94

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

94

System Description .................................................94

Schematic ...............................................................98

Wiring Diagram - INT/L - .........................................99

Terminal and Reference Value for BCM ...............103

How to Proceed with Trouble Diagnosis ...............103

Preliminary Check .................................................104

CONSULT-III Function (BCM) ............................. .104

Interior Room Lamp Control Does Not Operate

(With Map Lamp) ..................................................

105

Interior Room Lamp Control Does Not Operate

(Without Map Lamp) .............................................

107

Bulb Replacement .................................................108

Removal and Installation .......................................109

ILLUMINATION .............................................. ..110

System Description .............................................. .110

CAN Communication System Description ............111

Schematic .............................................................112

Wiring Diagram - ILL - ...........................................113

BULB SPECIFICATIONS ............................... ..117

Headlamp ............................................................. .117

Exterior Lamp ........................................................117

Interior Lamp/Illumination ......................................117

Revision: January 20102010 Versa

Page 3112 of 3745

BULB SPECIFICATIONSLT-117

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

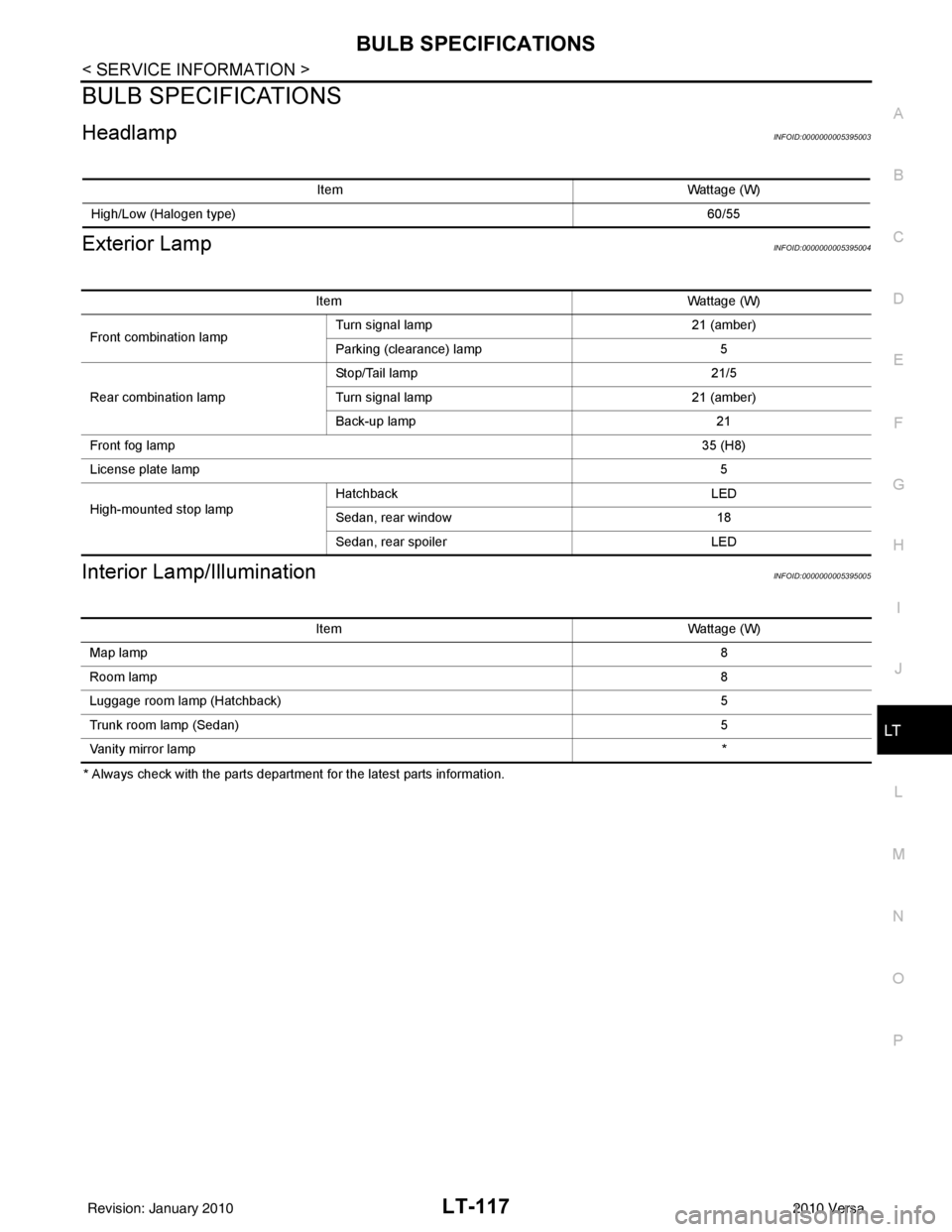

BULB SPECIFICATIONS

HeadlampINFOID:0000000005395003

Exterior LampINFOID:0000000005395004

Interior Lamp/IlluminationINFOID:0000000005395005

* Always check with the parts department for the latest parts information. Item Wattage (W)

High/Low (Halogen type) 60/55

ItemWattage (W)

Front combination lamp Turn signal lamp

21 (amber)

Parking (clearance) lamp 5

Rear combination lamp Stop/Tail lamp

21/5

Turn signal lamp 21 (amber)

Back-up lamp 21

Front fog lamp 35 (H8)

License plate lamp 5

High-mounted stop lamp Hatchback

LED

Sedan, rear window 18

Sedan, rear spoiler LED

ItemWattage (W)

Map lamp 8

Room lamp 8

Luggage room lamp (Hatchback) 5

Trunk room lamp (Sedan) 5

Vanity mirror lamp *

Revision: January 20102010 Versa

Page 3113 of 3745

LU-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION LU

A

LU

N

O P

CONTENTS

ENGINE LUBRICATION SYSTEM

HR16DE

PRECAUTION ....... ........................................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

FUNCTION DIAGNOSIS ...............................6

DESCRIPTION ............................................... .....6

Engine Lubrication System ................................. ......6

Engine Lubrication System Schematic ......................6

ON-VEHICLE MAINTENANCE .....................7

ENGINE OIL ................................................... .....7

Inspection ............................................................ ......7

Draining .....................................................................8

Refilling .....................................................................8

OIL FILTER .........................................................9

Removal and Installation ...........................................9

ON-VEHICLE REPAIR .... .............................10

OIL PUMP ....................................................... ....10

Removal and Installation .........................................10

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

11

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

11

Engine Oil Capacity ............................................. ....11

Engine Oil Pressure .................................................11

MR18DE

SERVICE INFORMATION .. .........................

12

PRECAUTIONS .................................................12

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

12

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

12

Precaution for Liquid Gasket ...................................13

PREPARATION .................................................14

Special Service Tool ................................................14

Commercial Service Tool ........................................14

LUBRICATION SYSTEM ..................................16

Lubrication Circuit ....................................................16

ENGINE OIL ......................................................17

Inspection ................................................................17

Changing Engine Oil ................................................18

OIL FILTER .......................................................20

Removal and Installation .........................................20

OIL PUMP .........................................................21

Component ..............................................................21

Removal and Installation .........................................21

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

23

Standard and Limit ..................................................23

Revision: January 20102010 Versa

Page 3123 of 3745

![NISSAN TIIDA 2010 Service Owners Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-11

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) NISSAN TIIDA 2010 Service Owners Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-11

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)](/img/5/57397/w960_57397-3122.png)

SERVICE DATA AND SPECIFICATIONS (SDS)LU-11

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Oil CapacityINFOID:0000000005398161

Unit: (US qt, lmp qt)

Engine Oil PressureINFOID:0000000005398162

Unit: kPa (bar, kg/cm2, psi)

*: Engine oil temperature at 80

°C (176 °F)

Drain and refill With oil filter change

Approximately 3.0 (3 1/8, 2 5/8)

Without oil filter change Approximately 2.8 (3, 2 1/2)

Dry engine (engine overhaul) Approximately 3.5 (3 3/4, 3 1/8)

Engine speed Approximate discharge oil pressure*

Idle speed More than 60 (0.60, 0.61, 9)

2,000 rpm More than 270 (2.7, 2.8, 39)

Revision: January 20102010 Versa

Page 3131 of 3745

![NISSAN TIIDA 2010 Service Owners Manual ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil. NISSAN TIIDA 2010 Service Owners Manual ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil.](/img/5/57397/w960_57397-3130.png)

ENGINE OILLU-19

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil.

5. Install drain plug (2) with new washer. Refer to EM-143, "

Com-

ponent".

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14

.

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to LU-17, "

Inspection".

PBIC3915E

Revision: January 20102010 Versa

Page 3135 of 3745

![NISSAN TIIDA 2010 Service Owners Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005398174

ENGINE OIL P NISSAN TIIDA 2010 Service Owners Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005398174

ENGINE OIL P](/img/5/57397/w960_57397-3134.png)

SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005398174

ENGINE OIL PRESSURE

Unit: kPa (bar, kg/cm2, psi)

ENGINE OIL CAPACITY

Unit: (US qt, Imp qt)

Engine speed

Approximate discharge oil pressure

Idle speed 60 (0.60, 0.61, 9)

2,000 rpm 200 (2.0, 2.0, 29)

Drain and refillWith oil filter change Approximately 4.1 (4 3/8, 3 5/8)

Without oil filter change

Approximately 3.9 (4 1/8, 3 3/8)

Dry engine (engine overhaul) Approximately 4.9 (5 1/8, 4 3/8)

Revision: January 20102010 Versa

Page 3154 of 3745

ENGINE MAINTENANCE (HR16DE)MA-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

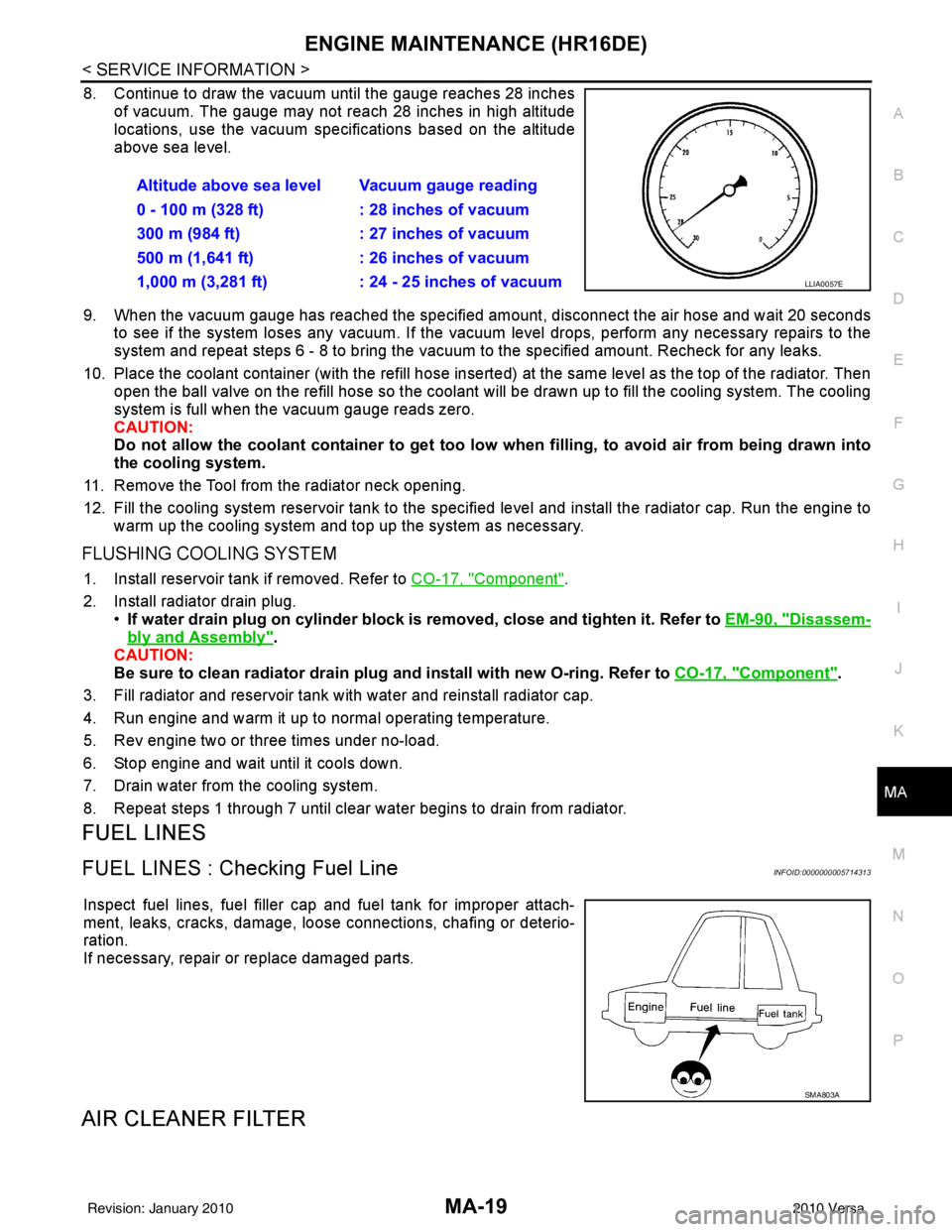

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-17, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-90, "

Disassem-

bly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-17, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005714313

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

SMA803A

Revision: January 20102010 Versa