engine NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3228 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-44

< SERVICE INFORMATION >[RS6F94R]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777026

NISSAN TIIDA 2010 Service Repair Manual MT-44

< SERVICE INFORMATION >[RS6F94R]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777026](/img/5/57397/w960_57397-3227.png)

MT-44

< SERVICE INFORMATION >[RS6F94R]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777026

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005716038

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3238 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-54

< SERVICE INFORMATION >[RS6F94R]

M/T OIL

M/T OIL

Changing M/T OilINFOID:0000000005397191

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and d NISSAN TIIDA 2010 Service Repair Manual MT-54

< SERVICE INFORMATION >[RS6F94R]

M/T OIL

M/T OIL

Changing M/T OilINFOID:0000000005397191

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and d](/img/5/57397/w960_57397-3237.png)

MT-54

< SERVICE INFORMATION >[RS6F94R]

M/T OIL

M/T OIL

Changing M/T OilINFOID:0000000005397191

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-61, "

Com-

ponent".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug (1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-61, "

Component".

CAUTION:

Do not reuse gasket.

Checking M/T OilINFOID:0000000005397192

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine wh ile checking oil level.

3. Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-61, "

Com-

ponent".

CAUTION:

Do not reuse gasket.

SCIA7622E

Oil grade and capacity

: Refer to MA-14, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

Revision: January 20102010 Versa

Page 3245 of 3745

![NISSAN TIIDA 2010 Service Repair Manual TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005716041

Removal and InstallationINFOID:0000000005716042

CAUTION:

NISSAN TIIDA 2010 Service Repair Manual TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005716041

Removal and InstallationINFOID:0000000005716042

CAUTION:](/img/5/57397/w960_57397-3244.png)

TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005716041

Removal and InstallationINFOID:0000000005716042

CAUTION:

If transaxle assembly is removed from the vehicle , always replace CSC (Concentric Slave Cylinder).

Inserted CSC returns to the origin al position when removing transaxle assembly. Dust on clutch disc

sliding parts may damage CSC seal, and may cause clutch fluid leakage.

REMOVAL

1. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-13, "Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

2. Remove engine and transaxle assembly. Refer to EM-191, "

Removal and Installation".

3. Remove starter motor. Refer to SC-20, "

Removal and Installation MR18DE".

4. Remove transaxle assembly to engine bolts.

5. Separate transaxle assembly from engine.

INSTALLATION

Installation is in the reverse order of removal.

• If transaxle is removed from the v ehicle, always replace CSC. Refer to CL-13, "

Removal and Installation" .

1. LH engine mount bracket (transaxle side) 2. Transaxle assembly 3. Rear engine mount bracket

4. Washer 5. Rear torque rod Front

: Refer to MT-61, "

Removal and Installation".

SCIA7631E

Revision: January 20102010 Versa

Page 3246 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-62

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

• When installing the transaxle assembly to the engine, install the

bolts as shown.

CAUTION:

When installing transaxle assembly, be careful NISSAN TIIDA 2010 Service Repair Manual MT-62

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

• When installing the transaxle assembly to the engine, install the

bolts as shown.

CAUTION:

When installing transaxle assembly, be careful](/img/5/57397/w960_57397-3245.png)

MT-62

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

• When installing the transaxle assembly to the engine, install the

bolts as shown.

CAUTION:

When installing transaxle assembly, be careful not to bring

transaxle input shaft into co ntact with clutch cover.

A: M/T to engine

B: Engine to M/T

• Bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding Procedure".

• After installation, check oil level, and check for leaks and loose mechanisms. Refer to MT-54, "

Checking M/T

Oil".

Disassembly and AssemblyINFOID:0000000005716043

COMPONENTS

Case and Housing Components

Bolt No.12

Quantity 36

Bolt length “ ” mm (in) 60 (2.36)

50 (1.97)

Tightening torque

N·m (kg-m, ft-lb) 62.0 (6.3, 46)

PCIB1786E

Revision: January 20102010 Versa

Page 3279 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transax](/img/5/57397/w960_57397-3278.png)

SERVICE DATA AND SPECIFICATIONS (SDS)MT-95

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397206

Transaxle type RS6F94R

Engine type MR18DE

Number of speed 6

Synchromesh type Warner

Shift pattern

Gear ratio 1st 3.727

2nd 2.105

3rd 1.452

4th 1.171

5th 0.971

6th 0.811

Reverse 3.687

Final gear 3.933

Number of teeth Input gear 1st 11

2nd 19

3rd 31

4th 35

5th 35

6th 37

Reverse 11

Main gear 1st 41

2nd 40

3rd 45

4th 41

5th 34

6th 30

Reverse 42

Reverse idler gear Input/Output 28/29

Final gear Final gear/Pinion 59/15

Side gear/Pinion

mate gear 21/18

Oil capacity (Reference) (US pt, Imp pt)Approx. 2.0 (4-1/4, 3-1/2)

Remarks Reverse synchronizer Installed

Triple-cone synchronizer 1st and 2nd

PCIB1769E

Revision: January 20102010 Versa

Page 3282 of 3745

PRECAUTIONSMTC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006022079

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005396473

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3287 of 3745

MTC-8

< SERVICE INFORMATION >

PRECAUTIONS

•When the compressor is removed, store it in th e same position as it is when mounted on the car.

• When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to MTC-17, "

Maintenance of Oil Quantity in Compressor".

• Keep friction surfaces between clut ch and pulley clean. If the surface is contaminated, with oil, wipe

it off by using a clean waste cloth moistened with thinner.

• After compressor service operation, turn the compresso r shaft by hand more than five turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for one hour.

• After replacing the compressor magnet clutch, ap ply voltage to the new one and check for usual

operation.

Precaution for Service EquipmentINFOID:0000000005396480

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

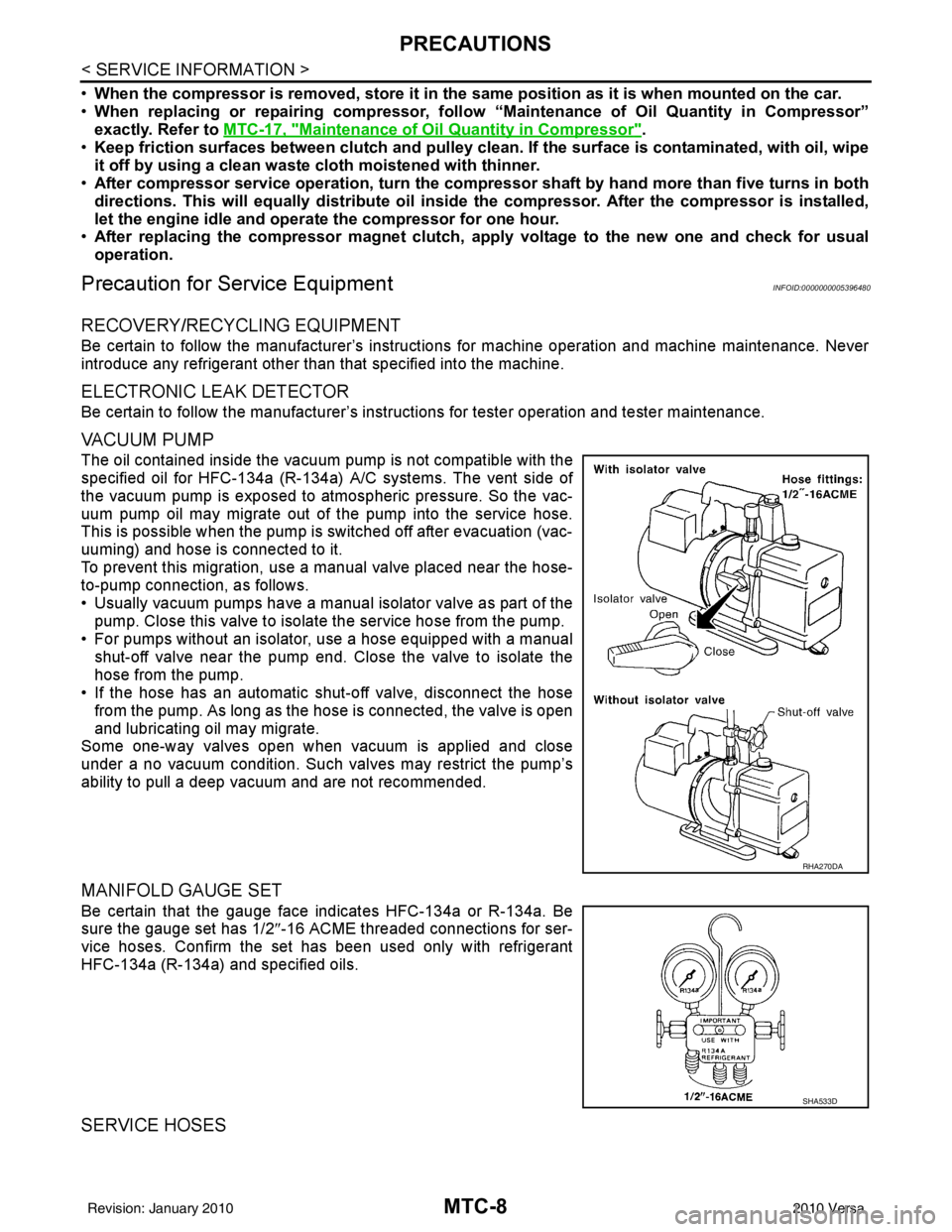

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. So the vac-

uum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vac-

uuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

• Usually vacuum pumps have a manual isolator valve as part of the pump. Close this valve to isolat e the service hose from the pump.

• For pumps without an isolator, use a hose equipped with a manual

shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

• If the hose has an automatic shut -off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

RHA270DA

SHA533D

Revision: January 20102010 Versa

Page 3289 of 3745

MTC-10

< SERVICE INFORMATION >

PRECAUTIONS

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bot tle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/C s ystem or CFC-12 (R-12) leak detector dye in HFC-

134a (R-134a) A/C syst em or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have an identification label on the front underside of the hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Revision: January 20102010 Versa

Page 3302 of 3745

TROUBLE DIAGNOSISMTC-23

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

WORK SUPPORT

Display Item List

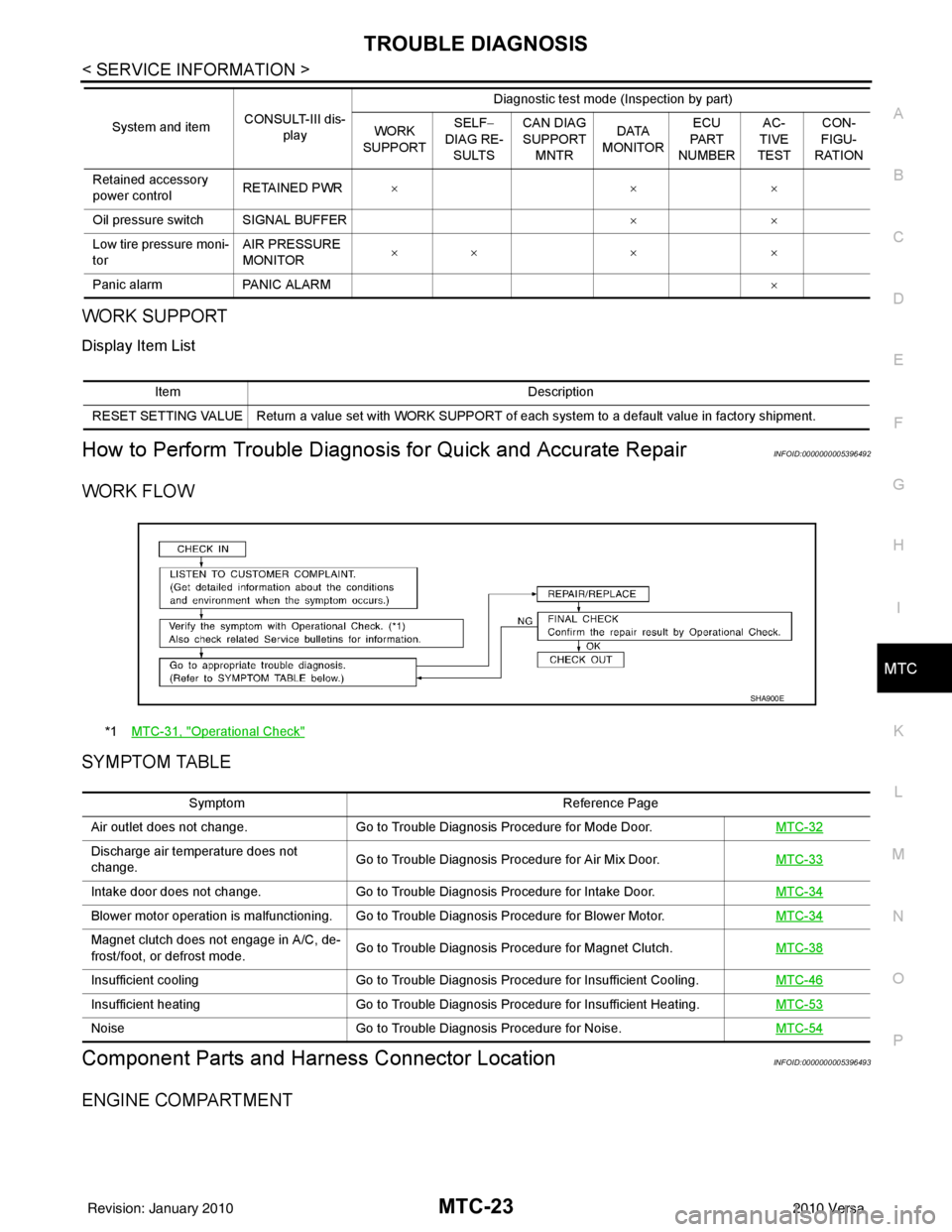

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005396492

WORK FLOW

SYMPTOM TABLE

Component Parts and Har ness Connector LocationINFOID:0000000005396493

ENGINE COMPARTMENT

Retained accessory

power controlRETAINED PWR

×× ×

Oil pressure switch SIGNAL BUFFER ××

Low tire pressure moni-

tor AIR PRESSURE

MONITOR

××

× ×

Panic alarm PANIC ALARM ×

System and item

CONSULT-III dis-

play Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

−

DIAG RE-

SULTS CAN DIAG

SUPPORT

MNTR DATA

MONITOR ECU

PA R T

NUMBER AC-

TIVE

TEST CON-

FIGU-

RATION

Item Description

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

*1 MTC-31, "Operational Check"

SHA900E

Symptom Reference Page

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door. MTC-32

Discharge air temperature does not

change.Go to Trouble Diagnosis Procedure for Air Mix Door.

MTC-33

Intake door does not change.Go to Trouble Diagnosis Procedure for Intake Door. MTC-34

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor. MTC-34

Magnet clutch does not engage in A/C, de-

frost/foot, or defrost mode.Go to Trouble Diagnosis Procedure for Magnet Clutch.

MTC-38

Insufficient coolingGo to Trouble Diagnosis Procedure for Insufficient Cooling. MTC-46

Insufficient heatingGo to Trouble Diagnosis Procedure for Insufficient Heating. MTC-53

NoiseGo to Trouble Diagnosis Procedure for Noise. MTC-54

Revision: January 20102010 Versa

Page 3310 of 3745

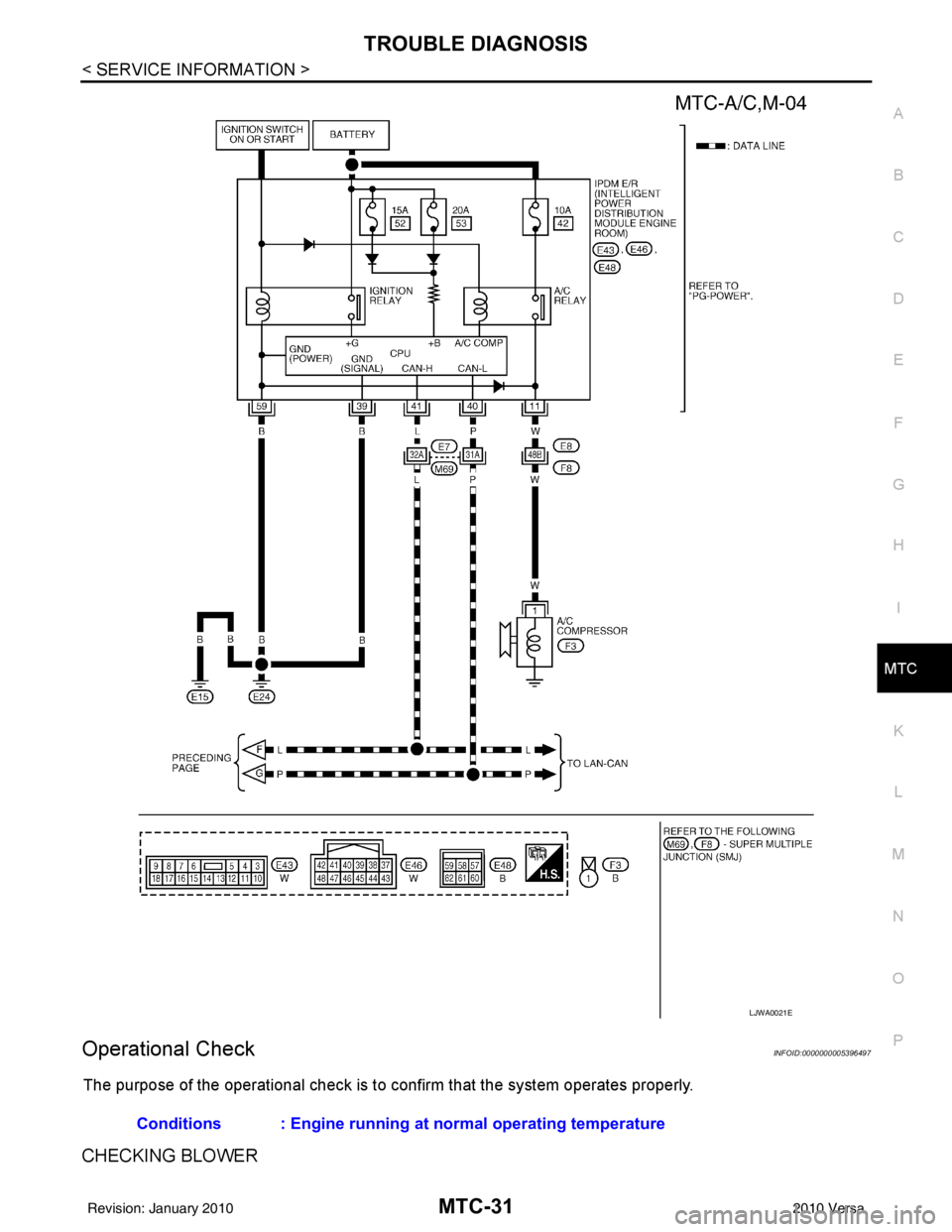

TROUBLE DIAGNOSISMTC-31

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Operational CheckINFOID:0000000005396497

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

LJWA0021E

Conditions : Engine running at normal operating temperature

Revision: January 20102010 Versa