engine NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3174 of 3745

CHASSIS AND BODY MAINTENANCEMA-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

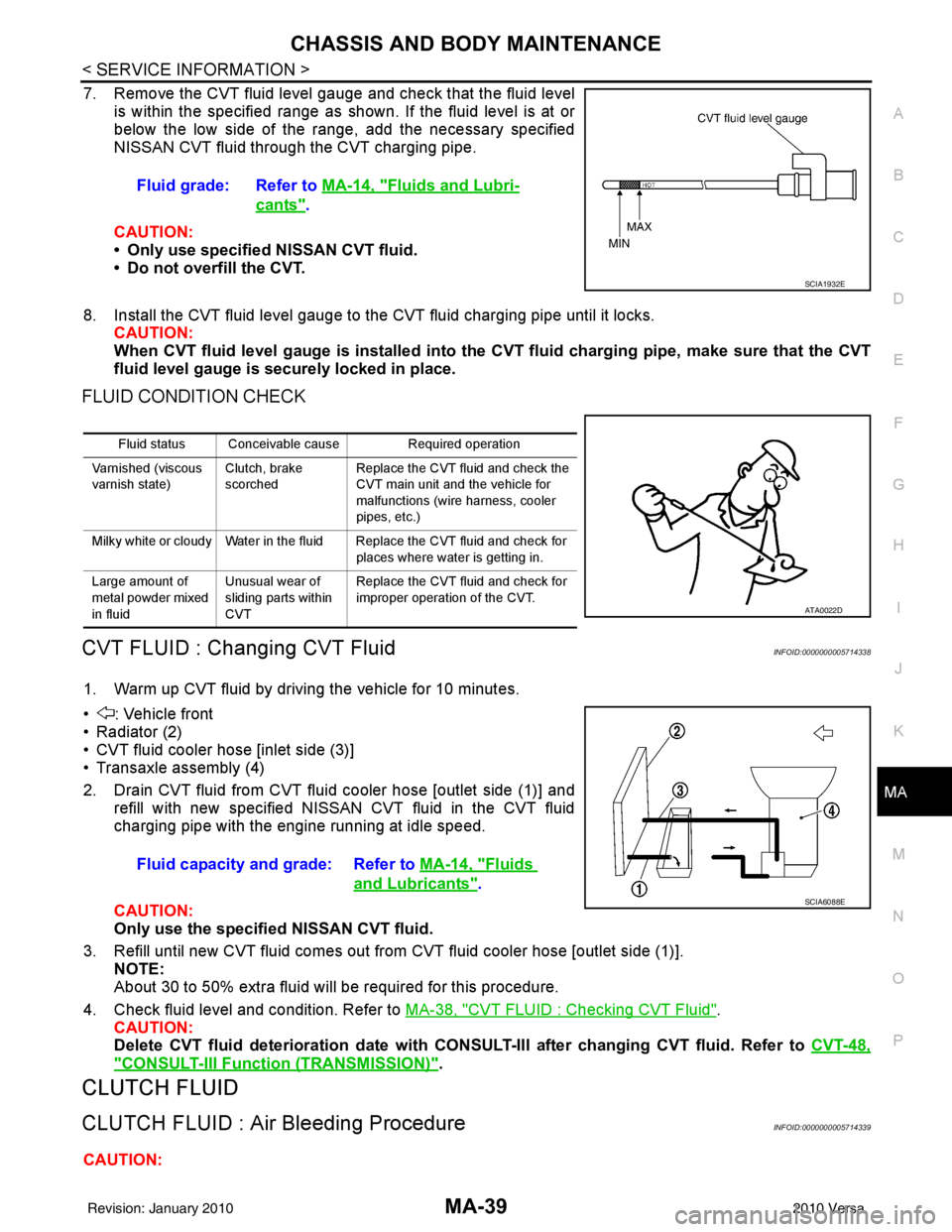

7. Remove the CVT fluid level gauge and check that the fluid level is within the specified range as shown. If the fluid level is at or

below the low side of the range, add the necessary specified

NISSAN CVT fluid through the CVT charging pipe.

CAUTION:

• Only use specified NISSAN CVT fluid.

• Do not overfill the CVT.

8. Install the CVT fluid level gauge to the CVT fluid charging pipe until it locks. CAUTION:

When CVT fluid level gauge is installed into the CVT fluid charging pipe, make sure that the CVT

fluid level gauge is securely locked in place.

FLUID CONDITION CHECK

CVT FLUID : Changing CVT FluidINFOID:0000000005714338

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to MA-38, "

CVT FLUID : Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CLUTCH FLUID

CLUTCH FLUID : Air Bleeding ProcedureINFOID:0000000005714339

CAUTION:Fluid grade: Refer to

MA-14, "

Fluids and Lubri-

cants".

SCIA1932E

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: January 20102010 Versa

Page 3176 of 3745

CHASSIS AND BODY MAINTENANCEMA-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

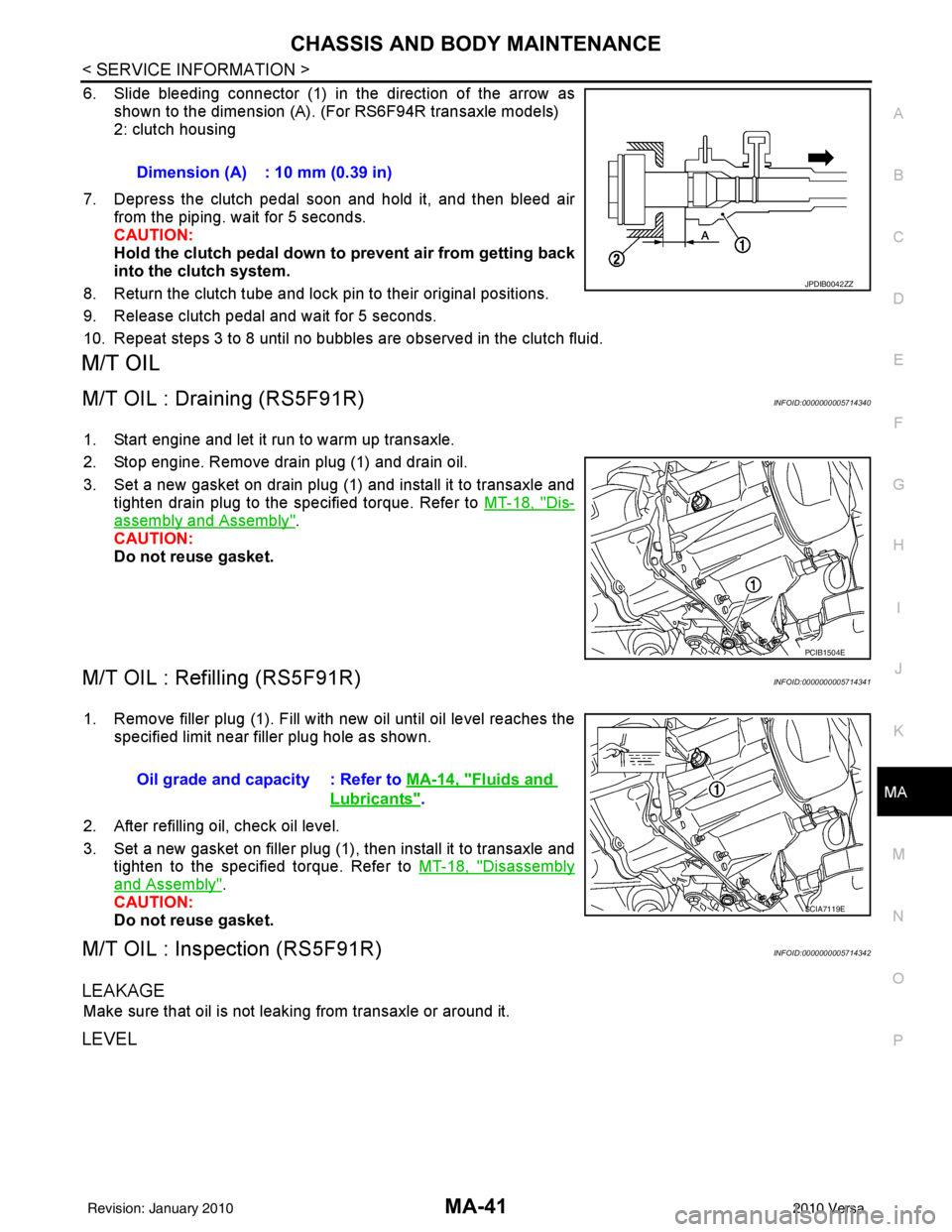

6. Slide bleeding connector (1) in the direction of the arrow as shown to the dimension (A). (For RS6F94R transaxle models)

2: clutch housing

7. Depress the clutch pedal soon and hold it, and then bleed air from the piping. wait for 5 seconds.

CAUTION:

Hold the clutch pedal down to prevent air from getting back

into the clutch system.

8. Return the clutch tube and lock pin to their original positions.

9. Release clutch pedal and wait for 5 seconds.

10. Repeat steps 3 to 8 until no bubbles are observed in the clutch fluid.

M/T OIL

M/T OIL : Draining (RS5F91R)INFOID:0000000005714340

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Set a new gasket on drain plug (1) and install it to transaxle and tighten drain plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Refilling (RS5F91R)INFOID:0000000005714341

1. Remove filler plug (1). Fill with new oil until oil level reaches the specified limit near filler plug hole as shown.

2. After refilling oil, check oil level.

3. Set a new gasket on filler plug (1), then install it to transaxle and tighten to the specified torque. Refer to MT-18, "

Disassembly

and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Inspection (RS5F91R)INFOID:0000000005714342

LEAKAGE

Make sure that oil is not leaking from transaxle or around it.

LEVEL

Dimension (A) : 10 mm (0.39 in)

JPDIB0042ZZ

PCIB1504E

Oil grade and capacity : Refer to MA-14, "Fluids and

Lubricants".

SCIA7119E

Revision: January 20102010 Versa

Page 3177 of 3745

MA-42

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

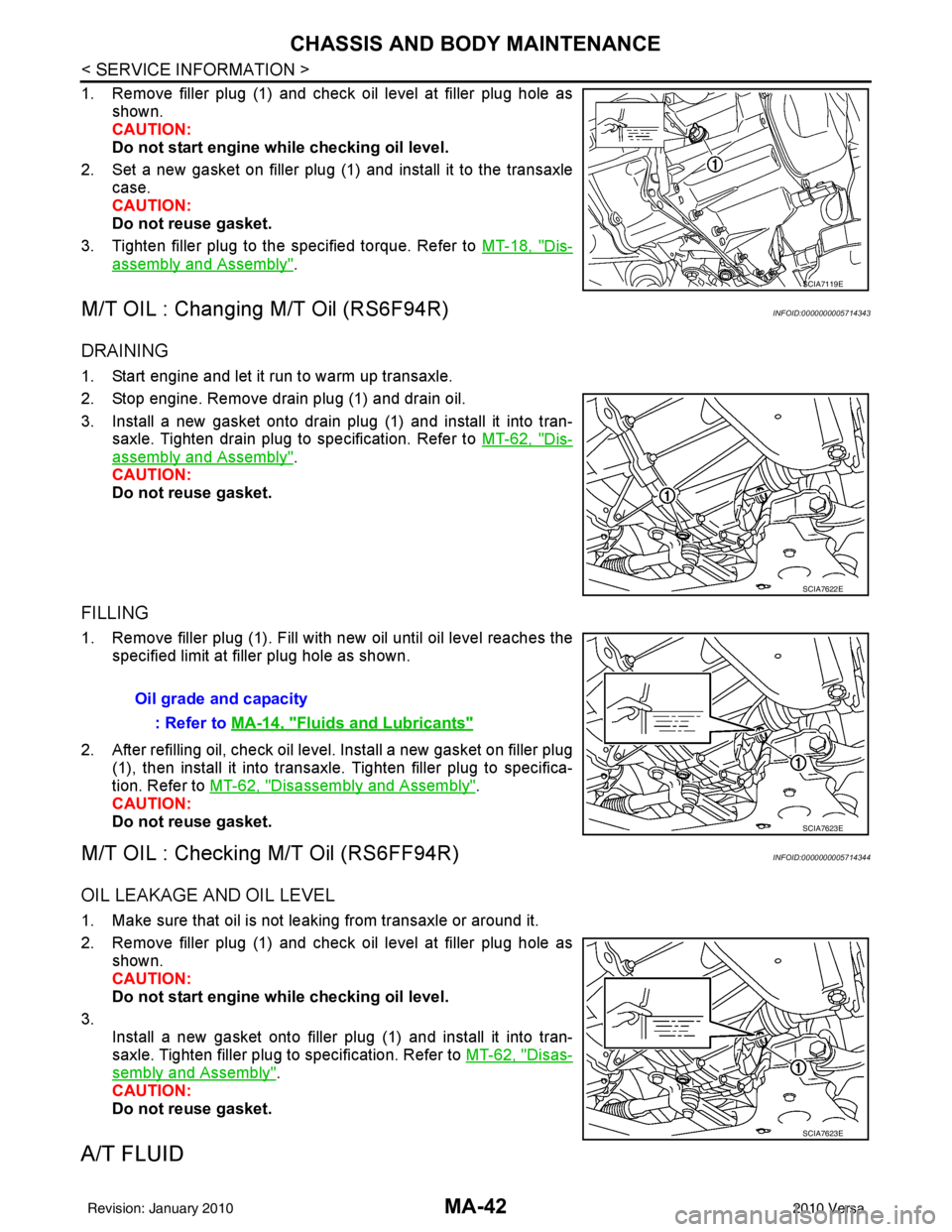

1. Remove filler plug (1) and check oil level at filler plug hole asshown.

CAUTION:

Do not start engine wh ile checking oil level.

2. Set a new gasket on filler plug (1) and install it to the transaxle case.

CAUTION:

Do not reuse gasket.

3. Tighten filler plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

M/T OIL : Changing M/T Oil (RS6F94R)INFOID:0000000005714343

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-62, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug (1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-62, "

Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Checking M/T Oil (RS6FF94R)INFOID:0000000005714344

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine wh ile checking oil level.

3. Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-62, "

Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

A/T FLUID

SCIA7119E

SCIA7622E

Oil grade and capacity

: Refer to MA-14, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

Revision: January 20102010 Versa

Page 3178 of 3745

CHASSIS AND BODY MAINTENANCEMA-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

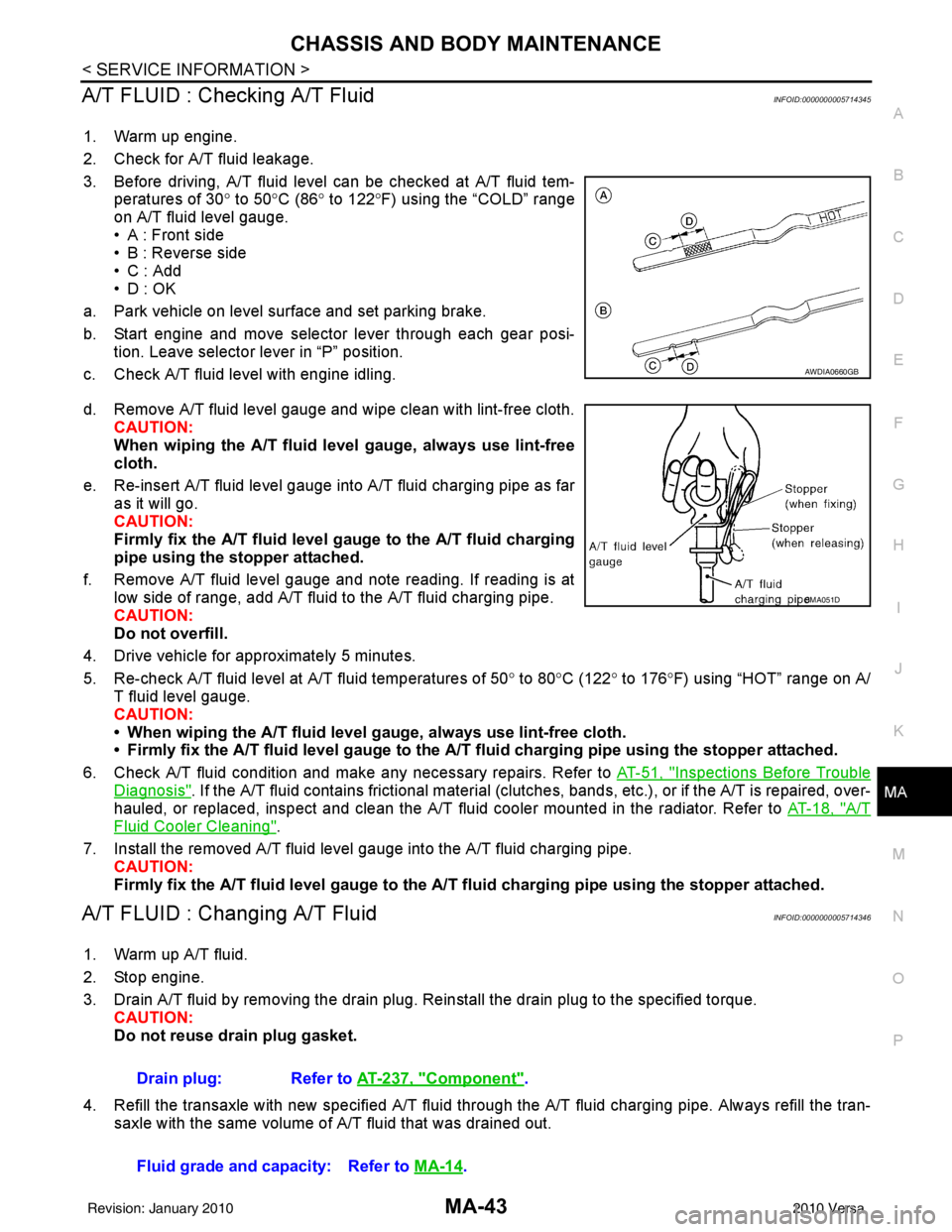

A/T FLUID : Checking A/T FluidINFOID:0000000005714345

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid tem- peratures of 30° to 50°C (86° to 122° F) using the “COLD” range

on A/T fluid level gauge.

• A : Front side

• B : Reverse side

•C : Add

• D : OK

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi- tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth. CAUTION:

When wiping the A/T fluid l evel gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

Firmly fix the A/T fluid level ga uge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50° to 80 °C (122° to 176°F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level ga uge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-51, "

Inspections Before Trouble

Diagnosis". If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired, over-

hauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-18, "

A/T

Fluid Cooler Cleaning".

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe. CAUTION:

Firmly fix the A/T fluid level gaug e to the A/T fluid charging pipe using the stopper attached.

A/T FLUID : Changing A/T FluidINFOID:0000000005714346

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Re install the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran- saxle with the same volume of A/T fluid that was drained out.

AWDIA0660GB

SMA051D

Drain plug: Refer to AT-237, "Component".

Fluid grade and capacity: Refer to MA-14

.

Revision: January 20102010 Versa

Page 3179 of 3745

MA-44

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-43, "

A/T FLUID : Checking A/T Fluid".

WHEELS

WHEELS : Balancing WheelsINFOID:0000000005714347

Adjust wheel balance using road wheel center.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

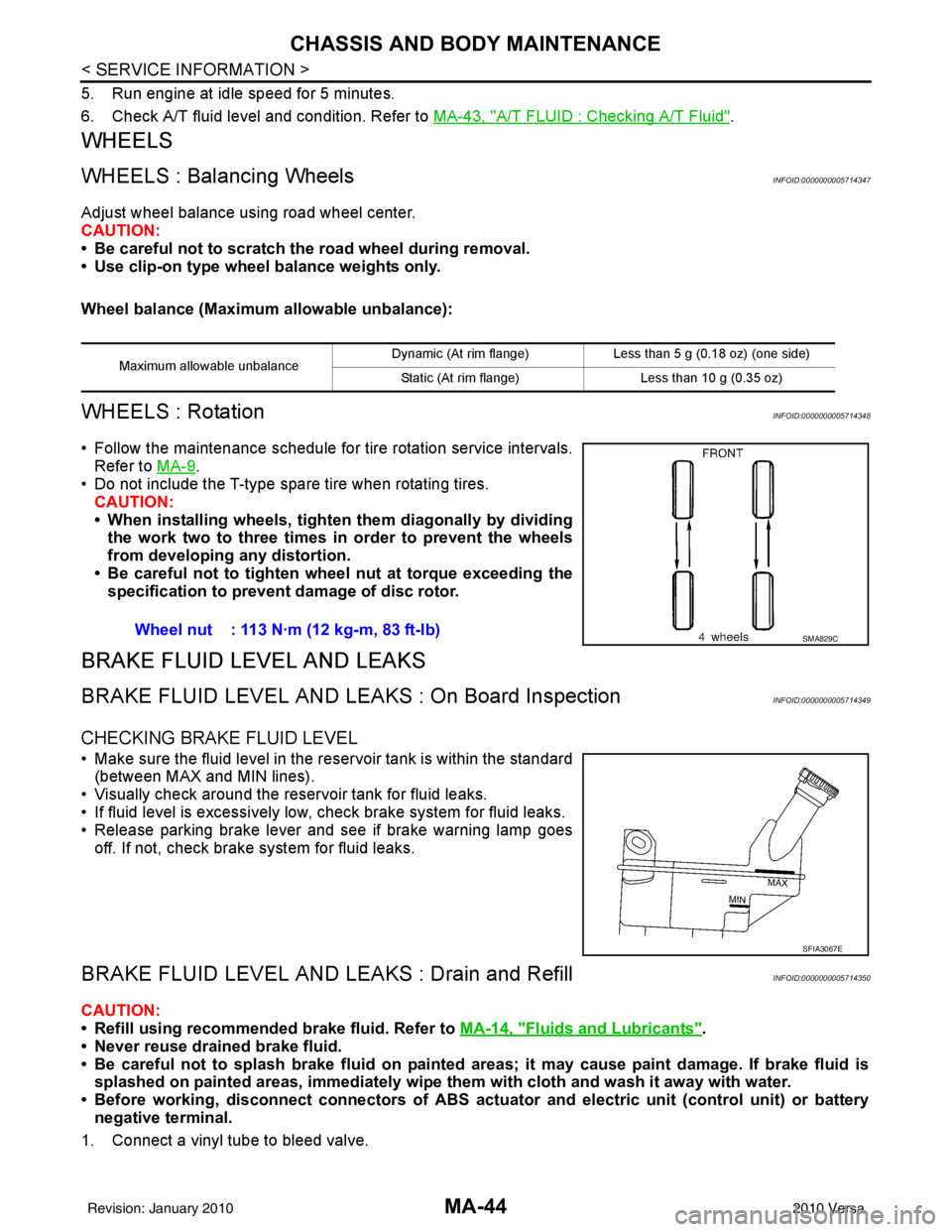

WHEELS : RotationINFOID:0000000005714348

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-9

.

• Do not include the T-type spare tire when rotating tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the specification to prevent damage of disc rotor.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAK S : On Board InspectionINFOID:0000000005714349

CHECKING BRAKE FLUID LEVEL

• Make sure the fluid level in the reservoir tank is within the standard

(between MAX and MIN lines).

• Visually check around the reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for fluid leaks.

• Release parking brake lever and see if brake warning lamp goes off. If not, check brake system for fluid leaks.

BRAKE FLUID LEVEL AND LE AKS : Drain and RefillINFOID:0000000005714350

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

• Before working, disconnect connectors of ABS actua tor and electric unit (control unit) or battery

negative terminal.

1. Connect a vinyl tube to bleed valve.

Maximum allowable unbalance Dynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C

SFIA3067E

Revision: January 20102010 Versa

Page 3187 of 3745

![NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TEN NISSAN TIIDA 2010 Service Repair Manual PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TEN](/img/5/57397/w960_57397-3186.png)

PRECAUTIONSMT-3

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777024

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005716034

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3195 of 3745

![NISSAN TIIDA 2010 Service Repair Manual M/T OILMT-11

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

M/T OIL

DrainingINFOID:0000000005397166

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drai NISSAN TIIDA 2010 Service Repair Manual M/T OILMT-11

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

M/T OIL

DrainingINFOID:0000000005397166

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drai](/img/5/57397/w960_57397-3194.png)

M/T OILMT-11

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

M/T OIL

DrainingINFOID:0000000005397166

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Set a new gasket on drain plug (1) and install it to transaxle and tighten drain plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

RefillingINFOID:0000000005397167

1. Remove filler plug (1). Fill with new oil until oil level reaches the specified limit near filler plug hole as shown.

2. After refilling oil, check oil level.

3. Set a new gasket on filler plug (1), then install it to transaxle and tighten to the specified torque. Refer to MT-18, "

Disassembly

and Assembly".

CAUTION:

Do not reuse gasket.

InspectionINFOID:0000000005397168

LEAKAGE

Make sure that oil is not leaking from transaxle or around it.

LEVEL

1. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

2. Set a new gasket on filler plug (1) and install it to the transaxle case.

CAUTION:

Do not reuse gasket.

3. Tighten filler plug to the specified torque. Refer to MT-18, "

Dis-

assembly and Assembly".

PCIB1504E

Oil grade and capacity : Refer to MA-14, "Fluids and

Lubricants".

SCIA7119E

SCIA7119E

Revision: January 20102010 Versa

Page 3201 of 3745

![NISSAN TIIDA 2010 Service Repair Manual TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005397176

Removal and InstallationINFOID:0000000005397177

CAUTI NISSAN TIIDA 2010 Service Repair Manual TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005397176

Removal and InstallationINFOID:0000000005397177

CAUTI](/img/5/57397/w960_57397-3200.png)

TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005397176

Removal and InstallationINFOID:0000000005397177

CAUTION:

If transaxle assembly is removed from the vehicle , always replace CSC (Concentric Slave Cylinder).

Return CSC insert to original pos ition to remove transaxle assembly. Du st on clutch disc sliding parts

may damage seal of CSC and may cau se clutch fluid leakage. Refer to CL-13, "

Removal and Installa-

tion".

REMOVAL

1. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-13, "Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

2. Remove the engine and transaxle as an assembly from the vehicle. Refer t\

o EM-82, "

Removal and Instal-

lation".

3. Remove the transaxle to engine and engine to transaxle bolts.

4. Separate the transaxle assembly from the engine.

INSTALLATION

Installation is in the reverse order of removal.

1. LH engine mount bracket (transaxle side) 2. Transaxle assembly 3. Rear engine mount bracket

4. Washer 5. Rear torque rod Front

: Refer to installation.

PCIB1514E

Revision: January 20102010 Versa

Page 3202 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-18

< SERVICE INFORMATION >[RS5F91R]

TRANSAXLE ASSEMBLY

CAUTION:

• Make sure the transaxle assembly does not interfer

e with the wire harnesses and clutch tube.

• When installing transaxle assem NISSAN TIIDA 2010 Service Repair Manual MT-18

< SERVICE INFORMATION >[RS5F91R]

TRANSAXLE ASSEMBLY

CAUTION:

• Make sure the transaxle assembly does not interfer

e with the wire harnesses and clutch tube.

• When installing transaxle assem](/img/5/57397/w960_57397-3201.png)

MT-18

< SERVICE INFORMATION >[RS5F91R]

TRANSAXLE ASSEMBLY

CAUTION:

• Make sure the transaxle assembly does not interfer

e with the wire harnesses and clutch tube.

• When installing transaxle assembly, do not bring input shaft into contact with clutch cover.

• If transaxle is removed from the vehicle, always replace CSC. Refer to CL-13, "

Removal and Installa-

tion".

• When installing the transaxle assembly to the engine, install the

bolts according to the following:

(A): Transaxle to engine

(B): Engine to transaxle

• After installation perform the following:

- Bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding Procedure".

- Check for oil leakage and oil level. Refer to MT-11, "

Inspection".

- Check the control linkage. Refer to MT-15, "

Inspection".

Disassembly and AssemblyINFOID:0000000005397178

COMPONENTS

Case and Housing Component

Bolt No.1234

Quantity 2213

Bolt length “ ”

mm (in) 55

(2.17) 49

(1.93) 69

(2.72) 55

(2.17)

Tightening torque

N·m (kg-m, ft-lb) 48.0

(4.9, 35)

PCIB1517E

Revision: January 20102010 Versa

Page 3227 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAX NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAX](/img/5/57397/w960_57397-3226.png)

SERVICE DATA AND SPECIFICATIONS (SDS)MT-43

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397183

TRANSAXLE

Transaxle type RS5F91R

Engine type HR16DE

Number of speed 5

Synchromesh type Warner

Shift pattern

Gear ratio 1st 3.7272

2nd 2.0476

3rd 1.3928

4th 1.0294

5th 0.8205

Reverse 3.5454

Final gear 4.0666

Number of teeth Input gear 1st 11

2nd 21

3rd 28

4th 34

5th 39

Reverse 11

Main gear 1st 41

2nd 43

3rd 39

4th 35

5th 32

Reverse 39

Reverse idler gear 26

Final gear Final gear/Pinion 61/15

Side gear/Pinion

mate gear 13/9

Oil capacity (Reference) (US pt, Imp pt)Approx. 2.6 (5-1/2, 4-5/8)

Remarks Reverse synchronizer Installed

Double-cone synchronizer 1st and 2nd

SCIA0821E

Revision: January 20102010 Versa