stop start NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3673 of 3745

![NISSAN TIIDA 2010 Service Repair Manual STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

St NISSAN TIIDA 2010 Service Repair Manual STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

St](/img/5/57397/w960_57397-3672.png)

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-27

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

STEERING WHEEL TURNING FO RCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000005600199

Steering wheel turning force is heavy or light.

Diagnosis ProcedureINFOID:0000000005600200

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform EPS control unit self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-24, "DTC Index".

NO >> GO TO 3.

3.CHECK EPS CONTROL UNIT SIGNAL

With CONSULT-III

1. Start the engine. CAUTION:

Stop the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” of “DATA MONITOR” for EPS control unit.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-13, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the specific malfunctioning part.

5.CHECK STEERING WH EEL TURNING FORCE

Check the steering wheel turning force. Refer to PS-6, "

On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> Inspection End

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to PS-6, "

On-Vehicle

Inspection and Service".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steer-

ing (There is no steering

force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: January 20102010 Versa

Page 3674 of 3745

![NISSAN TIIDA 2010 Service Repair Manual STC-28

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TU RNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

DescriptionINFOI NISSAN TIIDA 2010 Service Repair Manual STC-28

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TU RNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

DescriptionINFOI](/img/5/57397/w960_57397-3673.png)

STC-28

< SYMPTOM DIAGNOSIS >[EPS]

UNBALANCE STEERING WHEEL TURNING FORCE AND RETURN BETWEEN

RIGHT AND LEFT

UNBALANCE STEERING WHEEL TU RNING FORCE AND RETURN BE-

TWEEN RIGHT AND LEFT

DescriptionINFOID:0000000005600201

Unbalance steering wheel turning force and return between right and left.

Diagnosis ProcedureINFOID:0000000005600202

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refer to STC-26, "

Diagnosis Procedure".

2.CHECK WHEEL ALIGNMENT

1. Check the wheel alignment. Refer to FSU-7, "

On-Vehicle Inspection and Service".

2. Perform EPS control unit self-diagnosis.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Adjustment of wheel alignment.

3.CHECK EPS CONTROL UNIT SIGNAL

With CONSULT-III

1. Start the engine. CAUTION:

Stop the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” of “DATA MONITOR” for EPS control unit.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-13, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the specific malfunctioning part.

5.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to PS-6, "

On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to PS-6, "

On-Vehicle

Inspection and Service".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steer-

ing (There is no steering

force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: January 20102010 Versa

Page 3675 of 3745

![NISSAN TIIDA 2010 Service Repair Manual UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-29

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionI NISSAN TIIDA 2010 Service Repair Manual UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-29

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionI](/img/5/57397/w960_57397-3674.png)

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-29

< SYMPTOM DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionINFOID:0000000005600203

Unbalance steering wheel turning force (torque variation).

Diagnosis ProcedureINFOID:0000000005600204

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refer to STC-26, "

Diagnosis Procedure".

2.CHECK STEERING COLU MN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to PS-9, "

Removal and Installation".

• Steering gear assembly. Refer to PS-12, "

Disassembly and Assembly".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the specific malfunctioning part.

3.CHECK EPS CONTROL UNIT SIGNAL

With CONSULT-III

1. Start the engine. CAUTION:

Stop the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” of “DATA MONITOR” for EPS control unit.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-13, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the specific malfunctioning part.

5.CHECK STEERING WH EEL TURNING FORCE

Check the steering wheel turning force. Refer to PS-6, "

On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to PS-6, "

On-Vehicle

Inspection and Service".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steer-

ing (There is no steering

force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: January 20102010 Versa

Page 3711 of 3745

WW-6

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

• to front wiper high relay (located in IPDM E/R), and

• to CPU (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 15A fuse [No. 4, located in fuse block (J/B)]

• to combination switch terminal 14.

Ground is supplied

• to IPDM E/R terminals 39 and 59, and

• to front wiper motor terminal 2

• through grounds E15 and E24

• to BCM terminal 67, and

• to combination switch terminal 12

• through grounds M57 and M61.

LOW SPEED WIPER OPERATION

When the front wiper switch is in LO position, the BCM detects the low speed wiper ON signal by means of the

BCM wiper switch reading function.

The BCM sends a front wiper request signal (LO) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (LO) , it turns ON front wiper relay, located in IPDM E/

R, power is supplied

• through IPDM E/R terminal 33 and front wiper high relay and front wiper relay

• to front wiper motor terminal 3.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at low speed.

HIGH SPEED WIPER OPERATION

When the front wiper switch is in HI position, the BCM detects a high speed wiper ON signal by means of the

BCM wiper switch reading function.

The BCM sends a front wiper request signal (HI) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (HI), it turns ON front wiper relay and front wiper high

relay, located in IPDM E/R, power is supplied

• through IPDM E/R terminal 32

• to front wiper motor terminal 5.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at high speed.

INTERMITTENT OPERATION

Wiper intermittent operation delay interval is determined from the intermittent wiper dial position inputs. During

each intermittent operation delay interval, the BCM s ends a front wiper request signal to the IPDM E/R to

operate the wipers.

When the ignition switch is in the ON or START position, and the front wiper switch is turned to the intermittent

position, the BCM detects a front wiper (intermittent) ON signal by means of the BCM wiper switch reading

function.

BCM then sends front wiper (intermittent) request signal through the CAN communication lines

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When BCM determines that combination switch status is front wiper intermittent ON, it performs the following

operations.

• BCM detects ON/OFF status of intermittent wiper dial position

• BCM calculates operation interval from wiper dial position.

• BCM sends a front wiper request signal (INT) to IPDM E/R at calculated operation interval.

When IPDM E/R receives the front wiper request signal (INT), it supplies ground to energize the front wiper

relay. It then sends auto-stop signal to the BCM and conducts intermittent front wiper motor operation.

Revision: January 20102010 Versa

Page 3720 of 3745

FRONT WIPER AND WASHER SYSTEMWW-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

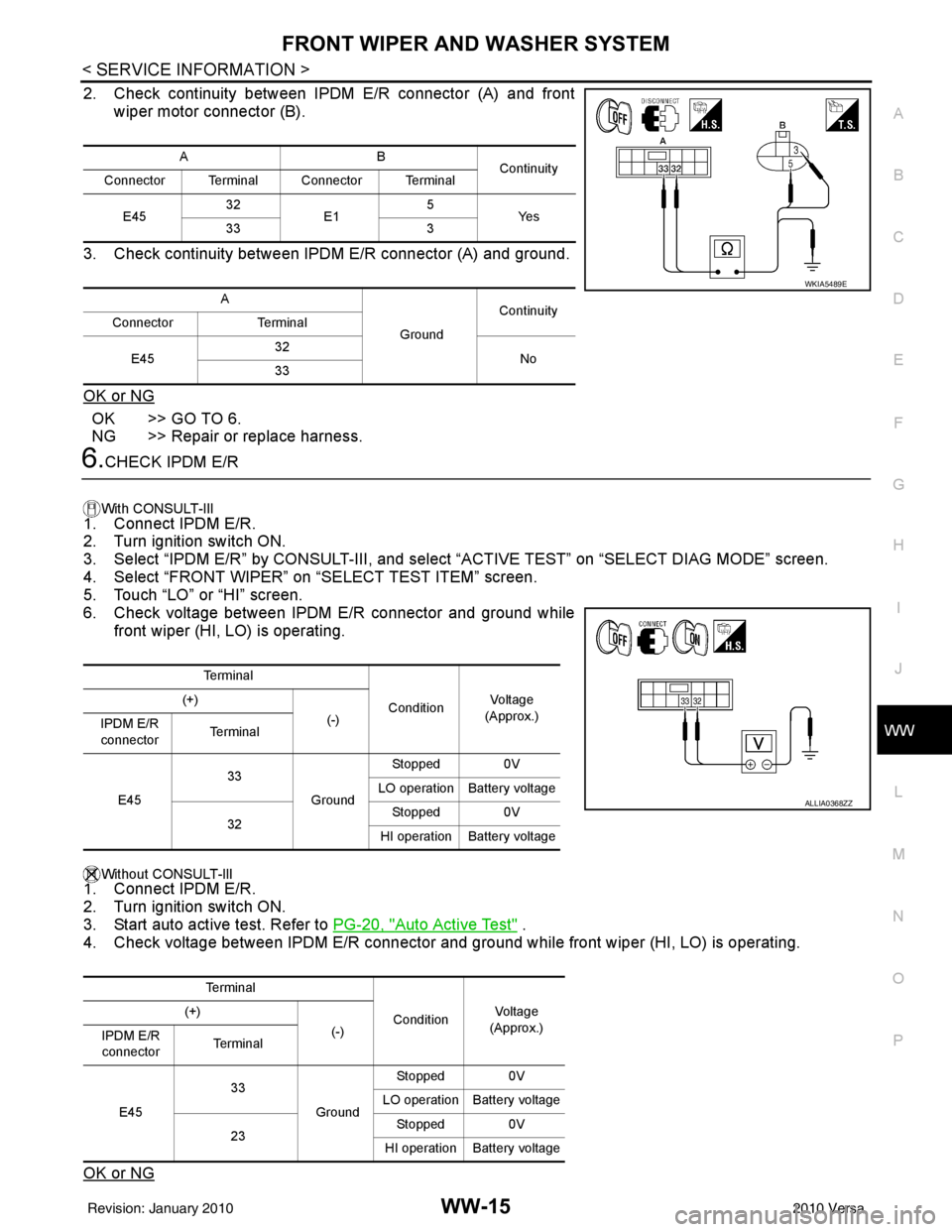

2. Check continuity between IPDM E/R connector (A) and front wiper motor connector (B).

3. Check continuity between IPDM E/R connector (A) and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness.

6.CHECK IPDM E/R

With CONSULT-lIl

1. Connect IPDM E/R.

2. Turn ignition switch ON.

3. Select “IPDM E/R” by CONSULT-III, and sele ct “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “FRONT WIPER” on “SELECT TEST ITEM” screen.

5. Touch “LO” or “HI” screen.

6. Check voltage between IPDM E/R connector and ground while

front wiper (HI, LO) is operating.

Without CONSULT-llI1. Connect IPDM E/R.

2. Turn ignition switch ON.

3. Start auto active test. Refer to PG-20, "

Auto Active Test" .

4. Check voltage between IPDM E/R connector and gr ound while front wiper (HI, LO) is operating.

OK or NG

AB Continuity

Connector Terminal Connector Terminal

E45 32

E1 5

Ye s

33 3

A GroundContinuity

Connector Terminal

E45 32

No

33

WKIA5489E

Te r m i n a l

ConditionVo l ta g e

(Approx.)

(+)

(-)

IPDM E/R

connector Te r m i n a l

E45 33

GroundStopped 0V

LO operation Battery voltage

32 Stopped 0V

HI operation Battery voltage

Te r m i n a l ConditionVol tag e

(Approx.)

(+)

(-)

IPDM E/R

connector Te r m i n a l

E45 33

GroundStopped 0V

LO operation Battery voltage

23 Stopped 0V

HI operation Battery voltage

ALLIA0368ZZ

Revision: January 20102010 Versa

Page 3732 of 3745

REAR WIPER AND WASHER SYSTEMWW-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

• to rear wiper motor terminal 3

• through grounds B117, B132 and D402.

With power and ground supplied, the rear wiper motor operates.

INTERMITTENT OPERATION

The rear wiper motor operates the wiper arm at low speed approximately every 7 seconds.

When the wiper switch is in the rear wiper INT positi on, the BCM detects a rear wiper INT request through the

combination switch (wiper switch) reading function.

When BCM operates rear wiper motor, power is supplied

• through BCM terminal 55

• to rear wiper motor terminal 1.

Ground is supplied

• to rear wiper motor terminal 3

• through grounds B117, B132 and D402.

With power and ground supplied, the rear wiper operates in intermittent mode.

AUTO STOP OPERATION

When the rear wiper arm is not located at the base of the rear window, and the rear wiper switch is turned

OFF, the rear wiper motor will continue to operate until the rear wiper arm is at the base of the rear window.

When the rear wiper arm reaches the base, r ear wiper motor terminals 2 and 1 are connected.

Ground is supplied

• to BCM terminal 44

• through rear wiper motor terminal 2, and

• through rear wiper motor terminal 3, and

• through grounds B117, B132 and D402.

REAR WASHER OPERATION

When the ignition switch is in the ON or START positi on, and the front and rear washer switches are OFF, the

front and rear washer motor is supplied power

• through 15A fuse [No. 4, located in the fuse block (J/B)]

• to combination switch (wiper switch) terminal 14

• through combination switch (wiper switch) terminal 11

• to front and rear washer motor terminal 2.

When the rear wiper switch is in rear washer positi on, the BCM detects a rear washer signal by BCM wiper

switch reading function. Combination switch ground is supplied

• to front and rear washer motor terminal 1

• through combination switch (wiper switch) terminal 13, and

• through combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

With ground supplied, the front and rear washer motor is operated in the rear direction.

When the BCM detects that the rear washer motor has operated for 0.4 seconds or longer, BCM operates the

rear wiper motor.

When the BCM detects that the rear washer switch is in OFF, the rear wiper motor cycles approximately 3

times and then stops.

If the rear washer is operated with the rear wiper switch in the INT position, normal rear wiper operation will

take over. Once the rear washer switch is re leased the rear wiper will return to INT operation.

BCM Combination Switch Reading Function

Refer to BCS-4, "System Description" .

Revision: January 20102010 Versa