turn signal NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 20 of 3745

AT-3

DE

F

G H

I

J

K L

M A

B

AT

N

O

P

N

P1760 OVERRUN CLUTCH

SOLENOID .........148

Description .......................................................... ..148

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

148

On Board Diagnosis Logic ....................................148

Possible Cause .....................................................148

DTC Confirmation Procedure ................................148

Wiring Diagram - AT - OVRCSV ...........................149

Diagnosis Procedure .............................................150

Component Inspection ..........................................151

VEHICLE SPEED SIGNAL ...............................153

Description .......................................................... ..153

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

153

On Board Diagnosis Logic ....................................153

Possible Cause .....................................................153

DTC Confirmation Procedure ................................153

Wiring Diagram - AT - VSSMTR ...........................154

Diagnosis Procedure ........................................... ..155

BATT/FLUID TEMP SEN .................................156

Description .......................................................... ..156

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

156

On Board Diagnosis Logic ....................................156

Possible Cause .....................................................156

DTC Confirmation Procedure ................................156

Wiring Diagram - AT - BA/FTS ..............................157

Diagnosis Procedure .............................................158

Component Inspection ..........................................160

INPUT SPEED SENSOR A ..............................162

Description .......................................................... ..162

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

162

On Board Diagnosis Logic ....................................162

Possible Cause .....................................................162

DTC Confirmation Procedure ................................162

Wiring Diagram - AT - PT/SEN .............................163

Diagnosis Procedure .............................................164

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

167

Description .......................................................... ..167

On Board Diagnosis Logic ....................................167

Possible Cause .....................................................167

DTC Confirmation Procedure ................................167

Diagnosis Procedure .............................................167

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

168

Wiring Diagram - AT - MAIN ............................... ..168

Diagnosis Procedure .............................................169

TR SW, OD SW AND CLOSED THROTTLE,

WIDE OPEN THROTTLE POSITION SIGNAL

CIRCUIT ......................................................... ..

171

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

171

TCM Terminal and Reference Value .....................171

Diagnosis Procedure ........................................... ..171

Component Inspection ...........................................175

SHIFT POSITION INDICATOR CIRCUIT ........176

Description .............................................................176

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

176

Diagnosis Procedure .............................................176

TROUBLE DIAGNOSIS FOR SYMPTOMS ....177

Wiring Diagram - AT - NONDTC ...........................177

OD OFF Indicator Lamp Does Not Come On ........180

Engine Cannot Be Started in "P" and "N" Position ..182

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

183

In "N" Position, Vehicle Moves ..............................183

Large Shock "N" → "R" Position .......................... ..184

Vehicle Does Not Creep Backward in "R" Position ..185

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ................................................................ ..

186

Vehicle Cannot Be Started from D1 .......................187

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 ..................................................... ..189

A/T Does Not Shift: D2→ D3 ................................ ..190

A/T Does Not Shift: D3→ D4 ................................ ..192

A/T Does Not Perform Lock-up ........................... ..193

A/T Does Not Hold Lock-up Condition ...................194

Lock-up Is Not Released .......................................195

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ................................................. ..196

A/T Does Not Shift: D4→ D3, When OD OFF ...... ..197

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position ............................................... ..

198

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ................................................ ..

199

Vehicle Does Not Decelerate by Engine Brake ... ..201

TCM Self-Diagnosis Does Not Activate .................204

A/T SHIFT LOCK SYSTEM .............................206

Description .............................................................206

Shift Lock System Parts Location ..........................207

Wiring Diagram - AT - SHIFT ................................208

Diagnosis Procedure .............................................208

TRANSMISSION CONTROL MODULE ..........212

Removal and Installation .......................................212

SHIFT CONTROL SYSTEM ............................213

A/T Shift Selector Removal and Installation ........ ..213

A/T Shift Selector Disassembly and Assembly ......216

Shift Lever Handle Removal and Installation .........216

Adjustment of A/T Position ....................................217

Checking of A/T Position .......................................217

KEY INTERLOCK CABLE ..............................219

Removal and Installation .......................................219

ON-VEHICLE SERVICE ..................................222

Control Valve Assembly and Accumulators ...........222

Revision: January 20102010 Versa

Page 25 of 3745

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000005397211

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure th e harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000005397212

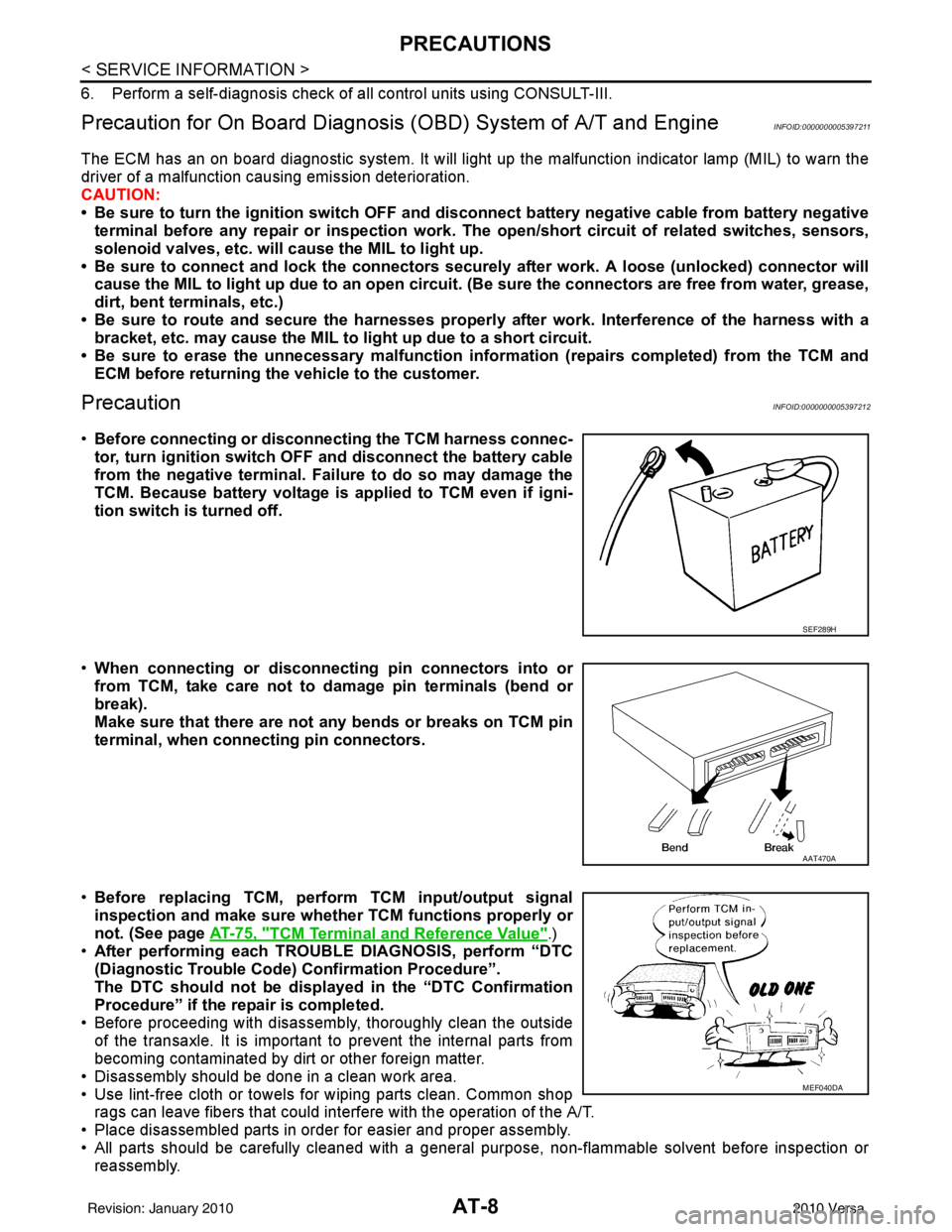

•Before connecting or disconn ecting the TCM harness connec-

tor, turn ignition switch OF F and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

• When connecting or disconnect ing pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

• Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-75, "

TCM Terminal and Reference Value".)

• After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displ ayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could in terfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or reassembly.

SEF289H

AAT470A

MEF040DA

Revision: January 20102010 Versa

Page 56 of 3745

ON BOARD DIAGNOSTIC (OBD) SYSTEMAT-39

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005397230

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD-II) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malf unction indicator lamp) and is stored as a DTC in the

ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are ov erlapped with OBD-II self-diagnostic items. For detail,

refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" .

OBD-II Function for A/T SystemINFOID:0000000005397231

The ECM provides emission-related on board diagnostic (O BD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-rela ted parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indica tor lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000005397232

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000005397233

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONS ULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected curr ently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driv ing condition such as fuel system status, calculated

load value, engine coolant temperature, short term f uel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Revision: January 20102010 Versa

Page 60 of 3745

TROUBLE DIAGNOSISAT-43

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

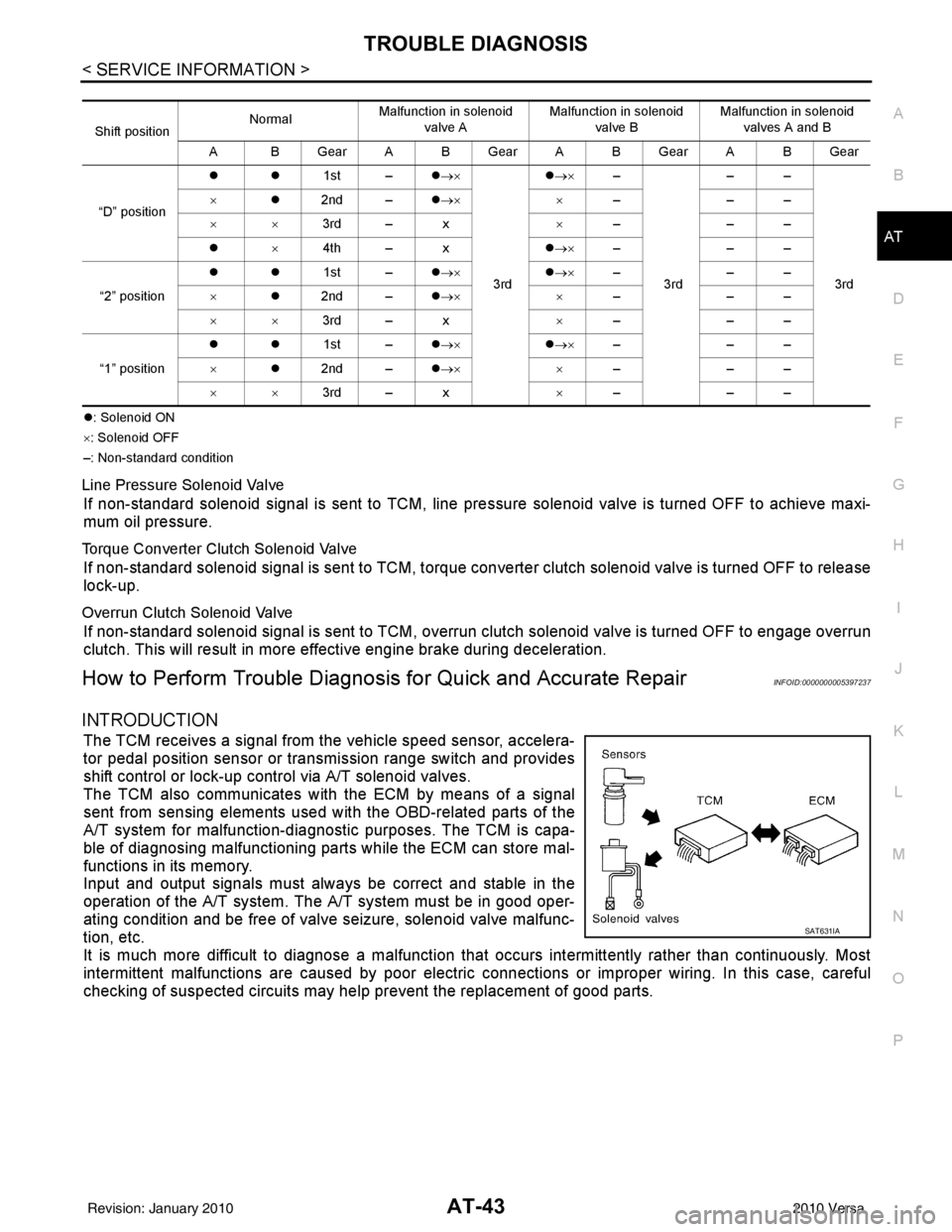

�z : Solenoid ON

× : Solenoid OFF

–: Non-standard condition

Line Pressure Solenoid Valve

If non-standard solenoid signal is sent to TCM, line pre ssure solenoid valve is turned OFF to achieve maxi-

mum oil pressure.

Torque Converter Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, torque conv erter clutch solenoid valve is turned OFF to release

lock-up.

Overrun Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, overr un clutch solenoid valve is turned OFF to engage overrun

clutch. This will result in more effective engine brake during deceleration.

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005397237

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor or transmission range switch and provides

shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. T he A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a malfunction that occurs intermittently rather than continuously. Most

intermittent malfunctions are caused by poor electric c onnections or improper wiring. In this case, careful

checking of suspected circuits may hel p prevent the replacement of good parts.

Shift positionNormal

Malfunction in solenoid

valve A Malfunction in solenoid

valve B Malfunction in solenoid

valves A and B

A BGearABGearABGearABGear

“D” position �z�z

1st –�z→×

3rd �z

→× –

3rd ––

3rd

×

�z2nd – �z→× ×–––

×× 3rd – x ×–––

�z ×4th – x �z→× –––

“2” position �z�z

1st –�z→× �z→× –––

× �z2nd – �z→× ×–––

×× 3rd – x ×–––

“1” position �z�z

1st –�z→× �z→× –––

× �z2nd – �z→× ×–––

×× 3rd – x ×–––

SAT631IA

Revision: January 20102010 Versa

Page 65 of 3745

AT-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

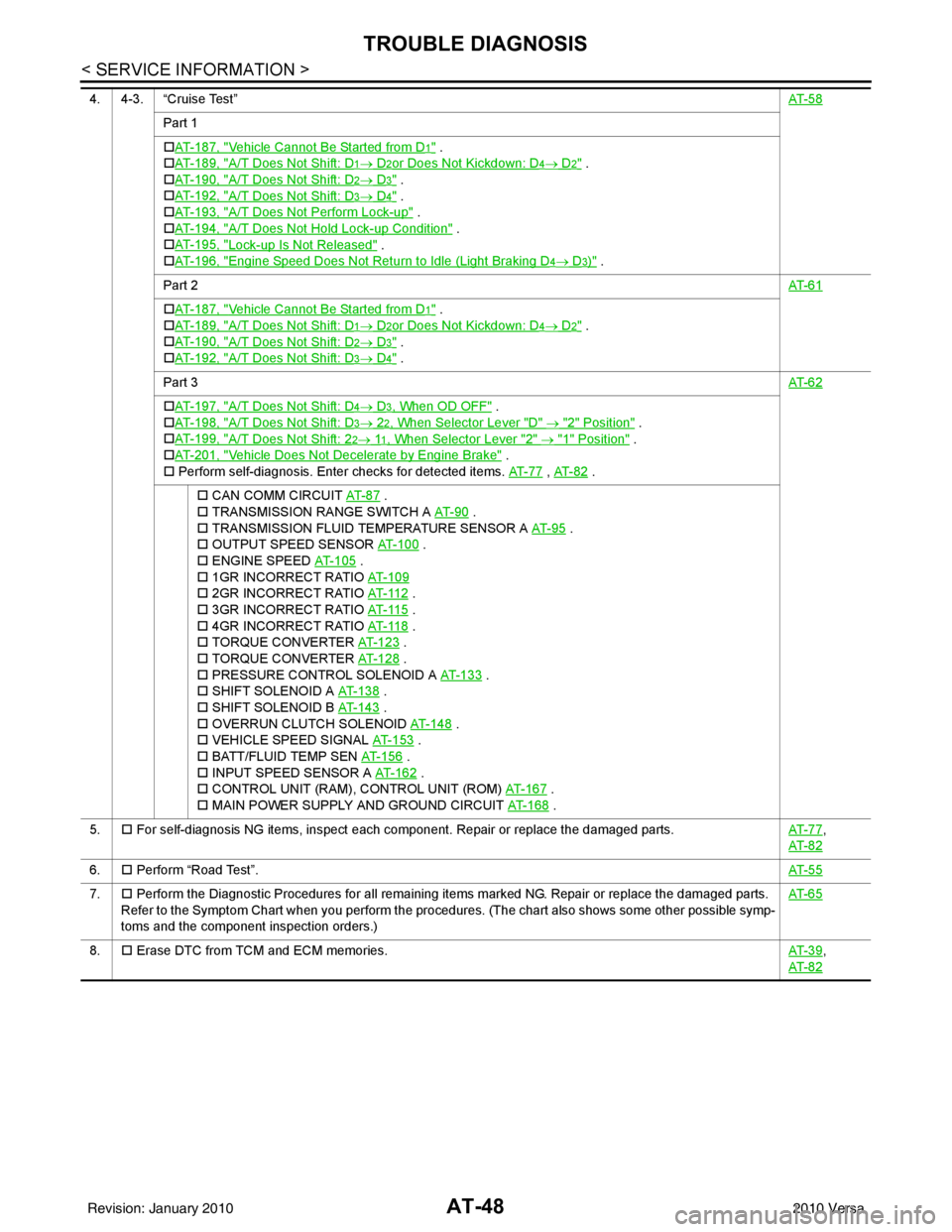

4. 4-3. “Cruise Test”AT- 5 8

Part 1

�†AT- 1 8 7 , "

Vehicle Cannot Be Started from D1" .

�† AT- 1 8 9 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

�† AT- 1 9 0 , "

A/T Does Not Shift: D2→ D3" .

�† AT- 1 9 2 , "

A/T Does Not Shift: D3→ D4" .

�† AT- 1 9 3 , "

A/T Does Not Perform Lock-up" .

�† AT- 1 9 4 , "

A/T Does Not Hold Lock-up Condition" .

�† AT- 1 9 5 , "

Lock-up Is Not Released" .

�† AT- 1 9 6 , "

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)" .

Part 2 AT- 6 1

�†AT- 1 8 7 , "Vehicle Cannot Be Started from D1" .

�† AT- 1 8 9 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

�† AT- 1 9 0 , "

A/T Does Not Shift: D2→ D3" .

�† AT- 1 9 2 , "

A/T Does Not Shift: D3→ D4" .

Part 3 AT- 6 2

�†AT- 1 9 7 , "A/T Does Not Shift: D4→ D3, When OD OFF" .

�† AT- 1 9 8 , "

A/T Does Not Shift: D3→ 22, When Selector Lever "D" → "2" Position" .

�† AT- 1 9 9 , "

A/T Does Not Shift: 22→ 11, When Selector Lever "2" → "1" Position" .

�† AT- 2 0 1 , "

Vehicle Does Not Decelerate by Engine Brake" .

�† Perform self-diagnosis. Enter checks for detected items. AT- 7 7

, AT- 8 2 .

�† CAN COMM CIRCUIT AT- 8 7

.

�† TRANSMISSION RANGE SWITCH A AT- 9 0

.

�† TRANSMISSION FLUID TEMPERATURE SENSOR A AT- 9 5

.

�† OUTPUT SPEED SENSOR AT- 1 0 0

.

�† ENGINE SPEED AT- 1 0 5

.

�† 1GR INCORRECT RATIO AT- 1 0 9

�† 2GR INCORRECT RATIO AT- 11 2 .

�† 3GR INCORRECT RATIO AT- 11 5

.

�† 4GR INCORRECT RATIO AT- 11 8

.

�† TORQUE CONVERTER AT-123

.

�† TORQUE CONVERTER AT-128

.

�† PRESSURE CONTROL SOLENOID A AT- 1 3 3

.

�† SHIFT SOLENOID A AT- 1 3 8

.

�† SHIFT SOLENOID B AT- 1 4 3

.

�† OVERRUN CLUTCH SOLENOID AT- 1 4 8

.

�† VEHICLE SPEED SIGNAL AT- 1 5 3

.

�† BATT/FLUID TEMP SEN AT-156

.

�† INPUT SPEED SENSOR A AT- 1 6 2

.

�† CONTROL UNIT (RAM), CONTROL UNIT (ROM) AT-167

.

�† MAIN POWER SUPPLY AND GROUND CIRCUIT AT- 1 6 8

.

5. �† For self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT- 7 7

,

AT- 8 2

6. �† Perform “Road Test”. AT- 5 5

7.�† Perform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible symp-

toms and the component inspection orders.) AT- 6 5

8.

�† Erase DTC from TCM and ECM memories. AT- 3 9,

AT- 8 2

Revision: January 20102010 Versa

Page 99 of 3745

AT-82

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

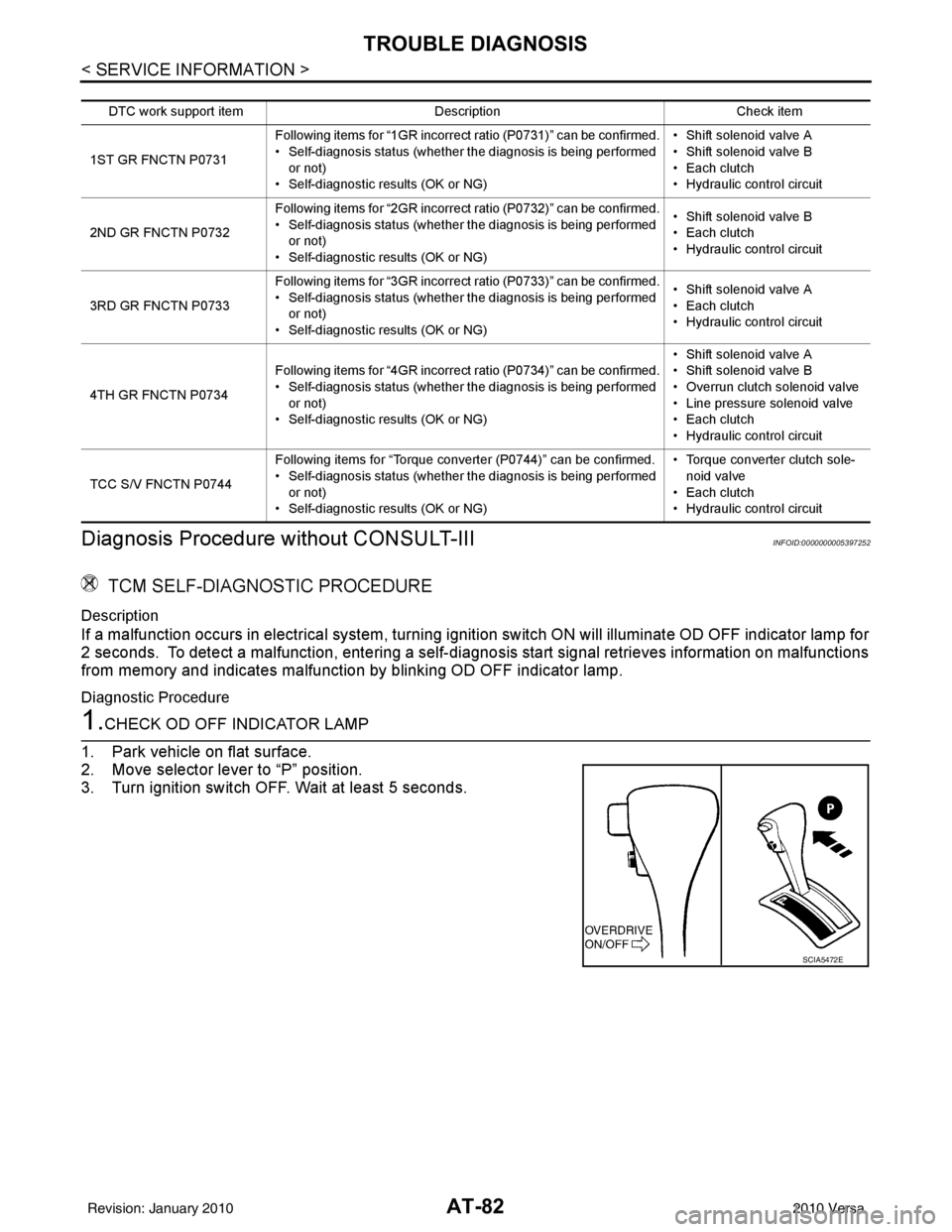

Diagnosis Procedure without CONSULT-III

INFOID:0000000005397252

TCM SELF-DIAGNOSTIC PROCEDURE

Description

If a malfunction occurs in electrical system, turning ignition switch ON will illuminate OD OFF indicator lamp for

2 seconds. To detect a malfunction, entering a self-diagnosis start signal retrieves information on malfunctions

from memory and indicates malfunction by blinking OD OFF indicator lamp.

Diagnostic Procedure

1.CHECK OD OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

DTC work support item Description Check item

1ST GR FNCTN P0731 Following items for “1GR incorrect ratio (P0731)” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Shift solenoid valve B

• Each clutch

•Hydraulic co

ntrol circuit

2ND GR FNCTN P0732 Following items for “2GR incorrect ratio (P0732)” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve B

• Each clutch

•Hydraulic co

ntrol circuit

3RD GR FNCTN P0733 Following items for “3GR incorrect ratio (P0733)” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Each clutch

•Hydraulic co

ntrol circuit

4TH GR FNCTN P0734 Following items for “4GR incorrect ratio (P0734)” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Shift solenoid valve B

• Overrun clutch solenoid valve

• Line pressure solenoid valve

• Each clutch

•Hydraulic co

ntrol circuit

TCC S/V FNCTN P0744 Following items for “Torque converter (P0744)” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Torque converter clutch sole-

noid valve

• Each clutch

•Hydraulic co ntrol circuit

SCIA5472E

Revision: January 20102010 Versa

Page 103 of 3745

AT-86

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

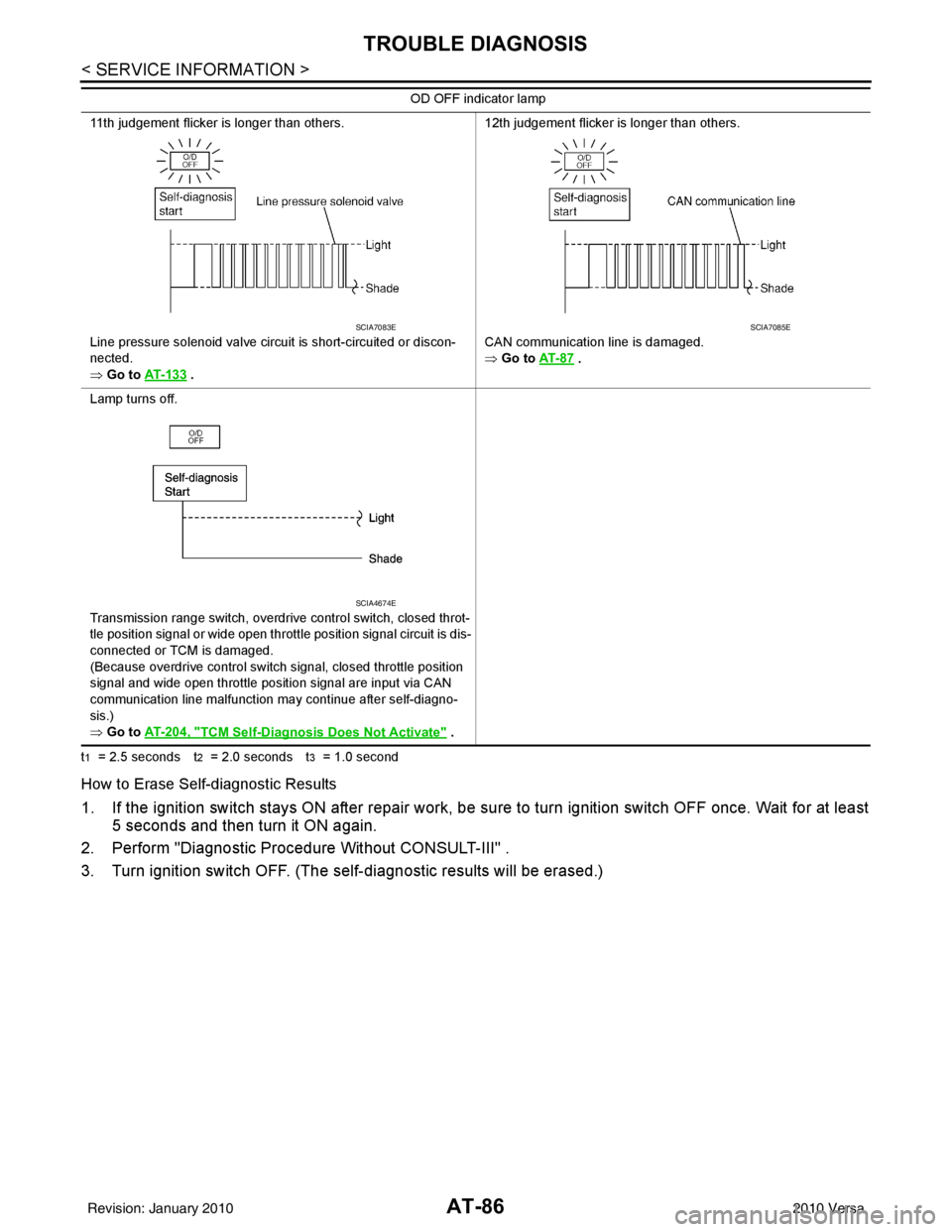

t1 = 2.5 seconds t2 = 2.0 seconds t3 = 1.0 second

How to Erase Self-diagnostic Results

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait for at least

5 seconds and then turn it ON again.

2. Perform "Diagnostic Procedure Without CONSULT-III" .

3. Turn ignition switch OFF. (The se lf-diagnostic results will be erased.)

11th judgement flicker is longer than others.

Line pressure solenoid valve circuit is short-circuited or discon-

nected.

⇒ Go to AT- 1 3 3

. 12th judgement flicker is longer than others.

CAN communication line is damaged.

⇒ Go to

AT- 8 7

.

Lamp turns off.

Transmission range switch, overdrive control switch, closed throt-

tle position signal or wide open throttle position signal circuit is dis-

connected or TCM is damaged.

(Because overdrive control switch signal, closed throttle position

signal and wide open throttle position signal are input via CAN

communication line malfunction may continue after self-diagno-

sis.)

⇒ Go to AT- 2 0 4 , "

TCM Self-Diagnosis Does Not Activate" .

OD OFF indicator lamp

SCIA7083ESCIA7085E

SCIA4674E

Revision: January 20102010 Versa

Page 107 of 3745

AT-90

< SERVICE INFORMATION >

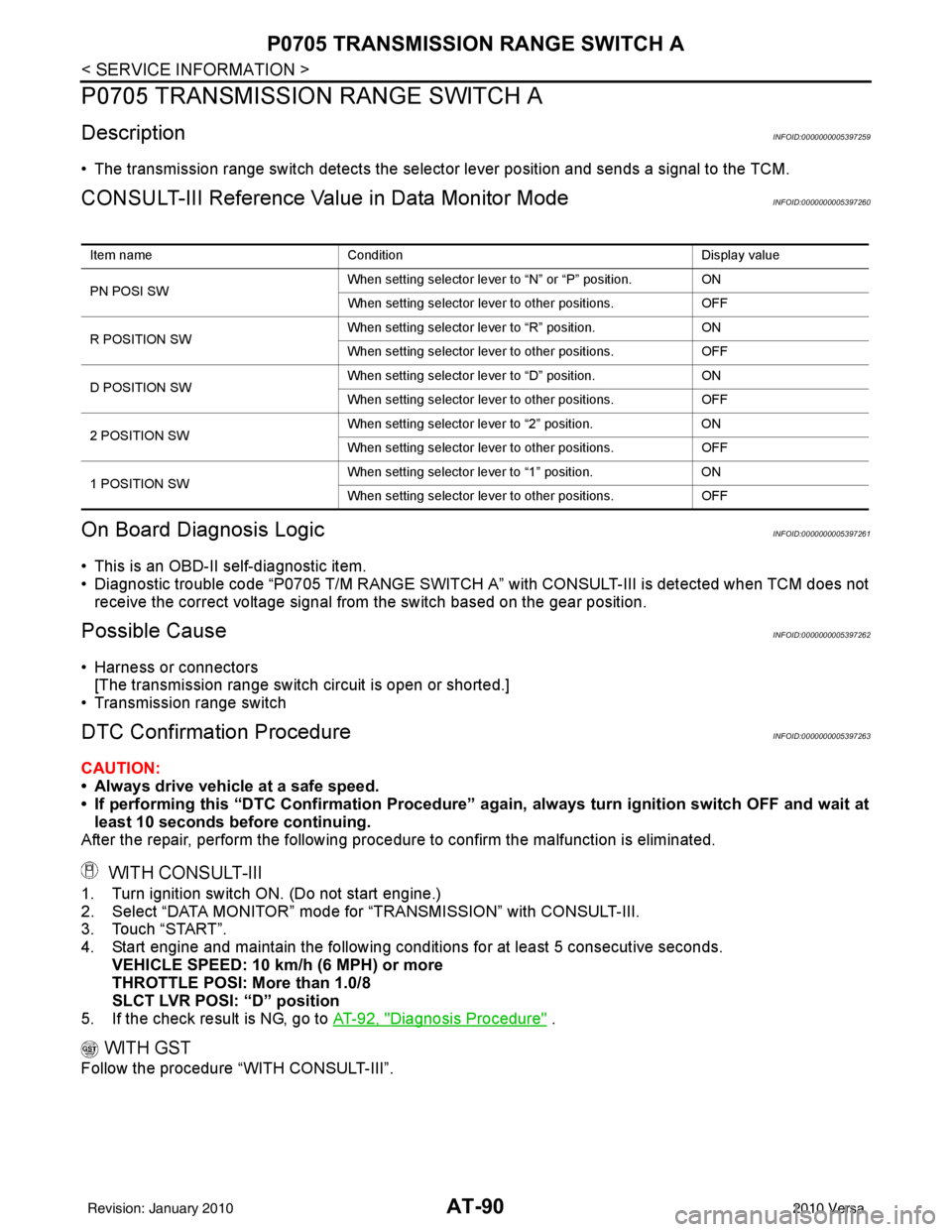

P0705 TRANSMISSION RANGE SWITCH A

P0705 TRANSMISSION RANGE SWITCH A

DescriptionINFOID:0000000005397259

• The transmission range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397260

On Board Diagnosis LogicINFOID:0000000005397261

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 T/M RANGE SWITCH A” with CONSULT-III is detected when TCM does not

receive the correct voltage signal from the switch based on the gear position.

Possible CauseINFOID:0000000005397262

• Harness or connectors [The transmission range switch circuit is open or shorted.]

• Transmission range switch

DTC Confirmation ProcedureINFOID:0000000005397263

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-92, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position.

ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position.

ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position.

ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position.

ON

When setting selector lever to other positions. OFF

Revision: January 20102010 Versa

Page 109 of 3745

AT-92

< SERVICE INFORMATION >

P0705 TRANSMISSION RANGE SWITCH A

Diagnosis Procedure

INFOID:0000000005397265

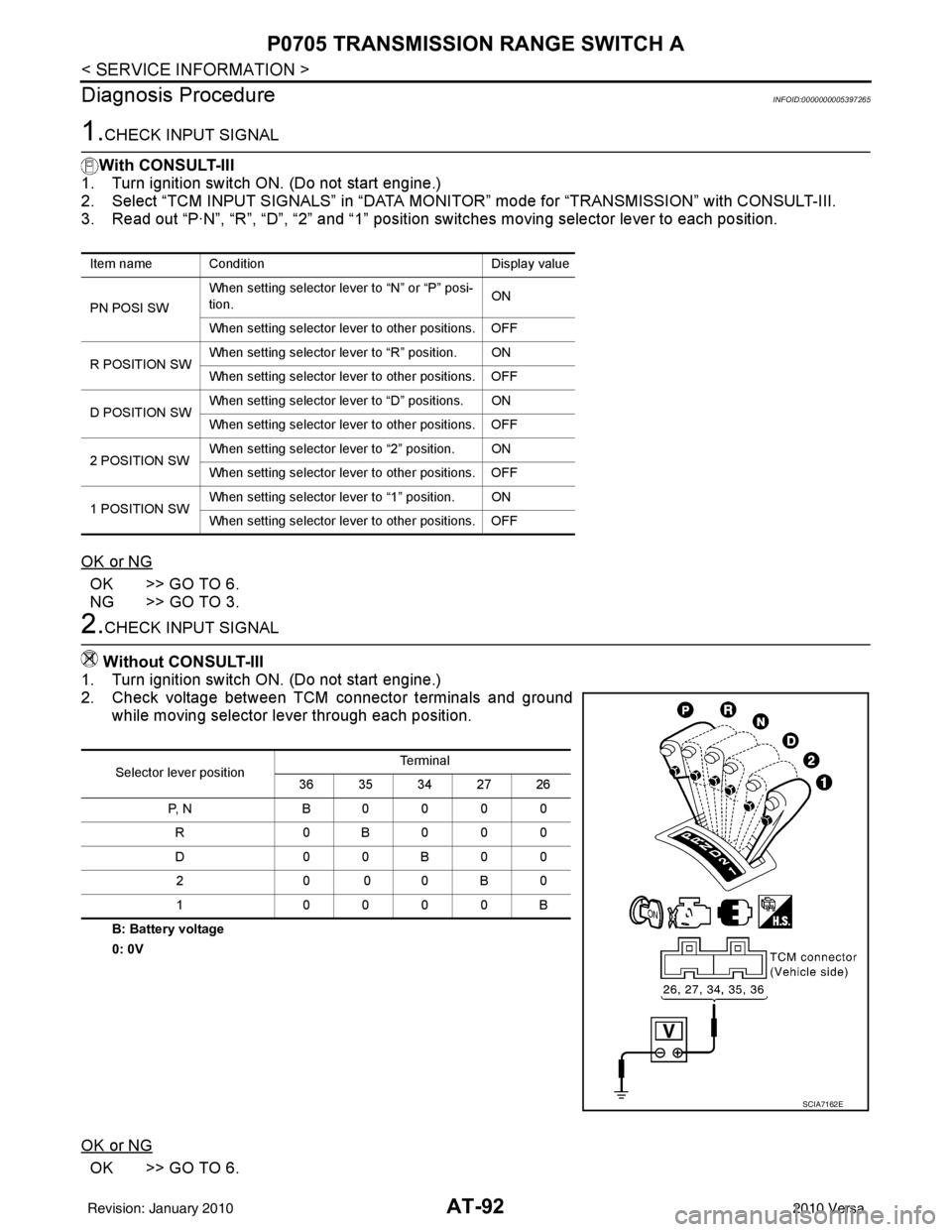

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

2.CHECK INPUT SIGNAL

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position.

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 6.

Item name Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Selector lever position Te r m i n a l

36 35 34 27 26

P, N B0000 R 0B000

D0 0B 00

20 00B 0

1 0000B

SCIA7162E

Revision: January 20102010 Versa

Page 110 of 3745

P0705 TRANSMISSION RANGE SWITCH A

AT-93

< SERVICE INFORMATION >

D E

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> GO TO 3.

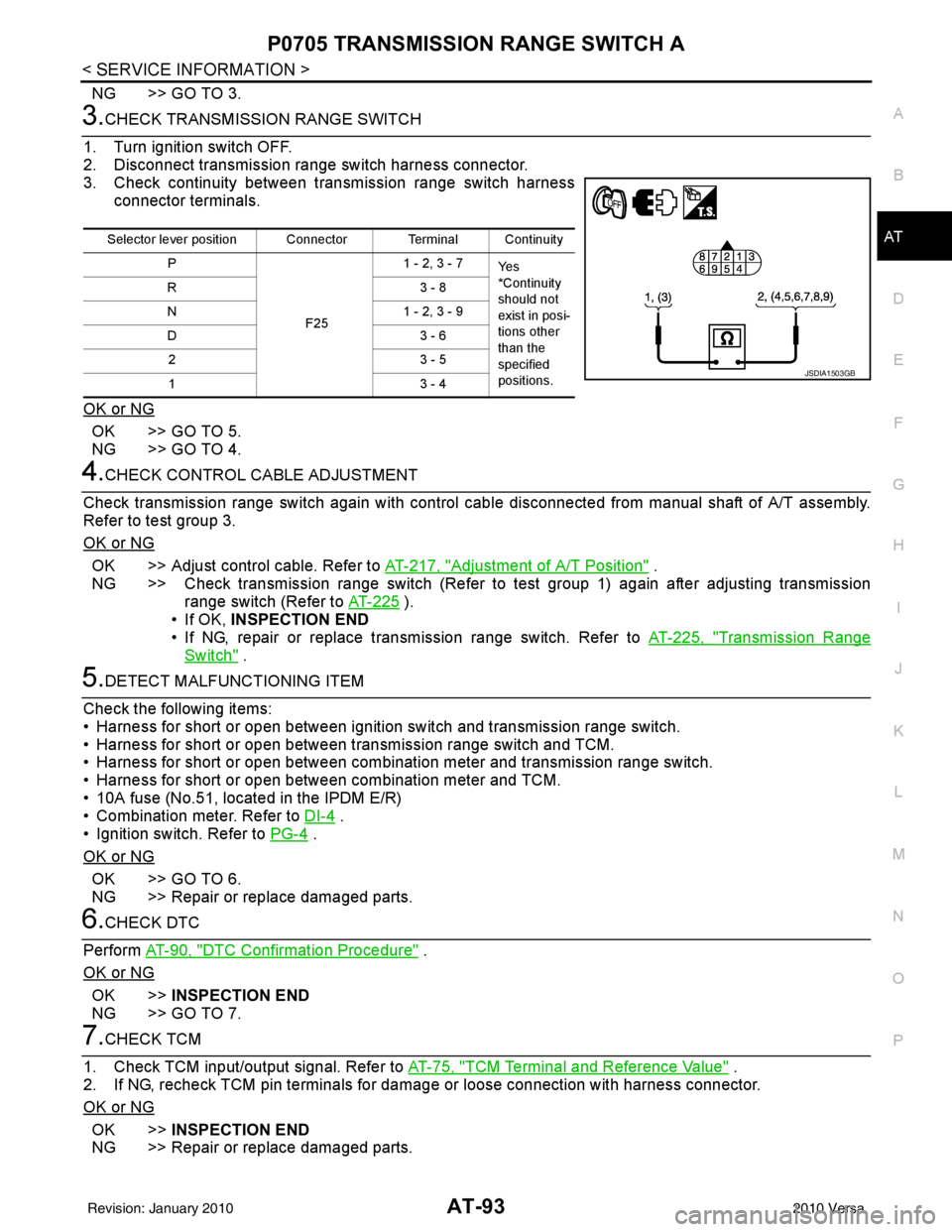

3.CHECK TRANSMISSION RANGE SWITCH

1. Turn ignition switch OFF.

2. Disconnect transmission range switch harness connector.

3. Check continuity between transmission range switch harness connector terminals.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK CONTROL CABLE ADJUSTMENT

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 3.

OK or NG

OK >> Adjust control cable. Refer to AT-217, "Adjustment of A/T Position" .

NG >> Check transmission range switch (Refer to test group 1) again after adjusting transmission range switch (Refer to AT-225

).

• If OK, INSPECTION END

• If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch" .

5.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between ignition switch and transmission range switch.

• Harness for short or open between transmission range switch and TCM.

• Harness for short or open between combination meter and transmission range switch.

• Harness for short or open between combination meter and TCM.

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-4

.

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK DTC

Perform AT-90, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Selector lever position Connector Terminal Continuity

P

F251 - 2, 3 - 7

Ye s

*Continuity

should not

exist in posi-

tions other

than the

specified

positions.

R3

- 8

N 1 - 2, 3 - 9

D3 - 6

23 - 5

13 - 4

JSDIA1503GB

Revision: January 20102010 Versa