ESP NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 155 of 3745

AT-138

< SERVICE INFORMATION >

P0750 SHIFT SOLENOID A

P0750 SHIFT SOLENOID A

DescriptionINFOID:0000000005397332

Shift solenoid valves A and B are turned ON or OFF by the TCM in response to signals sent from the transmis-

sion range switch, vehicle speed and ECM (throttle opening) . Gears will then be shifted to the optimum posi-

tion.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397333

On Board Diagn osis LogicINFOID:0000000005397334

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0750 SHIFT SOLENOID A” wi th CONSULT-III or 4th judgement flicker without

CONSULT-III is detected when TCM detects an improper voltage drop when it tries to operate the solenoid

valve.

Possible CauseINFOID:0000000005397335

• Harness or connector (The solenoid circuit is open or shorted.)

• Shift solenoid valve A

DTC Confirmation ProcedureINFOID:0000000005397336

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine.

4. Drive vehicle in “D” position and allow the transaxle to shift 1 → 2 (“GEAR”).

5. If the check result is NG, go to AT-140, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle in D

1→ D2 position.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-140, "

Diagnosis Procedure" .

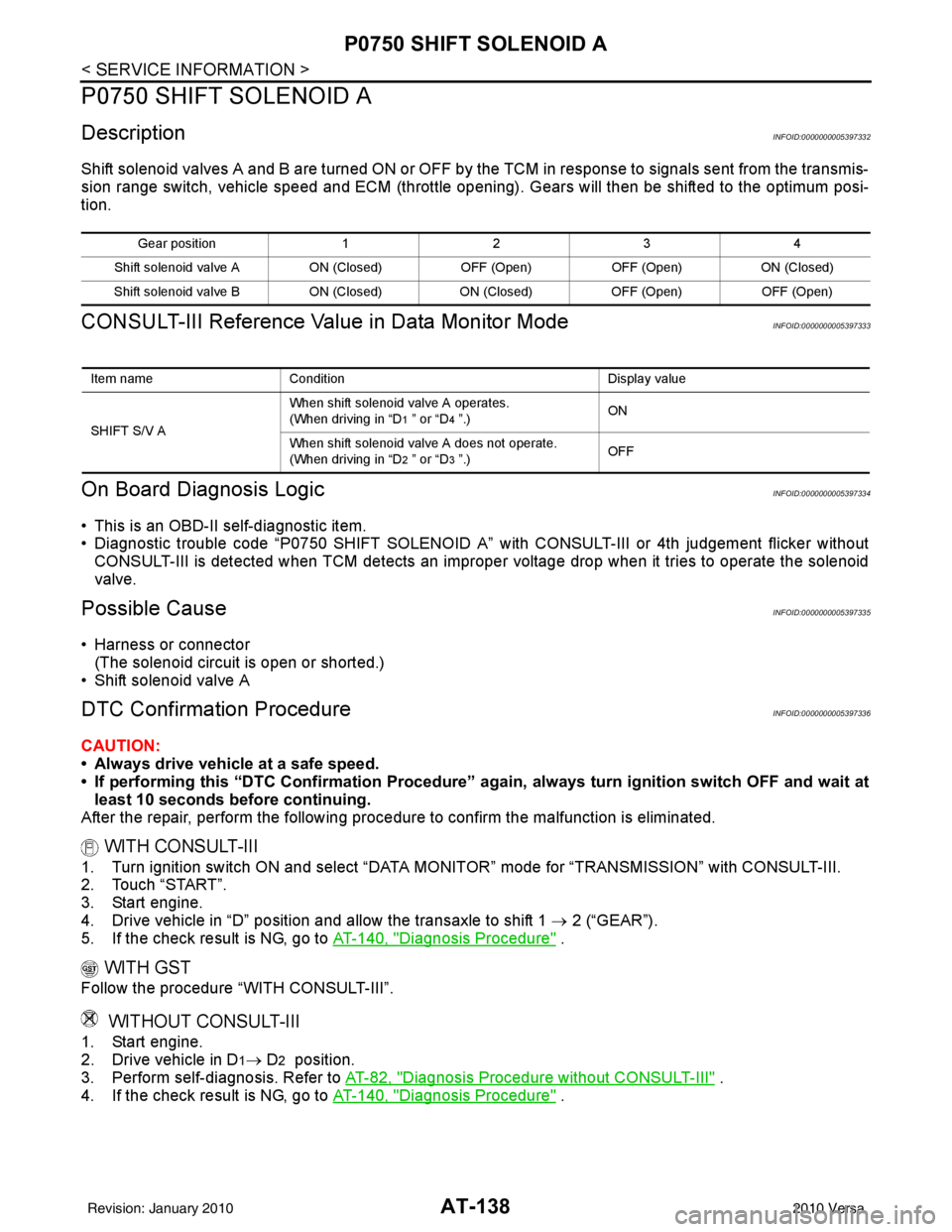

Gea r p osit io n1234

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Item name Condition Display value

SHIFT S/V A When shift solenoid valve A operates.

(When driving in “D

1 ” or “D4 ”.)

ON

When shift solenoid valve A does not operate.

(When driving in “D

2 ” or “D3 ”.) OFF

Revision: January 20102010 Versa

Page 160 of 3745

P0755 SHIFT SOLENOID BAT-143

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0755 SHIFT SOLENOID B

DescriptionINFOID:0000000005397340

Shift solenoid valves A and B are turned ON or OFF by the TCM in response to signals sent from the transmis-

sion range switch, vehicle speed and ECM (throttle openi ng). Gears will then be shifted to the optimum posi-

tion.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397341

On Board Diagnosis LogicINFOID:0000000005397342

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0755 SHIFT SOLENOID B” with CONSULT-III or 5th judgement flicker without

CONSULT-III is detected when TCM detects an improper voltage drop when it tries to operate the solenoid

valve.

Possible CauseINFOID:0000000005397343

• Harness or connector

(The solenoid circuit is open or shorted.)

• Shift solenoid valve B

DTC Confirmation ProcedureINFOID:0000000005397344

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine.

4. Drive vehicle in D position and allow the transaxle to shift 1 → 2 → 3 (“GEAR”).

5. If the check result is NG, go to AT-145, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle in D

1→ D2→ D3 position.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-145, "

Diagnosis Procedure" .

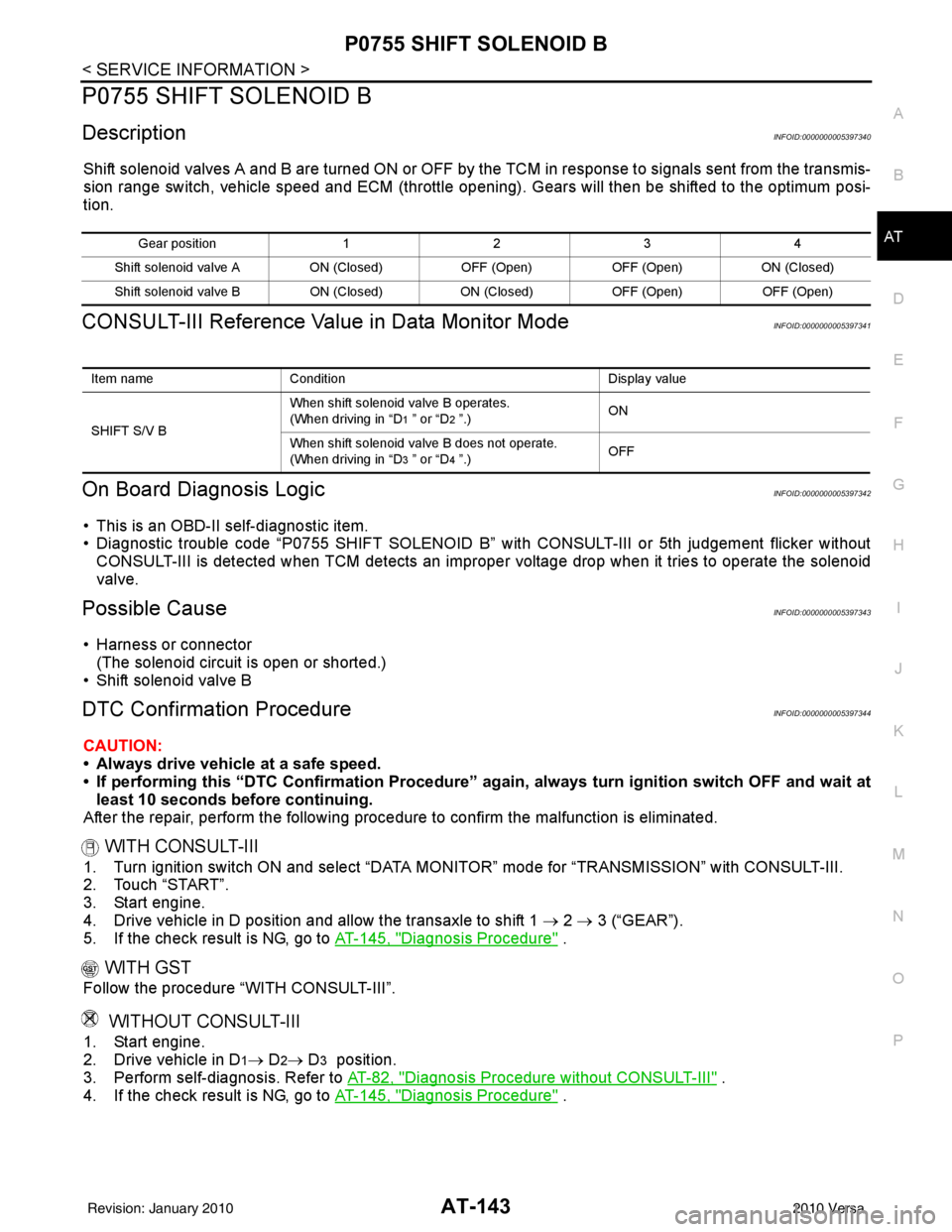

Gear position 123 4

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Item name Condition Display value

SHIFT S/V B When shift solenoid valve B operates.

(When driving in “D

1 ” or “D2 ”.)

ON

When shift solenoid valve B does not operate.

(When driving in “D

3 ” or “D4 ”.) OFF

Revision: January 20102010 Versa

Page 165 of 3745

AT-148

< SERVICE INFORMATION >

P1760 OVERRUN CLUTCH SOLENOID

P1760 OVERRUN CLUTCH SOLENOID

DescriptionINFOID:0000000005397348

The overrun clutch solenoid valve is activated by the TCM in response to signals sent from the transmission

range switch, overdrive control switch, vehicle speed and ECM (throttle opening). The overrun clutch opera-

tion will then be controlled.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397349

On Board Diagn osis LogicINFOID:0000000005397350

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1760 OVER CLUTCH SOLENOID ” with CONSULT-III or 6th judgement flicker

without CONSULT-III is detected when TCM detects an improper voltage drop when it tries to operate sole-

noid valve.

Possible CauseINFOID:0000000005397351

• Harness or connector

(The solenoid circuit is open or shorted.)

• Overrun clutch solenoid valve

DTC Confirmation ProcedureINFOID:0000000005397352

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine.

4. Accelerate vehicle to a speed of more t han 10 km/h (6 MPH) with “D” position (OD ON).

5. Release accelerator pedal completely with “D” position (OD OFF).

6. If the check result is NG, go to AT-150, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions:

Selector lever position: “D” position (OD ON)

Vehicle speed: Higher than 10 km/h (6 MPH)

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-150, "

Diagnosis Procedure" .

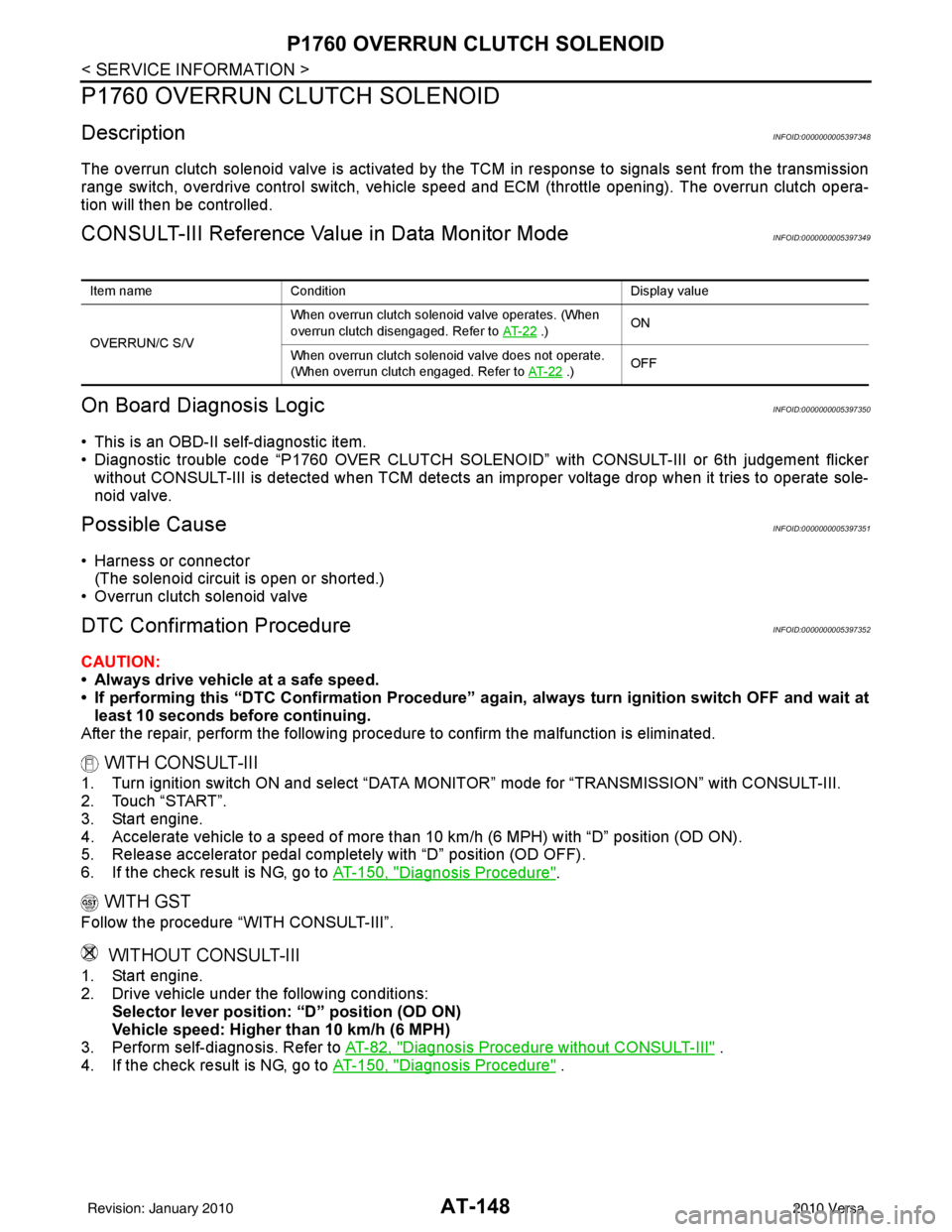

Item nameCondition Display value

OVERRUN/C S/V When overrun clutch solenoid valve operates. (When

overrun clutch disengaged. Refer to

AT- 2 2

.)ON

When overrun clutch solenoid valve does not operate.

(When overrun clutch engaged. Refer to AT- 2 2

.)OFF

Revision: January 20102010 Versa

Page 223 of 3745

AT-206

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

DescriptionINFOID:0000000005397413

WITH INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock:With the ignition knob switch turned to ON, selector lever cannot be shifted from “P” position to any other

position unless brake pedal is depressed.

With the ignition knob switch turned to OFF, selector lever cannot be shifted from “P” position to any other

position.

• The shift lock and key interlock mechanisms are contro lled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the i gnition knob switch, respectively.

WITHOUT INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock:

With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are contro lled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside key cylinder, respectively.

Revision: January 20102010 Versa

Page 247 of 3745

AT-230

< SERVICE INFORMATION >

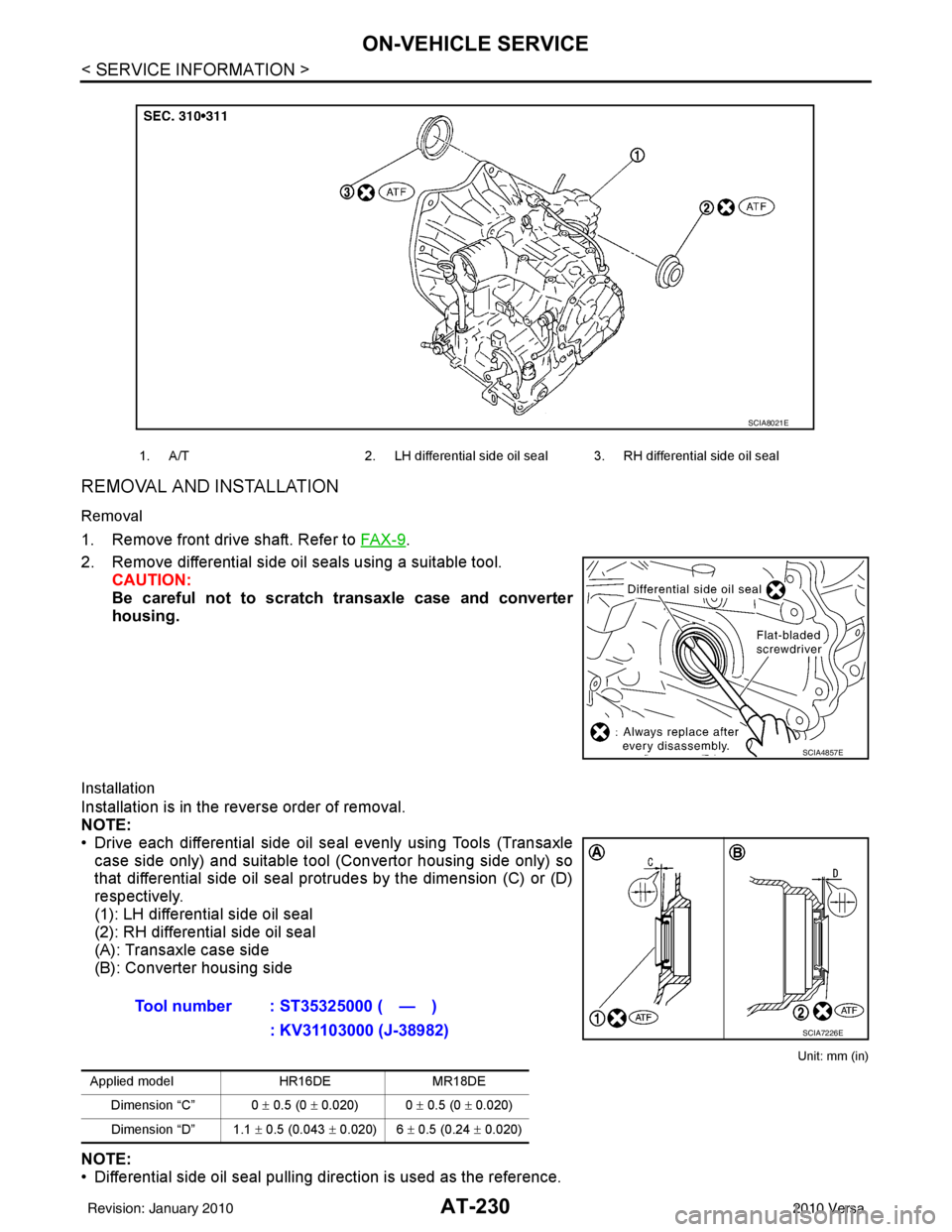

ON-VEHICLE SERVICE

REMOVAL AND INSTALLATION

Removal

1. Remove front drive shaft. Refer to FA X - 9.

2. Remove differential side oil seals using a suitable tool. CAUTION:

Be careful not to scratch transaxle case and converter

housing.

Installation

Installation is in the reverse order of removal.

NOTE:

• Drive each differential side oil seal evenly using Tools (Transaxlecase side only) and suitable tool (Convertor housing side only) so

that differential side oil seal prot rudes by the dimension (C) or (D)

respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

• Differential side oil seal pulling direction is used as the reference.

1. A/T 2. LH differential side oil seal 3. RH differential side oil seal

SCIA8021E

SCIA4857E

Tool number : ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DEMR18DE

Dimension “C” 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension “D” 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

Revision: January 20102010 Versa

Page 332 of 3745

REPAIR FOR COMPONENT PARTSAT-315

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

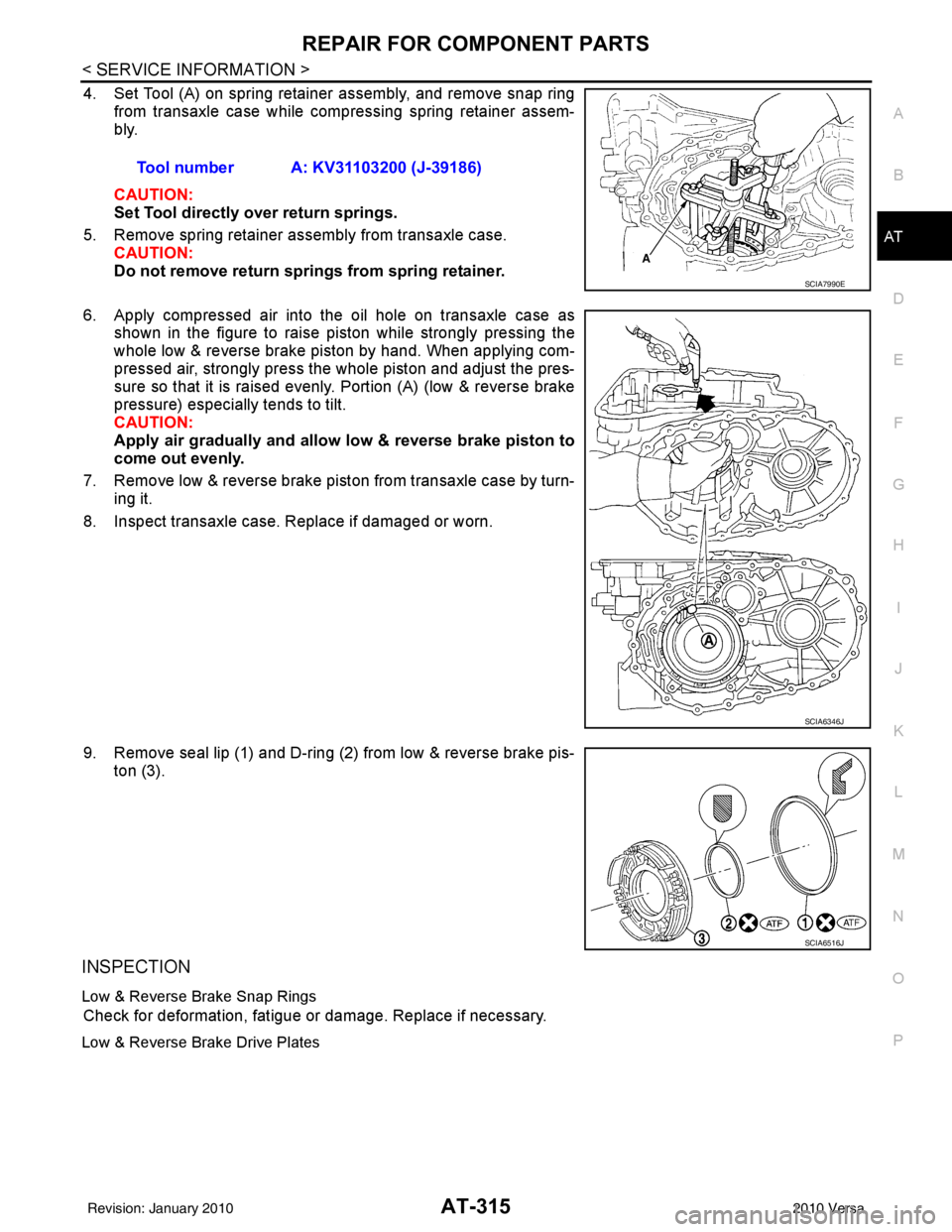

4. Set Tool (A) on spring retainer assembly, and remove snap ring from transaxle case while compressing spring retainer assem-

bly.

CAUTION:

Set Tool directly over return springs.

5. Remove spring retainer assembly from transaxle case. CAUTION:

Do not remove return springs from spring retainer.

6. Apply compressed air into the oil hole on transaxle case as shown in the figure to raise piston while strongly pressing the

whole low & reverse brake piston by hand. When applying com-

pressed air, strongly press the whole piston and adjust the pres-

sure so that it is raised evenly. Portion (A) (low & reverse brake

pressure) especially tends to tilt.

CAUTION:

Apply air gradually and allow low & reverse brake piston to

come out evenly.

7. Remove low & reverse brake piston from transaxle case by turn- ing it.

8. Inspect transaxle case. Replace if damaged or worn.

9. Remove seal lip (1) and D-ring (2) from low & reverse brake pis- ton (3).

INSPECTION

Low & Reverse Brake Snap Rings

Check for deformation, fatigue or damage. Replace if necessary.

Low & Reverse Brake Drive Plates

Tool number A: KV31103200 (J-39186)

SCIA7990E

SCIA6346J

SCIA6516J

Revision: January 20102010 Versa

Page 361 of 3745

AT-344

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

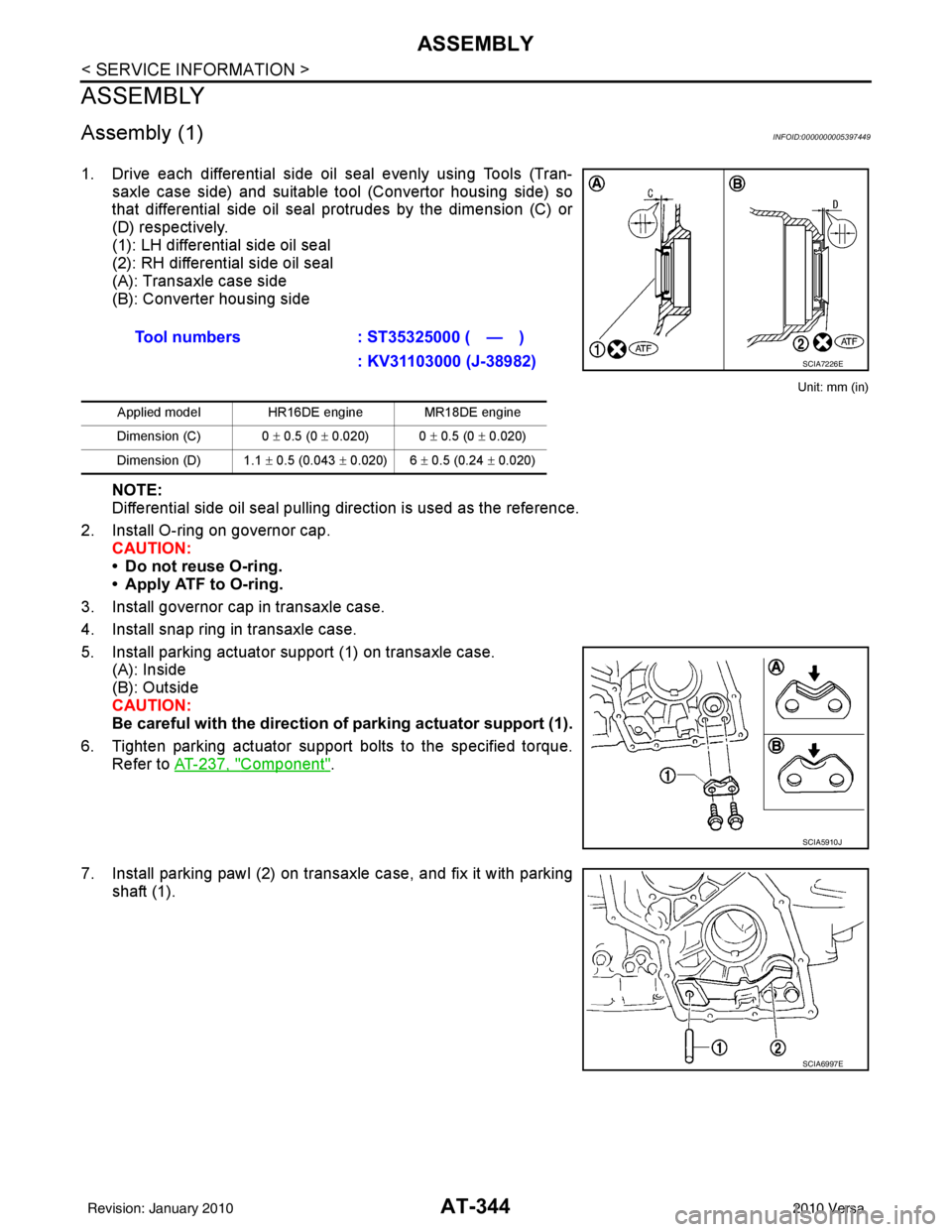

Assembly (1)INFOID:0000000005397449

1. Drive each differential side oil seal evenly using Tools (Tran-saxle case side) and suitable tool (Convertor housing side) so

that differential side oil seal protrudes by the dimension (C) or

(D) respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case. (A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque. Refer to AT-237, "

Component".

7. Install parking pawl (2) on transaxle case, and fix it with parking shaft (1).Tool numbers

: ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DE engine MR18DE engine

Dimension (C) 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension (D) 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

SCIA5910J

SCIA6997E

Revision: January 20102010 Versa

Page 418 of 3745

![NISSAN TIIDA 2010 Service User Guide AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or e NISSAN TIIDA 2010 Service User Guide AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or e](/img/5/57397/w960_57397-417.png)

AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or external noise

from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the antenna at a different time from the waves t hat reflect off of mountains or buildings.

Noise InspectionINFOID:0000000005395318

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

TYPE OF NOISE AND POSSIBLE CAUSE

No sound can be heard from one or several speakers. • Open or short in audio signal circuit between audio unit and front

speaker. Refer to AV- 2 4 , "

Sound Is Not Heard from Front Door

Speaker (Base System)" or AV- 2 6 , "Sound Is Not Heard from

Front Door Speaker or Tweeter (Premium System)" .

• Front speaker. Refer to AV- 2 4 , "

Sound Is Not Heard from Front

Door Speaker (Base System)" or AV- 2 6 , "Sound Is Not Heard

from Front Door Speaker or Tweeter (Premium System)" .

• Open or short in audio signal circuit between audio unit and rear

speaker. Refer to AV- 2 5 , "

Sound Is Not Heard from Rear Door

Speaker (Base System)" or AV- 2 7 , "Sound Is Not Heard from

Rear Door Speaker (Premium System)" .

• Rear speaker. Refer to AV- 2 5 , "

Sound Is Not Heard from Rear

Door Speaker (Base System)" or AV- 2 7 , "Sound Is Not Heard

from Rear Door Speaker (Premium System)" .

• Tweeter (mid level and premium system) AV- 2 6 , "

Sound Is Not

Heard from Front Door Speaker or Tweeter (Premium System)"

or AV- 2 7 , "

Sound Is Not Heard from Rear Door Speaker (Premi-

um System)" .

• Audio unit. Refer to AV- 2 9 , "

Removal and Installation" .

No sound can be heard from radio or noise is heard. • Antenna feeder. Refer to

AV- 3 3

.

• Antenna. Refer to AV- 3 3

.

• Audio unit. Refer to AV- 2 9 , "

Removal and Installation" .

Symptom

Check item

Occurrence condition Possible cause

Occurs only when engine is ON. A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.

Ignition components

A whistling noise occurs while the engine speed is

high. A booming noise occurs while the engine is

running and the lighting switch is ON. Generator

Noise only occurs when various

electrical components are oper-

ating. A cracking or snapping sound occurs with the op-

eration of various switches.

Relay malfunction, radio malfunction

The noise occurs when various motors are operat-

ing. • Motor case ground

•Motor

The noise occurs constantly, not just under certain conditions. • Rear defogger coil malfunction

• Open circuit in printed heater

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. • Ground wire of body parts.

• Ground due to improper part installation

• Wiring connections or a short circuit

Revision: January 20102010 Versa

Page 459 of 3745

![NISSAN TIIDA 2010 Service User Guide AV-62

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

On-Board Diagnosis

INFOID:0000000005988546

METHOD OF STARTING

1. Start the engine.

2. Turn OFF audio.

3. While pressing the “SET UP” s wi NISSAN TIIDA 2010 Service User Guide AV-62

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

On-Board Diagnosis

INFOID:0000000005988546

METHOD OF STARTING

1. Start the engine.

2. Turn OFF audio.

3. While pressing the “SET UP” s wi](/img/5/57397/w960_57397-458.png)

AV-62

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

On-Board Diagnosis

INFOID:0000000005988546

METHOD OF STARTING

1. Start the engine.

2. Turn OFF audio.

3. While pressing the “SET UP” s witch, turn the MENU dial coun-

terclockwise 3 clicks or more first, then clockwise and counter-

clockwise 3 clicks or more, respectively. (After the diagnosis

mode starts, the initial screen of the diagnosis mode appears.)

• On-board diagnosis can be performed in the service test mode.

• On-board diagnosis checks that the system can be operated normally.

Service test mode

46 (L) — AUX sound

signal LH—— —

——

47 (W) — USB D- — — —— —

48 (GR) — AUX sound

signal RH—— —

——

49 (G) — USB D+ — — —— —

50 (BR) — AUX sound

signal

ground—— —

——

51 (R) — USB V BUS

signal—— —

——

53 (GR) — SHIELD — — —— —

54 — Satellite an-

tenna signal

—— —

——

55 — GPS anten-

na signal—— —

——

56 — SHIELD — — —— —

57 — Antenna on

signal—— —

——

58 — Main anten-

na signal

—— —

——

Te r m i n a l

(Wire color) ItemSignal

input/

output Condition

Reference value

(Approx.) Example of symp-

tom

+– Ignition

switch Operation

JSNIA2456ZZ

Mode

ItemContent

Service version —The version data of the parts is shown

displayed.

Revision: January 20102010 Versa

Page 461 of 3745

![NISSAN TIIDA 2010 Service User Guide AV-64

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

System stateRunning system status

• SD card slot Access

• Power Supply

• Speed Signal

• Direction Signal

• Illumination Signal

• NISSAN TIIDA 2010 Service User Guide AV-64

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

System stateRunning system status

• SD card slot Access

• Power Supply

• Speed Signal

• Direction Signal

• Illumination Signal

•](/img/5/57397/w960_57397-460.png)

AV-64

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

System stateRunning system status

• SD card slot Access

• Power Supply

• Speed Signal

• Direction Signal

• Illumination Signal

• GPS Antenna

• EXT. Phone Sig

• Microphone Current

• Radio Antenna

• USB Device

•iPod

® firmware version

• Steering wheel X11C The current system status is dis-

played.

System history •Bluetooth

® Module - Sub-Unit

Connection Malfunction

• SD-card Slot - Sub-Unit Connec- tion Malfunction

• Programming Error

• Radio-Antenna Circuit Malfunc- tion

• FM-Antenna 1 Connection Mal- function

• Satellite Antenna Connection

Failure

• GPS Antenna Circuit Malfunc- tion

• CD-Drive Mechanical Malfunc- tion

• CD Read Malfunction

• Power Supply voltage: Lower

Limit Exceeded

• Power Supply voltage: Upper

Limit Exceeded

• Reduced system Functionality due to over temperature

• Display switched OFF due to over temperature

• SD card removed without being de-mounted

• Code plug missing The history of the system status is re-

ported in the report memory, dis-

played.

Speaker test 100Hz —This activates a sequence of test tone

outputs to the four speaker lines one

after the other for 1 second.

The frequency can be chosen by user

selection (100Hz and 4KHz).

Speaker test 4KHz

Display test —This provides a test sequence where

test displays (plain colored display:

e.g. white, black, red, blue, green) are

shown one after the other.

The respective color is shown for an

indicated period of time (parameter).

After the display test, the design of the

display previously available is stored.

While the screen shows a plain col-

ored display, a pixel malfunction may

be detected.

Mode

ItemContent

Revision: January 20102010 Versa