ESP NISSAN TIIDA 2010 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1133 of 3745

![NISSAN TIIDA 2010 Service Service Manual CVT-100

< SERVICE INFORMATION >[RE0F08B]

P0778 PRESSURE CONTROL SOLENOID B

P0778 PRESSURE CONTROL SOLENOID B

DescriptionINFOID:0000000005397892

• The secondary pressure solenoid valve is included in NISSAN TIIDA 2010 Service Service Manual CVT-100

< SERVICE INFORMATION >[RE0F08B]

P0778 PRESSURE CONTROL SOLENOID B

P0778 PRESSURE CONTROL SOLENOID B

DescriptionINFOID:0000000005397892

• The secondary pressure solenoid valve is included in](/img/5/57397/w960_57397-1132.png)

CVT-100

< SERVICE INFORMATION >[RE0F08B]

P0778 PRESSURE CONTROL SOLENOID B

P0778 PRESSURE CONTROL SOLENOID B

DescriptionINFOID:0000000005397892

• The secondary pressure solenoid valve is included in the control valve assembly.

• The secondary pressure solenoid valve regulates the oi

l pump discharge pressure to suit the driving condi-

tion in response to a signal sent from the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397893

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397894

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0778” with CONSULT-III is detected under the following conditions.

- TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM compares target value with monitor value and detects an irregularity.

Possible CauseINFOID:0000000005397895

• Harness or connectors (Solenoid circuit is open or shorted.)

• Secondary pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000005397896

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and wait at least 5 seconds.

4. If DTC is detected, go to CVT-102, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

ISOLT3 Secondary pressure low - Secondary pressure high 0.8 - 0.0 A

SOLMON3 “N” position idle

0.6 - 0.7 A

When stalled 0.4 - 0.6 A

Revision: January 20102010 Versa

Page 1144 of 3745

![NISSAN TIIDA 2010 Service Service Manual P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pres NISSAN TIIDA 2010 Service Service Manual P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pres](/img/5/57397/w960_57397-1143.png)

P0868 TRANSMISSION FLUID PRESSURECVT-111

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P0868 TRANSMISSION FLUID PRESSURE

DescriptionINFOID:0000000005397913

• The secondary pressure solenoid valve is included in the control valve assembly.

• The secondary pressure solenoid valve regulates the secondary pressure to suit the driving condition in

response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005397914

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397915

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0868” with CONSULT-III is det ected when secondary fluid pressure is too low

compared with the commanded value while driving.

Possible CauseINFOID:0000000005397916

• Harness or connectors (Solenoid circuit is open or shorted.)

• Secondary pressure solenoid valve system

• Secondary pressure sensor

• Line pressure control system

DTC Confirmation ProcedureINFOID:0000000005397917

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and maintain the following conditions for at least 10 consecutive seconds. VEHICLE SPEED (accelerate slowly): 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN: 0.5/8 - 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-111, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005397918

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start vehicle and read out the value of “SEC PRESS”.

OK or NG

Item name Condition Display value (Approx.)

SEC PRESS “N” position idle 0.8 MPa

Item nameConditionDisplay value (Approx.)

SEC PRESS “N” position idle0.8 MPa

Revision: January 20102010 Versa

Page 1161 of 3745

![NISSAN TIIDA 2010 Service Service Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005397955

The line pressure solenoid valve regulates the oil pump discharge pr NISSAN TIIDA 2010 Service Service Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005397955

The line pressure solenoid valve regulates the oil pump discharge pr](/img/5/57397/w960_57397-1160.png)

CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005397955

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

On Board Diagn

osis LogicINFOID:0000000005397956

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1745” with CONSULT-III is detected when TCM detects the unexpected line pres-

sure.

Possible CauseINFOID:0000000005397957

TCM

DTC Confirmation ProcedureINFOID:0000000005397958

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. If DTC is detected, go to CVT-128, "

Diagnosis Procedure" .

Diagnosis ProcedureINFOID:0000000005397959

1.CHECK DTC

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode fo r “TRANSMISSION” with CONSULT-III.

3. Erase self-diagnostic results. Refer to CVT-27, "

OBD-II Diagnostic Trouble Code (DTC)".

4. Turn ignition switch OFF, and wait for 10 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-48, "

CONSULT-III Function (TRANSMISSION)" .

Is the

“P1745” displayed?

YES >> Replace TCM. Refer to CVT-159, "Removal and Installation" .

NO >> INSPECTION END

Revision: January 20102010 Versa

Page 1162 of 3745

![NISSAN TIIDA 2010 Service Service Manual P1777 STEP MOTORCVT-129

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1777 STEP MOTOR

DescriptionINFOID:0000000005397960

• The step motor is included in the control valve asse NISSAN TIIDA 2010 Service Service Manual P1777 STEP MOTORCVT-129

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1777 STEP MOTOR

DescriptionINFOID:0000000005397960

• The step motor is included in the control valve asse](/img/5/57397/w960_57397-1161.png)

P1777 STEP MOTORCVT-129

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1777 STEP MOTOR

DescriptionINFOID:0000000005397960

• The step motor is included in the control valve assembly.

• The step motor changes the step with turning 4 coils ON/OF F according to the signal from TCM. As a result,

the flow of line pressure to primary pu lley is changed and pulley ratio is controlled

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397961

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005397962

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1777” with CONSULT-III is detected under the following conditions.

- When operating step motor ON and OFF, there is no proper change in the voltage of TCM terminal which

corresponds to it.

Possible CauseINFOID:0000000005397963

• Step motor

• Harness or connectors(Step motor circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005397964

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Drive vehicle for at least 5 consecutive seconds.

3. If DTC is detected, go to CVT-131, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name ConditionDisplay value (Approx.)

STM STEP

During driving(−

20) - (+180) step

SMCOIL A

Changes on⇔off.

SMCOIL B

SMCOIL C

SMCOIL D

Revision: January 20102010 Versa

Page 1186 of 3745

![NISSAN TIIDA 2010 Service Service Manual CVT SHIFT LOCK SYSTEMCVT-153

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT SHIFT LOCK SYSTEM

DescriptionINFOID:0000000005397994

WITH INTELLIGENT KEY

• The mechanical key in NISSAN TIIDA 2010 Service Service Manual CVT SHIFT LOCK SYSTEMCVT-153

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT SHIFT LOCK SYSTEM

DescriptionINFOID:0000000005397994

WITH INTELLIGENT KEY

• The mechanical key in](/img/5/57397/w960_57397-1185.png)

CVT SHIFT LOCK SYSTEMCVT-153

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT SHIFT LOCK SYSTEM

DescriptionINFOID:0000000005397994

WITH INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock: With the ignition knob switch turned to ON, selector lever cannot be shifted from “P” position to any other

position unless brake pedal is depressed.

With the ignition knob switch turned to OFF, selector lever cannot be shifted from “P” position to any other

position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole- noid and by the operation of the ignition knob switch, respectively.

WITHOUT INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock:With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and sli der located inside key cylinder, respectively.

Revision: January 20102010 Versa

Page 1259 of 3745

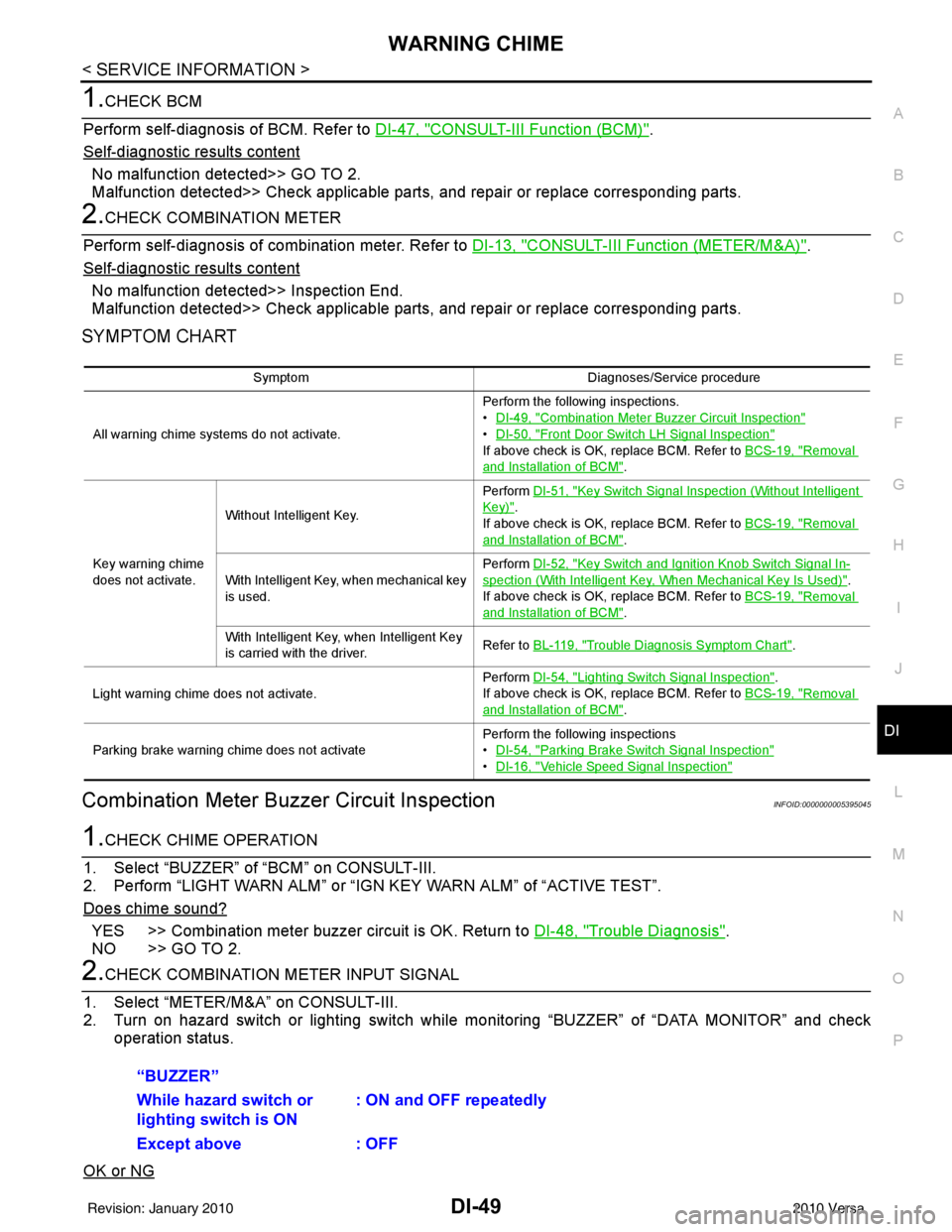

WARNING CHIMEDI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

1.CHECK BCM

Perform self-diagnosis of BCM. Refer to DI-47, "

CONSULT-III Function (BCM)".

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK COMBINATION METER

Perform self-diagnosis of combination meter. Refer to DI-13, "

CONSULT-III Function (METER/M&A)".

Self

-diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Combination Meter Buzzer Circuit InspectionINFOID:0000000005395045

1.CHECK CHIME OPERATION

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> Combination meter buzzer circuit is OK. Return to DI-48, "Trouble Diagnosis".

NO >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Turn on hazard switch or lighting switch while monitoring “BUZZER” of “DATA MONITOR” and check

operation status.

OK or NG

Symptom Diagnoses/Service procedure

All warning chime systems do not activate. Perform the following inspections.

•

DI-49, "

Combination Meter Buzzer Circuit Inspection"

•DI-50, "Front Door Switch LH Signal Inspection"

If above check is OK, replace BCM. Refer to BCS-19, "Removal

and Installation of BCM".

Key warning chime

does not activate. Without Intelligent Key.

Perform

DI-51, "

Key Switch Signal Inspection (Without Intelligent

Key)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when mechanical key

is used. Perform

DI-52, "

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when Intelligent Key

is carried with the driver. Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

Light warning chime does not activate. Perform

DI-54, "

Lighting Switch Signal Inspection".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

Parking brake warning chime does not activate Perform the following inspections

•

DI-54, "

Parking Brake Switch Signal Inspection"

•DI-16, "Vehicle Speed Signal Inspection"

“BUZZER”

While hazard switch or

lighting switch is ON : ON and OFF repeatedly

Except above : OFF

Revision: January 20102010 Versa

Page 1285 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-20

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000000005398231

1.INSPECTION START

1. Check NISSAN TIIDA 2010 Service Service Manual EC-20

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000000005398231

1.INSPECTION START

1. Check](/img/5/57397/w960_57397-1284.png)

EC-20

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000000005398231

1.INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

Is any DTC detected?

YES >> GO TO 2.

NO >> GO TO 3.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3

3.CHECK IDLE SPEED

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Revision: January 20102010 Versa

Page 1325 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-60

< FUNCTION DIAGNOSIS >[HR16DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000005398265

System DescriptionINFOID:0000000005398266

INPUT/OUTPUT SIGNAL CHART

*1: The ECM deter NISSAN TIIDA 2010 Service Service Manual EC-60

< FUNCTION DIAGNOSIS >[HR16DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000005398265

System DescriptionINFOID:0000000005398266

INPUT/OUTPUT SIGNAL CHART

*1: The ECM deter](/img/5/57397/w960_57397-1324.png)

EC-60

< FUNCTION DIAGNOSIS >[HR16DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000005398265

System DescriptionINFOID:0000000005398266

INPUT/OUTPUT SIGNAL CHART

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM via the CAN communication line.

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle

speed, engine coolant temperature, refrigerant pres-

sure, air conditioner ON signal. Then contro l system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

JMBIA2196GB

SensorInput signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

1

Cooling fan

controlIPDM E/R

↓

Cooling fan relay

↓

Cooling fan motor

Battery

Battery voltage*

1

ABS actuator and electric unit (control unit)

Vehicle speed*2Combination meter

Engine coolant temperature sensorEngine coolant temperature

BCM Air conditioner ON signal*

2

Refrigerant pressure sensorRefrigerant pressure

Revision: January 20102010 Versa

Page 1352 of 3745

![NISSAN TIIDA 2010 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-87

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, an NISSAN TIIDA 2010 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-87

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, an](/img/5/57397/w960_57397-1351.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-87

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test

may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT i ndicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If permanent DTC is stored or MIL illuminates during the state emissions inspection, the vehicle is also

returned to the customer untested even though the SRT indicates “CMPLT” for all test items. Therefore, it is

important to check SRT (“CMPLT ”), DTC (No DTCs) and permanent DT C (No permanent DTCs) before the

inspection.

SRT Item

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*: If completion of several SRTs is required, perform driving patterns (DTC CONFIRMATION PROCEDURE), one by one based on the

priority for models with CONSULT-III.

SRT Set Timing

SRT is set as “CMPLT” after self-diagnosis has been performed one or more times. Completion of SRT is

done regardless of whether the result is OK or NG. T he set timing is different between OK and NG results and

is shown in the table below.

SRT item

(CONSULT-III indication) Performance

Priority* Required self-diagnostic items to set the SRT to “CMPLT” Corresponding

DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 P0133

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

EGR/VVT SYSTEM 3 Intake value timing control function P0011

Self-diagnosis resultExample

Diagnosis Ignition cycle

← ON →OFF ← ON → OFF← ON →OFF ← ON →

All OK Case 1 P0400 OK (1) — (1) OK (2) — (2) P0402OK (1) — (1)— (1)OK (2)

P1402 OK (1) OK (2) — (2)— (2)

SRT of EGR “CMPLT” “CMPLT” “CMPLT” “CMPLT”

Case 2 P0400OK (1) — (1)— (1) — (1)

P0402 — (0)— (0)OK (1) — (1)

P1402 OK (1) OK (2) — (2)— (2)

SRT of EGR “INCMP” “INCMP” “CMPLT” “CMPLT”

Revision: January 20102010 Versa

Page 1353 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-88

< FUNCTION DIAGNOSIS >[HR16DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

OK: Self-diagnosis is carried out and the result is OK.

NG: Self-diagnosis is carried out and the result is NG.

—: Self-diagnosi NISSAN TIIDA 2010 Service Service Manual EC-88

< FUNCTION DIAGNOSIS >[HR16DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

OK: Self-diagnosis is carried out and the result is OK.

NG: Self-diagnosis is carried out and the result is NG.

—: Self-diagnosi](/img/5/57397/w960_57397-1352.png)

EC-88

< FUNCTION DIAGNOSIS >[HR16DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

OK: Self-diagnosis is carried out and the result is OK.

NG: Self-diagnosis is carried out and the result is NG.

—: Self-diagnosis is not carried out.

When all SRT related self-diagnoses showed OK results in a single cycle (Ignition OFF-ON-OFF), the SRT will

indicate “CMPLT”.

→ Case 1 above

When all SRT related self-diagnoses showed OK results through several different cycles, the SRT will indicate

“CMPLT” at the time the respective se lf-diagnoses have at least one OK result. → Case 2 above

If one or more SRT related self-diagnoses showed NG resu lts in 2 consecutive cycles, the SRT will also indi-

cate “CMPLT”. → Case 3 above

The table above shows that the minimum number of cycl es for setting SRT as “INCMP” is one (1) for each

self-diagnosis (Case 1 & 2) or two (2) for one of self-diagnoses (Case 3). However, in preparation for the state

emissions inspection, it is unnecessary for each self-d iagnosis to be executed twice (Case 3) for the following

reasons:

• The SRT will indicate “CMPLT” at the time the respective self-diagnoses have one (1) OK result.

• The emissions inspection requires “CMPLT” of the SRT only with OK self-diagnosis results.

• When, during SRT driving pattern, 1st trip DTC (NG) is detected prior to “CMPLT” of SRT, the self-diagnosis

memory must be erased from ECM after repair.

• If the 1st trip DTC is erased, all the SRT will indicate “INCMP”. NOTE:

SRT can be set as “CMPLT” together with the DTC(s). Therefore, DTC check must always be carried out

prior to the state emission inspection even though the SRT indicates “CMPLT”.

SRT Service Procedure

NG exists Case 3 P0400OKOK ——

P0402 ——— —

P1402 NG—NG NG

(Consecutive

NG)

(1st trip) DTC 1st trip DTC

—1st trip DTC DTC

(= MIL ON)

SRT of EGR “INCMP” “INCMP” “INCMP” “CMPLT”

Revision: January 20102010 Versa