Engine cooling system NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 995 of 3745

![NISSAN TIIDA 2010 Service User Guide ENGINE COOLANTCO-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. NISSAN TIIDA 2010 Service User Guide ENGINE COOLANTCO-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug.](/img/5/57397/w960_57397-994.png)

ENGINE COOLANTCO-13

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir

tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

•Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, "

Anti-freeze Coolant Mixture Ratio".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be visible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. Th is will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

Radiator drain plug : Refer to

CO-17, "

Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, "

Fluids

and Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: January 20102010 Versa

Page 996 of 3745

![NISSAN TIIDA 2010 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the r NISSAN TIIDA 2010 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the r](/img/5/57397/w960_57397-995.png)

CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-17, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-90, "

Disassem-

bly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-17, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Revision: January 20102010 Versa

Page 1013 of 3745

![NISSAN TIIDA 2010 Service User Guide PREPARATIONCO-31

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PREPARATION

Special Service ToolINFOID:0000000005398208

The actual shapes of Kent-Moore tools may from

those of speci NISSAN TIIDA 2010 Service User Guide PREPARATIONCO-31

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PREPARATION

Special Service ToolINFOID:0000000005398208

The actual shapes of Kent-Moore tools may from

those of speci](/img/5/57397/w960_57397-1012.png)

PREPARATIONCO-31

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PREPARATION

Special Service ToolINFOID:0000000005398208

The actual shapes of Kent-Moore tools may from

those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005398209

Tool number

(Kent-Moore No.)

Tool name Description

WS39930000

(—)

Tube pressure Pressing the tube of liquid gasket

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing chain tensioner cover and water

pump cover

—

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

S-NT052

LMA053

S-NT564

NT046

WBIA0539E

Revision: January 20102010 Versa

Page 1015 of 3745

![NISSAN TIIDA 2010 Service User Guide OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005398210

Symptom

Check items

Cooling sys NISSAN TIIDA 2010 Service User Guide OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005398210

Symptom

Check items

Cooling sys](/img/5/57397/w960_57397-1014.png)

OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005398210

Symptom

Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed Thermostat

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — —

Improper engine coolant

mixture ratio —

Engine coolant viscosity —

Poor engine coolant quality — —

Insufficient engine coolant Engine coolant leaks Cooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing systemCylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: January 20102010 Versa

Page 1018 of 3745

![NISSAN TIIDA 2010 Service User Guide CO-36

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

ENGINE COOLANT

InspectionINFOID:0000000005398212

LEVEL CHECK

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX NISSAN TIIDA 2010 Service User Guide CO-36

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

ENGINE COOLANT

InspectionINFOID:0000000005398212

LEVEL CHECK

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX](/img/5/57397/w960_57397-1017.png)

CO-36

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

ENGINE COOLANT

InspectionINFOID:0000000005398212

LEVEL CHECK

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

• Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantINFOID:0000000005398213

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-196

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-40, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm

2, 23 psi)

WBIA0568E

PBIC3799E

Revision: January 20102010 Versa

Page 1020 of 3745

![NISSAN TIIDA 2010 Service User Guide CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refi NISSAN TIIDA 2010 Service User Guide CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refi](/img/5/57397/w960_57397-1019.png)

CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-40, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-196, "

Disas-

sembly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-40, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Revision: January 20102010 Versa

Page 1025 of 3745

![NISSAN TIIDA 2010 Service User Guide COOLING FANCO-43

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000005398220

REMOVAL

1. Partially drain engine coolant from radiator. Refer to

CO- NISSAN TIIDA 2010 Service User Guide COOLING FANCO-43

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000005398220

REMOVAL

1. Partially drain engine coolant from radiator. Refer to

CO-](/img/5/57397/w960_57397-1024.png)

COOLING FANCO-43

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000005398220

REMOVAL

1. Partially drain engine coolant from radiator. Refer to

CO-36, "Changing Engine Coolant".

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-135, "

Component".

3. Remove reservoir tank. Refer to CO-40, "

Component".

4. Disconnect radiator hose (upper) at radiator side. Refer to CO-40, "

Component".

5. Disconnect harness connectors from fan motor, and move harness aside.

6. Remove cooling fan assembly. CAUTION:

Be careful not to damage or scratch the radiator core.

INSTALLATION

Installation is in the reverse order of removal.

• Cooling fans are controlled by ECM. For details, refer to EC-910, "

System Description".

CAUTION:

Be careful not to damage or scratch the radiator core.

Disassembly and AssemblyINFOID:0000000005398221

DISASSEMBLY

1. Remove cooling fan from fan motor.

2. Remove fan motor from fan shroud.

INSPECTION AFTER DISASSEMBLY

Inspect cooling fan for crack or unusual bend.

• If anything is found, replace cooling fan.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Revision: January 20102010 Versa

Page 1271 of 3745

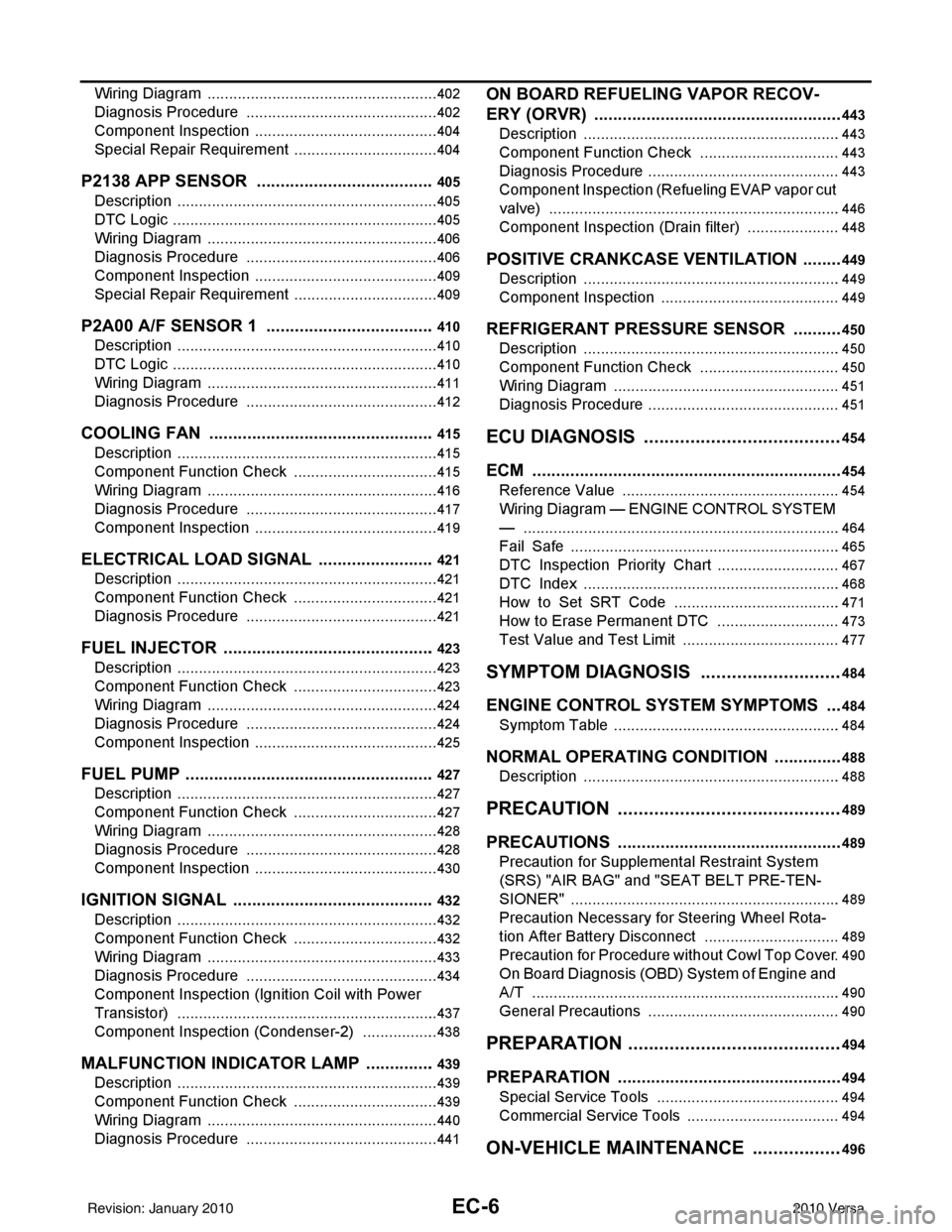

EC-6

Wiring Diagram ......................................................402

Diagnosis Procedure .............................................402

Component Inspection ...........................................404

Special Repair Requirement ..................................404

P2138 APP SENSOR ..................................... .405

Description ........................................................... ..405

DTC Logic ..............................................................405

Wiring Diagram ......................................................406

Diagnosis Procedure .............................................406

Component Inspection ...........................................409

Special Repair Requirement ..................................409

P2A00 A/F SENSOR 1 ................................... .410

Description ........................................................... ..410

DTC Logic ..............................................................410

Wiring Diagram ......................................................411

Diagnosis Procedure .............................................412

COOLING FAN ................................................415

Description ........................................................... ..415

Component Function Check ..................................415

Wiring Diagram ......................................................416

Diagnosis Procedure .............................................417

Component Inspection ...........................................419

ELECTRICAL LOAD SIGNAL .........................421

Description ........................................................... ..421

Component Function Check ..................................421

Diagnosis Procedure .............................................421

FUEL INJECTOR .............................................423

Description ........................................................... ..423

Component Function Check ..................................423

Wiring Diagram ......................................................424

Diagnosis Procedure .............................................424

Component Inspection ...........................................425

FUEL PUMP .....................................................427

Description ........................................................... ..427

Component Function Check ..................................427

Wiring Diagram ......................................................428

Diagnosis Procedure .............................................428

Component Inspection ...........................................430

IGNITION SIGNAL ...........................................432

Description ........................................................... ..432

Component Function Check ..................................432

Wiring Diagram ......................................................433

Diagnosis Procedure .............................................434

Component Inspection (Ignition Coil with Power

Transistor) .............................................................

437

Component Inspection (Condenser-2) ..................438

MALFUNCTION INDICATOR LAMP ...............439

Description ........................................................... ..439

Component Function Check ..................................439

Wiring Diagram ......................................................440

Diagnosis Procedure .............................................441

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

443

Description ........................................................... .443

Component Function Check .................................443

Diagnosis Procedure .............................................443

Component Inspection (Refueling EVAP vapor cut

valve) ................................................................... .

446

Component Inspection (Drain filter) ......................448

POSITIVE CRANKCASE VENTILATION .........449

Description ........................................................... .449

Component Inspection ..........................................449

REFRIGERANT PRESSURE SENSOR ...........450

Description ........................................................... .450

Component Function Check .................................450

Wiring Diagram .....................................................451

Diagnosis Procedure .............................................451

ECU DIAGNOSIS ......................................454

ECM ................................................................ ..454

Reference Value .................................................. .454

Wiring Diagram — ENGINE CONTROL SYSTEM

— ..........................................................................

464

Fail Safe ...............................................................465

DTC Inspection Priority Chart .............................467

DTC Index ............................................................468

How to Set SRT Code .......................................471

How to Erase Permanent DTC .............................473

Test Value and Test Limit .....................................477

SYMPTOM DIAGNOSIS ...........................484

ENGINE CONTROL SYSTEM SYMPTOMS .. ..484

Symptom Table .................................................... .484

NORMAL OPERATING CONDITION ...............488

Description ........................................................... .488

PRECAUTION ...........................................489

PRECAUTIONS .............................................. ..489

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

489

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

489

Precaution for Procedure without Cowl Top Cover .490

On Board Diagnosis (OBD) System of Engine and

A/T ........................................................................

490

General Precautions .............................................490

PREPARATION .........................................494

PREPARATION .............................................. ..494

Special Service Tools .......................................... .494

Commercial Service Tools ....................................494

ON-VEHICLE MAINTENANCE .................496

Revision: January 20102010 Versa

Page 1295 of 3745

![NISSAN TIIDA 2010 Service User Guide EC-30

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000005398249

ECM performs various controls such as fuel injection control and ignition timing control.

Componen NISSAN TIIDA 2010 Service User Guide EC-30

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000005398249

ECM performs various controls such as fuel injection control and ignition timing control.

Componen](/img/5/57397/w960_57397-1294.png)

EC-30

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000005398249

ECM performs various controls such as fuel injection control and ignition timing control.

Component Parts LocationINFOID:0000000005398250

1. Ignition coil (with power transistor) and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve

PBIB2939E

Revision: January 20102010 Versa

Page 1299 of 3745

![NISSAN TIIDA 2010 Service User Guide EC-34

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

Component Description

INFOID:0000000005398251

1. Cooling fan motor harness connec- tor 2. Crankshaft position sensor

3. Stop lamp switch

4. B NISSAN TIIDA 2010 Service User Guide EC-34

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

Component Description

INFOID:0000000005398251

1. Cooling fan motor harness connec- tor 2. Crankshaft position sensor

3. Stop lamp switch

4. B](/img/5/57397/w960_57397-1298.png)

EC-34

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

Component Description

INFOID:0000000005398251

1. Cooling fan motor harness connec- tor 2. Crankshaft position sensor

3. Stop lamp switch

4. Brake pedal 5. Accelerator pedal position sensor

harness connector 6. Accelerator pedal position sensor

7. Accelerator pedal 8. Fuel level sensor unit and fuel pump

harness connector (view with in-

spection hole cover removed) 9. Fuel pressure regulator

10. Fuel pump

AWBIA0044ZZ

Component Reference

A/F sensor 1 EC-176, "

Description"

A/F sensor 1 heaterEC-130, "Description"

Accelerator pedal position sensorEC-392, "Description"

Camshaft position sensor (PHASE)EC-262, "Description"

Revision: January 20102010 Versa