Manual transaxle NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 288 of 3745

DISASSEMBLYAT-271

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

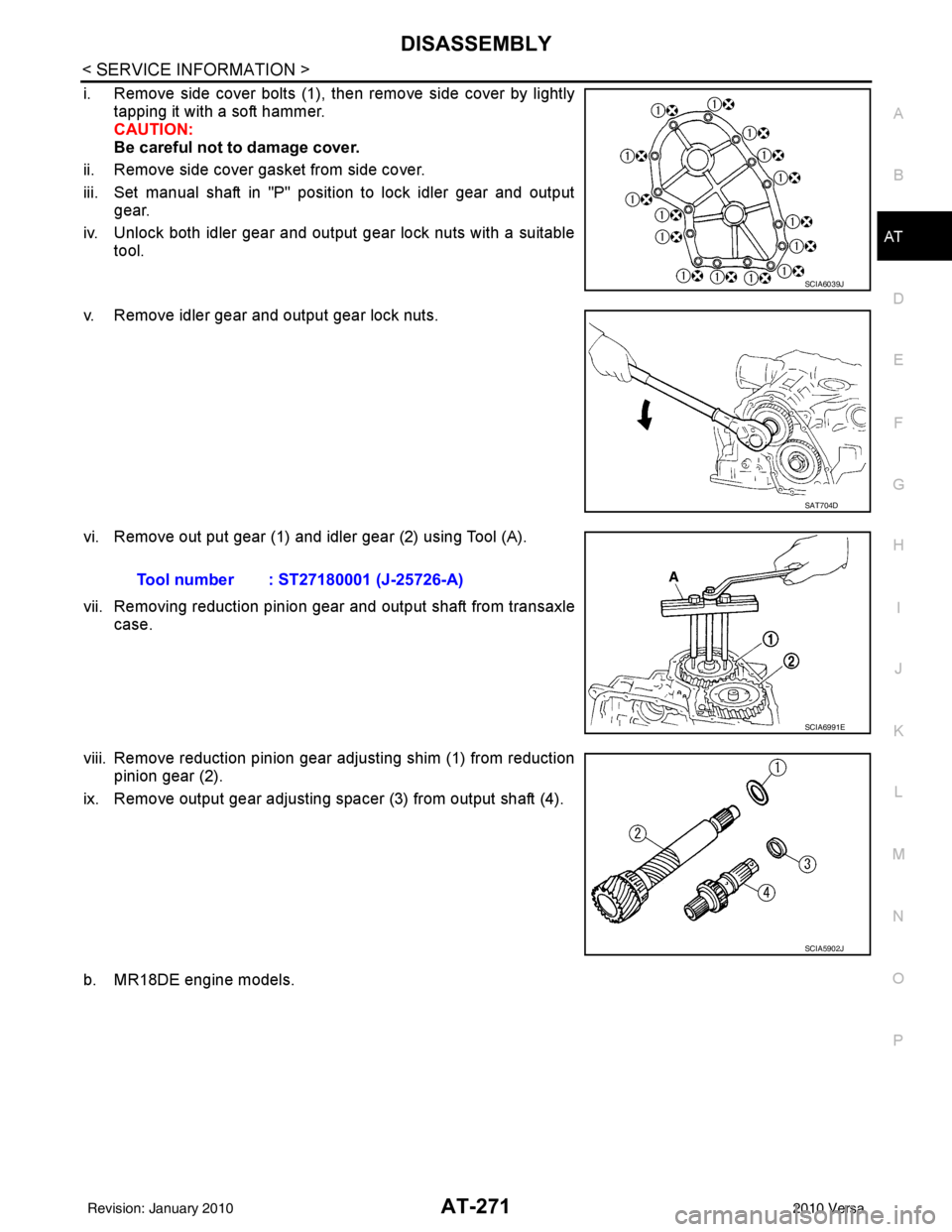

i. Remove side cover bolts (1), then remove side cover by lightly tapping it with a soft hammer.

CAUTION:

Be careful not to damage cover.

ii. Remove side cover gasket from side cover.

iii. Set manual shaft in "P" position to lock idler gear and output gear.

iv. Unlock both idler gear and output gear lock nuts with a suitable tool.

v. Remove idler gear and output gear lock nuts.

vi. Remove out put gear (1) and idler gear (2) using Tool (A).

vii. Removing reduction pinion gear and output shaft from transaxle case.

viii. Remove reduction pinion gear adjusting shim (1) from reduction pinion gear (2).

ix. Remove output gear adjusting spacer (3) from output shaft (4).

b. MR18DE engine models.

SCIA6039J

SAT704D

Tool number : ST27180001 (J-25726-A)

SCIA6991E

SCIA5902J

Revision: January 20102010 Versa

Page 292 of 3745

REPAIR FOR COMPONENT PARTSAT-275

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

REPAIR FOR COMPONENT PARTS

Manual ShaftINFOID:0000000005397436

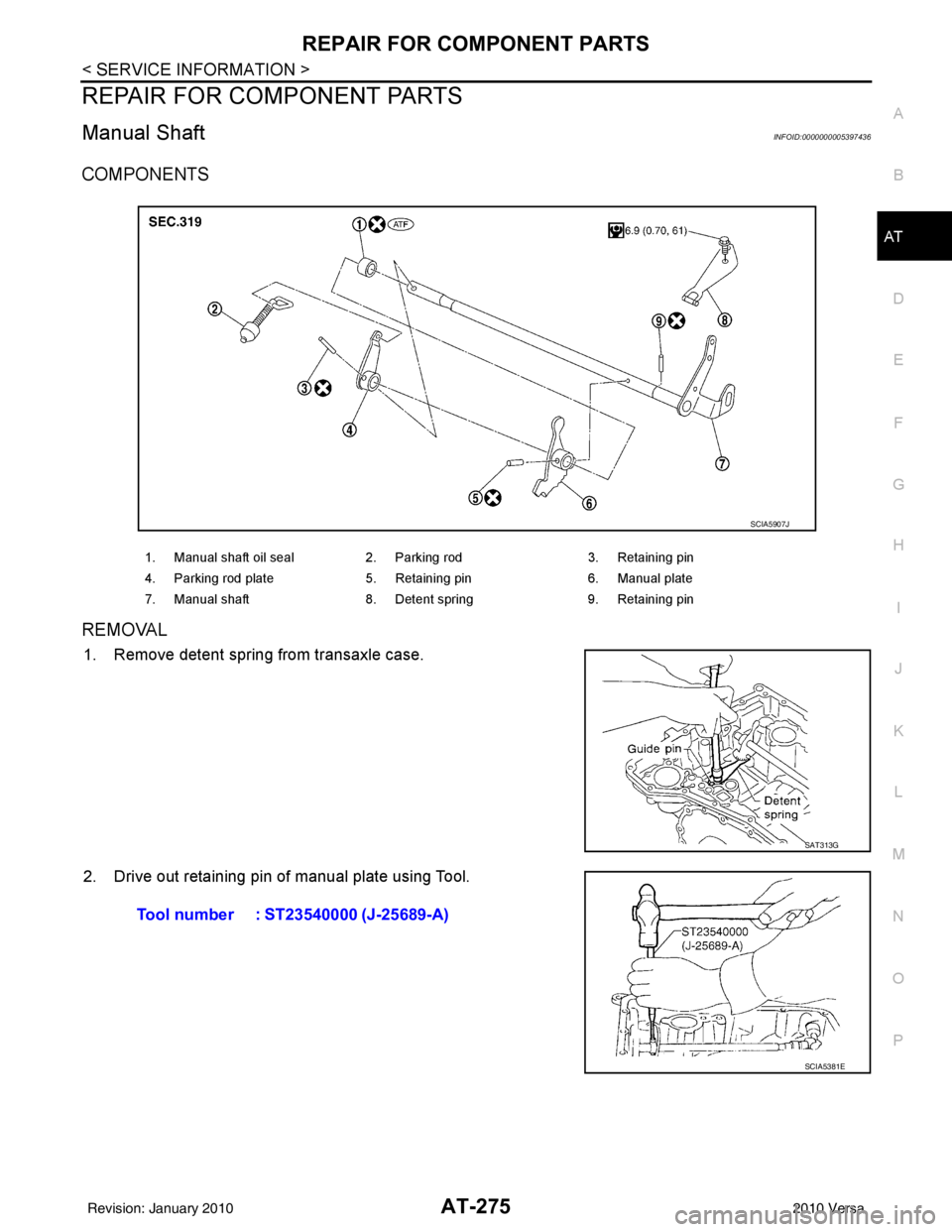

COMPONENTS

REMOVAL

1. Remove detent spring from transaxle case.

2. Drive out retaining pin of manual plate using Tool.

1. Manual shaft oil seal 2. Parking rod 3. Retaining pin

4. Parking rod plate 5. Retaining pin 6. Manual plate

7. Manual shaft 8. Detent spring 9. Retaining pin

SCIA5907J

SAT313G

Tool number : ST23540000 (J-25689-A)

SCIA5381E

Revision: January 20102010 Versa

Page 293 of 3745

AT-276

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

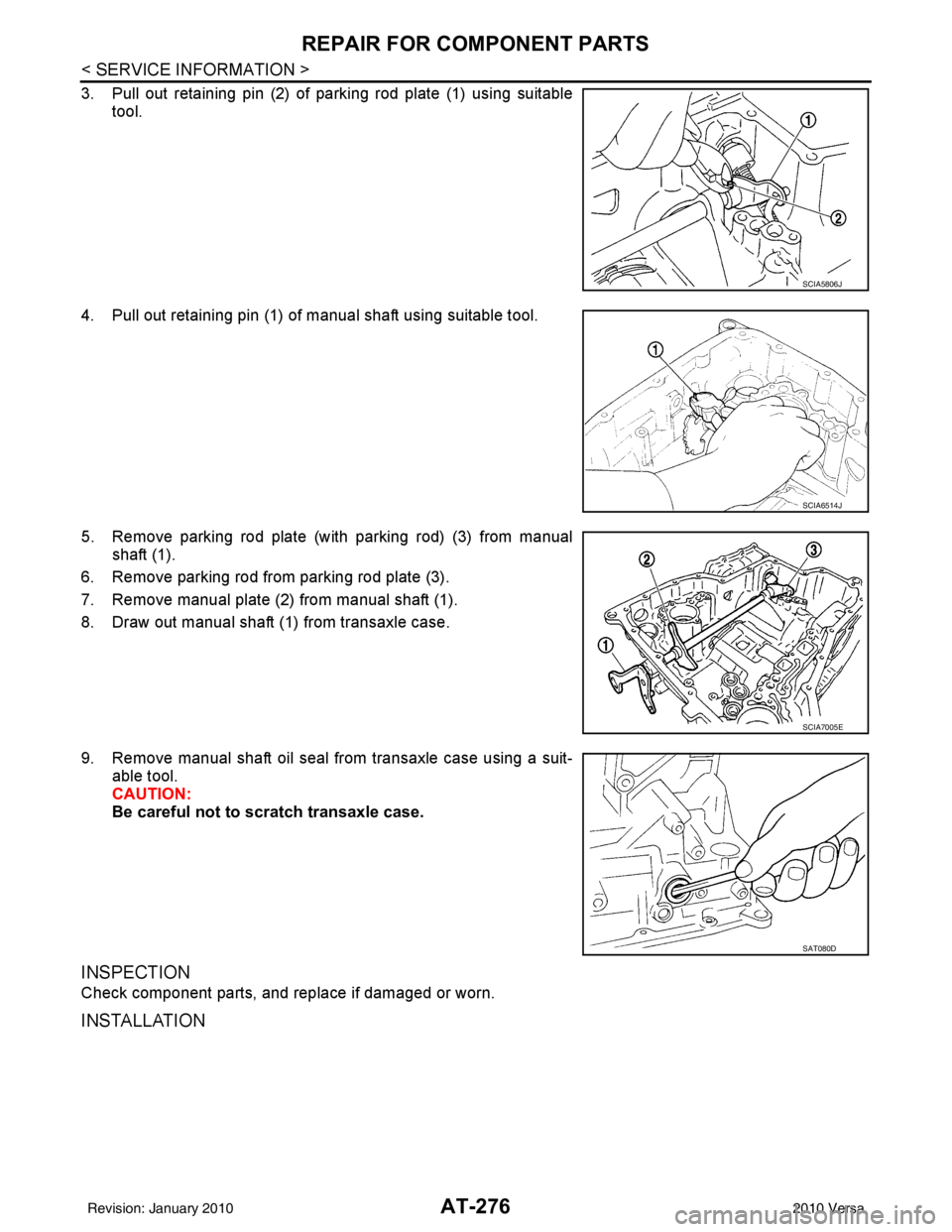

3. Pull out retaining pin (2) of parking rod plate (1) using suitabletool.

4. Pull out retaining pin (1) of manual shaft using suitable tool.

5. Remove parking rod plate (with parking rod) (3) from manual shaft (1).

6. Remove parking rod from parking rod plate (3).

7. Remove manual plate (2) from manual shaft (1).

8. Draw out manual shaft (1) from transaxle case.

9. Remove manual shaft oil seal from transaxle case using a suit- able tool.

CAUTION:

Be careful not to scratch transaxle case.

INSPECTION

Check component parts, and replace if damaged or worn.

INSTALLATION

SCIA5806J

SCIA6514J

SCIA7005E

SAT080D

Revision: January 20102010 Versa

Page 294 of 3745

REPAIR FOR COMPONENT PARTSAT-277

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

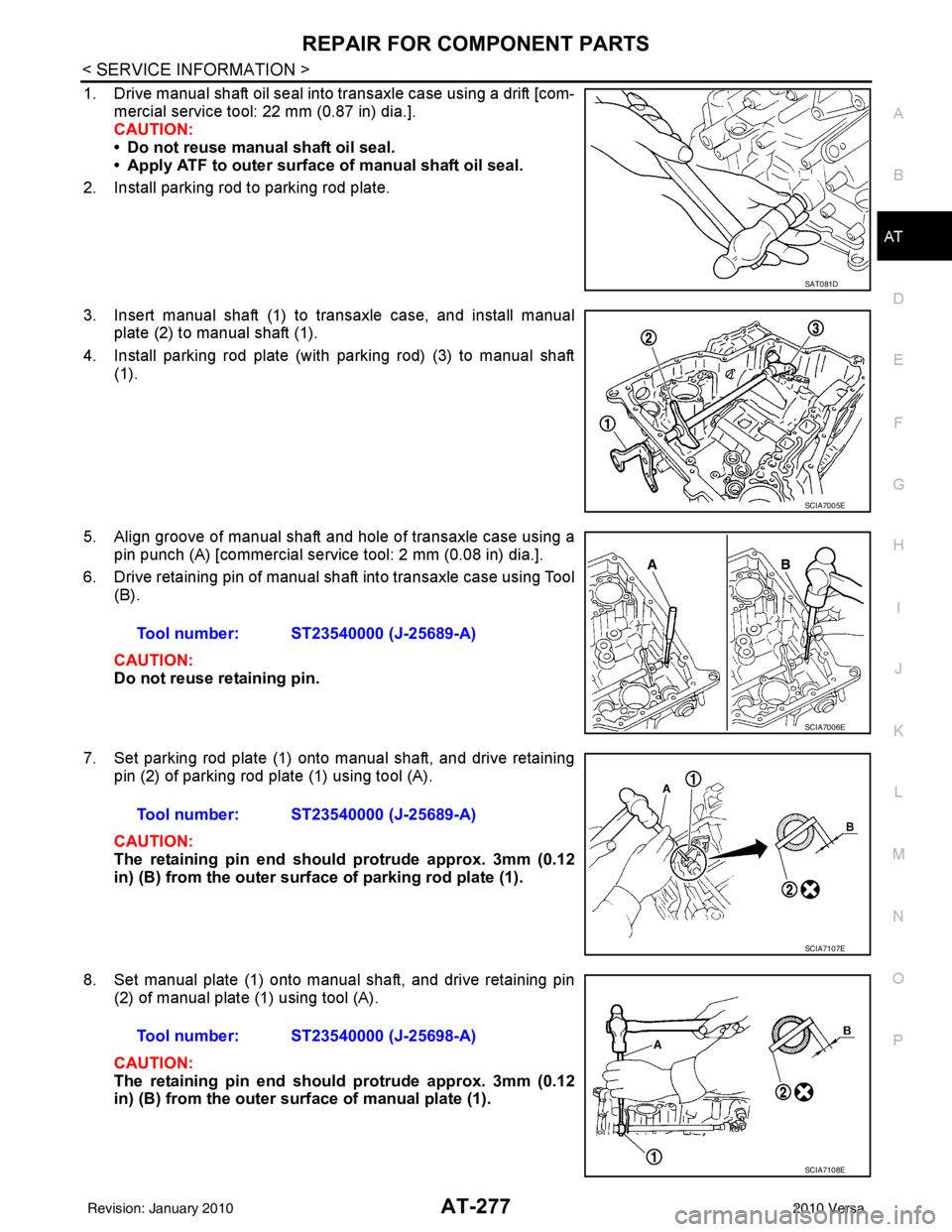

1. Drive manual shaft oil seal into transaxle case using a drift [com- mercial service tool: 22 mm (0.87 in) dia.].

CAUTION:

• Do not reuse manual shaft oil seal.

• Apply ATF to outer surface of manual shaft oil seal.

2. Install parking rod to parking rod plate.

3. Insert manual shaft (1) to transaxle case, and install manual plate (2) to manual shaft (1).

4. Install parking rod plate (with parking rod) (3) to manual shaft (1).

5. Align groove of manual shaft and hole of transaxle case using a pin punch (A) [commercial service tool: 2 mm (0.08 in) dia.].

6. Drive retaining pin of manual shaft into transaxle case using Tool (B).

CAUTION:

Do not reuse retaining pin.

7. Set parking rod plate (1) onto manual shaft, and drive retaining pin (2) of parking rod plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of parking rod plate (1).

8. Set manual plate (1) onto manual shaft, and drive retaining pin (2) of manual plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of manual plate (1).

SAT081D

SCIA7005E

Tool number: ST23540000 (J-25689-A)

SCIA7006E

Tool number: ST23540000 (J-25689-A)

SCIA7107E

Tool number: ST23540000 (J-25698-A)

SCIA7108E

Revision: January 20102010 Versa

Page 295 of 3745

AT-278

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

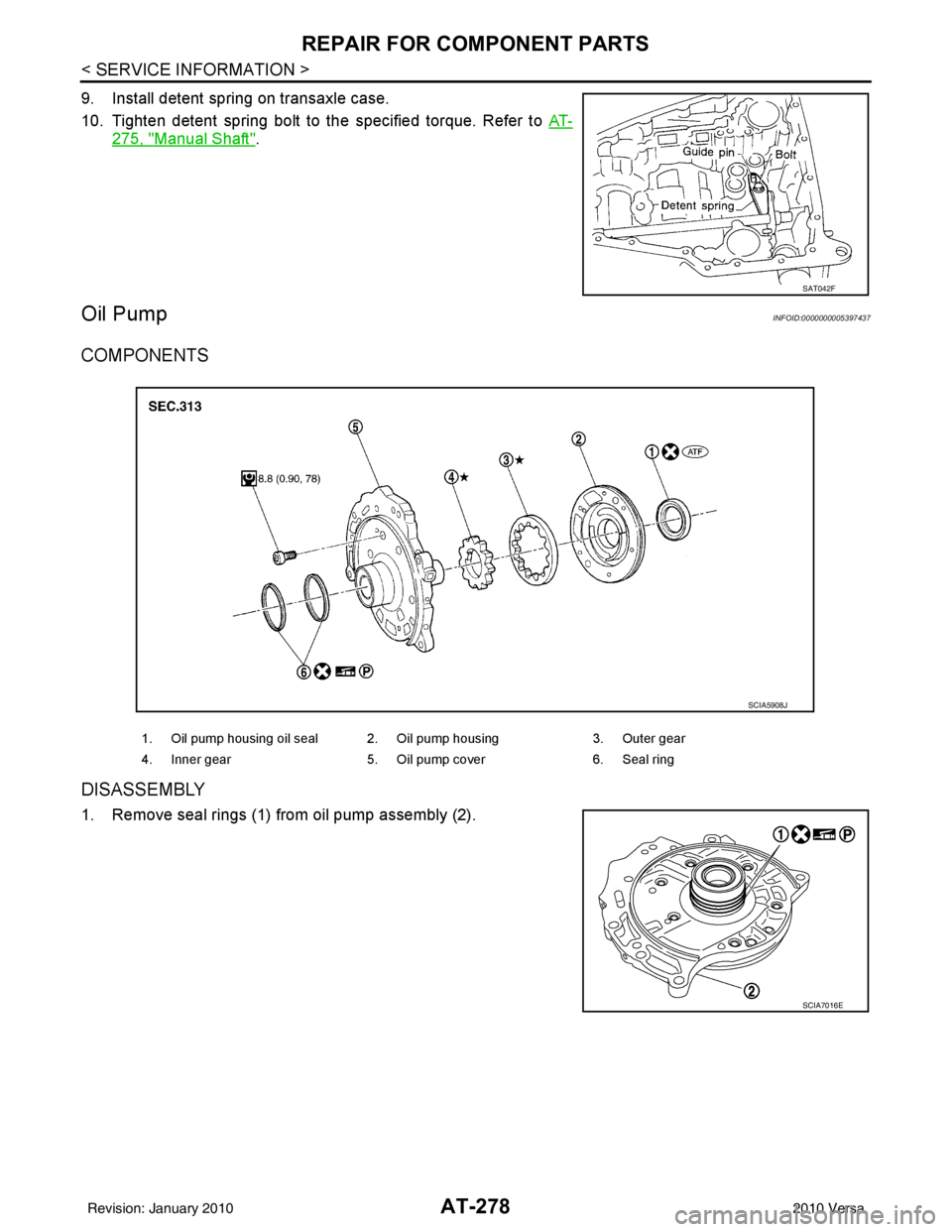

9. Install detent spring on transaxle case.

10. Tighten detent spring bolt to the specified torque. Refer to AT-

275, "Manual Shaft".

Oil PumpINFOID:0000000005397437

COMPONENTS

DISASSEMBLY

1. Remove seal rings (1) from oil pump assembly (2).

SAT042F

1. Oil pump housing oil seal 2. Oil pump housing 3. Outer gear

4. Inner gear 5. Oil pump cover6. Seal ring

SCIA5908J

SCIA7016E

Revision: January 20102010 Versa

Page 363 of 3745

AT-346

< SERVICE INFORMATION >

ASSEMBLY

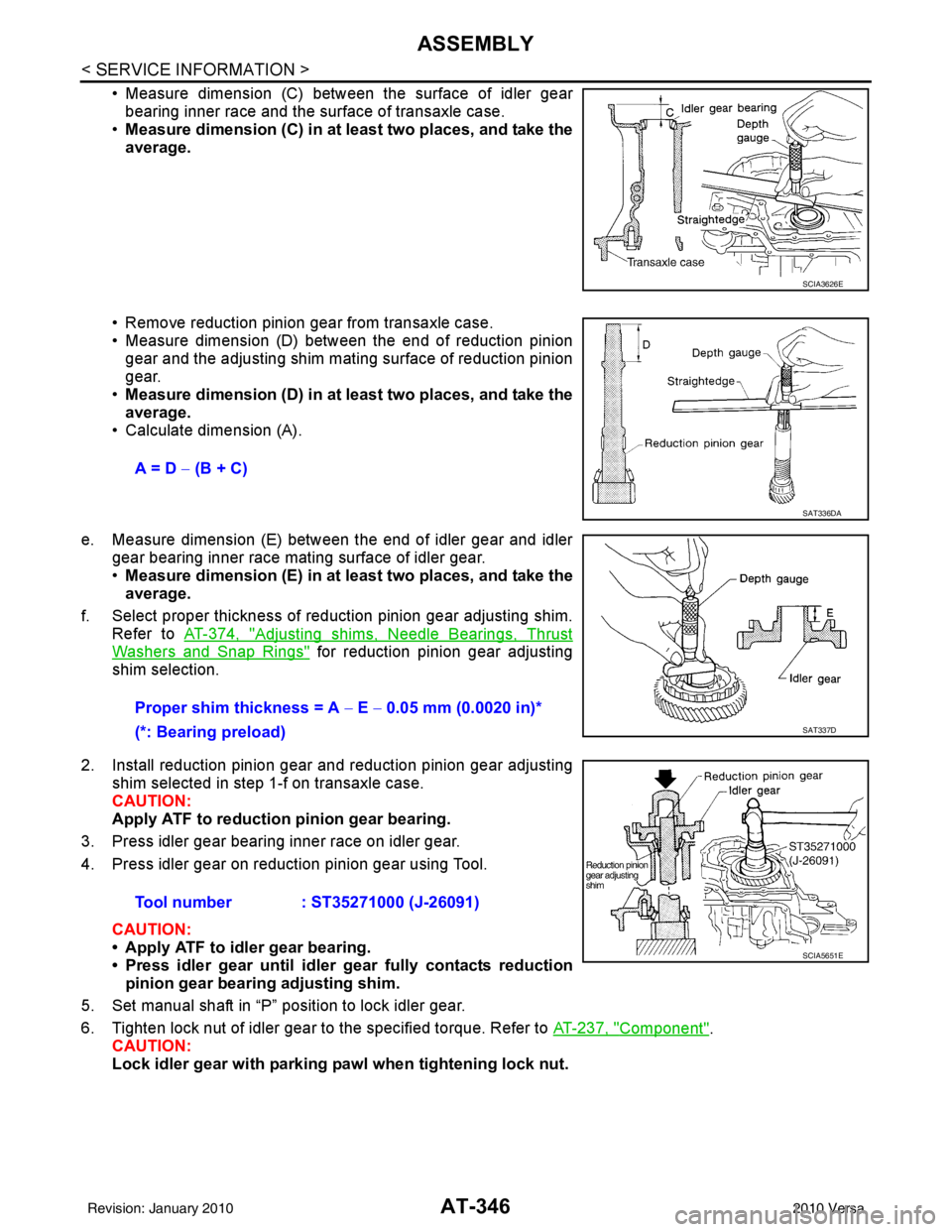

• Measure dimension (C) between the surface of idler gearbearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

•Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to AT-374, "

Adjusting shims, Needle Bearings, Thrust

Washers and Snap Rings" for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear.

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction

pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to lock idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-237, "

Component".

CAUTION:

Lock idler gear with parking pawl when tightening lock nut.

SCIA3626E

A = D − (B + C)

SAT336DA

Proper shim thickness = A − E − 0.05 mm (0.0020 in)*

(*: Bearing preload)

SAT337D

Tool number : ST35271000 (J-26091)

SCIA5651E

Revision: January 20102010 Versa

Page 365 of 3745

AT-348

< SERVICE INFORMATION >

ASSEMBLY

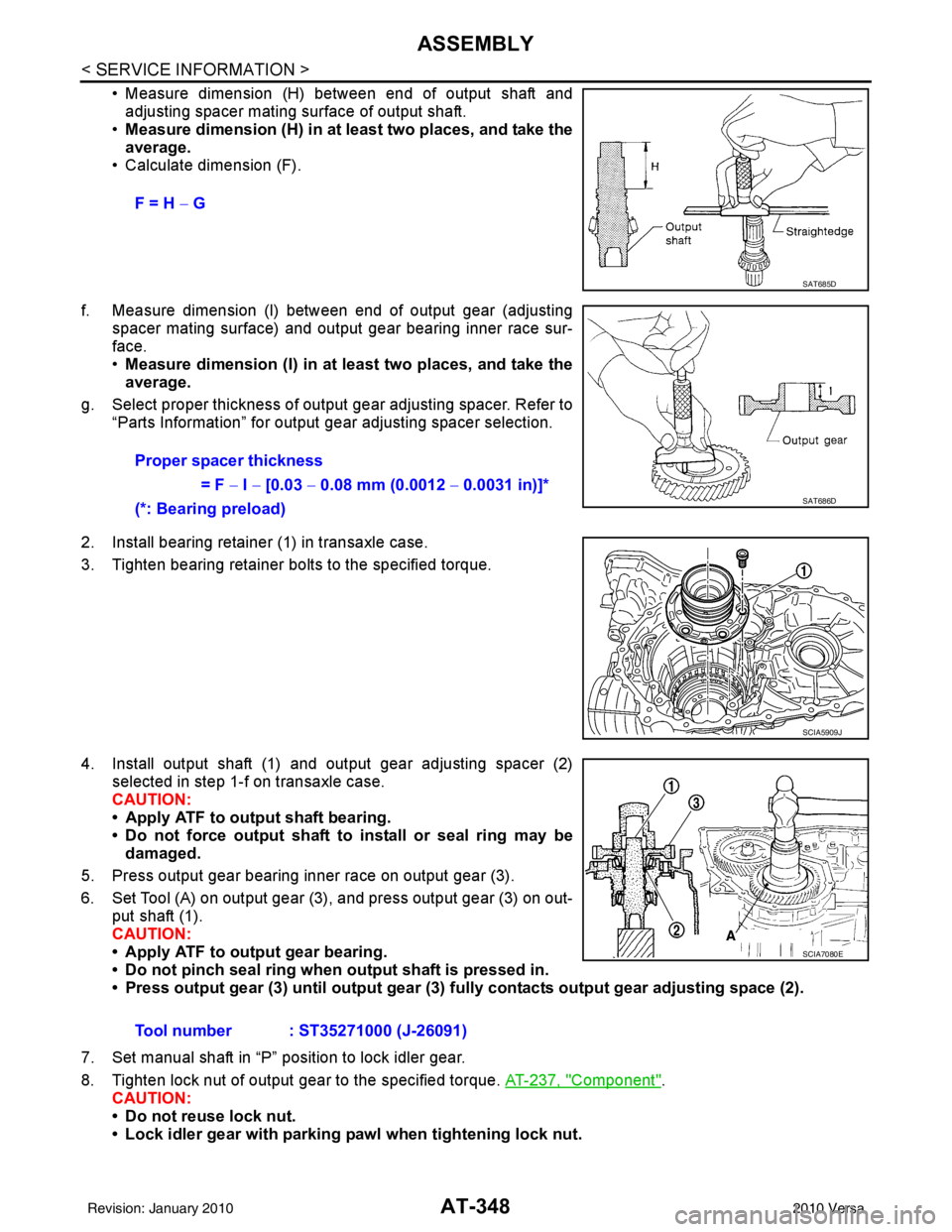

• Measure dimension (H) between end of output shaft andadjusting spacer mating surface of output shaft.

• Measure dimension (H) in at least two places, and take the

average.

• Calculate dimension (F).

f. Measure dimension (I) between end of output gear (adjusting spacer mating surface) and output gear bearing inner race sur-

face.

•Measure dimension (I) in at least two places, and take the

average.

g. Select proper thickness of output gear adjusting spacer. Refer to “Parts Information” for output gear adjusting spacer selection.

2. Install bearing retainer (1) in transaxle case.

3. Tighten bearing retainer bolts to the specified torque.

4. Install output shaft (1) and output gear adjusting spacer (2) selected in step 1-f on transaxle case.

CAUTION:

• Apply ATF to output shaft bearing.

• Do not force output shaft to install or seal ring may be

damaged.

5. Press output gear bearing inner race on output gear (3).

6. Set Tool (A) on output gear (3), and press output gear (3) on out- put shaft (1).

CAUTION:

• Apply ATF to output gear bearing.

• Do not pinch seal ring when output shaft is pressed in.

• Press output gear (3) until output gear (3) fully contacts output gear adjusting space (2).

7. Set manual shaft in “P” position to lock idler gear.

8. Tighten lock nut of output gear to the specified torque. AT-237, "

Component".

CAUTION:

• Do not reuse lock nut.

• Lock idler gear with parking pawl when tightening lock nut. F = H −

G

SAT685D

Proper spacer thickness

= F − I − [0.03 − 0.08 mm (0.0012 − 0.0031 in)]*

(*: Bearing preload)

SAT686D

SCIA5909J

Tool number : ST35271000 (J-26091)

SCIA7080E

Revision: January 20102010 Versa

Page 369 of 3745

AT-352

< SERVICE INFORMATION >

ASSEMBLY

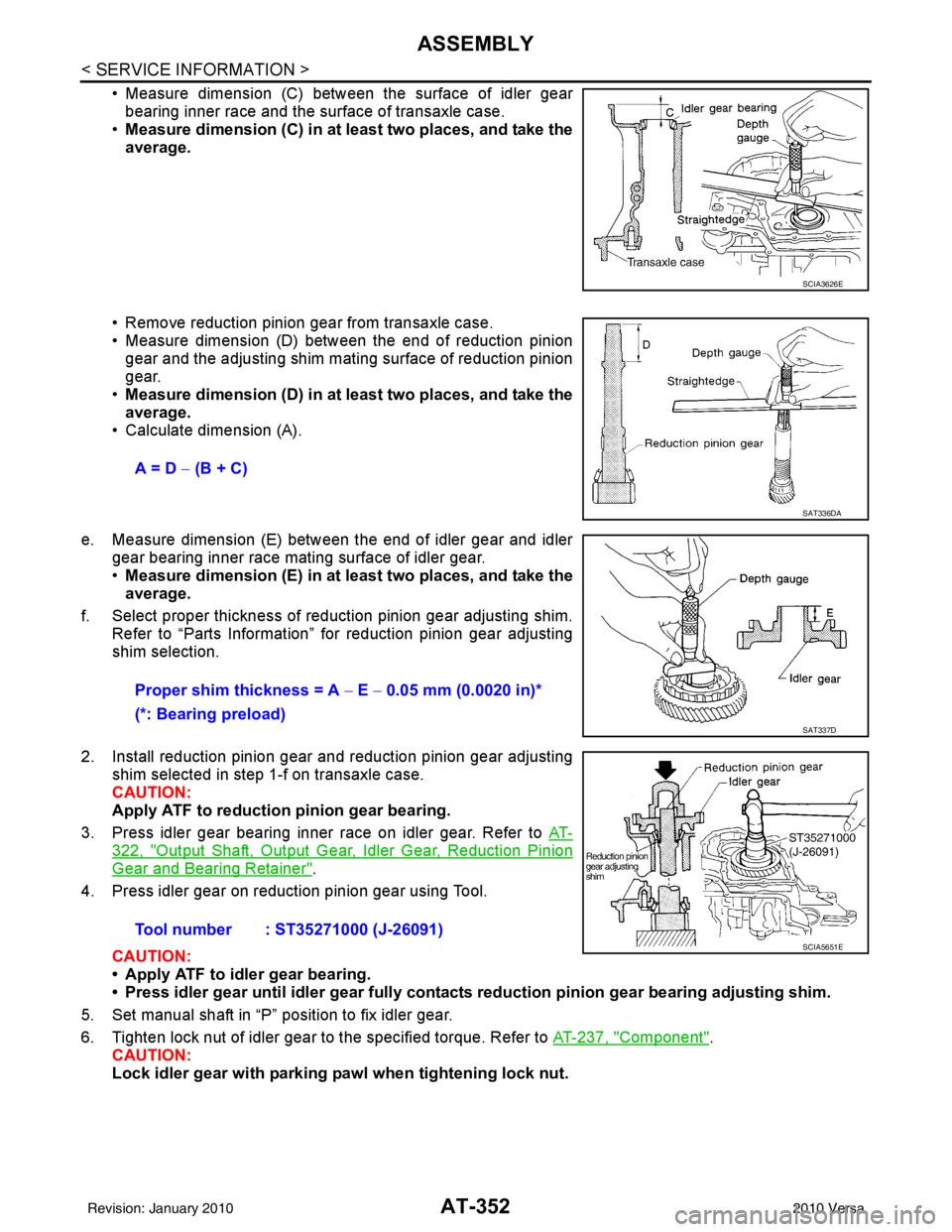

• Measure dimension (C) between the surface of idler gearbearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

•Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to “Parts Information” for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear. Refer to AT-

322, "Output Shaft, Output Gear, Idler Gear, Reduction Pinion

Gear and Bearing Retainer".

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to fix idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-237, "

Component".

CAUTION:

Lock idler gear with parking pawl when tightening lock nut.

SCIA3626E

A = D − (B + C)

SAT336DA

Proper shim thickness = A − E − 0.05 mm (0.0020 in)*

(*: Bearing preload)

SAT337D

Tool number : ST35271000 (J-26091)SCIA5651E

Revision: January 20102010 Versa

Page 386 of 3745

ASSEMBLYAT-369

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

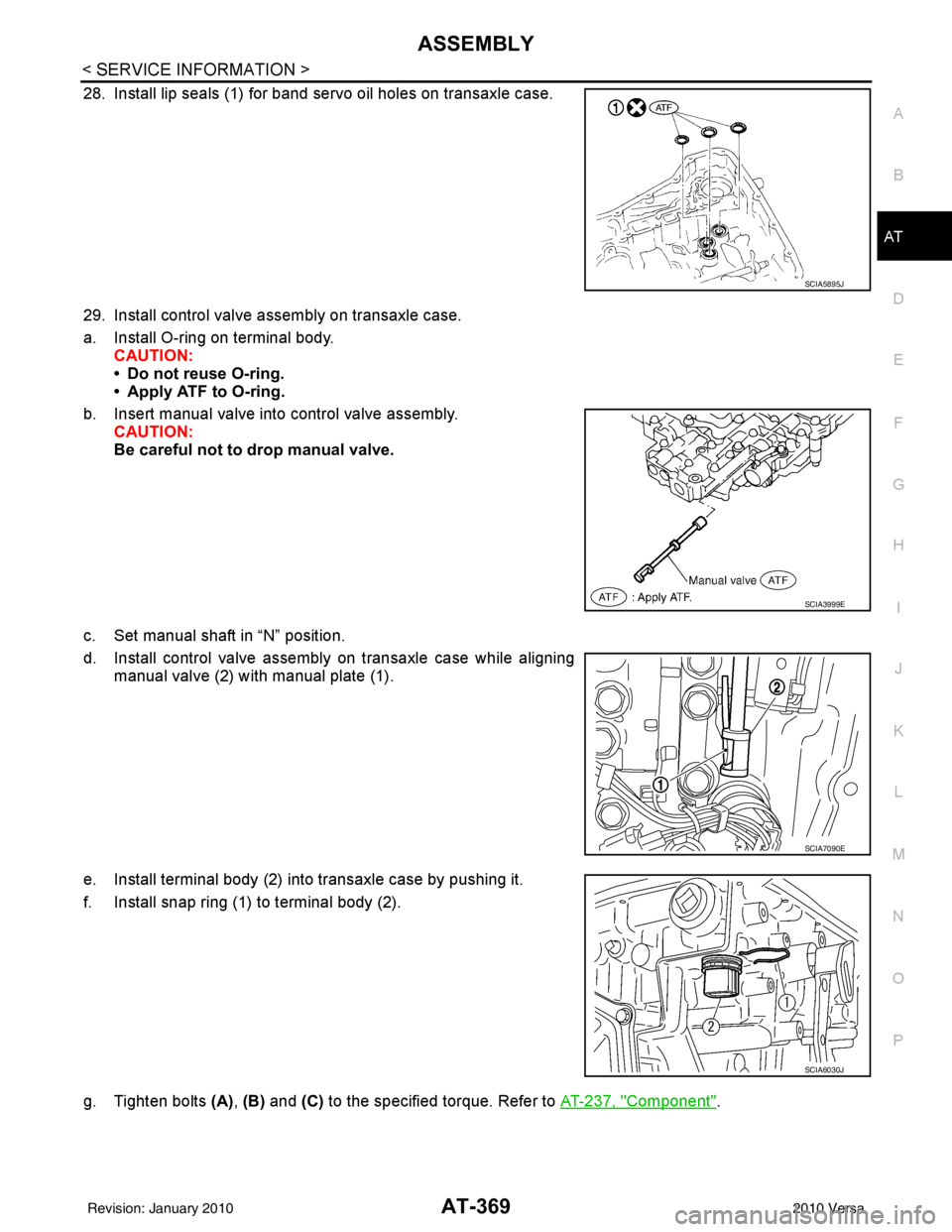

28. Install lip seals (1) for band servo oil holes on transaxle case.

29. Install control valve assembly on transaxle case.

a. Install O-ring on terminal body. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

b. Insert manual valve into control valve assembly. CAUTION:

Be careful not to drop manual valve.

c. Set manual shaft in “N” position.

d. Install control valve assembly on transaxle case while aligning manual valve (2) with manual plate (1).

e. Install terminal body (2) into transaxle case by pushing it.

f. Install snap ring (1) to terminal body (2).

g. Tighten bolts (A), (B) and (C) to the specified torque. Refer to AT-237, "

Component".

SCIA5895J

SCIA3999E

SCIA7090E

SCIA6030J

Revision: January 20102010 Versa

Page 388 of 3745

ASSEMBLYAT-371

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

31. Install transmission range switch (2) on transaxle case. : Bolt

a. Set manual shaft (1) in “P” position.

b. Temporarily install transmission range switch (2) on manual shaft (1).

c. Set manual shaft (1) in “N” position.

d. Use a 4 mm (0.16 in) dia. pin for this adjustment.

i. Insert the pin straight into the manual shaft (1) adjustment hole.

ii. Rotate transmission range switch (2) until the pin can also be inserted straight into hole in transmission range switch (2).

e. Tighten transmission range switch bolts to the specified torque. Refer to AT-237, "

Component".

f. Remove pin from adjustment hole after adjusting transmission range switch (2).

32. Install O-ring (3) to input speed sensor (1).

33. Install input speed sensor (1) to transaxle case (2). : Bolt

34. Tighten input speed sensor bolt to the specified torque. Refer to AT-237, "

Component".

35. Install output speed sensor (1) to transaxle case (2).

36. Tighten output speed sensor bolts to the specified torque. Refer to AT-237, "

Component".

: Bolt

CAUTION:

Ensure output speed sensor harness is firmly secured with

bolt.

(1): Output speed sensor

: Bolt

SCIA5904J

SCIA7004J

SCIA7170J

SCIA6518J

Revision: January 20102010 Versa