PS-9 NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2929 of 3745

![NISSAN TIIDA 2010 Service User Guide LAN-120

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 9)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531862

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Di NISSAN TIIDA 2010 Service User Guide LAN-120

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 9)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531862

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Di](/img/5/57397/w960_57397-2928.png)

LAN-120

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 9)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531862

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 916Approx. 54 – 66

Revision: January 20102010 Versa

Page 2939 of 3745

![NISSAN TIIDA 2010 Service User Guide LAN-130

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531882

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D NISSAN TIIDA 2010 Service User Guide LAN-130

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531882

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D](/img/5/57397/w960_57397-2938.png)

LAN-130

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531882

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 916Approx. 54 – 66

Revision: January 20102010 Versa

Page 2950 of 3745

![NISSAN TIIDA 2010 Service User Guide EPS BRANCH LINE CIRCUITLAN-141

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531902

1.CHECK CONNECTOR

1. NISSAN TIIDA 2010 Service User Guide EPS BRANCH LINE CIRCUITLAN-141

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531902

1.CHECK CONNECTOR

1.](/img/5/57397/w960_57397-2949.png)

EPS BRANCH LINE CIRCUITLAN-141

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531902

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circui t of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 9 16 Approx. 54 – 66

Revision: January 20102010 Versa

Page 2962 of 3745

![NISSAN TIIDA 2010 Service User Guide EPS BRANCH LINE CIRCUITLAN-153

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531922

1.CHECK CONNECTOR

1. NISSAN TIIDA 2010 Service User Guide EPS BRANCH LINE CIRCUITLAN-153

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531922

1.CHECK CONNECTOR

1.](/img/5/57397/w960_57397-2961.png)

EPS BRANCH LINE CIRCUITLAN-153

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531922

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circui t of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 9 16 Approx. 54 – 66

Revision: January 20102010 Versa

Page 2975 of 3745

![NISSAN TIIDA 2010 Service User Guide LAN-166

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531942

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D NISSAN TIIDA 2010 Service User Guide LAN-166

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531942

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D](/img/5/57397/w960_57397-2974.png)

LAN-166

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531942

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 916Approx. 54 – 66

Revision: January 20102010 Versa

Page 2987 of 3745

![NISSAN TIIDA 2010 Service User Guide LAN-178

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 14)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531962

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D NISSAN TIIDA 2010 Service User Guide LAN-178

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 14)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531962

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. D](/img/5/57397/w960_57397-2986.png)

LAN-178

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 14)]

EPS BRANCH LINE CIRCUIT

EPS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005531962

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the EPS control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of EPS control unit.

2. Check the resistance between the EPS control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the EPS control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the EPS control unit. Refer to STC-9, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES (Present error)>>Replace the EPS control unit. Refer to PS-9, "Removal and Installation".

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit.

EPS control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M53 916Approx. 54 – 66

Revision: January 20102010 Versa

Page 3339 of 3745

MTC-60

< SERVICE INFORMATION >

A/C UNIT ASSEMBLY

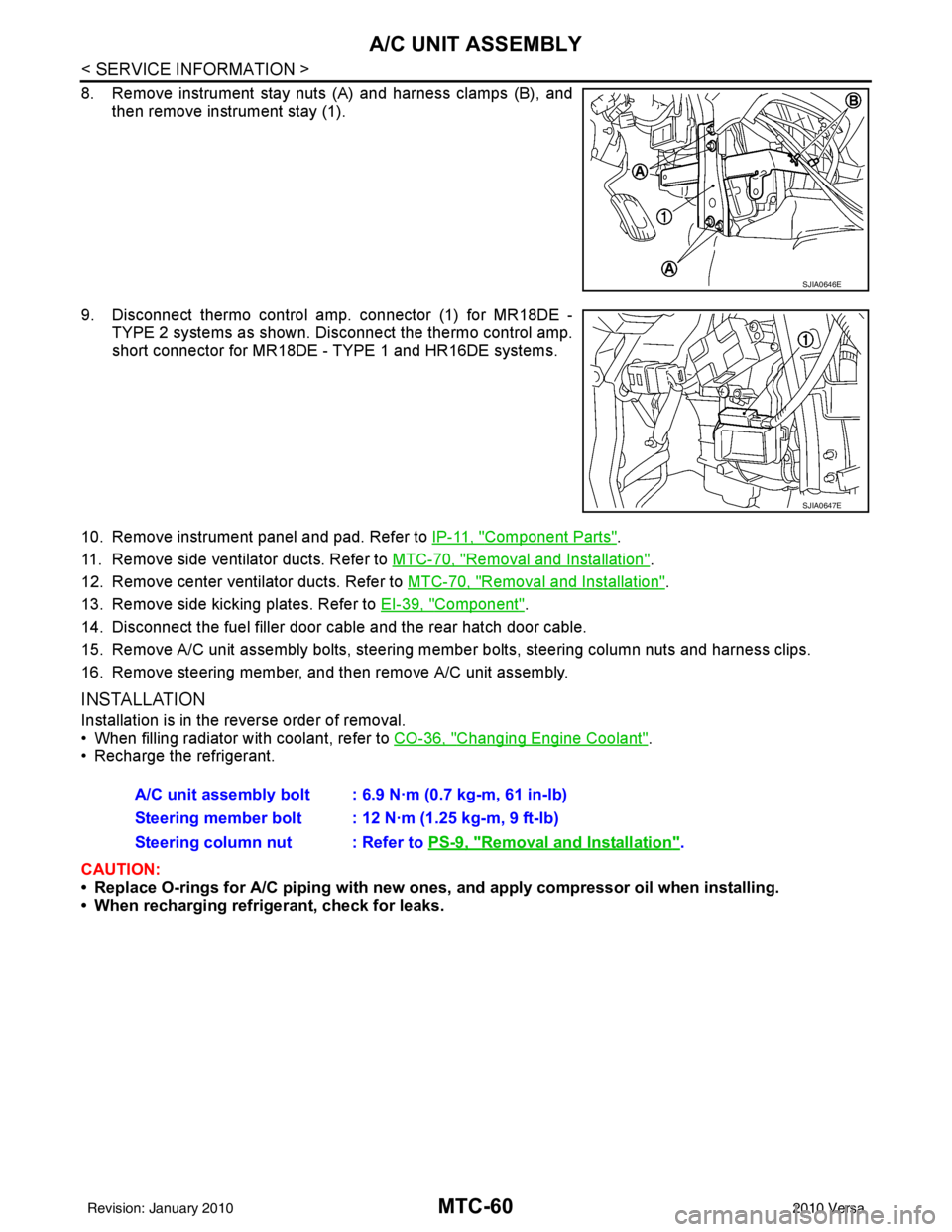

8. Remove instrument stay nuts (A) and harness clamps (B), andthen remove instrument stay (1).

9. Disconnect thermo control amp. connector (1) for MR18DE - TYPE 2 systems as shown. Di sconnect the thermo control amp.

short connector for MR18DE - TYPE 1 and HR16DE systems.

10. Remove instrument panel and pad. Refer to IP-11, "

Component Parts".

11. Remove side ventilator ducts. Refer to MTC-70, "

Removal and Installation".

12. Remove center ventilator ducts. Refer to MTC-70, "

Removal and Installation".

13. Remove side kicking plates. Refer to EI-39, "

Component".

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

• When filling radiator with coolant, refer to CO-36, "

Changing Engine Coolant".

• Recharge the refrigerant.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to PS-9, "

Removal and Installation".

Revision: January 20102010 Versa

Page 3463 of 3745

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPS-5

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

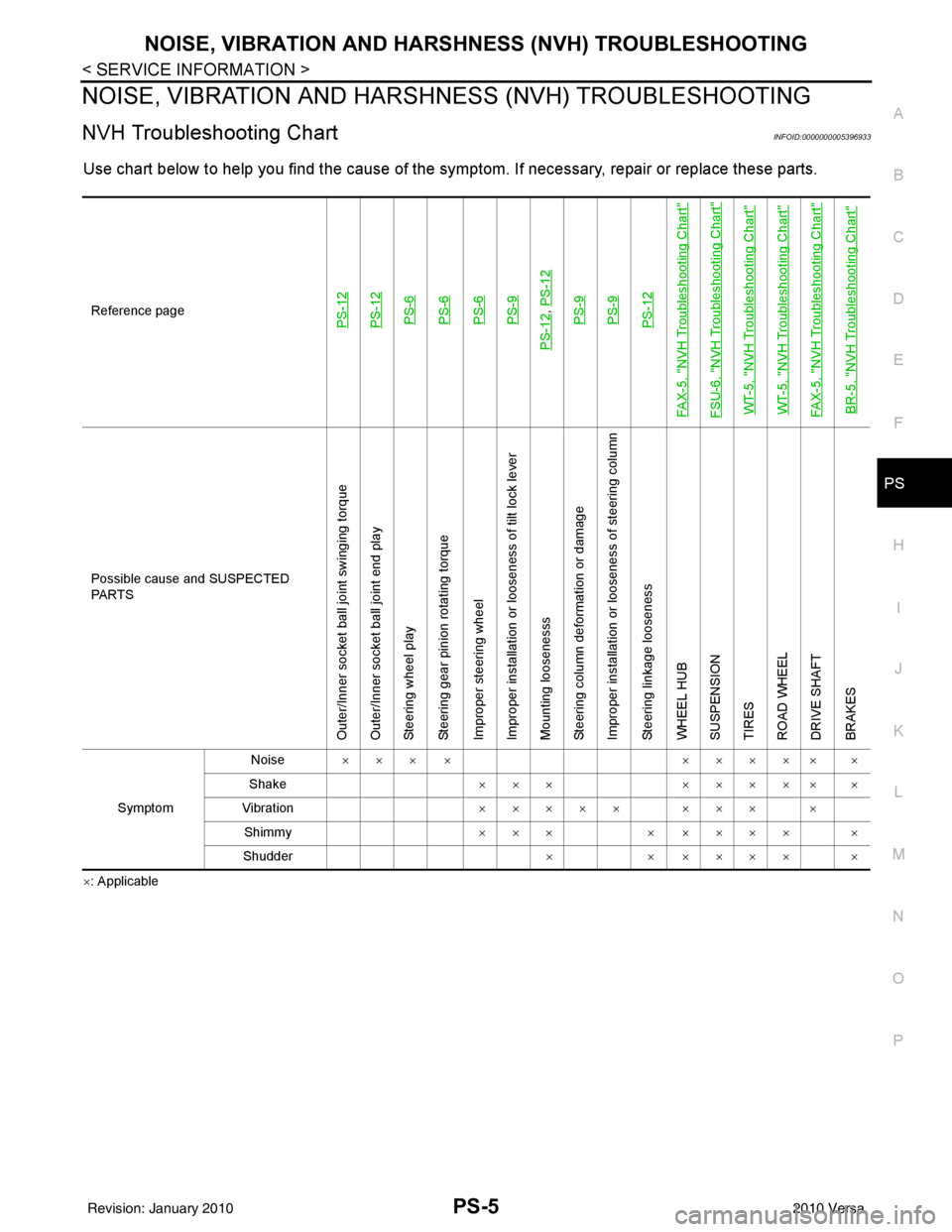

NVH Troubleshooting ChartINFOID:0000000005396933

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

PS-12PS-12PS-6PS-6PS-6PS-9

PS-12

,

PS-12PS-9PS-9PS-12

FAX-5, "

NVH Troubleshooting Chart

"

FSU-6, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED

PA R T S

Outer/Inner socket ball joint swinging torque

Outer/Inner socket ball joint end play

Steering wheel play

Steering gear pinion rotating torque

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting loosenesss

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom Noise

××× × ××××× ×

Shake ×××××××× ×

Vibration ××××× ××× ×

Shimmy ×××× ×××× ×

Shudder ×× ×××× ×

Revision: January 20102010 Versa

Page 3467 of 3745

STEERING COLUMNPS-9

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

STEERING COLUMN

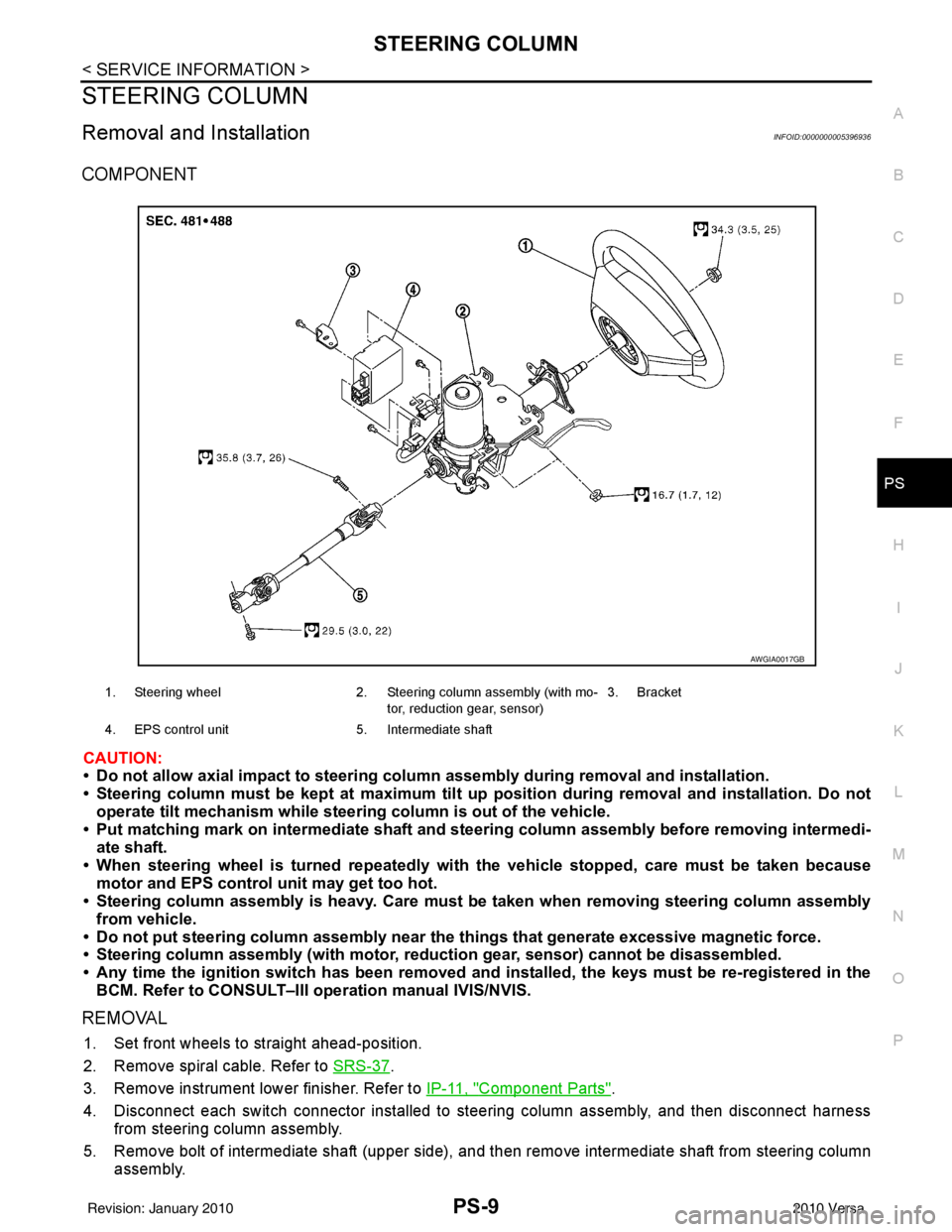

Removal and InstallationINFOID:0000000005396936

COMPONENT

CAUTION:

• Do not allow axial impact to steering colu mn assembly during removal and installation.

• Steering column must be kept at maximum tilt up position during removal and installation. Do not

operate tilt mechanism while steeri ng column is out of the vehicle.

• Put matching mark on intermediate shaft and st eering column assembly before removing intermedi-

ate shaft.

• When steering wheel is turned re peatedly with the vehicle stopped, care must be taken because

motor and EPS control unit may get too hot.

• Steering column assembly is heavy. Care must be taken when removing steering column assembly

from vehicle.

• Do not put steering column assem bly near the things that generate excessive magnetic force.

• Steering column assembly (with motor, reduc tion gear, sensor) cannot be disassembled.

• Any time the ignition switch h as been removed and installed, the keys must be re-registered in the

BCM. Refer to CONSULT–III ope ration manual IVIS/NVIS.

REMOVAL

1. Set front wheels to straight ahead-position.

2. Remove spiral cable. Refer to SRS-37

.

3. Remove instrument lower finisher. Refer to IP-11, "

Component Parts".

4. Disconnect each switch connector installed to steering column assembly, and then disconnect harness from steering column assembly.

5. Remove bolt of intermediate shaft (upper side), and then remove intermediate shaft from steering column assembly.

1. Steering wheel 2. Steering column assembly (with mo-

tor, reduction gear, sensor) 3. Bracket

4. EPS control unit 5. Intermediate shaft

AWGIA0017GB

Revision: January 20102010 Versa

Page 3656 of 3745

![NISSAN TIIDA 2010 Service User Guide STC-10

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1601 BATTERY POWER SUPPLY

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts.

NISSAN TIIDA 2010 Service User Guide STC-10

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1601 BATTERY POWER SUPPLY

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts.](/img/5/57397/w960_57397-3655.png)

STC-10

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1601 BATTERY POWER SUPPLY

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts.

• 10A fuse (#2) open

- Harness for short between 10A fuse (#2) and pow er steering control unit harness connector No.

10 terminal.

• 60A fusible link (M) open

- Harness for short between 60A fusible link (M) and power steering control unit harness connec-

tor No. 10 terminal.

• Harness for open between ignition switch and power steering control unit harness connector No. 17 terminal.

• Harness for open between battery and power steering control unit harness connector No. 17 ter-

minal.

• Battery or ignition switch.

3.CHECK BATTERY VOLTAGE SIGNAL (1)

With CONSULT-III

1. Connect EPS control unit harness connector.

2. Start the engine. CAUTION:

Stop the vehicle.

3. Select “EPS”, “DATA MONITOR” and “MOTOR VO LT”, and perform the battery voltage inspection.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace EPS control unit. Refer to PS-9, "

Removal and Installation".

4.CHECK MOTOR VOLTAGE SIGNAL (2)

With CONSULT-III

Select “MOTOR VOLT” in “DATA MONITOR” of the EPS control unit. Check motor voltage with the steering

wheel fully turned leftward or rightward.

Is the value in

“DATA MONITOR”“between 9 V and 17.5 V”?

YES >> Check pin terminal and connection of each harness connector for damage or loose connection.

NO >> Check battery power supply and ignition power supply. Refer to STC-22, "

Wiring Diagram - ELEC-

TRONICALLY CONTROLLED POWER STEERING SYSTEM -".

EPS control unit

—Volt a ge

Connector Terminal

M53 10

Ground Battery voltage

M54 17

Monitor item ConditionDisplay value

MOTOR VOLT Engine runningBattery voltage

Revision: January 20102010 Versa