Radiator NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 528 of 3745

RADIATOR CORE SUPPORTBL-19

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

RADIATOR CORE SUPPORT

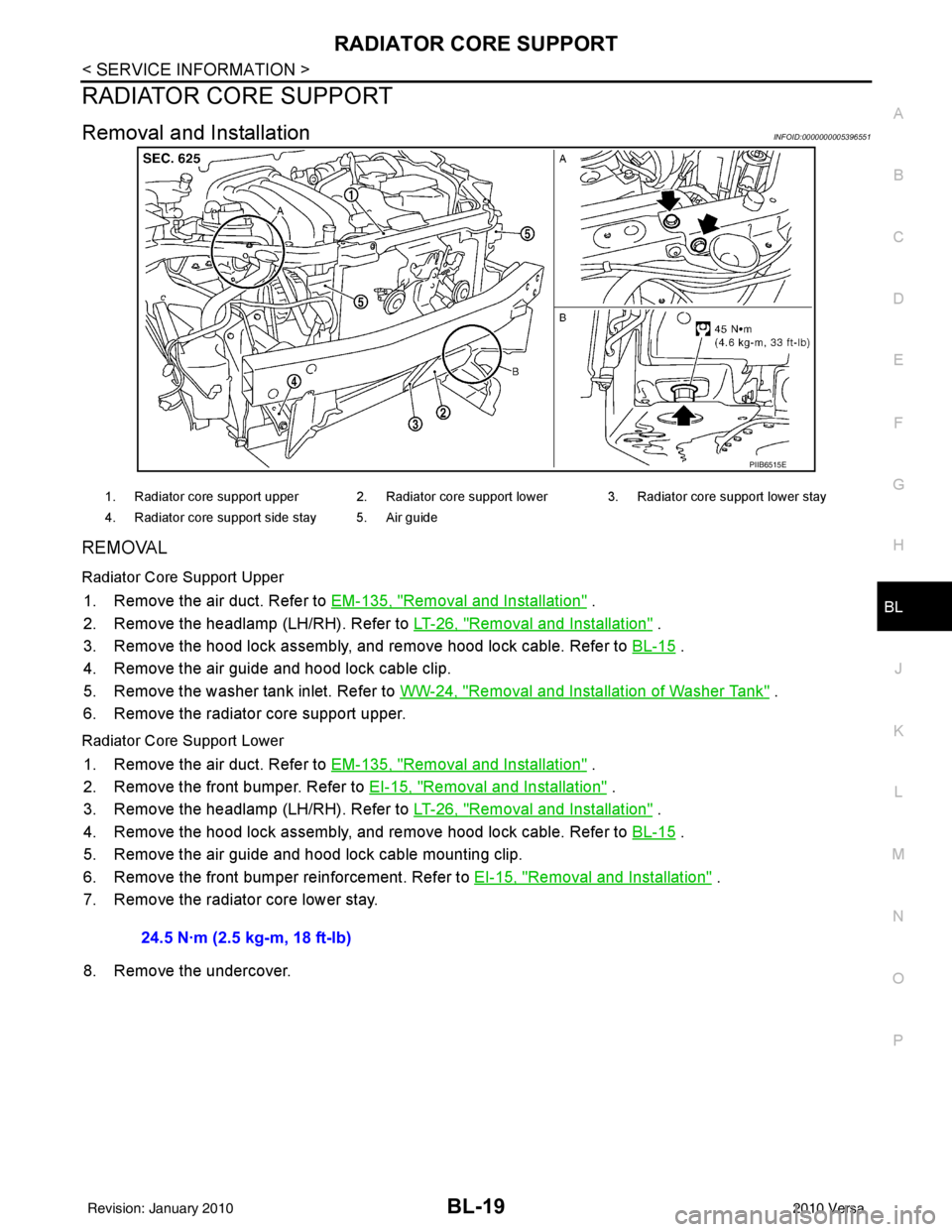

Removal and InstallationINFOID:0000000005396551

REMOVAL

Radiator Core Support Upper

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the headlamp (LH/RH). Refer to LT-26, "

Removal and Installation" .

3. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

4. Remove the air guide and hood lock cable clip.

5. Remove the washer tank inlet. Refer to WW-24, "

Removal and Installation of Washer Tank" .

6. Remove the radiator core support upper.

Radiator Core Support Lower

1. Remove the air duct. Refer to EM-135, "Removal and Installation" .

2. Remove the front bumper. Refer to EI-15, "

Removal and Installation" .

3. Remove the headlamp (LH/RH). Refer to LT-26, "

Removal and Installation" .

4. Remove the hood lock assembly, and remove hood lock cable. Refer to BL-15

.

5. Remove the air guide and hood lock cable mounting clip.

6. Remove the front bumper reinforcement. Refer to EI-15, "

Removal and Installation" .

7. Remove the radiator core lower stay.

8. Remove the undercover.

PIIB6515E

1. Radiator core support upper 2. Radiator core support lower 3. Radiator core support lower stay

4. Radiator core support side stay 5. Air guide

24.5 N·m (2.5 kg-m, 18 ft-lb)

Revision: January 20102010 Versa

Page 529 of 3745

BL-20

< SERVICE INFORMATION >

RADIATOR CORE SUPPORT

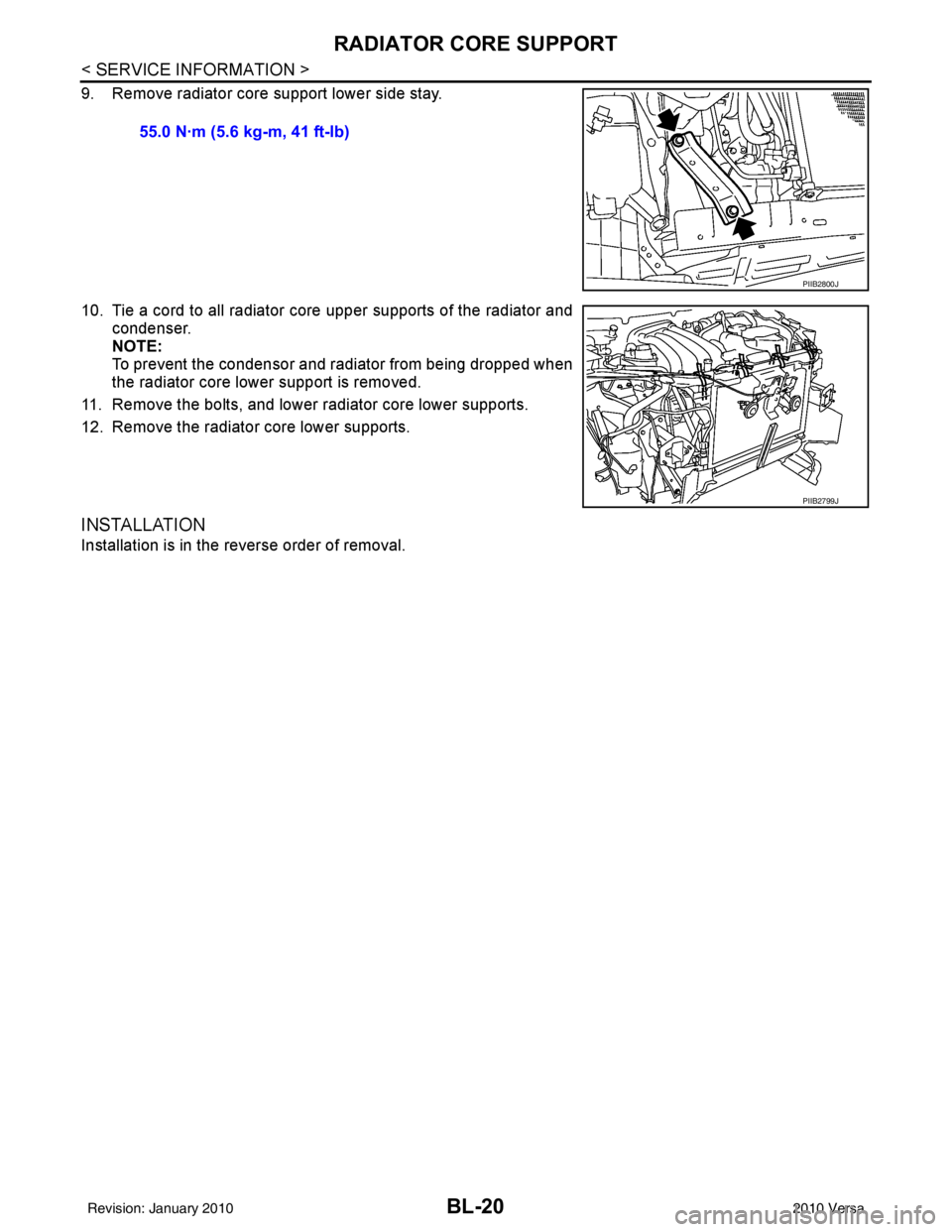

9. Remove radiator core support lower side stay.

10. Tie a cord to all radiator core upper supports of the radiator andcondenser.

NOTE:

To prevent the condensor and radiator from being dropped when

the radiator core lower support is removed.

11. Remove the bolts, and lower radiator core lower supports.

12. Remove the radiator core lower supports.

INSTALLATION

Installation is in the reverse order of removal. 55.0 N·m (5.6 kg-m, 41 ft-lb)

PIIB2800J

PIIB2799J

Revision: January 20102010 Versa

Page 779 of 3745

BL-270

< SERVICE INFORMATION >

BODY REPAIR

4. Front pillar inner reinforcement (RH&LH)

5. Lower dash reinforcement

6. 4th crossmember (RH&LH)

7. Front side member rear extension (RH&LH)

8. 3rd crossmember (RH&LH)

9. Front seat outer rear bracket (RH&LH)

10. Front seat inner rear bracket (RH&LH)

11. 2nd crossmember (RH&LH)

12. Front seat outer front bracket (RH&LH)

13. Front seat inner front bracket (RH&LH)

14. Fender bracket (RH&LH)

15. Strut housing assembly RH

16. Cowl top side upper (RH&LH)

17. Front strut housing (RH&LH)

18. Upper torque rod reinforcement

19. Closing plate assembly RH

20. Engine mount reinforcement

21. Strut tower front reinforcement RH

22. Front hoodledge lower RH

23. Frame bracket outer (RH&LH)

24. Front bumper support bracket (RH&LH)

25. Closing plate (RH&LH)

26. Front suspension rear bracket (RH&LH)

27. Front side member outrigger (RH&LH)

28. Front side member assembly (RH&LH)

29. Front side member (RH&LH)

30. Frame bracket (RH&LH)

31. Closing plate assembly LH

32. Hoodledge connector (RH&LH)

33. Radiator core side support (RH&LH)

34. Radiator core support upper (RH&LH)

35. Hoodledge upper (RH&LH)

36. Hoodledge reinforcement assembly (RH&LH)

37. Dash side (RH&LH)

38. Dash side assembly (RH& LH)

39. Front floor reinforcement (RH&LH)

40. Front floor front (RH&LH)

41. Front floor center

42. Rear seat crossmember

43. Rear center crossmember

44. Rear seat upper crossmember

45. Rear side member (RH&LH)

46. Sill inner extension (RH&LH)

47. Rear side member extension (RH&LH)

48. Rear side member assembly (RH & LH)

49. Rear floor front

50. Rear floor front assembly

51. Rear floor side (RH&LH)

52. Rear floor rear

Revision: January 20102010 Versa

Page 825 of 3745

BL-316

< SERVICE INFORMATION >

BODY REPAIR

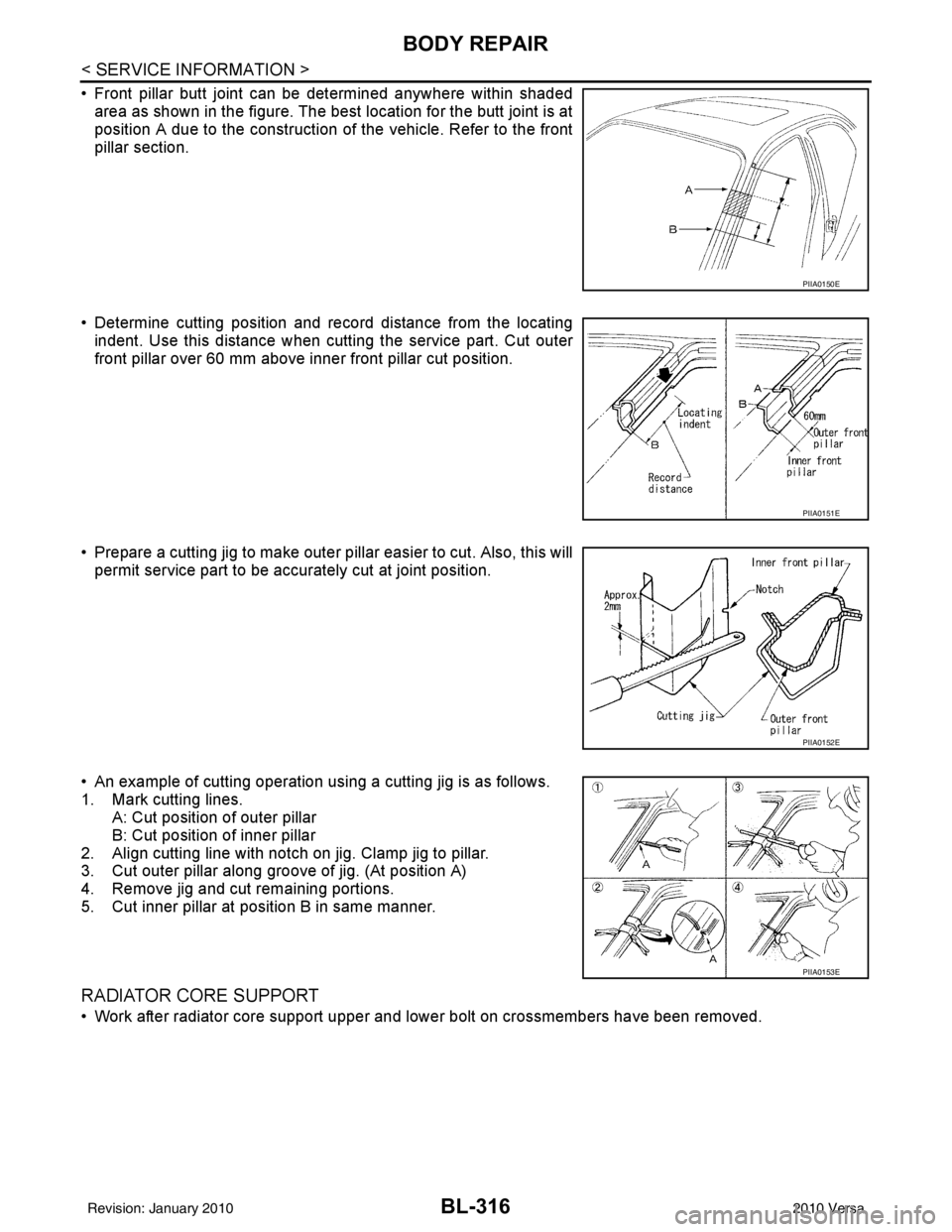

• Front pillar butt joint can be determined anywhere within shadedarea as shown in the figure. The best location for the butt joint is at

position A due to the construction of the vehicle. Refer to the front

pillar section.

• Determine cutting position and record distance from the locating indent. Use this distance when cutt ing the service part. Cut outer

front pillar over 60 mm above inner front pillar cut position.

• Prepare a cutting jig to make outer pillar easier to cut. Also, this will permit service part to be accurately cut at joint position.

• An example of cutting operation using a cutting jig is as follows.

1. Mark cutting lines. A: Cut position of outer pillar

B: Cut position of inner pillar

2. Align cutting line with notch on jig. Clamp jig to pillar.

3. Cut outer pillar along groove of jig. (At position A)

4. Remove jig and cut remaining portions.

5. Cut inner pillar at position B in same manner.

RADIATOR CORE SUPPORT

• Work after radiator core support upper and lower bolt on crossmembers have been removed.

PIIA0150E

PIIA0151E

PIIA0152E

PIIA0153E

Revision: January 20102010 Versa

Page 826 of 3745

BODY REPAIRBL-317

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

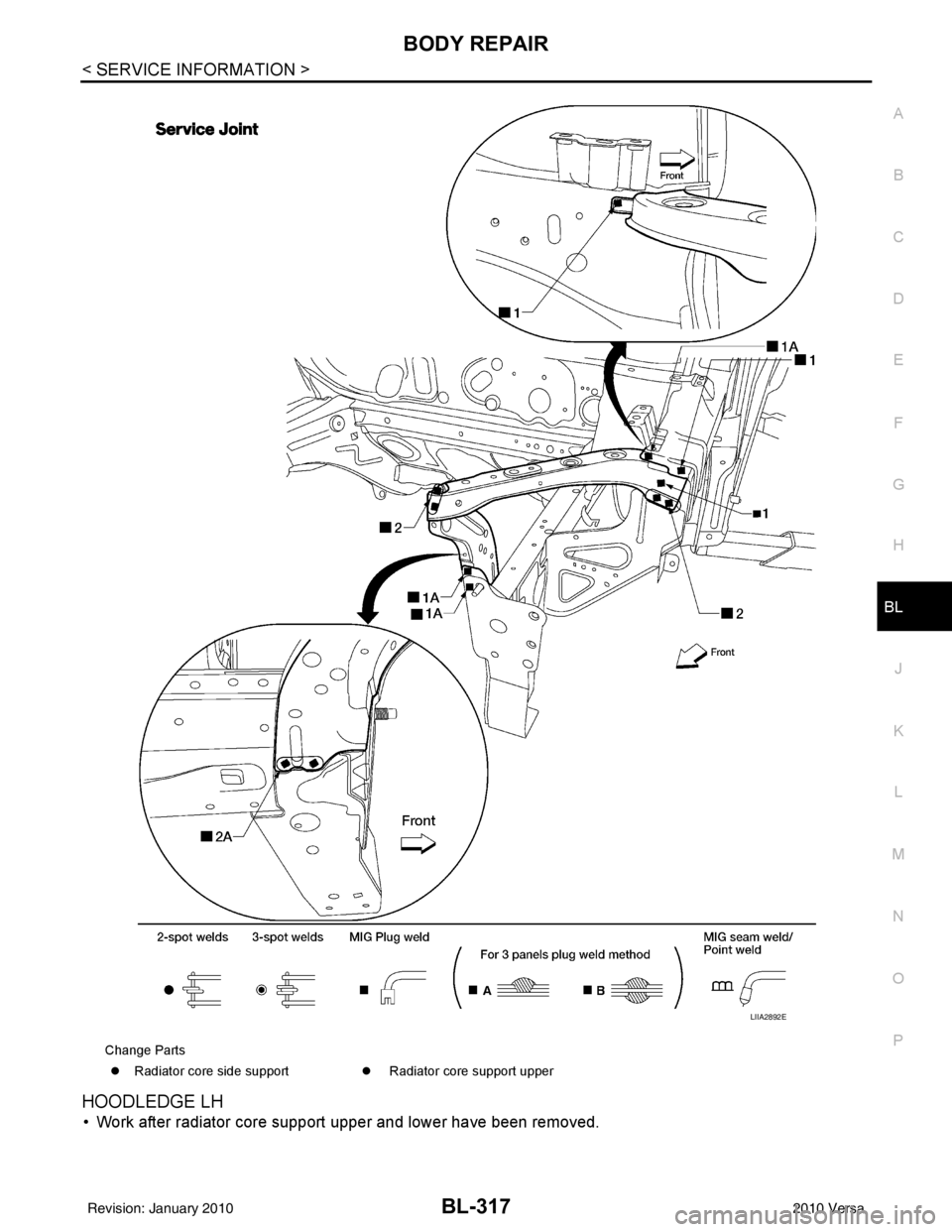

HOODLEDGE LH

• Work after radiator core support upper and lower have been removed.

Change Parts �z Radiator core side support �z Radiator core support upper

LIIA2892E

Revision: January 20102010 Versa

Page 827 of 3745

BL-318

< SERVICE INFORMATION >

BODY REPAIR

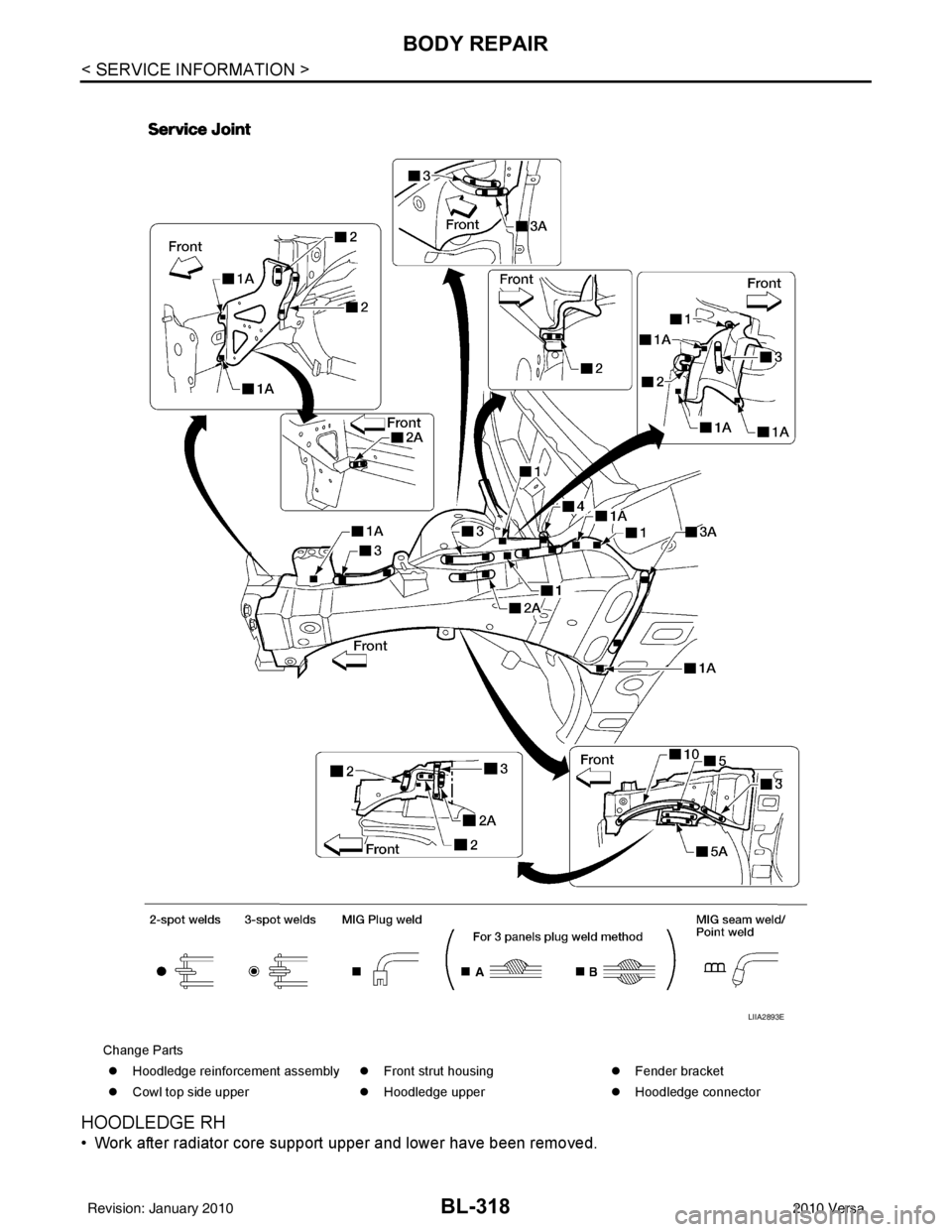

HOODLEDGE RH

• Work after radiator core support upper and lower have been removed.

Change Parts�z Hoodledge reinforcement assembly �zFront strut housing �zFender bracket

�z Cowl top side upper �zHoodledge upper �zHoodledge connector

LIIA2893E

Revision: January 20102010 Versa

Page 828 of 3745

BODY REPAIRBL-319

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

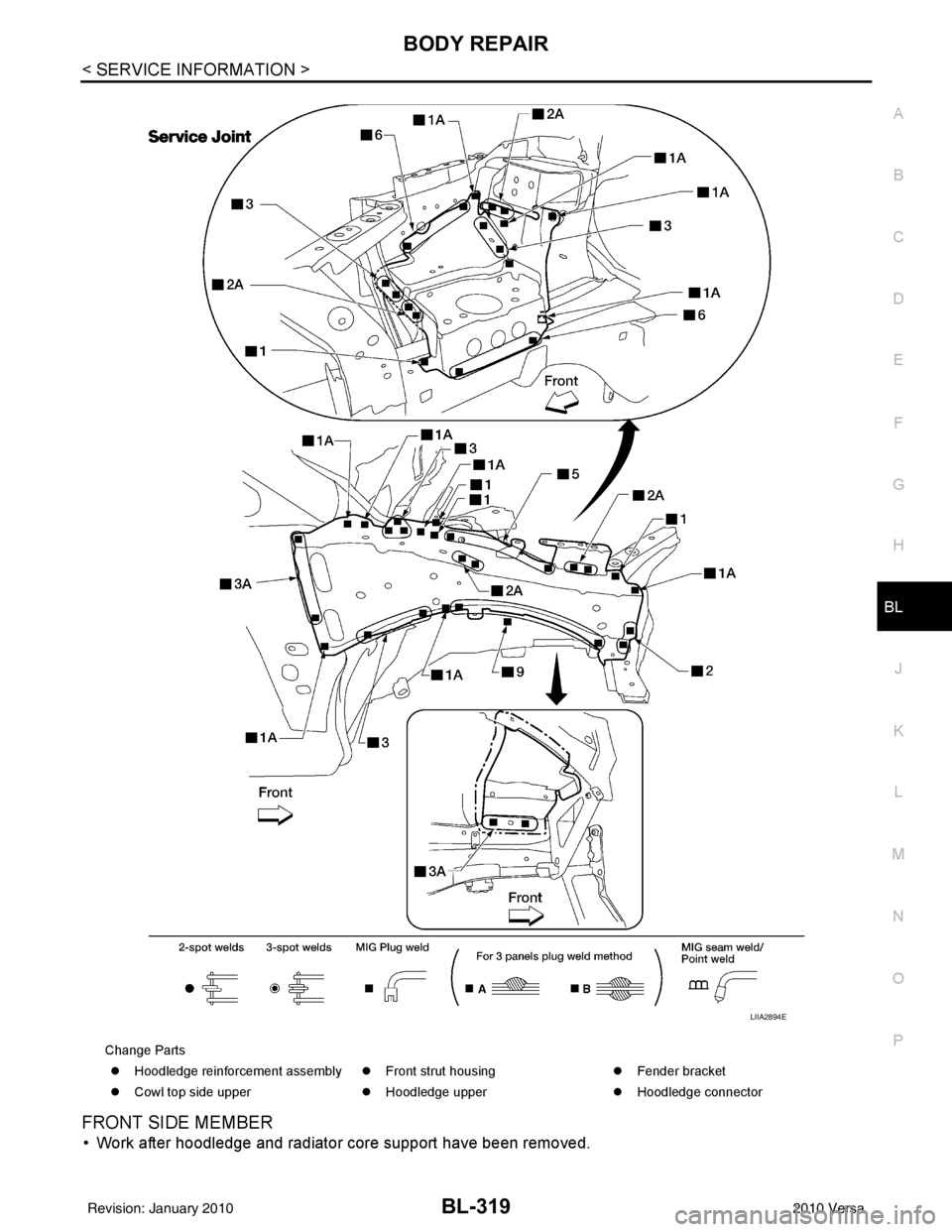

FRONT SIDE MEMBER

• Work after hoodledge and radiator core support have been removed.

Change Parts �z Hoodledge reinforcement assembly �zFront strut housing �zFender bracket

�z Cowl top side upper �zHoodledge upper �zHoodledge connector

LIIA2894E

Revision: January 20102010 Versa

Page 829 of 3745

BL-320

< SERVICE INFORMATION >

BODY REPAIR

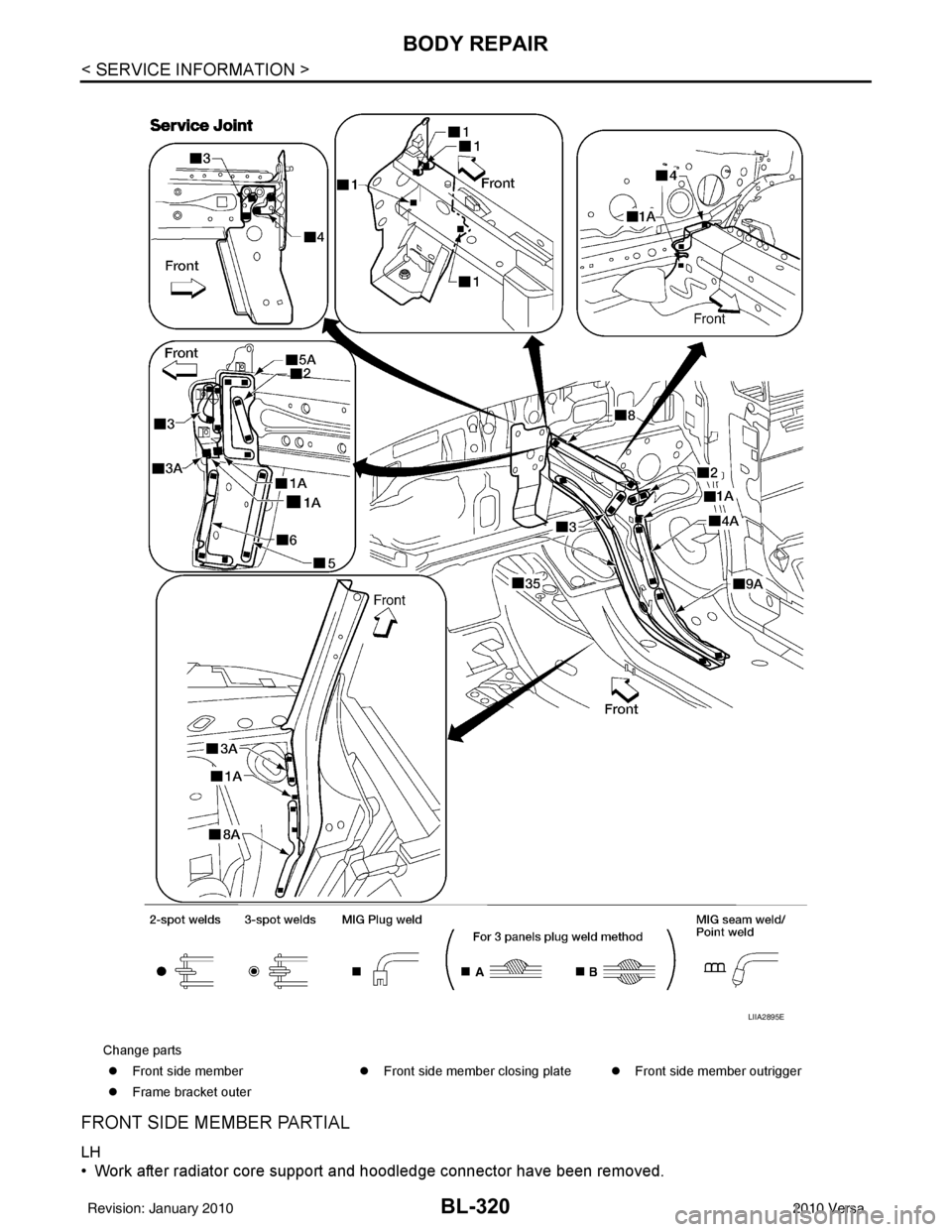

FRONT SIDE MEMBER PARTIAL

LH

• Work after radiator core support and hoodledge connector have been removed.

Change parts�z Front side member �zFront side member closing plate �zFront side member outrigger

�z Frame bracket outer

LIIA2895E

Revision: January 20102010 Versa

Page 830 of 3745

BODY REPAIRBL-321

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

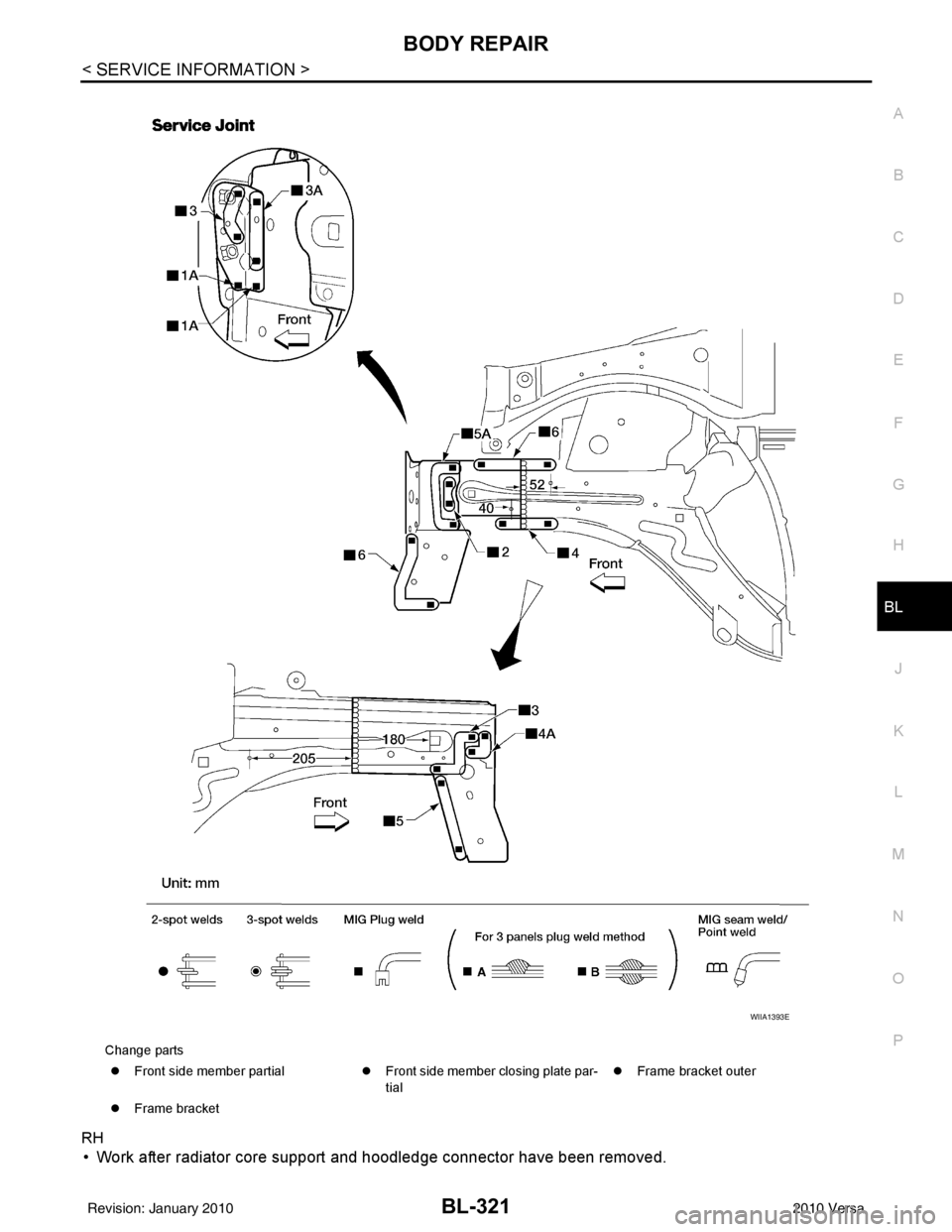

RH

• Work after radiator core support and hoodledge connector have been removed.

Change parts �z Front side member partial �zFront side member closing plate par-

tial �z

Frame bracket outer

�z Frame bracket

WIIA1393E

Revision: January 20102010 Versa

Page 983 of 3745

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Liquid Gasket .....................................4

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SYMPTOM DIAGNOSIS ...............................8

OVERHEATING CAUSE ANALYSIS ............. .....8

Troubleshooting Chart ...............................................8

FUNCTION DIAGNOSIS .. ............................10

DESCRIPTION ............................................... ....10

Engine Cooling System ....................................... ....10

Engine Cooling System Schematic .........................11

ON-VEHICLE MAINTENANCE ....................12

ENGINE COOLANT ....................................... ....12

Inspection ............................................................ ....12

Changing Engine Coolant .......................................12

RADIATOR .........................................................15

Checking Radiator Cap ....................................... ....15

Checking Radiator ...................................................15

ON-VEHICLE REPAIR .................................17

RADIATOR ..................................................... ....17

Component .......................................................... ....17

Removal and Installation ..................................... ....17

COOLING FAN ..................................................19

Component (Models with A/C) .................................19

Component (Models without A/C) ............................19

Removal and Installation .........................................20

Disassembly and Assembly .....................................20

WATER PUMP ..................................................21

Exploded View .........................................................21

Removal and Installation .........................................21

Inspection ................................................................22

THERMOSTAT ..................................................23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection ................................................................24

WATER OUTLET ..............................................25

Exploded View .........................................................25

Removal and Installation .........................................25

Inspection ................................................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

27

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

27

Periodical Maintenance Specification .................. ....27

Radiator ...................................................................27

Thermostat ..............................................................27

MR18DE

SERVICE INFORMATION .. .........................

28

PRECAUTIONS .................................................28

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

28

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

28

Precaution for Liquid Gasket ...................................29

Revision: January 20102010 Versa