light NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 233 of 3745

AT-216

< SERVICE INFORMATION >

SHIFT CONTROL SYSTEM

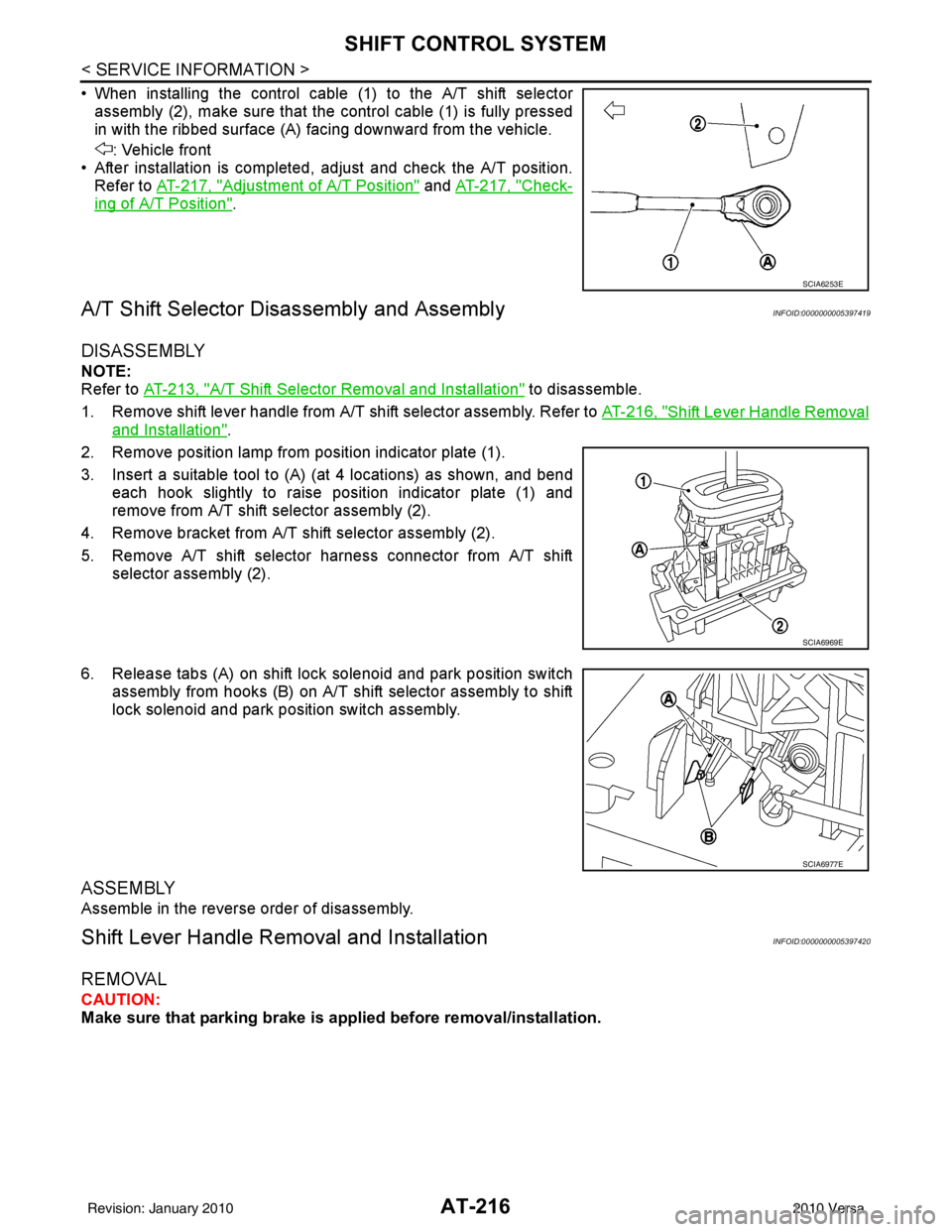

• When installing the control cable (1) to the A/T shift selectorassembly (2), make sure that the control cable (1) is fully pressed

in with the ribbed surface (A) facing downward from the vehicle.

: Vehicle front

• After installation is completed, adjust and check the A/T position.

Refer to AT-217, "

Adjustment of A/T Position" and AT-217, "Check-

ing of A/T Position".

A/T Shift Selector Di sassembly and AssemblyINFOID:0000000005397419

DISASSEMBLY

NOTE:

Refer to AT-213, "

A/T Shift Selector Removal and Installation" to disassemble.

1. Remove shift lever handle from A/T shift selector assembly. Refer to AT-216, "

Shift Lever Handle Removal

and Installation".

2. Remove position lamp from position indicator plate (1).

3. Insert a suitable tool to (A) (at 4 locations) as shown, and bend each hook slightly to raise position indicator plate (1) and

remove from A/T shift selector assembly (2).

4. Remove bracket from A/T shift selector assembly (2).

5. Remove A/T shift selector harness connector from A/T shift selector assembly (2).

6. Release tabs (A) on shift lock solenoid and park position switch assembly from hooks (B) on A/T shift selector assembly to shift

lock solenoid and park position switch assembly.

ASSEMBLY

Assemble in the reverse order of disassembly.

Shift Lever Handle Remo val and InstallationINFOID:0000000005397420

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation.

SCIA6253E

SCIA6969E

SCIA6977E

Revision: January 20102010 Versa

Page 279 of 3745

AT-262

< SERVICE INFORMATION >

DISASSEMBLY

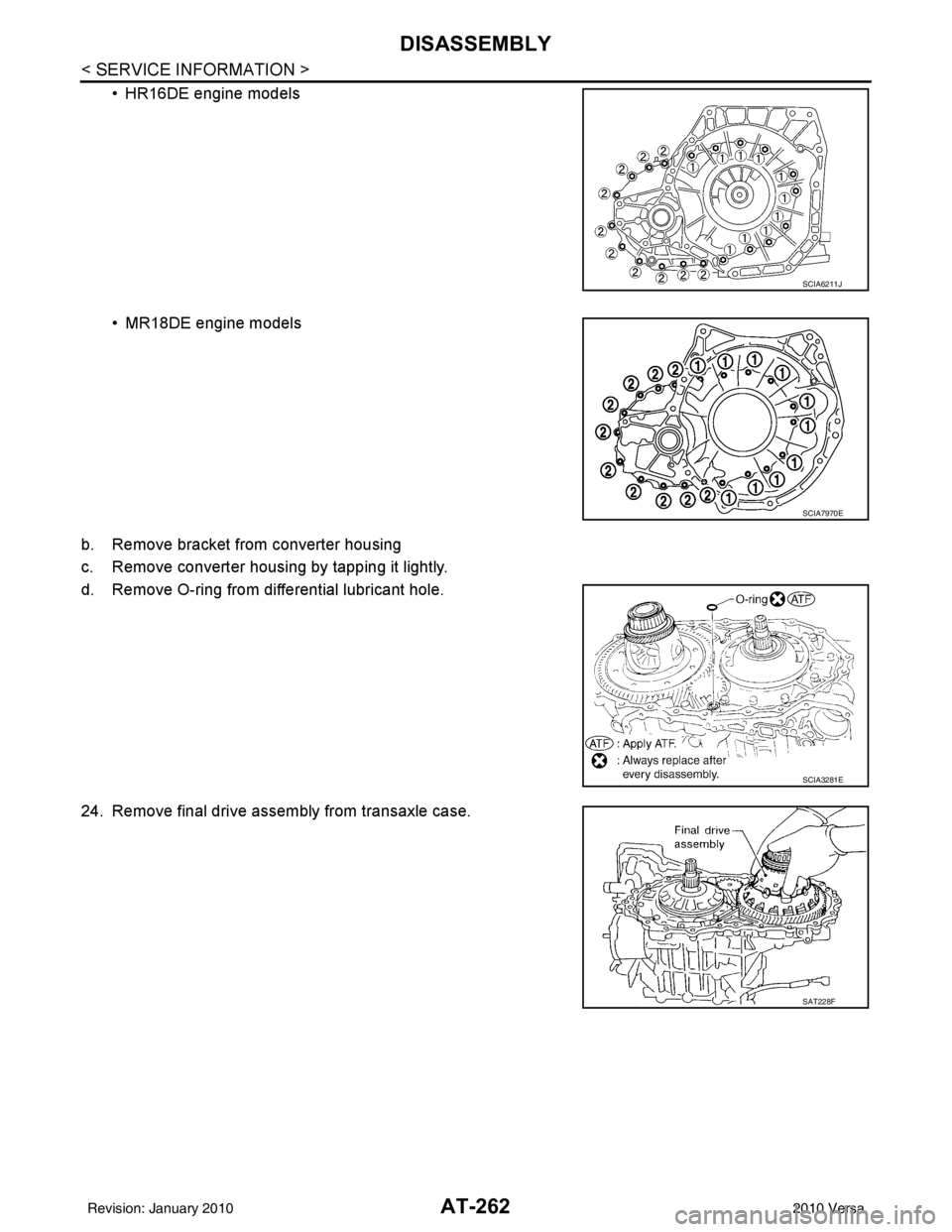

• HR16DE engine models

• MR18DE engine models

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case.

SCIA6211J

SCIA7970E

SCIA3281E

SAT228F

Revision: January 20102010 Versa

Page 288 of 3745

DISASSEMBLYAT-271

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

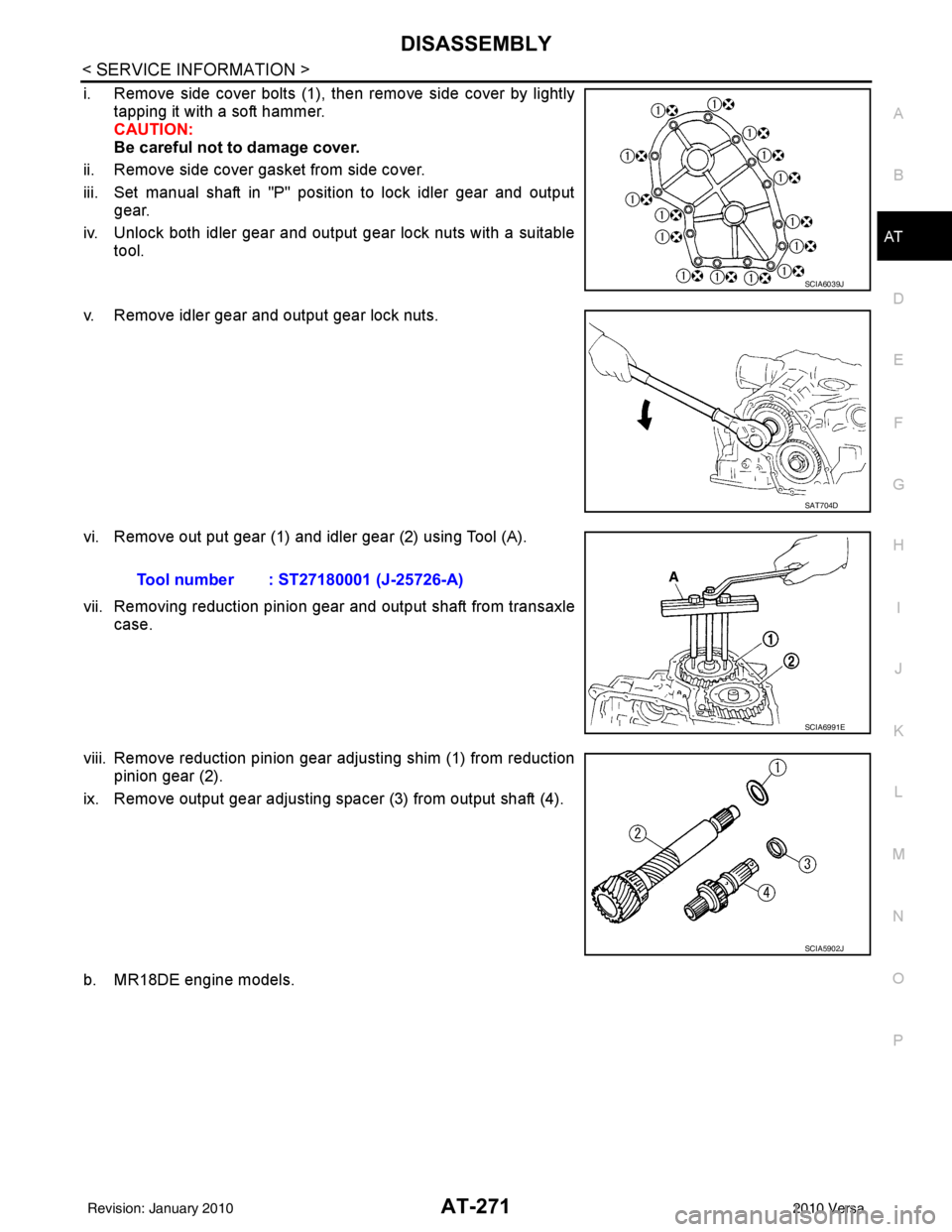

i. Remove side cover bolts (1), then remove side cover by lightly tapping it with a soft hammer.

CAUTION:

Be careful not to damage cover.

ii. Remove side cover gasket from side cover.

iii. Set manual shaft in "P" position to lock idler gear and output gear.

iv. Unlock both idler gear and output gear lock nuts with a suitable tool.

v. Remove idler gear and output gear lock nuts.

vi. Remove out put gear (1) and idler gear (2) using Tool (A).

vii. Removing reduction pinion gear and output shaft from transaxle case.

viii. Remove reduction pinion gear adjusting shim (1) from reduction pinion gear (2).

ix. Remove output gear adjusting spacer (3) from output shaft (4).

b. MR18DE engine models.

SCIA6039J

SAT704D

Tool number : ST27180001 (J-25726-A)

SCIA6991E

SCIA5902J

Revision: January 20102010 Versa

Page 289 of 3745

AT-272

< SERVICE INFORMATION >

DISASSEMBLY

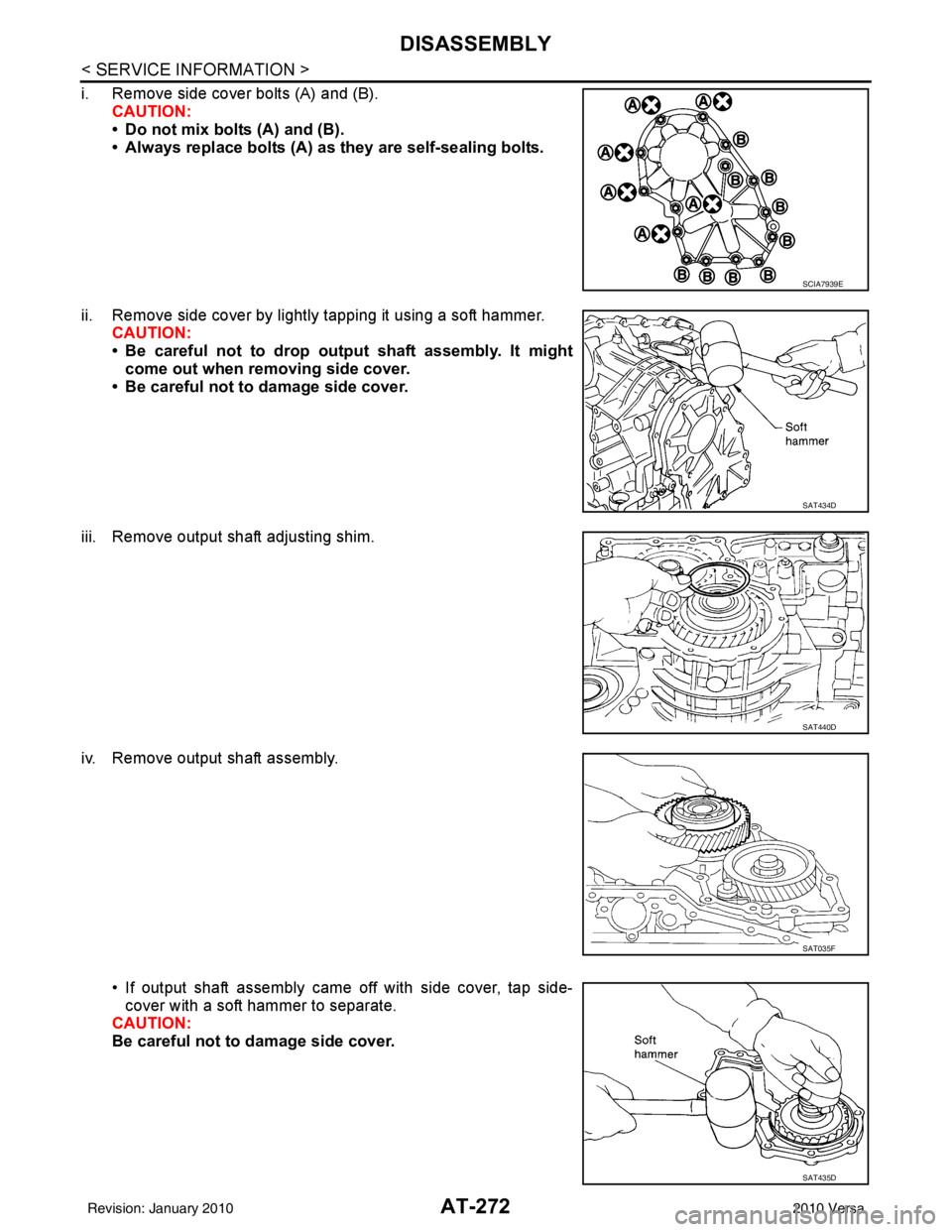

i. Remove side cover bolts (A) and (B).CAUTION:

• Do not mix bolts (A) and (B).

• Always replace bolts (A) as they are self-sealing bolts.

ii. Remove side cover by lightly tapping it using a soft hammer. CAUTION:

• Be careful not to drop output shaft assembly. It might

come out when removing side cover.

• Be careful not to damage side cover.

iii. Remove output shaft adjusting shim.

iv. Remove output shaft assembly.

• If output shaft assembly came off with side cover, tap side-cover with a soft hammer to separate.

CAUTION:

Be careful not to damage side cover.

SCIA7939E

SAT434D

SAT440D

SAT035F

SAT435D

Revision: January 20102010 Versa

Page 305 of 3745

AT-288

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

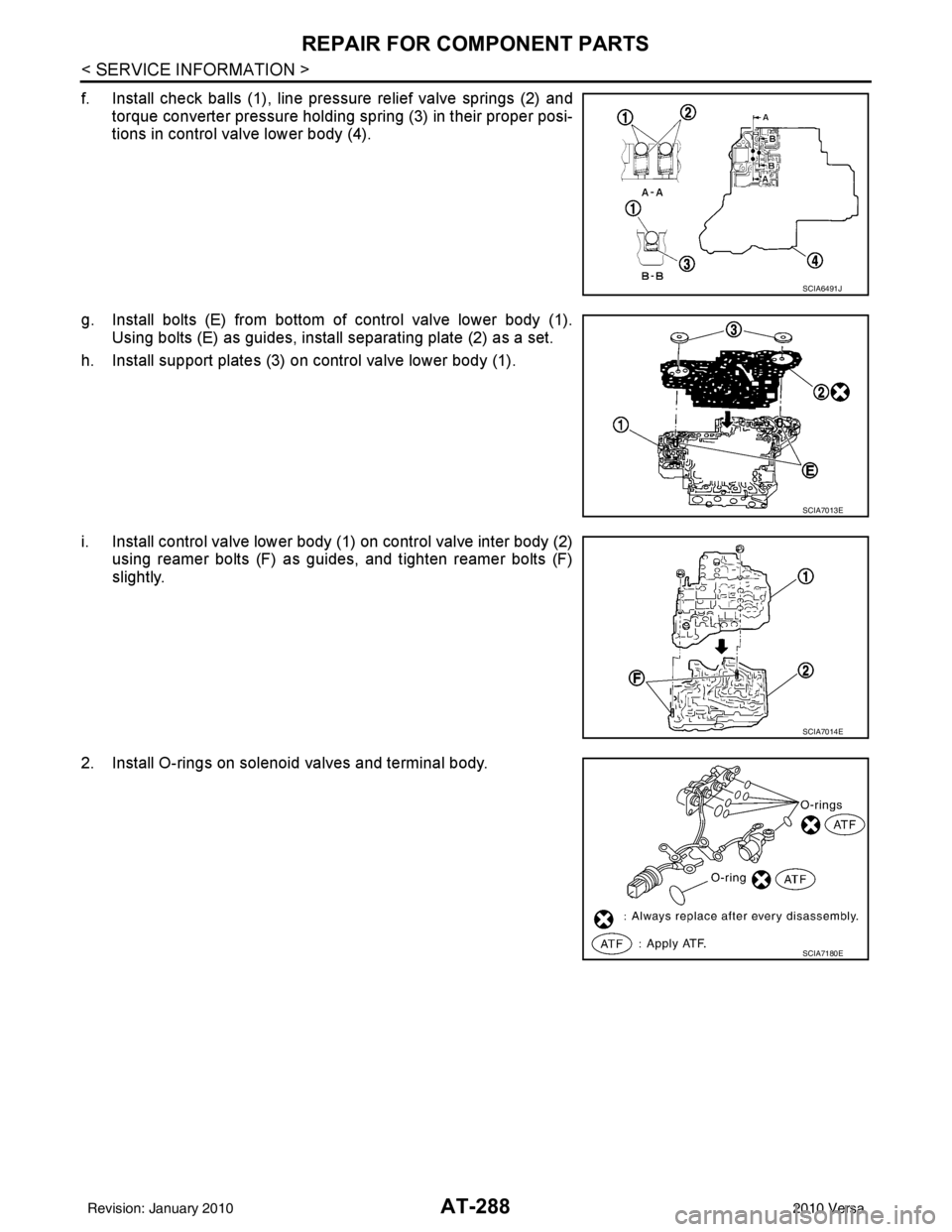

f. Install check balls (1), line pressure relief valve springs (2) andtorque converter pressure holding spring (3) in their proper posi-

tions in control valve lower body (4).

g. Install bolts (E) from bottom of control valve lower body (1). Using bolts (E) as guides, install separating plate (2) as a set.

h. Install support plates (3) on control valve lower body (1).

i. Install control valve lower body (1) on control valve inter body (2) using reamer bolts (F) as guides, and tighten reamer bolts (F)

slightly.

2. Install O-rings on solenoid valves and terminal body.

SCIA6491J

SCIA7013E

SCIA7014E

SCIA7180E

Revision: January 20102010 Versa

Page 310 of 3745

REPAIR FOR COMPONENT PARTSAT-293

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

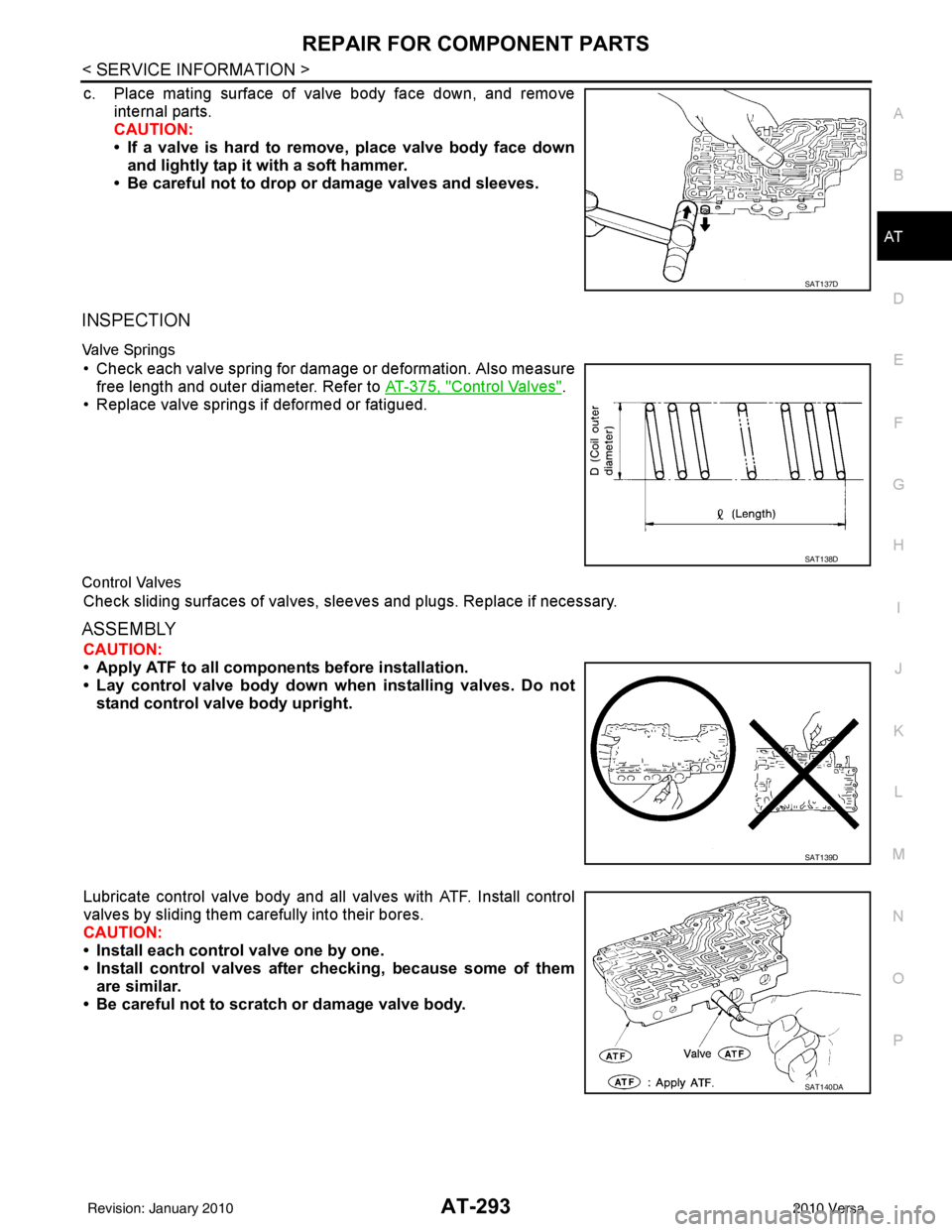

c. Place mating surface of valve body face down, and remove internal parts.

CAUTION:

• If a valve is hard to remove, place valve body face downand lightly tap it with a soft hammer.

• Be careful not to drop or damage valves and sleeves.

INSPECTION

Va l v e Sp r i n g s

• Check each valve spring for damage or deformation. Also measure

free length and outer diameter. Refer to AT-375, "

Control Valves".

• Replace valve springs if deformed or fatigued.

Control Valves

Check sliding surfaces of valves, sleeves and plugs. Replace if necessary.

ASSEMBLY

CAUTION:

• Apply ATF to all componen ts before installation.

• Lay control valve body down wh en installing valves. Do not

stand control valve body upright.

Lubricate control valve body and all valves with ATF. Install control

valves by sliding them carefully into their bores.

CAUTION:

• Install each control valve one by one.

• Install control valves after checking, because some of them are similar.

• Be careful not to scratch or damage valve body.

SAT137D

SAT138D

SAT139D

SAT140DA

Revision: January 20102010 Versa

Page 318 of 3745

REPAIR FOR COMPONENT PARTSAT-301

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

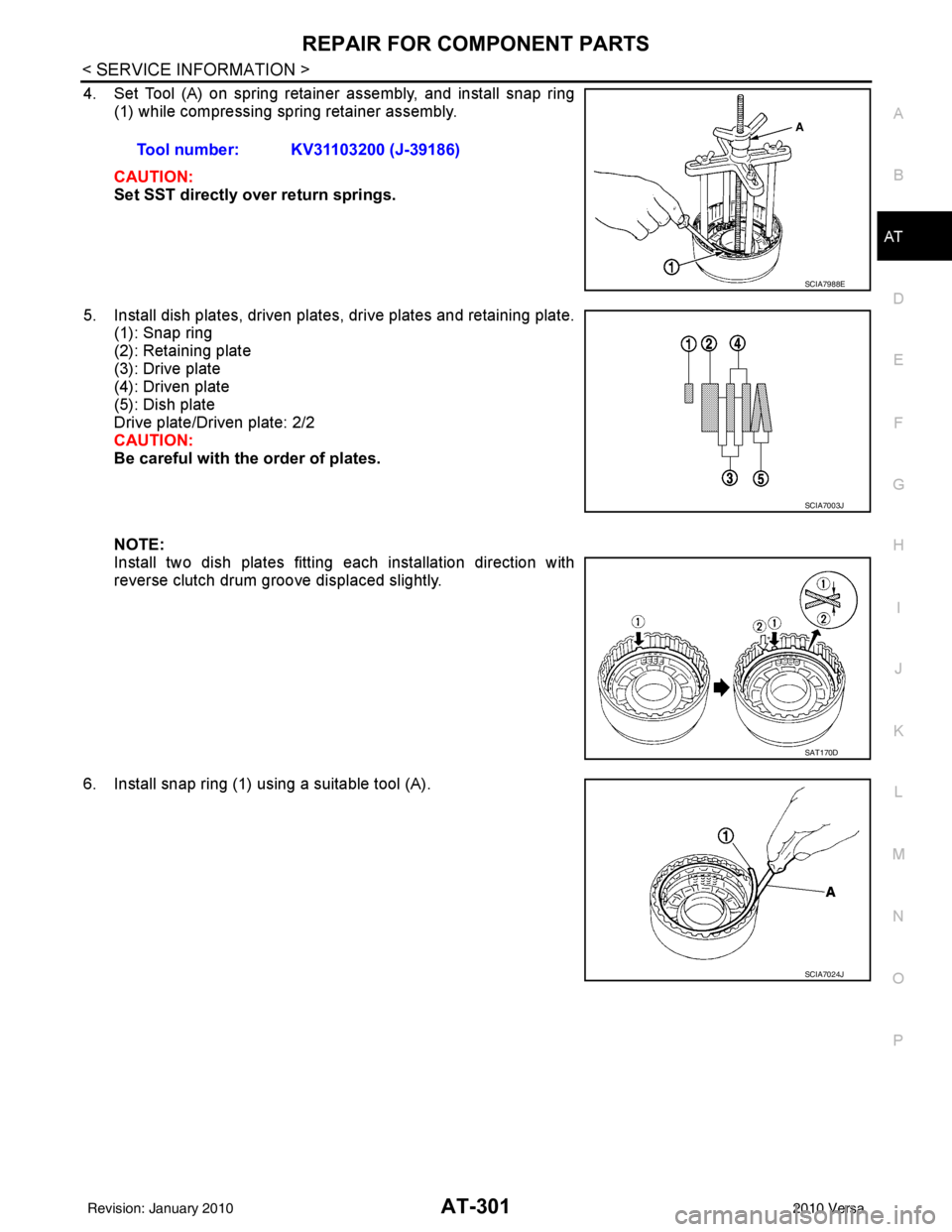

4. Set Tool (A) on spring retainer assembly, and install snap ring (1) while compressing spring retainer assembly.

CAUTION:

Set SST directly over return springs.

5. Install dish plates, driven plates, drive plates and retaining plate. (1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Dish plate

Drive plate/Driven plate: 2/2

CAUTION:

Be careful with the order of plates.

NOTE:

Install two dish plates fitting each installation direction with

reverse clutch drum groove displaced slightly.

6. Install snap ring (1) using a suitable tool (A). Tool number: KV31103200 (J-39186)

SCIA7988E

SCIA7003J

SAT170D

SCIA7024J

Revision: January 20102010 Versa

Page 335 of 3745

AT-318

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

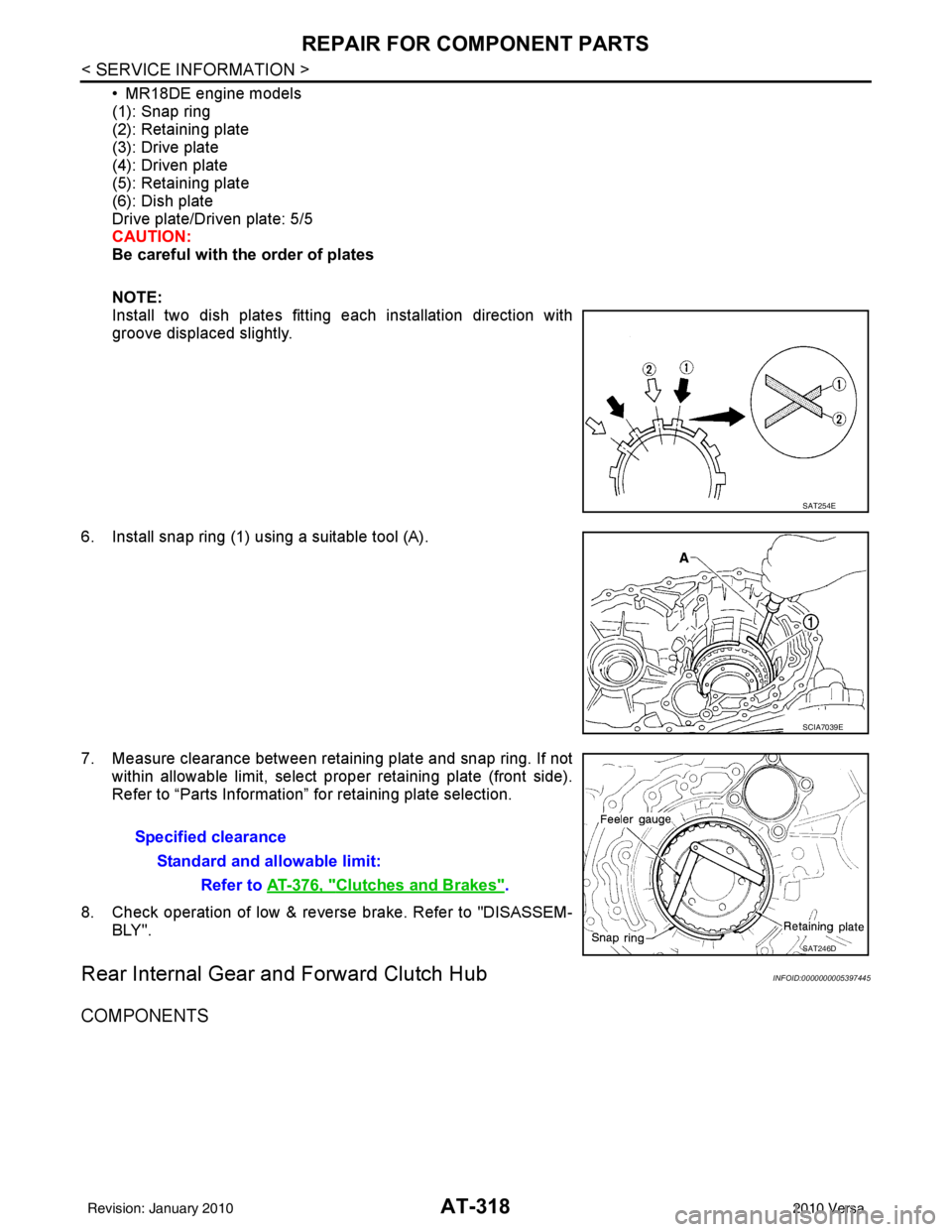

• MR18DE engine models

(1): Snap ring

(2): Retaining plate

(3): Drive plate

(4): Driven plate

(5): Retaining plate

(6): Dish plate

Drive plate/Driven plate: 5/5

CAUTION:

Be careful with the order of plates

NOTE:

Install two dish plates fitting each installation direction with

groove displaced slightly.

6. Install snap ring (1) using a suitable tool (A).

7. Measure clearance between retaining plate and snap ring. If not within allowable limit, select proper retaining plate (front side).

Refer to “Parts Information” for retaining plate selection.

8. Check operation of low & revers e brake. Refer to "DISASSEM-

BLY".

Rear Internal Gear and Forward Clutch HubINFOID:0000000005397445

COMPONENTS

SAT254E

SCIA7039E

Specified clearance

Standard and allowable limit: Refer to AT-376, "

Clutches and Brakes".

SAT246D

Revision: January 20102010 Versa

Page 368 of 3745

ASSEMBLYAT-351

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

m. Reinstall converter housing on transaxle case and ti ghten converter housing bolts to the specified torque.

Refer to AT-237, "

Component".

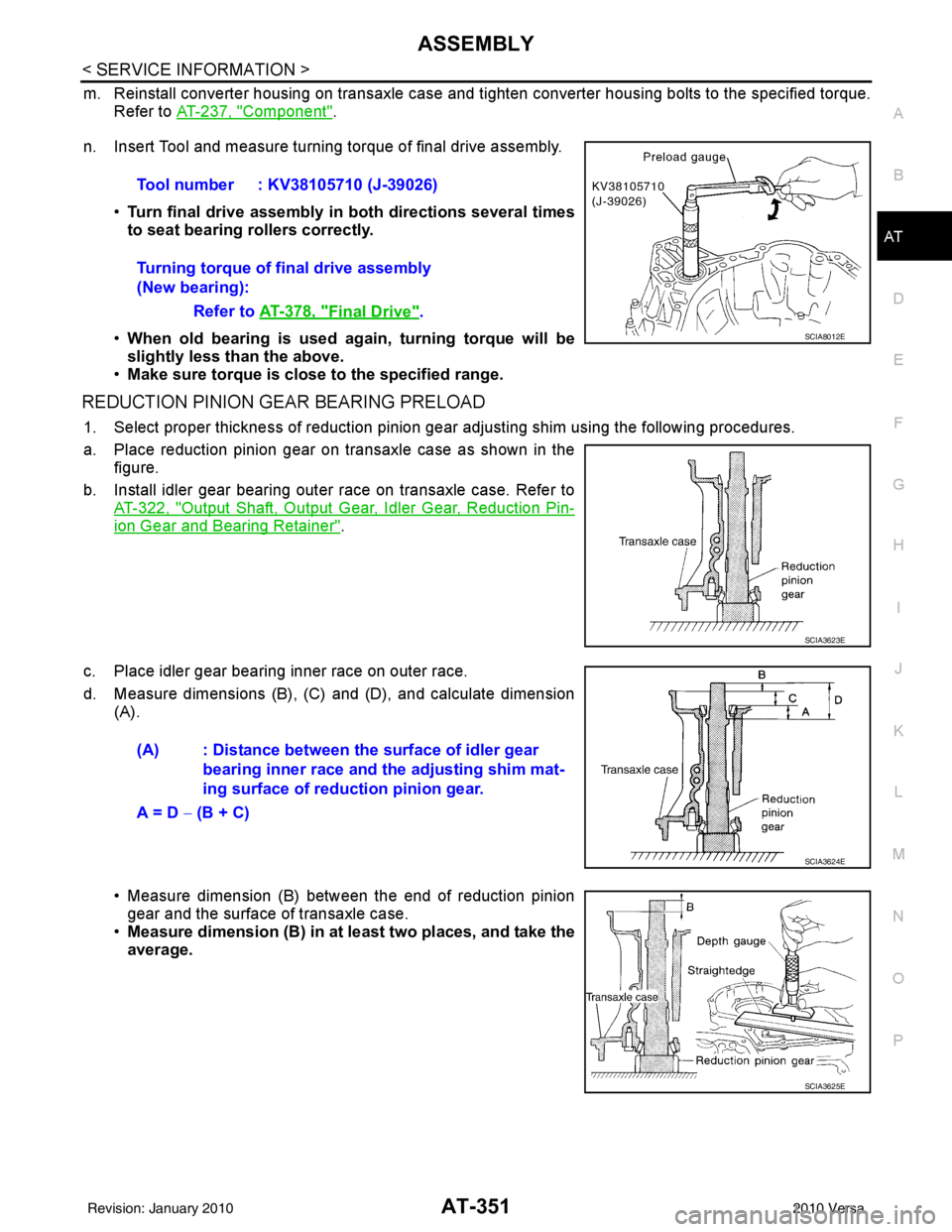

n. Insert Tool and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

• When old bearing is used ag ain, turning torque will be

slightly less than the above.

• Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.

a. Place reduction pinion gear on transaxle case as shown in the figure.

b. Install idler gear bearing outer race on transaxle case. Refer to AT-322, "

Output Shaft, Output Gear, Idler Gear, Reduction Pin-

ion Gear and Bearing Retainer".

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions (B), (C) and (D), and calculate dimension (A).

• Measure dimension (B) between the end of reduction pinion

gear and the surface of transaxle case.

• Measure dimension (B) in at least two places, and take the

average.Tool number : KV38105710 (J-39026)

Turning torque of final drive assembly

(New bearing):

Refer to AT-378, "

Final Drive".

SCIA8012E

SCIA3623E

(A) : Distance between the surface of idler gear

bearing inner race and th e adjusting shim mat-

ing surface of reduction pinion gear.

A = D − (B + C)

SCIA3624E

SCIA3625E

Revision: January 20102010 Versa

Page 372 of 3745

ASSEMBLYAT-355

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

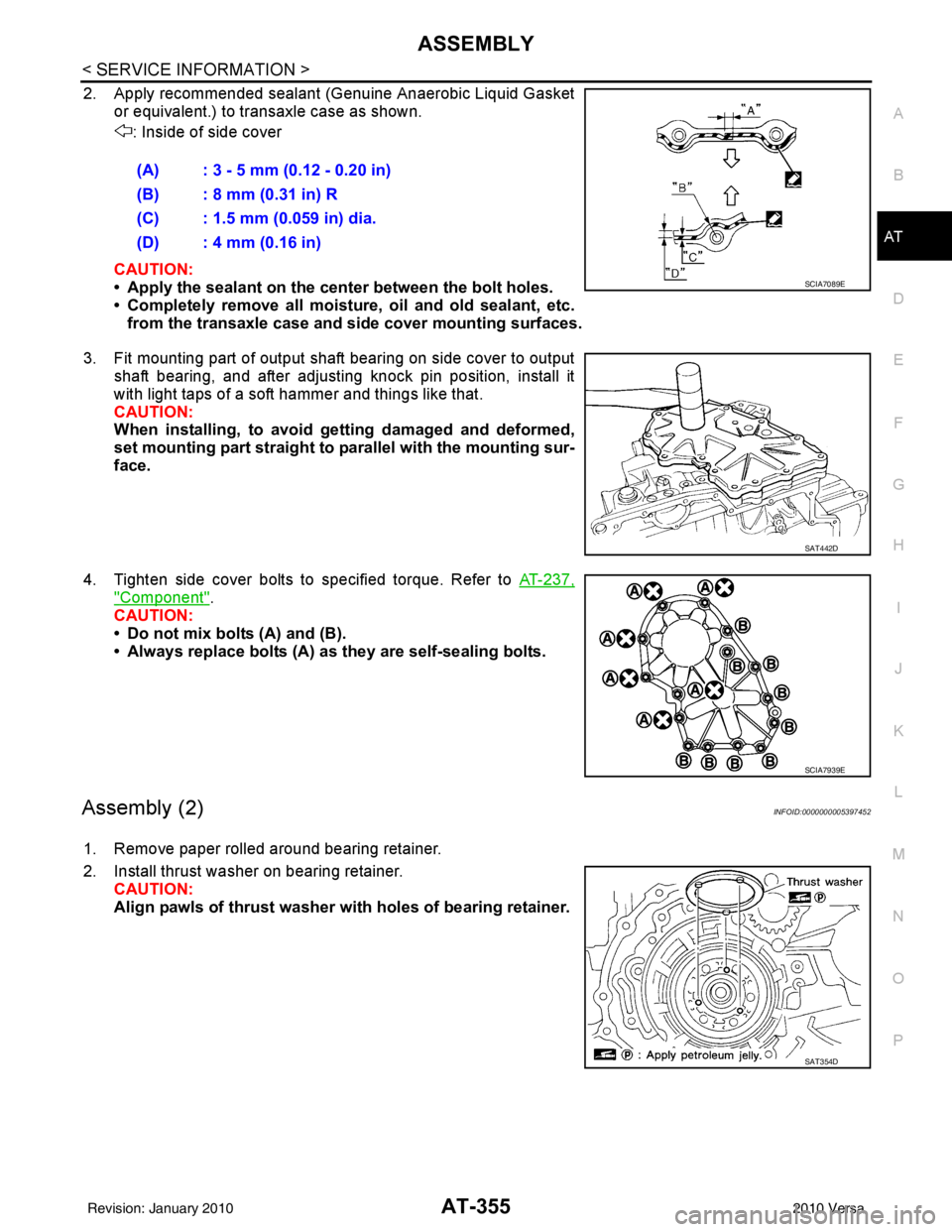

2. Apply recommended sealant (Genuine Anaerobic Liquid Gasket or equivalent.) to transaxle case as shown.

: Inside of side cover

CAUTION:

• Apply the sealant on the center between the bolt holes.

• Completely remove all moisture, oil and old sealant, etc. from the transaxle case and side cover mounting surfaces.

3. Fit mounting part of output shaft bearing on side cover to output shaft bearing, and after adjusting knock pin position, install it

with light taps of a soft hammer and things like that.

CAUTION:

When installing, to avoid getting damaged and deformed,

set mounting part straight to parallel with the mounting sur-

face.

4. Tighten side cover bolts to specified torque. Refer to AT-237,

"Component".

CAUTION:

• Do not mix bolts (A) and (B).

• Always replace bolts (A) as they are self-sealing bolts.

Assembly (2)INFOID:0000000005397452

1. Remove paper rolled around bearing retainer.

2. Install thrust washer on bearing retainer. CAUTION:

Align pawls of thrust washer with holes of bearing retainer.(A) : 3 - 5 mm (0.12 - 0.20 in)

(B) : 8 mm (0.31 in) R

(C) : 1.5 mm (0.059 in) dia.

(D) : 4 mm (0.16 in)

SCIA7089E

SAT442D

SCIA7939E

SAT354D

Revision: January 20102010 Versa