refrigerant type NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3356 of 3745

REFRIGERANT LINESMTC-77

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

ComponentINFOID:0000000005396520

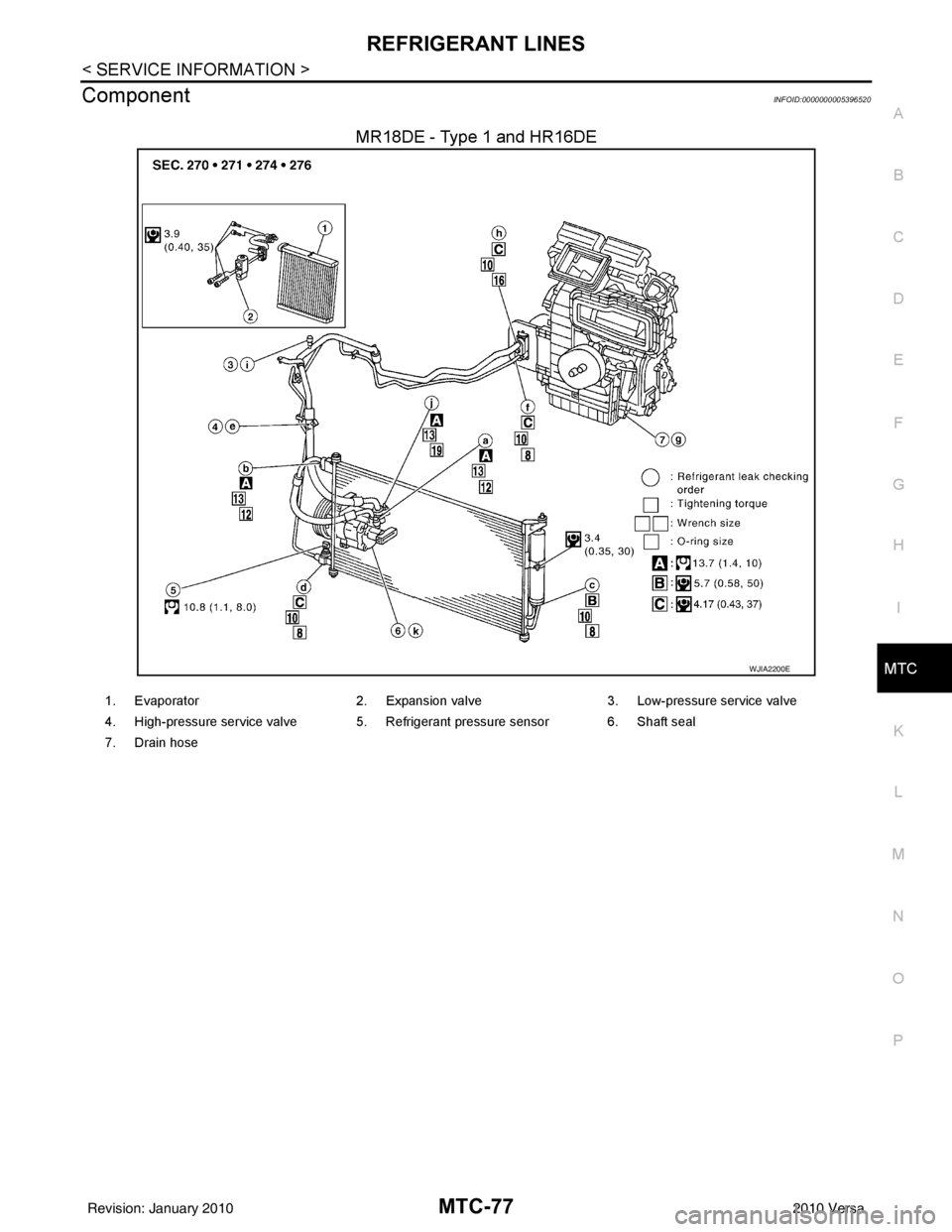

MR18DE - Type 1 and HR16DE

WJIA2200E

1. Evaporator 2. Expansion valve3. Low-pressure service valve

4. High-pressure service valve 5. Refrigerant pressure sensor 6. Shaft seal

7. Drain hose

Revision: January 20102010 Versa

Page 3357 of 3745

MTC-78

< SERVICE INFORMATION >

REFRIGERANT LINES

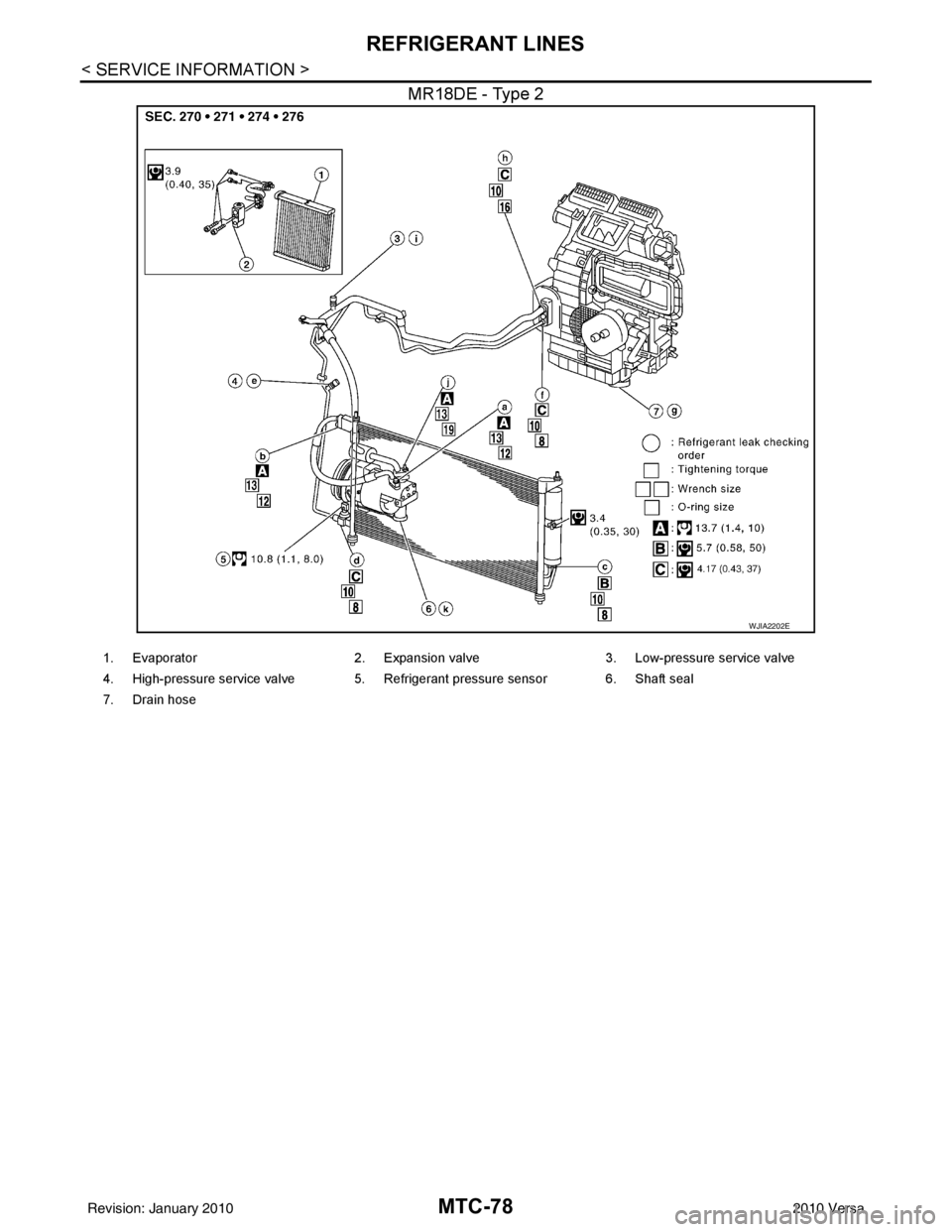

MR18DE - Type 2

WJIA2202E

1. Evaporator2. Expansion valve 3. Low-pressure service valve

4. High-pressure service valve 5. Refrigerant pressure sensor 6. Shaft seal

7. Drain hose

Revision: January 20102010 Versa

Page 3361 of 3745

MTC-82

< SERVICE INFORMATION >

REFRIGERANT LINES

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with a new ones, andapply compressor oil when installing.

• When recharging refrigerant, check for leaks. Refer to MTC-92, "

Checking of Refrigerant Leaks".

Removal and Installation for Compressor Clutch - Type 1INFOID:0000000005716140

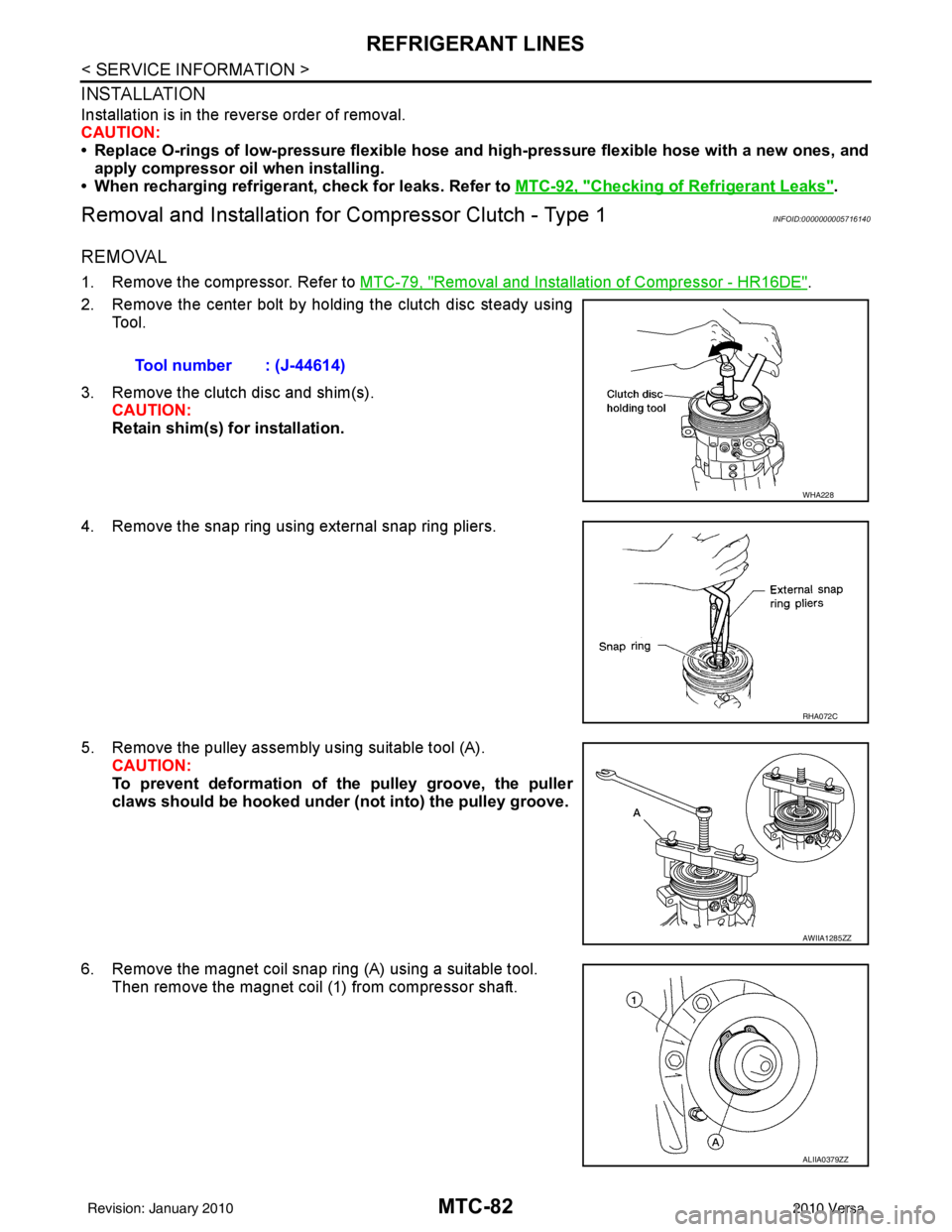

REMOVAL

1. Remove the compressor. Refer to MTC-79, "Removal and Installation of Compressor - HR16DE".

2. Remove the center bolt by holding the clutch disc steady using Tool.

3. Remove the clutch disc and shim(s). CAUTION:

Retain shim(s) for installation.

4. Remove the snap ring using external snap ring pliers.

5. Remove the pulley assembly using suitable tool (A). CAUTION:

To prevent deformation of th e pulley groove, the puller

claws should be ho oked under (not into) the pulley groove.

6. Remove the magnet coil snap ring (A) using a suitable tool. Then remove the magnet coil (1) from compressor shaft.Tool number : (J-44614)

WHA228

RHA072C

AWIIA1285ZZ

ALIIA0379ZZ

Revision: January 20102010 Versa

Page 3363 of 3745

MTC-84

< SERVICE INFORMATION >

REFRIGERANT LINES

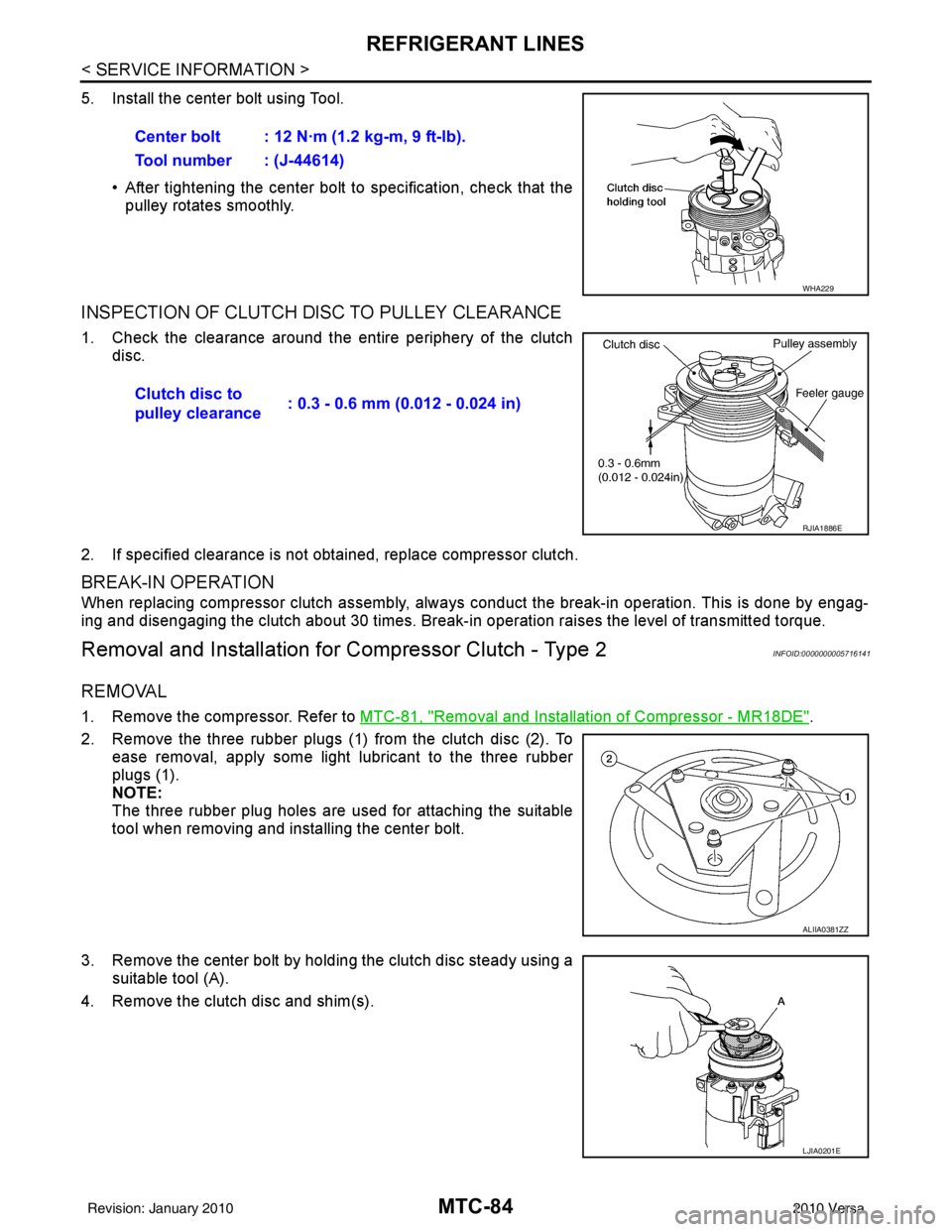

5. Install the center bolt using Tool.• After tightening the center bolt to specification, check that the

pulley rotates smoothly.

INSPECTION OF CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch

disc.

2. If specified clearance is not obtained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Compressor Clutch - Type 2INFOID:0000000005716141

REMOVAL

1. Remove the compressor. Refer to MTC-81, "Removal and Installation of Compressor - MR18DE".

2. Remove the three rubber plugs (1) from the clutch disc (2). To ease removal, apply some light lubricant to the three rubber

plugs (1).

NOTE:

The three rubber plug holes are used for attaching the suitable

tool when removing and installing the center bolt.

3. Remove the center bolt by holding the clutch disc steady using a suitable tool (A).

4. Remove the clutch disc and shim(s). Center bolt : 12 N·m (1.2 kg-m, 9 ft-lb).

Tool number : (J-44614)

WHA229

Clutch disc to

pulley clearance

: 0.3 - 0.6 mm (0.012 - 0.024 in)

RJIA1886E

ALIIA0381ZZ

LJIA0201E

Revision: January 20102010 Versa

Page 3366 of 3745

REFRIGERANT LINESMTC-87

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

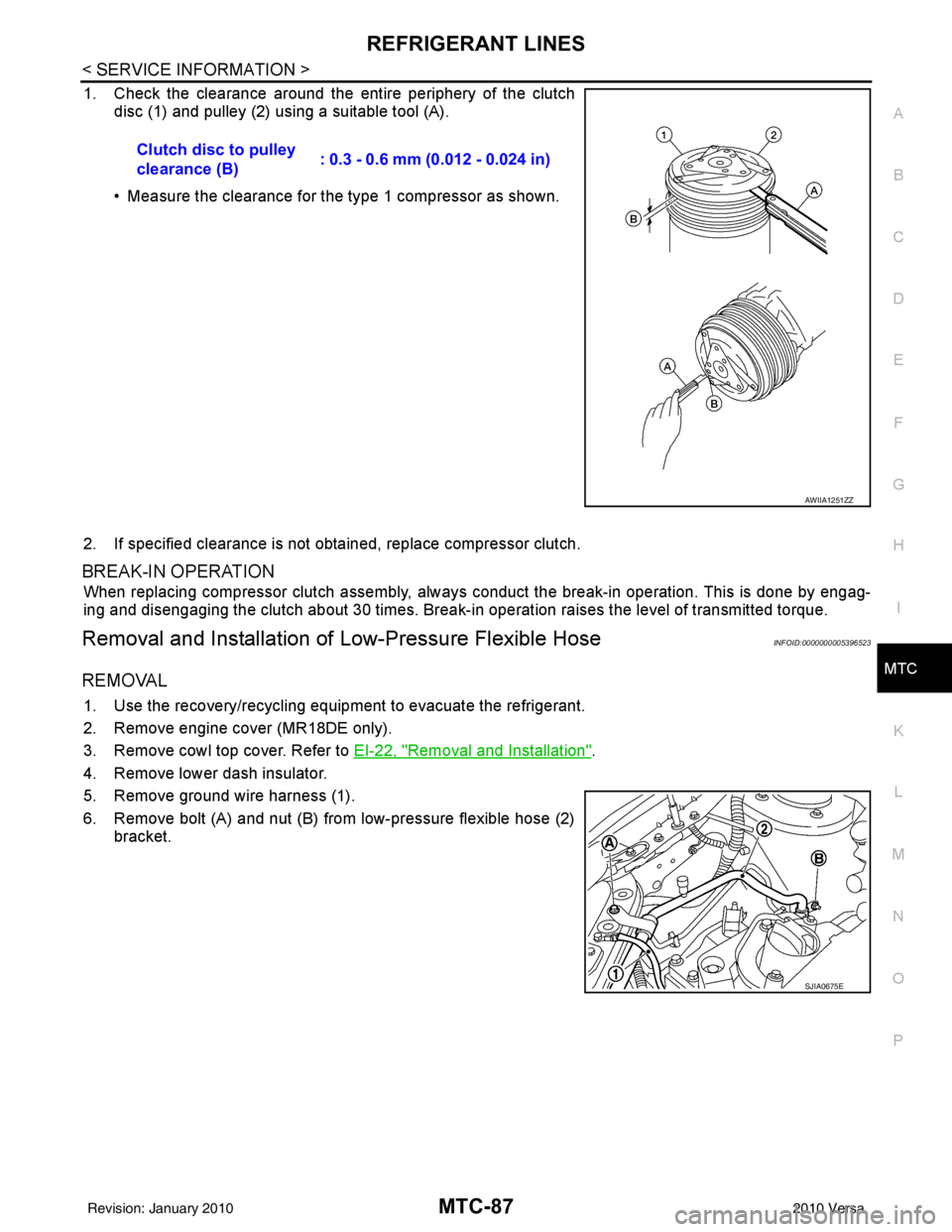

1. Check the clearance around the entire periphery of the clutch disc (1) and pulley (2) using a suitable tool (A).

• Measure the clearance for the type 1 compressor as shown.

2. If specified clearance is not obt ained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation of Low-Pressure Flexible HoseINFOID:0000000005396523

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove engine cover (MR18DE only).

3. Remove cowl top cover. Refer to EI-22, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2) bracket.Clutch disc to pulley

clearance (B)

: 0.3 - 0.6 mm (0.012 - 0.024 in)

AWIIA1251ZZ

SJIA0675E

Revision: January 20102010 Versa

Page 3371 of 3745

MTC-92

< SERVICE INFORMATION >

REFRIGERANT LINES

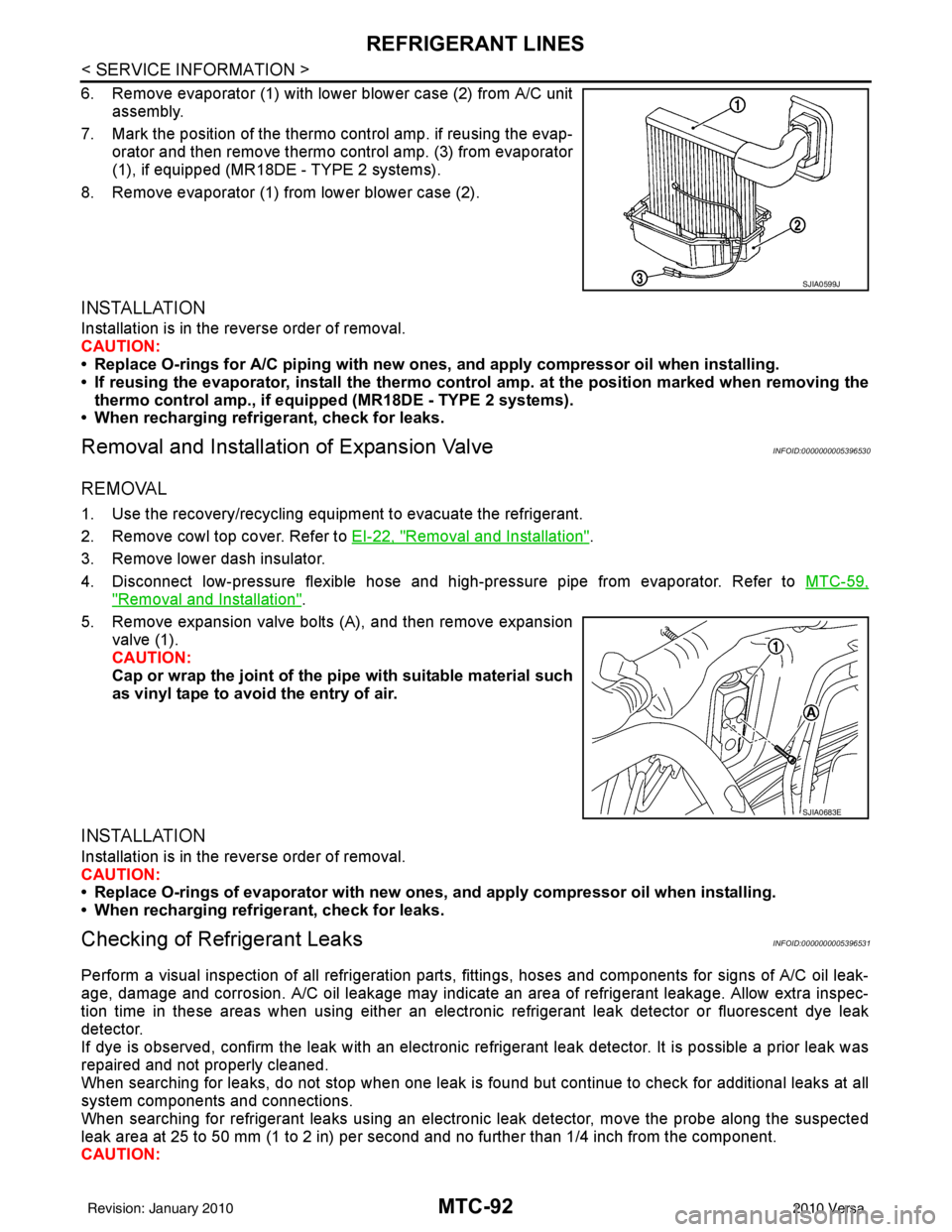

6. Remove evaporator (1) with lower blower case (2) from A/C unitassembly.

7. Mark the position of the thermo control amp. if reusing the evap- orator and then remove thermo c ontrol amp. (3) from evaporator

(1), if equipped (MR18DE - TYPE 2 systems).

8. Remove evaporator (1) from lower blower case (2).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• If reusing the evaporator, install the thermo contro l amp. at the position marked when removing the

thermo control amp., if equipped (MR18DE - TYPE 2 systems).

• When recharging refrigerant, check for leaks.

Removal and Installation of Expansion ValveINFOID:0000000005396530

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove cowl top cover. Refer to EI-22, "

Removal and Installation".

3. Remove lower dash insulator.

4. Disconnect low-pressure flexible hose and high-pressure pipe from evaporator. Refer to MTC-59,

"Removal and Installation".

5. Remove expansion valve bolts (A), and then remove expansion valve (1).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of evaporator with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000005396531

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage and corrosion. A/C oil leakage may indicate an area of refrigerant leakage. Allow extra inspec-

tion time in these areas when using either an electronic refrigerant leak detector or fluorescent dye leak

detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 25 to 50 mm (1 to 2 in) per second and no further than 1/4 inch from the component.

CAUTION:

SJIA0599J

SJIA0683E

Revision: January 20102010 Versa

Page 3375 of 3745

MTC-96

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

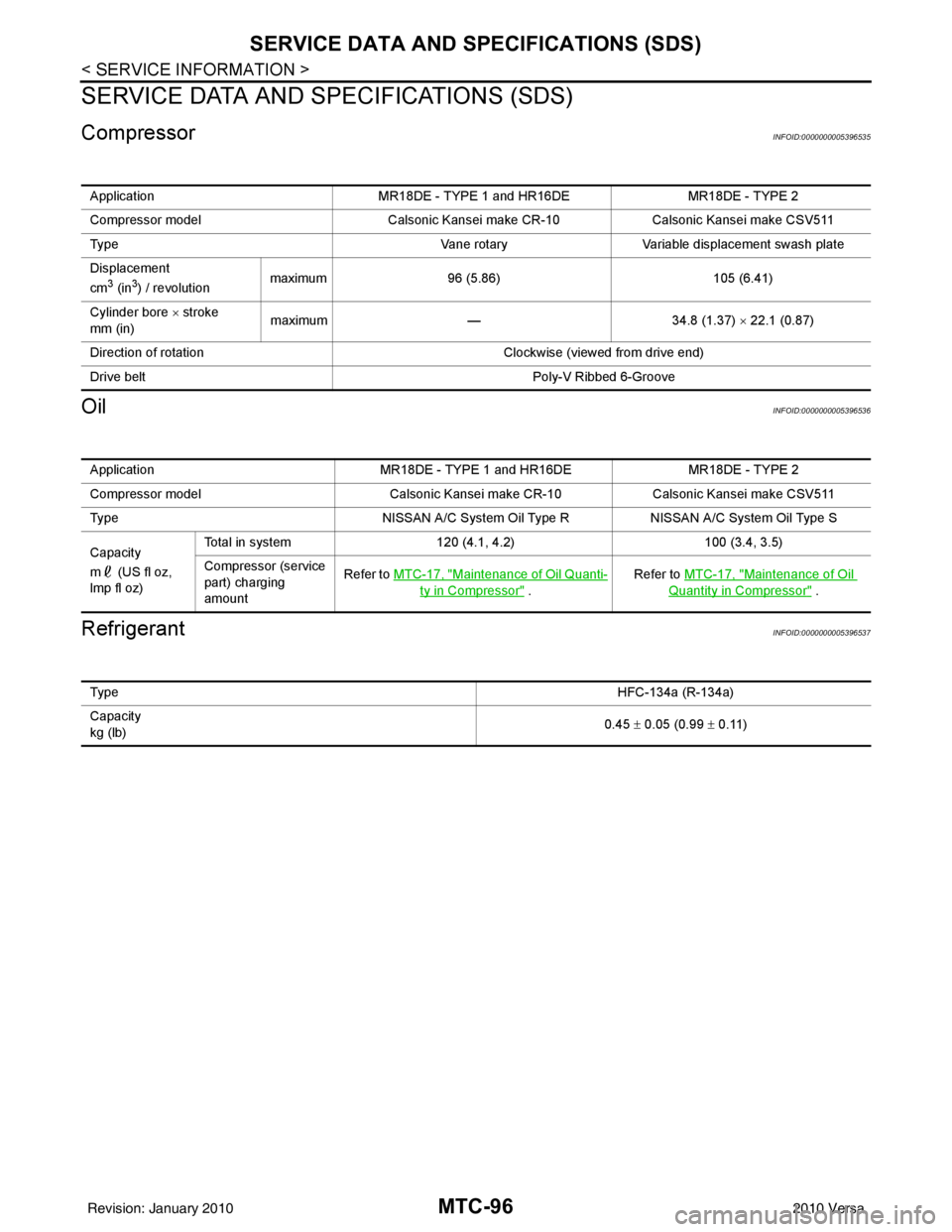

CompressorINFOID:0000000005396535

OilINFOID:0000000005396536

RefrigerantINFOID:0000000005396537

ApplicationMR18DE - TYPE 1 and HR16DE MR18DE - TYPE 2

Compressor model Calsonic Kansei make CR-10Calsonic Kansei make CSV511

Type Vane rotaryVariable displacement swash plate

Displacement

cm

3 (in3) / revolution maximum

96 (5.86) 105 (6.41)

Cylinder bore × stroke

mm (in) maximum

— 34.8 (1.37) × 22.1 (0.87)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly-V Ribbed 6-Groove

ApplicationMR18DE - TYPE 1 and HR16DE MR18DE - TYPE 2

Compressor model Calsonic Kansei make CR-10Calsonic Kansei make CSV511

Type NISSAN A/C System Oil Type RNISSAN A/C System Oil Type S

Capacity

m (US fl oz,

lmp fl oz) Total in system

120 (4.1, 4.2) 100 (3.4, 3.5)

Compressor (service

part) charging

amount Refer to

MTC-17, "

Maintenance of Oil Quanti-

ty in Compressor" . Refer to MTC-17, "

Maintenance of Oil

Quantity in Compressor" .

Ty p e

HFC-134a (R-134a)

Capacity

kg (lb) 0.45

± 0.05 (0.99 ± 0.11)

Revision: January 20102010 Versa