oil level NISSAN TIIDA 2010 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1048 of 3745

![NISSAN TIIDA 2010 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN TIIDA 2010 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57397/w960_57397-1047.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005397769

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: January 20102010 Versa

Page 1071 of 3745

![NISSAN TIIDA 2010 Service Owners Manual CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond NISSAN TIIDA 2010 Service Owners Manual CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond](/img/5/57397/w960_57397-1070.png)

CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid condition.

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the

CVT fluid temperature is 50 to 80 °C (122 to 176° F). Inspect the

amount of CVT fluid. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Install a tachometer where it can be seen by driver during test. •It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D” position.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harnesses, cool-

er pipes, etc.)

Milky white or

cloudy Water in the fluidReplace the CVT fluid and check for

places where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

CVT

Replace the CVT fluid and check for

improper operation of the CVT.

SAT638A

SAT647B

SAT513G

SAT775B

Revision: January 20102010 Versa

Page 1205 of 3745

![NISSAN TIIDA 2010 Service Owners Manual CVT-172

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005398012

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer NISSAN TIIDA 2010 Service Owners Manual CVT-172

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005398012

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer](/img/5/57397/w960_57397-1204.png)

CVT-172

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005398012

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer to

FAX-9.

2. Remove differential side oil seal using a suitable tool. CAUTION:

Do not scratch transaxle case or converter housing.

INSTALLATION

1. Drive the new differential side oil seal into the transaxle caseside (B) and converter housing side (C) until it is flush using

Tool.

Unit: mm (in)

CAUTION:

• Do not reuse differential side oil seals.

• Apply specified NISSAN CVT fluid to side oil seals.

2. Install drive shaft assembly. Refer to FA X - 9

.

3. Check CVT fluid level and leakage. Refer to CVT-14, "

Checking CVT Fluid".

1. CVT2. Differential side oil seal : Apply CVT Fluid NS-2.

WCIA0610E

SCIA2412E

Tool number : — (J-47244)

: ST33400001 (J-47005)

Dimensions (A) 0±0.5 (0 ±0.020)

WCIA0611E

Revision: January 20102010 Versa

Page 1211 of 3745

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: January 20102010 Versa

Page 1224 of 3745

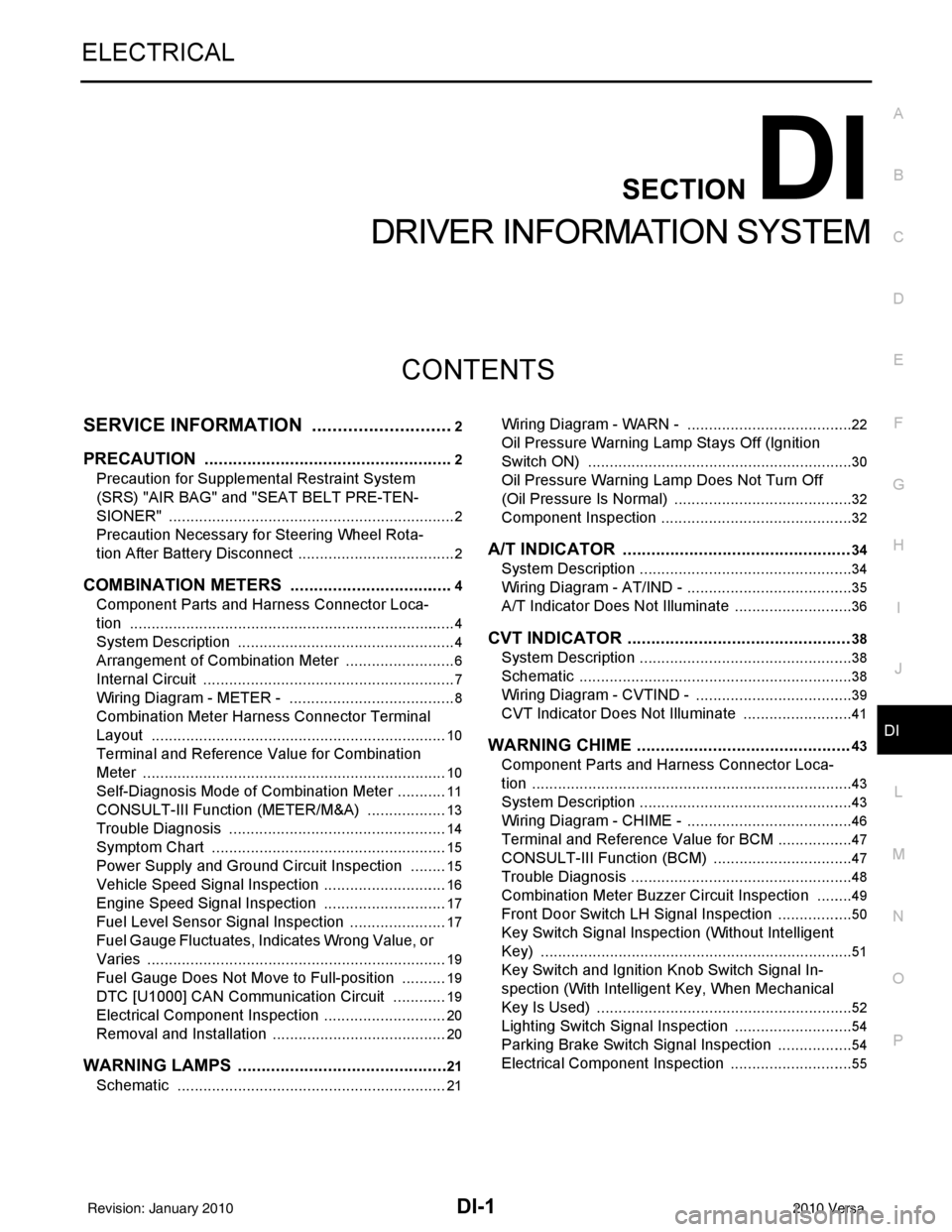

DI-14

< SERVICE INFORMATION >

COMBINATION METERS

NOTE:

Some items are not available due to vehicle specification.

*: The monitor will indicate “OFF” even though the brake warning lamp is on if either of the following conditions exist.

• The parking brake is engaged

• The brake fluid level is low

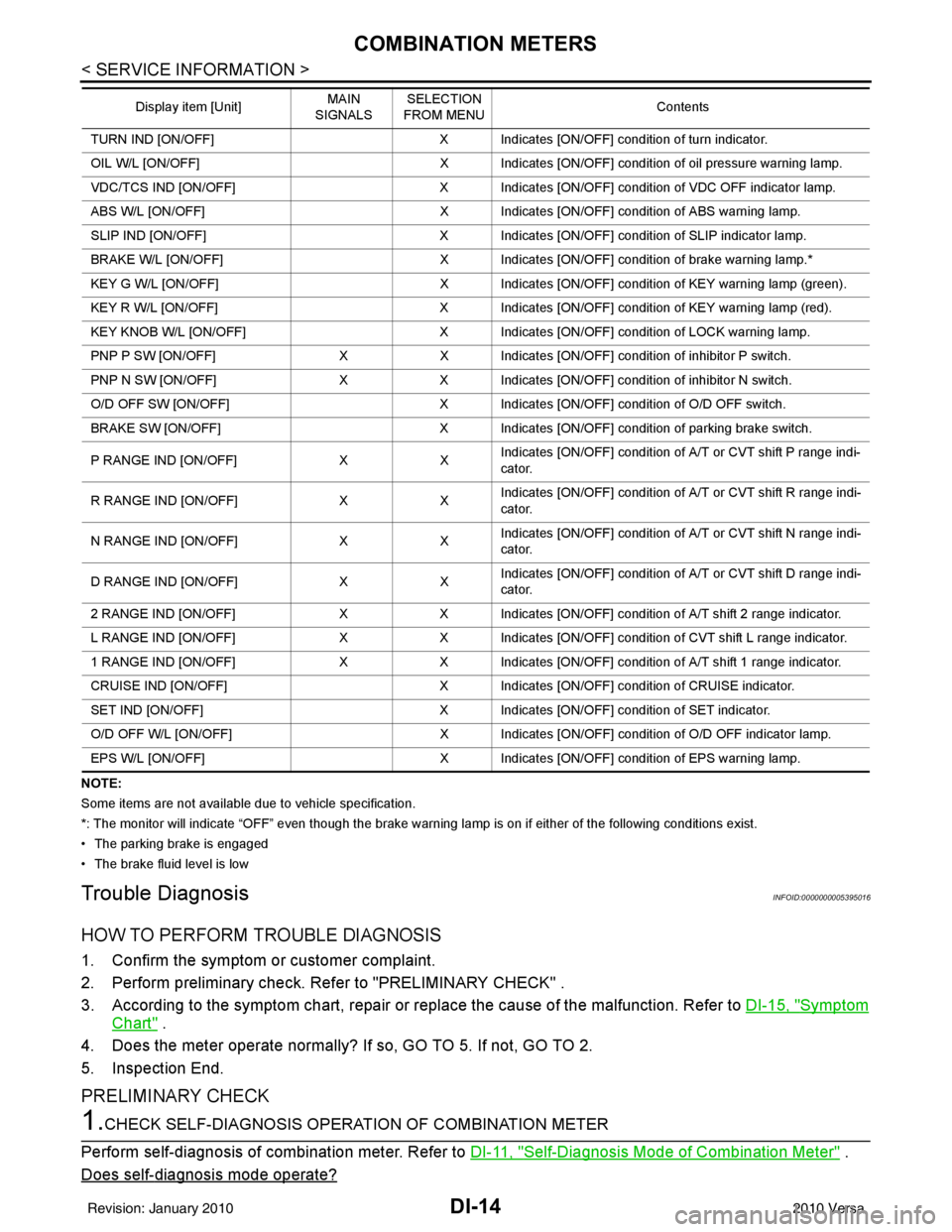

Trouble DiagnosisINFOID:0000000005395016

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to "PRELIMINARY CHECK" .

3. According to the symptom chart, repair or replace the cause of the malfunction. Refer to DI-15, "

Symptom

Chart" .

4. Does the meter operate normally? If so, GO TO 5. If not, GO TO 2.

5. Inspection End.

PRELIMINARY CHECK

1.CHECK SELF-DIAGNOSIS OPERAT ION OF COMBINATION METER

Perform self-diagnosis of combination meter. Refer to DI-11, "

Self-Diagnosis Mode of Combination Meter" .

Does self

-diagnosis mode operate?

TURN IND [ON/OFF] X Indicates [ON/OFF] condition of turn indicator.

OIL W/L [ON/OFF] X Indicates [ON/OFF] condition of oil pressure warning lamp.

VDC/TCS IND [ON/OFF] X Indicates [ON/OFF] condition of VDC OFF indicator lamp.

ABS W/L [ON/OFF] X Indicates [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Indicates [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Indicates [ON/OFF] condition of brake warning lamp.*

KEY G W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (green).

KEY R W/L [ON/OFF] X Indicates [ON/OFF] condition of KEY warning lamp (red).

KEY KNOB W/L [ON/OFF] X Indicates [ON/OFF] condition of LOCK warning lamp.

PNP P SW [ON/OFF] XX Indicates [ON/OFF] condition of inhibitor P switch.

PNP N SW [ON/OFF] XX Indicates [ON/OFF] condition of inhibitor N switch.

O/D OFF SW [ON/OFF] X Indicates [ON/OFF] condition of O/D OFF switch.

BRAKE SW [ON/OFF] X Indicates [ON/OFF] condition of parking brake switch.

P RANGE IND [ON/OFF] XXIndicates [ON/OFF] condition of A/T or CVT shift P range indi-

cator.

R RANGE IND [ON/OFF] XXIndicates [ON/OFF] condition of A/T or CVT shift R range indi-

cator.

N RANGE IND [ON/OFF] XXIndicates [ON/OFF] condition of A/T or CVT shift N range indi-

cator.

D RANGE IND [ON/OFF] XXIndicates [ON/OFF] condition of A/T or CVT shift D range indi-

cator.

2 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 2 range indicator.

L RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of CVT shift L range indicator.

1 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 1 range indicator.

CRUISE IND [ON/OFF] X Indicates [ON/OFF] condition of CRUISE indicator.

SET IND [ON/OFF] X Indicates [ON/OFF] condition of SET indicator.

O/D OFF W/L [ON/OFF] X Indicates [ON/OFF] condition of O/D OFF indicator lamp.

EPS W/L [ON/OFF] X Indicates [ON/OFF] condition of EPS warning lamp.

Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

Revision: January 20102010 Versa

Page 1376 of 3745

![NISSAN TIIDA 2010 Service Owners Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-111

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect ECM harness connector.

3. Check pin terminal and connector for damage, and NISSAN TIIDA 2010 Service Owners Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-111

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect ECM harness connector.

3. Check pin terminal and connector for damage, and](/img/5/57397/w960_57397-1375.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-111

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect ECM harness connector.

3. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within

the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-484, "

Symptom Table".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” m ode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO-1 >> More than the SP value: GO TO 18.

NO-2 >> Less than the SP value: GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

Is the inspection result normal?

YES >> GO TO 21.

NO >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that

each indication is within the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> “B/FUEL SCHDL” is more, “A/F ALPHA-B1” is less than the SP value: GO TO 21.

21.DISCONNECT AND RECONNECT MASS AI R FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector.

3. Check pin terminal and connector for damage and then reconnect it again.

>> GO TO 22.

Revision: January 20102010 Versa

Page 1377 of 3745

![NISSAN TIIDA 2010 Service Owners Manual EC-112

< COMPONENT DIAGNOSIS >[HR16DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

22.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITO R” mode, and NISSAN TIIDA 2010 Service Owners Manual EC-112

< COMPONENT DIAGNOSIS >[HR16DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

22.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITO R” mode, and](/img/5/57397/w960_57397-1376.png)

EC-112

< COMPONENT DIAGNOSIS >[HR16DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

22.CHECK “A/F ALPHA-B1”

1. Start engine.

2. Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITO R” mode, and make sure that the indication is within

the SP value.

Is the measurement value within the SP value?

YES >> Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-142, "DTC

Logic". Then GO TO 29.

NO >> GO TO 23.

23.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> GO TO 24.

NO >> More than the SP value: Replace mass air flow sensor, and then GO TO 29.

24.REPLACE ECM

1. Replace ECM.

2. Perform EC-23, "

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Require-

ment".

>> GO TO 29.

25.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

Is the inspection result normal?

YES >> GO TO 27.

NO >> Repair or replace malfunctioning part, and then GO TO 26.

26.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Less than the SP value: GO TO 27.

27.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

Is the measurement value within the SP value?

YES >> GO TO 28.

NO >> Less than the SP value: Replace mass air flow sensor, and then GO TO 30.

28.CHECK INTAKE SYSTEM

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

• Disconnection, looseness, and cracks in air duct

• Looseness of oil filler cap

• Disconnection of oil level gauge

• Open stuck, breakage, hose disconnecti on, or cracks of PCV valve

• Disconnection or cracks of EVAP purge hose, open stuc k of EVAP canister purge volume control solenoid

valve

• Malfunctioning seal of rocker cover gasket

• Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

Revision: January 20102010 Versa

Page 1627 of 3745

![NISSAN TIIDA 2010 Service Owners Manual EC-362

< COMPONENT DIAGNOSIS >[HR16DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000005398526

DTC DETECTION LOGIC

NOTE:

•

If DTC P1217 is displayed with DTC UX NISSAN TIIDA 2010 Service Owners Manual EC-362

< COMPONENT DIAGNOSIS >[HR16DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000005398526

DTC DETECTION LOGIC

NOTE:

•

If DTC P1217 is displayed with DTC UX](/img/5/57397/w960_57397-1626.png)

EC-362

< COMPONENT DIAGNOSIS >[HR16DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000005398526

DTC DETECTION LOGIC

NOTE:

•

If DTC P1217 is displayed with DTC UXXXX, first perform the trouble diagnosis for DTC UXXXX.

• If DTC P1217 is displayed with DTC P0607, first perform the trouble diagno sis for DTC P0607. Refer

to EC-351, "

DTC Logic".

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnorma lly high temperature condition, a malfunction is

indicated.

CAUTION:

When a malfunction is indicated, be su re to replace the coolant. Refer to CO-12, "

Changing Engine

Coolant". Also, replace the engine oil. Refer to LU-8, "Draining" and LU-8, "Refilling".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to MA-15, "

Anti-freeze Coolant Mixture Ratio".

2. After refilling coolant, run engine to en sure that no water-flow noise is emitted.

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-362, "

Component Function Check".

NOTE:

Use component function check to check the overall function of the cooling fan. During this check, a DTC might

not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-363, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000005398527

1.PERFORM COMPONENT FUNCTION CHECK-I

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P1217 Engine over temperature

(Overheat) • Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate properly (Overheat).

• Engine coolant was not added to the system using the proper filling method.

• Engine coolant is not within the specified range. • Harness or connectors

(The cooling fan circuit is open or

shorted.)

• IPDM E/R (Cooling fan relay-1)

• Cooling fan relays-2 and -3

• Cooling fan motor

•Radiator hose

•Radiator

•Radiator cap

• Reservoir tank

• Water pump

•Thermostat

• Water control valve

Revision: January 20102010 Versa

Page 1752 of 3745

![NISSAN TIIDA 2010 Service Owners Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-487

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5 NISSAN TIIDA 2010 Service Owners Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-487

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5](/img/5/57397/w960_57397-1751.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-487

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5 EM-49

Camshaft

EM-59

Intake valve timing controlEM-49

Intake valve

3EM-76

Exhaust valve

Exhaust Exhaust manifold/Tube/Muf- fler/Gasket 55555 55 5 EM-31

EX-5Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/ Oil filter/Oil gallery/Oil cooler 55555 55 5EM-39

EM-42

LU-7

LU-9

Oil level (Low)/Filthy oil

LU-7

Cooling Radiator/Hose/Radiator filler

cap

55555 55 45 CO-15

CO-15

Thermostat

5CO-24

Water pump CO-22

Water galleryCO-10

Cooling fan

5CO-20

Coolant level (Low)/Contami-

nated coolant

CO-10

NVIS (NISSAN Vehicle Immobilizer Sys-

tem — NATS)11

BL-257

SYMPTOM

Reference page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A

A AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: January 20102010 Versa

Page 1860 of 3745

![NISSAN TIIDA 2010 Service Owners Manual TROUBLE DIAGNOSISEC-595

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5EM-157

Camsh NISSAN TIIDA 2010 Service Owners Manual TROUBLE DIAGNOSISEC-595

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5EM-157

Camsh](/img/5/57397/w960_57397-1859.png)

TROUBLE DIAGNOSISEC-595

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection. Va l v e

mecha-

nism

Timing chain

55555 55 5EM-157

Camshaft

EM-166

Intake valve timing controlEM-157

Intake valve

3EM-185

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/ Gasket 55555 55 5EM-140

,

EX-11

Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 55 5EM-143

,

LU-20

Oil level (Low)/Filthy oil LU-17

Cooling Radiator/Hose/Radiator filler cap

55555 55 45 CO-41

Thermostat

5CO-46

Water control valve CO-48

Water pumpCO-44

Water galleryCO-35

Cooling fan

5CO-43

Coolant level (Low)/Contaminat-

ed coolant

CO-36

NVIS (NISSAN Vehicle

Immobilizer System-

NATS) 11

BL-257

SYMPTOM

Reference

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: January 20102010 Versa