display NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3401 of 3745

PG-18

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status • CAN communication is normally performed with other control units.

• Individual unit control by IPDM E/R is normally performed.

• When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status • Process to stop CAN communication is activated.

• All systems controlled by IPDM E/R are stopped. When 1 second has elapsed after CAN communica-tion with other control units is st opped, mode switches to sleep status.

3. Sleep status • IPDM E/R operates in low current-consumption mode.

• CAN communication is stopped.

• When a change in CAN communication signal is detec ted, mode switches to CAN communication sta-

tus.

• When a change in ignition switch signal is detected, mode switches to CAN communication status.

CAN Communication System DescriptionINFOID:0000000005395355

Refer to LAN-7, "System Diagram".

Function of Detecting I gnition Relay MalfunctionINFOID:0000000005395356

• When the integrated ignition relay is stuck in a "closed contact" position and cannot be turned OFF, IPDM E/

R turns ON tail and parking lamps for 10 minutes to indicate IPDM E/R malfunction.

• When the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received via CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

CONSULT-III Function (IPDM E/R)INFOID:0000000005395357

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

Rear window defoggerRear window defogger relay OFF

A/C compressor A/C relay is OFF

Front fog lamps Front fog lamp relay OFF

Controlled system

Fail-safe mode

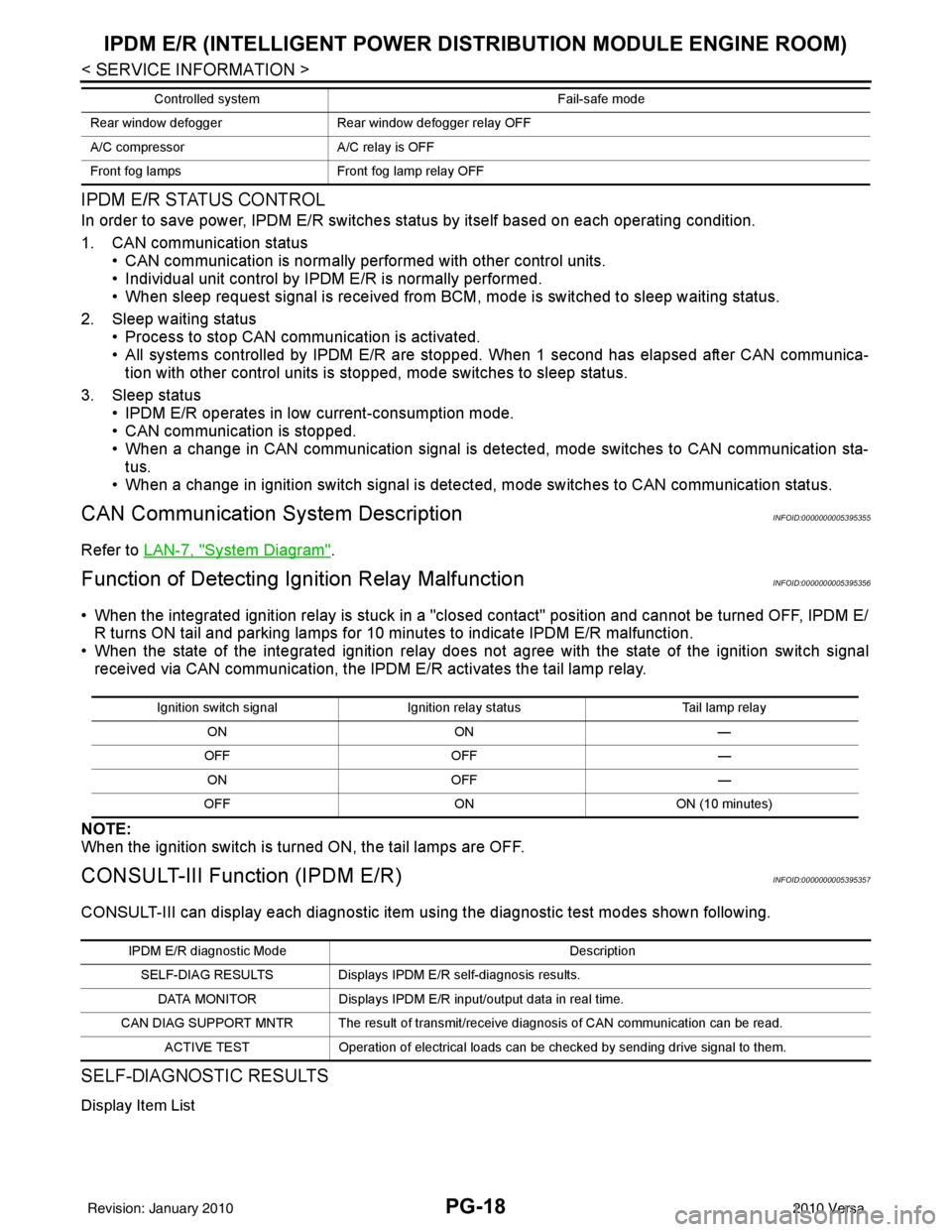

Ignition switch signalIgnition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

IPDM E/R diagnostic Mode Description

SELF-DIAG RESULTS Displays IPDM E/R self-diagnosis results. DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Revision: January 20102010 Versa

Page 3402 of 3745

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display items CONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ———

——

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have

errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is detected with the integrated EEPROM

memory diagnosis.

X X IPDM E/R

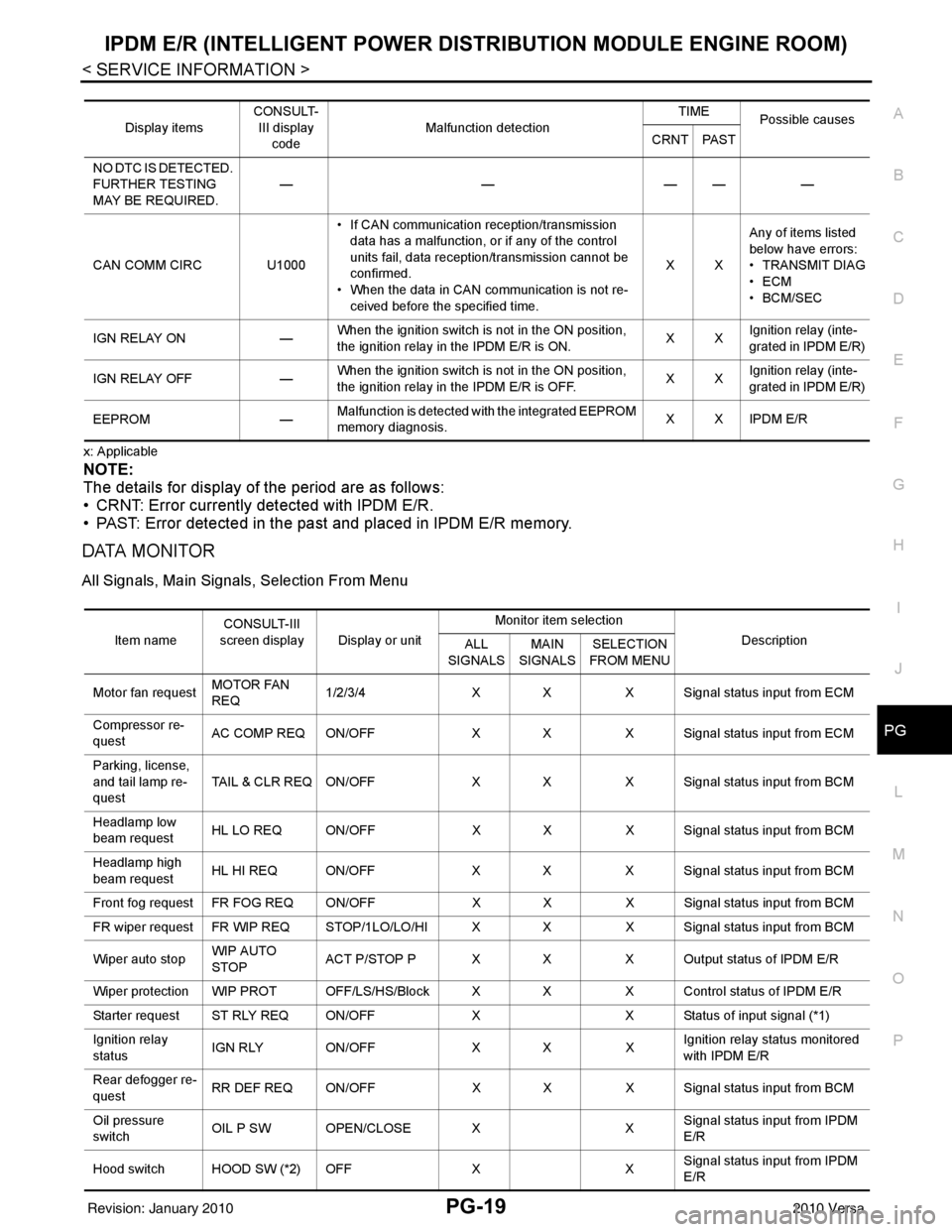

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: January 20102010 Versa

Page 3403 of 3745

PG-20

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

*1 Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position, display may no t be cor-

rect.

*2 This item is displayed, but does not function.

CAN DIAG SUPPORT MNTR

Refer to LAN-9, "Description" .

ACTIVE TEST

Display Item List

Auto Active TestINFOID:0000000005395358

DESCRIPTION

• In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems:

- Rear window defogger

- Front wipers

- Tail, license and parking lamps

- Daytime lamp system (Canada only)

- Front fog lamps

- Headlamps (High, Low)

- A/C compressor (magnet clutch)

- Cooling fan

OPERATION PROCEDURE

1. Close hood and front door RH, and lift wiper arms away from windshield (to prevent glass damage by wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON and, within 20 seconds, pres s front door switch LH 20 times. Then turn ignition

switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, horn chirps once.

6. After a series of operations is repeated three times, auto active test is completed.

Theft warning

horn request THFT HRN REQ ON/OFF

XX Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF XX Output status of IPDM E/R

Daytime light re-

quest DTRL REQ ON/OFF

XX Signal status input from BCM

Item name

CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Test name CONSULT-III screen display Description

Head, tail, fog lamp output EXTERNAL LAMPS With a certain ON-OFF operation (OFF, TAIL, LO, HI, FOG), the front

fog lamp, headlamp low, headlamp high RH, headlamp high LH, and

tail lamp relays can be operated.

Rear defogger output REAR DEFOGGER With a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPER With a certain operation (OFF, HI ON, LO ON), the front wiper relays

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan relays can be oper-

ated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

Revision: January 20102010 Versa

Page 3411 of 3745

PG-28

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

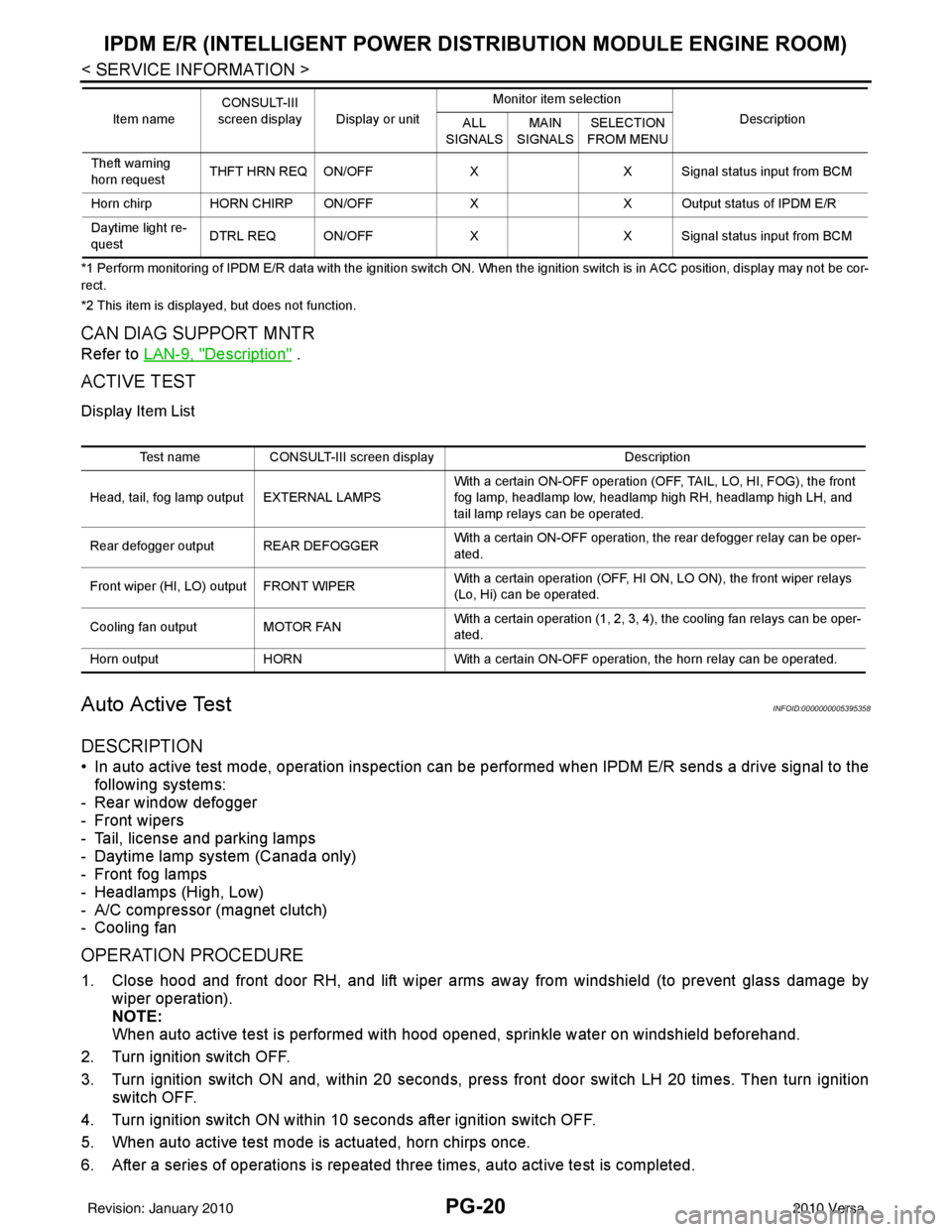

OK or NG

OK >> GO TO 3.

NG >> Repair or replace IPDM E/R power circuit harness.

3.GROUND CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connectors E46 and E48.

2. Check continuity between IPDM E/R harness connector E46 (A) terminal 39, E48 (B) terminal 59 and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace IPDM E/R ground circuit harness.

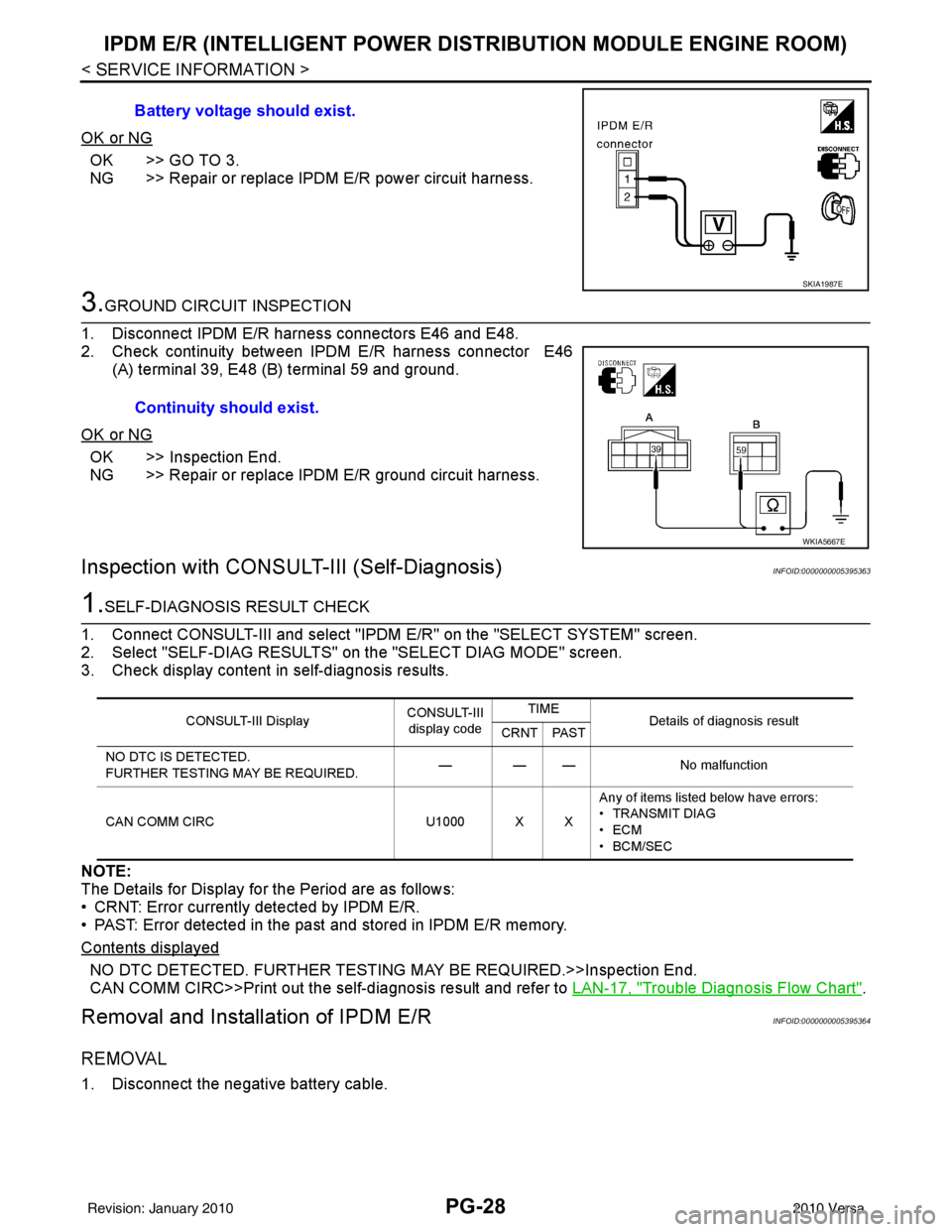

Inspection with CONSULT-III (Self-Diagnosis)INFOID:0000000005395363

1.SELF-DIAGNOSIS RESULT CHECK

1. Connect CONSULT-III and select "IPDM E/R" on the "SELECT SYSTEM" screen.

2. Select "SELF-DIAG RESULTS" on the "SELECT DIAG MODE" screen.

3. Check display content in self-diagnosis results.

NOTE:

The Details for Display for the Period are as follows:

• CRNT: Error currently detected by IPDM E/R.

• PAST: Error detected in the past and stored in IPDM E/R memory.

Contents displayed

NO DTC DETECTED. FURTHER TESTING MAY BE REQUIRED.>>Inspection End.

CAN COMM CIRC>>Print out the self-diagnosis result and refer to LAN-17, "

Trouble Diagnosis Flow Chart".

Removal and Installation of IPDM E/RINFOID:0000000005395364

REMOVAL

1. Disconnect the negative battery cable.Battery voltage should exist.

SKIA1987E

Continuity should exist.

WKIA5667E

CONSULT-III Display

CONSULT-III

display code TIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED. — — —

No malfunction

CAN COMM CIRC U1000 X XAny of items listed below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

Revision: January 20102010 Versa

Page 3500 of 3745

RF-16

< FUNCTION DIAGNOSIS >

TROUBLE DIAGNOSIS

Terminal and Reference Valu e for Sunroof Motor Assembly

INFOID:0000000005396799

Work FlowINFOID:0000000005396800

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to RF-11, "

System Description" .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to RF-17, "

Trouble Diagnosis Chart by Symptom" .

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005396801

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

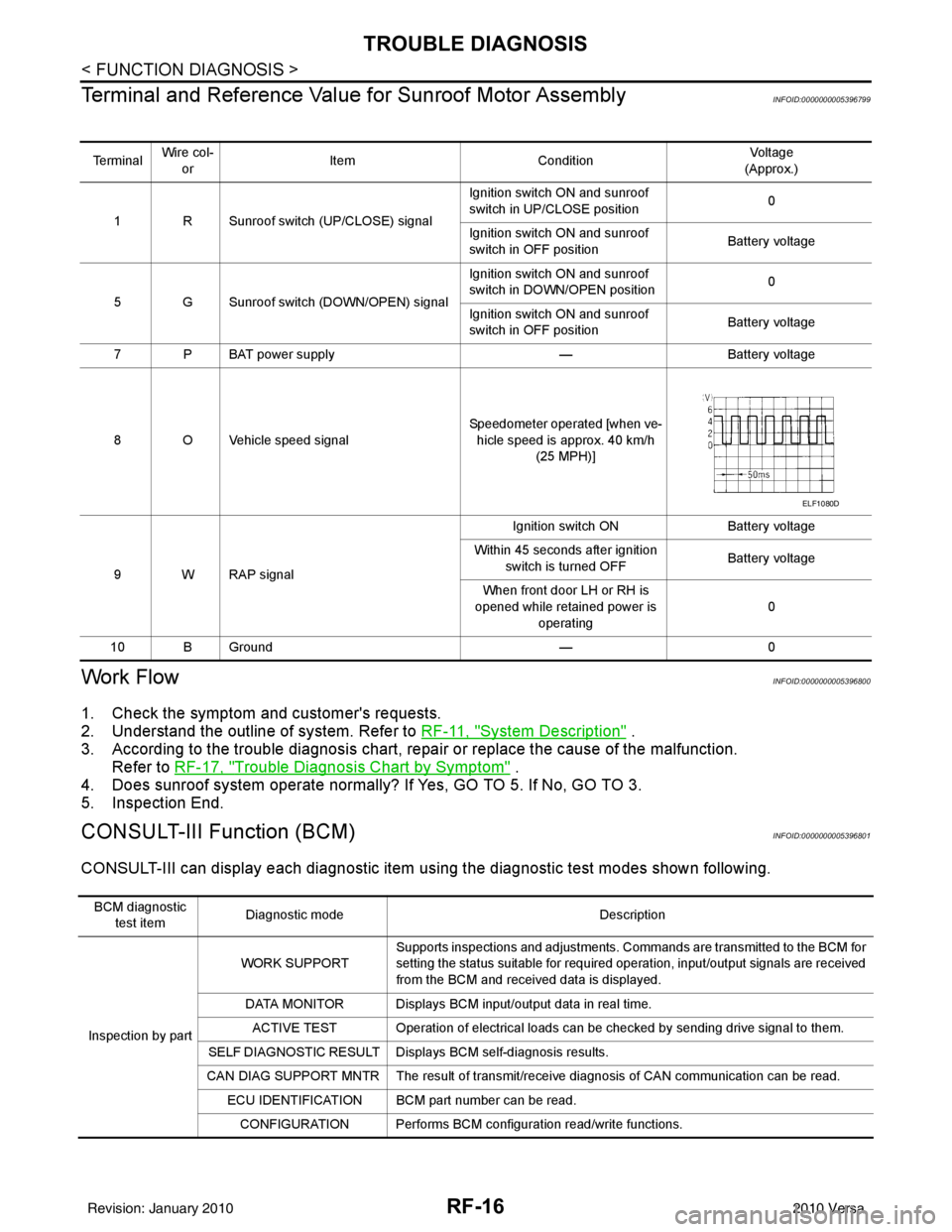

Te r m i n a lWire col-

or Item

Condition Vol tag e

(Approx.)

1 R Sunroof switch (UP/CLOSE) signal Ignition switch ON and sunroof

switch in UP/CLOSE position

0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

5 G Sunroof switch (DOWN/OPEN) signal Ignition switch ON and sunroof

switch in DOWN/OPEN position

0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

7 P BAT power supply —Battery voltage

8 O Vehicle speed signal Speedometer operated [when ve-

hicle speed is approx. 40 km/h (25 MPH)]

9 W RAP signal Ignition switch ON

Battery voltage

Within 45 seconds after ignition switch is turned OFF Battery voltage

When front door LH or RH is

opened while retained power is

operating 0

10 B Ground —0

ELF1080D

BCM diagnostic

test item Diagnostic mode

Description

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displa ys BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: January 20102010 Versa

Page 3520 of 3745

RSU-6

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000005397077

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentInspectionINFOID:0000000005397078

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6

.

3. Wheel bearing axial end play. Refer to RAX-6, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-13, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Revision: January 20102010 Versa

Page 3599 of 3745

SRS-6

< SYMPTOM DIAGNOSIS >

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Seat Belt Pre-te nsioner with Load Limiter

INFOID:0000000005396900

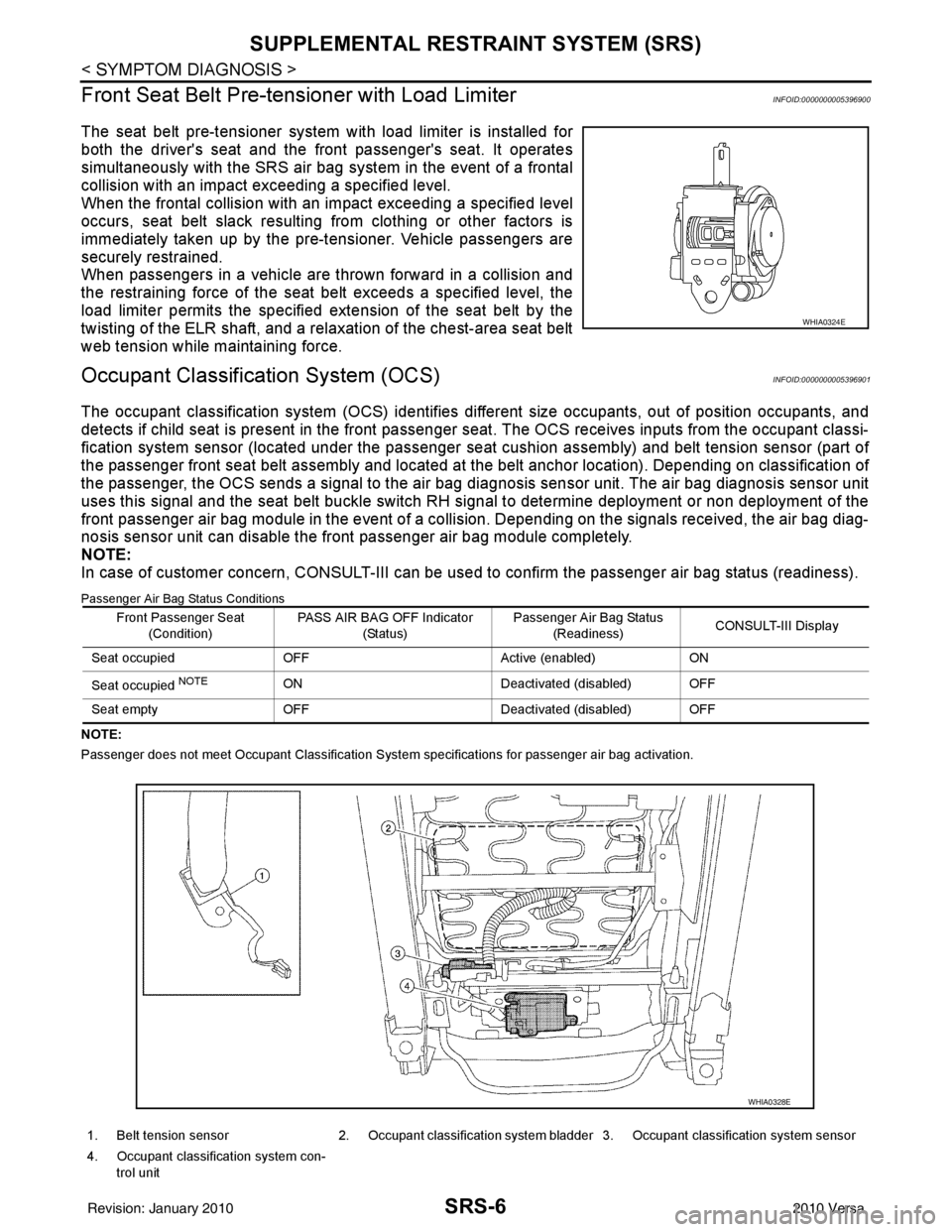

The seat belt pre-tensioner system wi th load limiter is installed for

both the driver's seat and the front passenger's seat. It operates

simultaneously with the SRS air bag system in the event of a frontal

collision with an impact exceeding a specified level.

When the frontal collision with an im pact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioner. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the

load limiter permits the specified extension of the seat belt by the

twisting of the ELR shaft, and a relaxation of the chest-area seat belt

web tension while maintaining force.

Occupant Classification System (OCS)INFOID:0000000005396901

The occupant classification system (OCS) identifies diff erent size occupants, out of position occupants, and

detects if child seat is present in the front passenger seat. The OCS receives inputs from the occupant classi-

fication system sensor (located under the passenger seat cushion assembly) and belt tension sensor (part of

the passenger front seat belt assembly and located at the belt anchor location). Depending on classification of

the passenger, the OCS sends a signal to the air bag di agnosis sensor unit. The air bag diagnosis sensor unit

uses this signal and the seat belt buckle switch RH signal to determine deployment or non deployment of the

front passenger air bag module in the event of a collision. Depending on the signals received, the air bag diag-

nosis sensor unit can disable the front passenger air bag module completely.

NOTE:

In case of customer concern, CONSULT-III can be used to confirm the passenger air bag status (readiness).

Passenger Air Bag Status Conditions

NOTE:

Passenger does not meet Occupant Classification System specifications for passenger air bag activation.

WHIA0324E

Front Passenger Seat

(Condition) PASS AIR BAG OFF Indicator

(Status) Passenger Air Bag Status

(Readiness) CONSULT-III Display

Seat occupied OFF Active (enabled)ON

Seat occupied

NOTEON Deactivated (disabled) OFF

Seat empty OFF Deactivated (disabled) OFF

1. Belt tension sensor 2. Occupant classification system bladder 3. Occupant classification system sensor

4. Occupant classification system con- trol unit

WHIA0328E

Revision: January 20102010 Versa

Page 3601 of 3745

SRS-8

< SYMPTOM DIAGNOSIS >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Trouble Diagnosis IntroductionINFOID:0000000005396903

CAUTION:

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to do so in

this Service Manual.

• Do not attempt to repair, splice or modify SRS wiring harnesses. If a harness is damaged, replace it

with a new one.

• Keep ground connections clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by usi ng “AIR BAG” warning lamp and/or CONSULT-III.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” warning lamp and CONSULT-III are as follows:

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information From Customer

WHAT - Vehicle model

WHEN - Date, Frequencies

WHERE - Road conditions

HOW - Operating conditions, Symptoms

Preliminary Check

Check that the following parts are in good order.

• Battery (Refer to SC-5, "

How to Handle Battery".)

• Fuses (Refer to SRS-11, "

Schematic".)

• System component-to-harness connections

WORK FLOW

User mode Diagnosis mode Display type

“AIR BAG” warning lamp XXON-OFF operation

CONSULT-III —XMonitoring

Revision: January 20102010 Versa

Page 3610 of 3745

TROUBLE DIAGNOSISSRS-17

< SYMPTOM DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

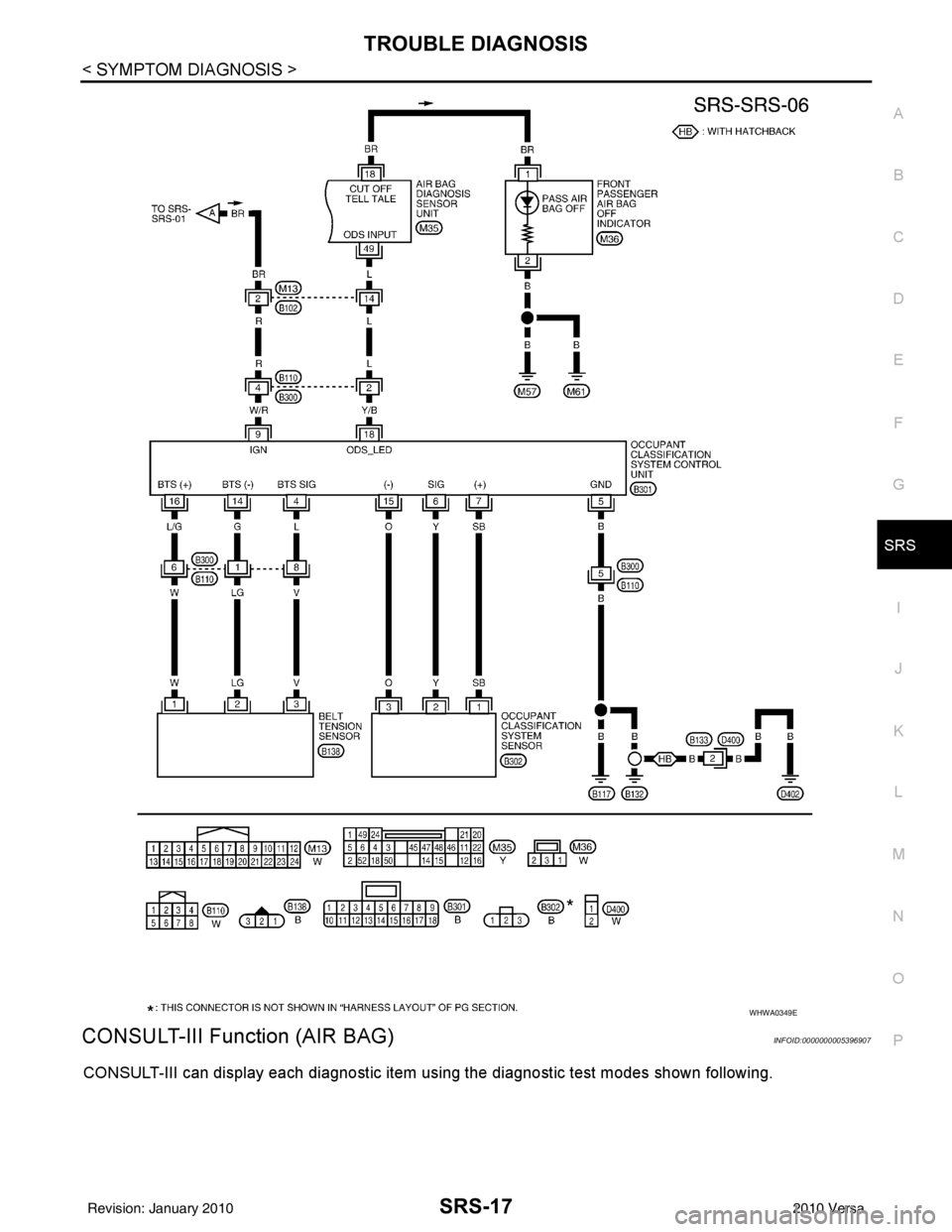

CONSULT-III Function (AIR BAG)INFOID:0000000005396907

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

WHWA0349E

Revision: January 20102010 Versa

Page 3611 of 3745

SRS-18

< SYMPTOM DIAGNOSIS >

TROUBLE DIAGNOSIS

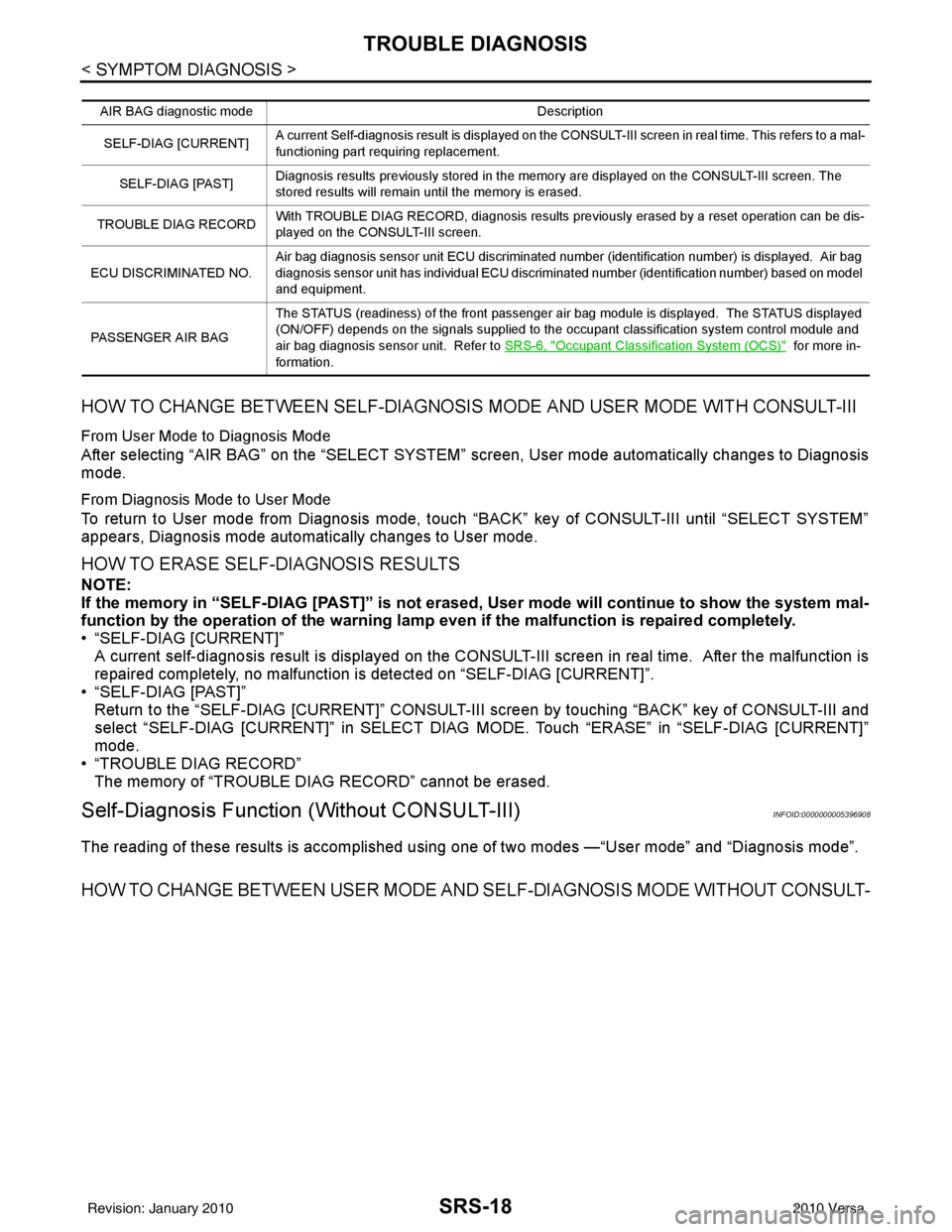

HOW TO CHANGE BETWEEN SELF-DIAGNOSIS MODE AND USER MODE WITH CONSULT-III

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-III until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

HOW TO ERASE SELF-DIAGNOSIS RESULTS

NOTE:

If the memory in “SELF-DIAG [PAST]” is not erased, User mode will continue to show the system mal-

function by the operation of th e warning lamp even if the malfun ction is repaired completely.

• “SELF-DIAG [CURRENT]” A current self-diagnosis result is displayed on the CO NSULT-III screen in real time. After the malfunction is

repaired completely, no malfunction is detected on “SELF-DIAG [CURRENT]”.

• “SELF-DIAG [PAST]” Return to the “SELF-DIAG [CURRENT]” CONSULT-III screen by touching “BACK” key of CONSULT-III and

select “SELF-DIAG [CURRENT]” in SELECT DIAG MODE. Touch “ERASE” in “SELF-DIAG [CURRENT]”

mode.

• “TROUBLE DIAG RECORD”

The memory of “TROUBLE DI AG RECORD” cannot be erased.

Self-Diagnosis Function (Without CONSULT-III)INFOID:0000000005396908

The reading of these results is accomplished using one of two modes —“User mode” and “Diagnosis mode”.

HOW TO CHANGE BETWEEN USER MODE AND SELF-DIAGNOSIS MODE WITHOUT CONSULT-

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT] A current Self-diagnosis result is displayed on the CO

NSULT-III screen in real time. This refers to a mal-

functioning part requiring replacement.

SELF-DIAG [PAST] Diagnosis results previously stored in the memory are displayed on the CONSULT-III screen. The

stored results will remain until the memory is erased.

TROUBLE DIAG RECORD With TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-III screen.

ECU DISCRIMINATED NO. Air bag diagnosis sensor unit ECU discriminated number (identification number) is displayed. Air bag

diagnosis sensor unit has individual ECU discriminated number (identification number) based on model

and equipment.

PASSENGER AIR BAG The STATUS (readiness) of the front passenger air bag module is displayed. The STATUS displayed

(ON/OFF) depends on the signals supplied to the occupant classification system control module and

air bag diagnosis sensor unit. Refer to

SRS-6, "

Occupant Classification System (OCS)" for more in-

formation.

Revision: January 20102010 Versa