center console NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 231 of 3745

AT-214

< SERVICE INFORMATION >

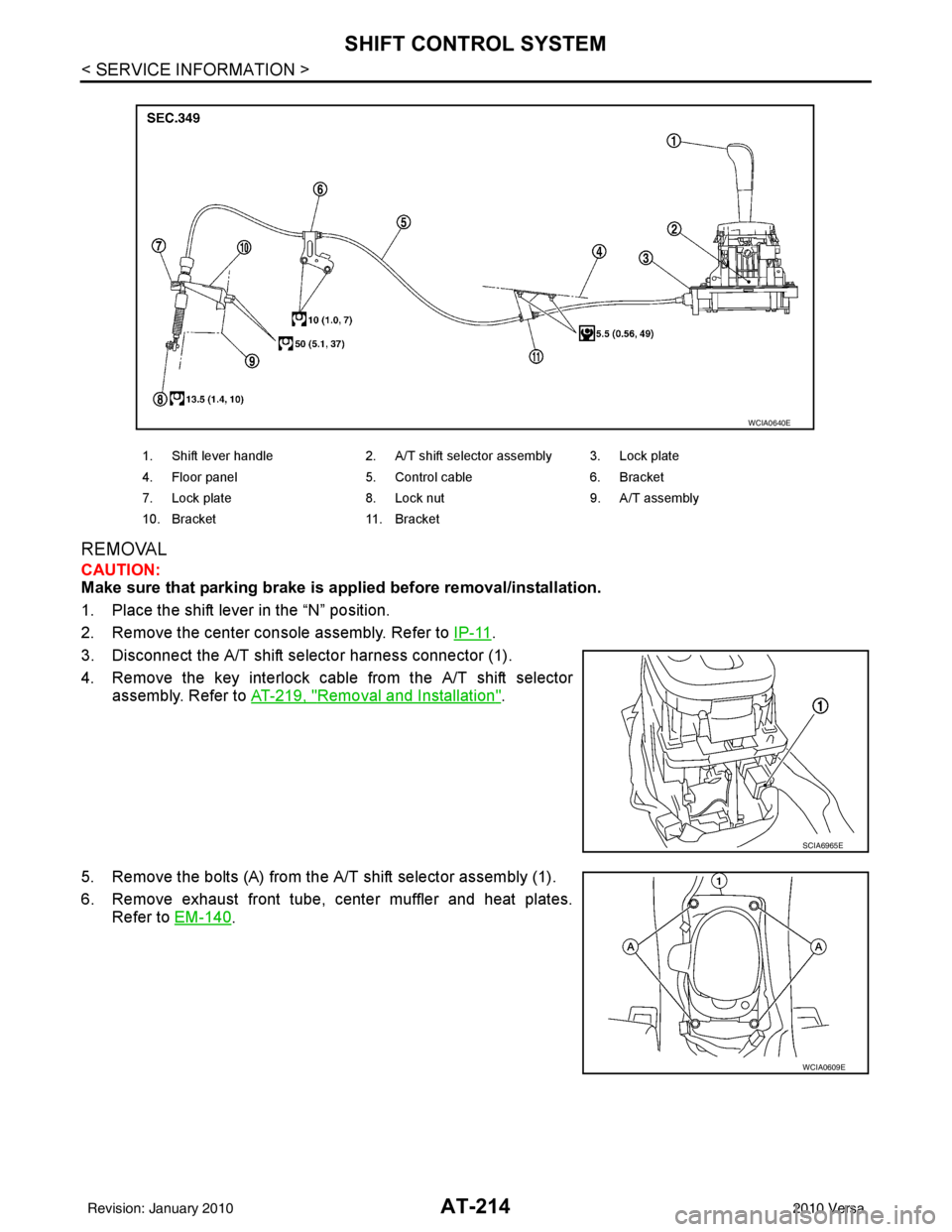

SHIFT CONTROL SYSTEM

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation.

1. Place the shift lever in the “N” position.

2. Remove the center console assembly. Refer to IP-11

.

3. Disconnect the A/T shift selector harness connector (1).

4. Remove the key interlock cable from the A/T shift selector assembly. Refer to AT-219, "

Removal and Installation".

5. Remove the bolts (A) from the A/T shift selector assembly (1).

6. Remove exhaust front tube, center muffler and heat plates. Refer to EM-140

.

1. Shift lever handle 2. A/T shift selector assembly 3. Lock plate

4. Floor panel 5. Control cable 6. Bracket

7. Lock plate 8. Lock nut 9. A/T assembly

10. Bracket 11. Bracket

WCIA0640E

SCIA6965E

WCIA0609E

Revision: January 20102010 Versa

Page 236 of 3745

KEY INTERLOCK CABLEAT-219

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

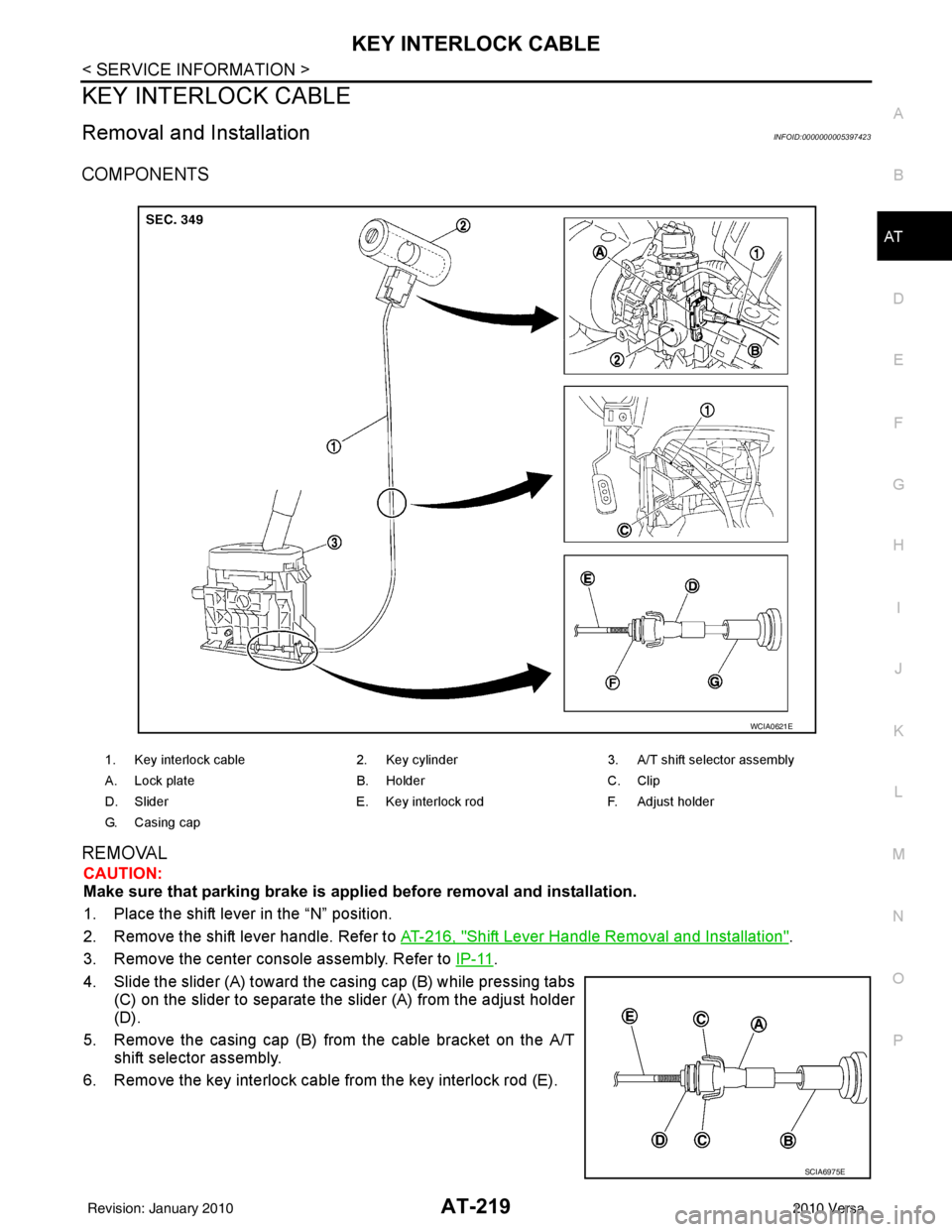

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005397423

COMPONENTS

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the shift lever in the “N” position.

2. Remove the shift lever handle. Refer to AT-216, "

Shift Lever Handle Removal and Installation".

3. Remove the center console assembly. Refer to IP-11

.

4. Slide the slider (A) toward the casing cap (B) while pressing tabs (C) on the slider to separate the slider (A) from the adjust holder

(D).

5. Remove the casing cap (B) from the cable bracket on the A/T shift selector assembly.

6. Remove the key interlock cable from the key interlock rod (E).

1. Key interlock cable 2. Key cylinder3. A/T shift selector assembly

A. Lock plate B. HolderC. Clip

D. Slider E. Key interlock rodF. Adjust holder

G. C a s i n g c a p

WCIA0621E

SCIA6975E

Revision: January 20102010 Versa

Page 238 of 3745

KEY INTERLOCK CABLEAT-221

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

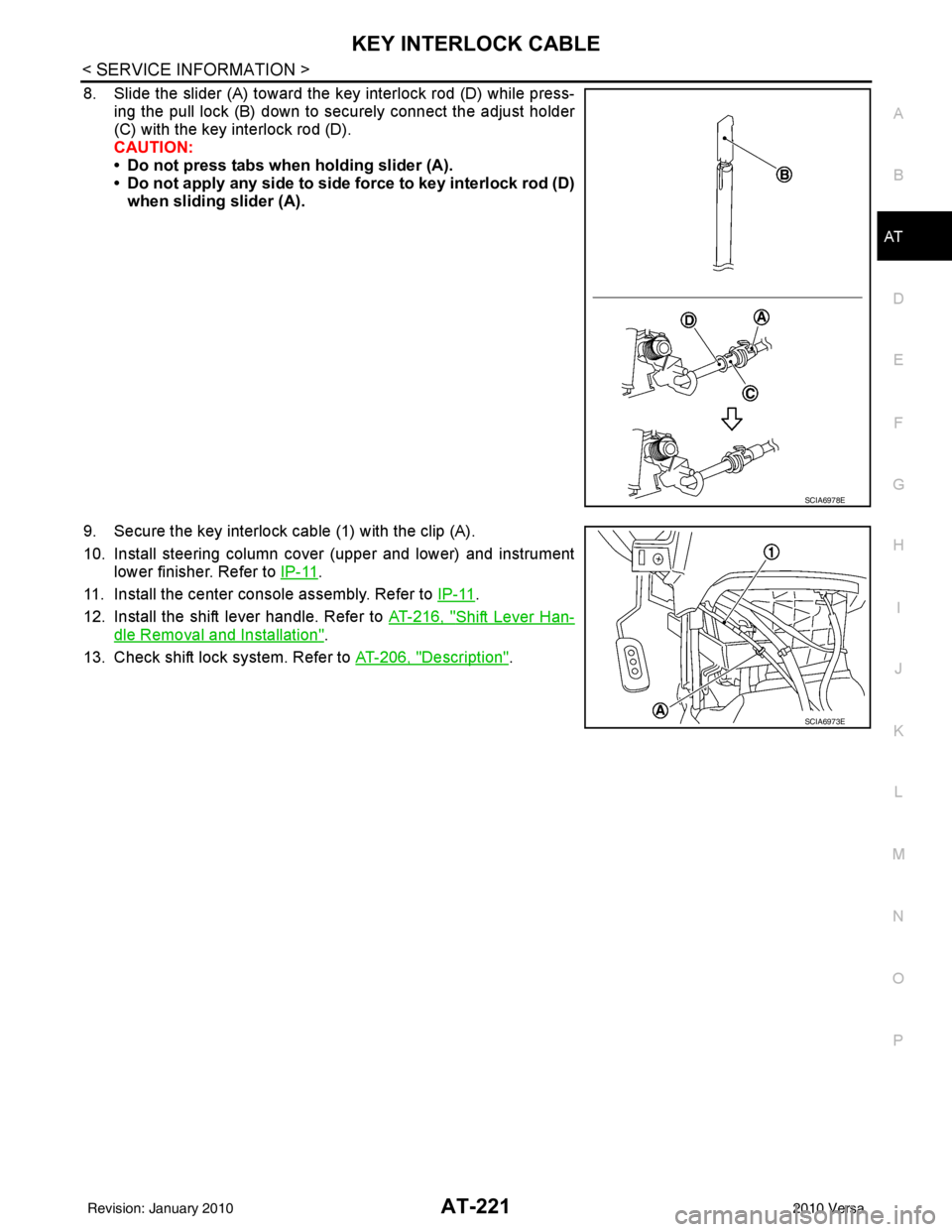

8. Slide the slider (A) toward the key interlock rod (D) while press- ing the pull lock (B) down to securely connect the adjust holder

(C) with the key interlock rod (D).

CAUTION:

• Do not press tabs when holding slider (A).

• Do not apply any side to side force to key interlock rod (D)when sliding slider (A).

9. Secure the key interlock cable (1) with the clip (A).

10. Install steering column cover (upper and lower) and instrument lower finisher. Refer to IP-11

.

11. Install the center console assembly. Refer to IP-11

.

12. Install the shift lever handle. Refer to AT-216, "

Shift Lever Han-

dle Removal and Installation".

13. Check shift lock system. Refer to AT-206, "

Description".

SCIA6978E

SCIA6973E

Revision: January 20102010 Versa

Page 518 of 3745

SQUEAK AND RATTLE TROUBLE DIAGNOSESBL-9

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005396545

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: January 20102010 Versa

Page 1194 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the NISSAN TIIDA 2010 Service Repair Manual SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the](/img/5/57397/w960_57397-1193.png)

SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the shift lever in the “N” position.

2. Remove the center console assembly. Refer to IP-11

.

3. Disconnect the CVT shift selector harness connector (1).

4. Remove the key interlock cable from the CVT shift selector assembly. Refer to CVT-166, "

Removal and Installation".

5. Remove the bolts (A) from the CVT shift selector assembly (1).

6. Remove exhaust front tube, center muffler and heat plates. Refer to EM-140

.

1. Shift lever handle 2. CVT shift selector assembly 3. Lock plate

4. Bracket 5. Control cable6. Bracket

7. Lock plate 8. Bracket9. Transaxle assembly

A. Floor

WCIA0639E

SCIA6965E

WCIA0609E

Revision: January 20102010 Versa

Page 1199 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005398004

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal NISSAN TIIDA 2010 Service Repair Manual CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005398004

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal](/img/5/57397/w960_57397-1198.png)

CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005398004

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal procedure.

CAUTION:

Make sure that parking brake is applied before removal/installation.

1. Place the shift lever in the "N" position.

2. Remove the center console assembly. Refer to

IP-11

.

3. Slide the slider (A) toward the casing cap (B) while pressing tabs (C) on the slider to separate the slider (A) from the adjust holder

(D).

4. Remove the casing cap (B) from the cable bracket on the CVT shift selector assembly.

5. Remove the key interlock cable from the key interlock rod (E).

1. Key interlock cable 2. Key cylinder 3. CVT shift selector assembly

A. Lock plate B. HolderC. Clip

D. Slider E. Key interlock rod F. Adjust holder

G. C a s i n g c a p

WCIA0621E

SCIA6975E

Revision: January 20102010 Versa

Page 1201 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C) NISSAN TIIDA 2010 Service Repair Manual CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C)](/img/5/57397/w960_57397-1200.png)

CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C) with the key interlock rod (D).

CAUTION:

• Do not press tabs when holding slider (A).

• Do not apply any side to side force to key interlock rod (D)when sliding slider (A).

9. Secure the key interlock cable (1) with the clip (A).

10. Install steering column cover (upper and lower) and instrument lower finisher. Refer to IP-11

.

11. Install the center console assembly. Refer to IP-11

.

12. Install the shift lever handle. Refer to CVT-163, "

Shift Lever Han-

dle Removal and Installation".

13. Check shift lock system. Refer to CVT-153, "

Description".

SCIA6978E

SCIA6973E

Revision: January 20102010 Versa

Page 2309 of 3745

EI-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005396819

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

Revision: January 20102010 Versa

Page 2347 of 3745

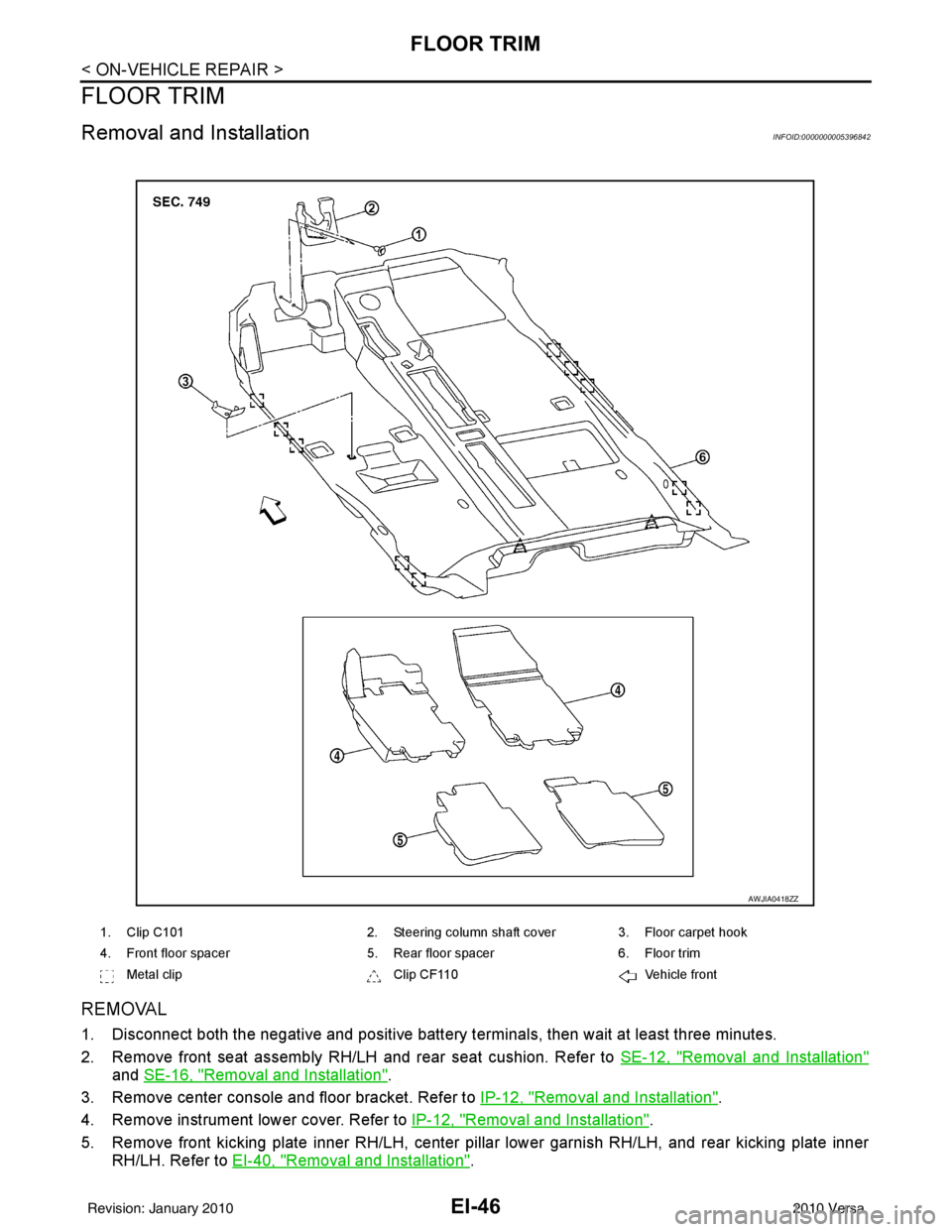

EI-46

< ON-VEHICLE REPAIR >

FLOOR TRIM

FLOOR TRIM

Removal and InstallationINFOID:0000000005396842

REMOVAL

1. Disconnect both the negative and positive battery terminals, then wait at least three minutes.

2. Remove front seat assembly RH/LH and rear seat cushion. Refer to SE-12, "

Removal and Installation"

and SE-16, "Removal and Installation".

3. Remove center console and floor bracket. Refer to IP-12, "

Removal and Installation".

4. Remove instrument lower cover. Refer to IP-12, "

Removal and Installation".

5. Remove front kicking plate inner RH/LH, center pillar lower garnish RH/LH, and rear kicking plate inner RH/LH. Refer to EI-40, "

Removal and Installation".

1. Clip C101 2. Steering column shaft cover 3. Floor carpet hook

4. Front floor spacer 5. Rear floor spacer6. Floor trim

Metal clip Clip CF110Vehicle front

AWJIA0418ZZ

Revision: January 20102010 Versa

Page 2351 of 3745

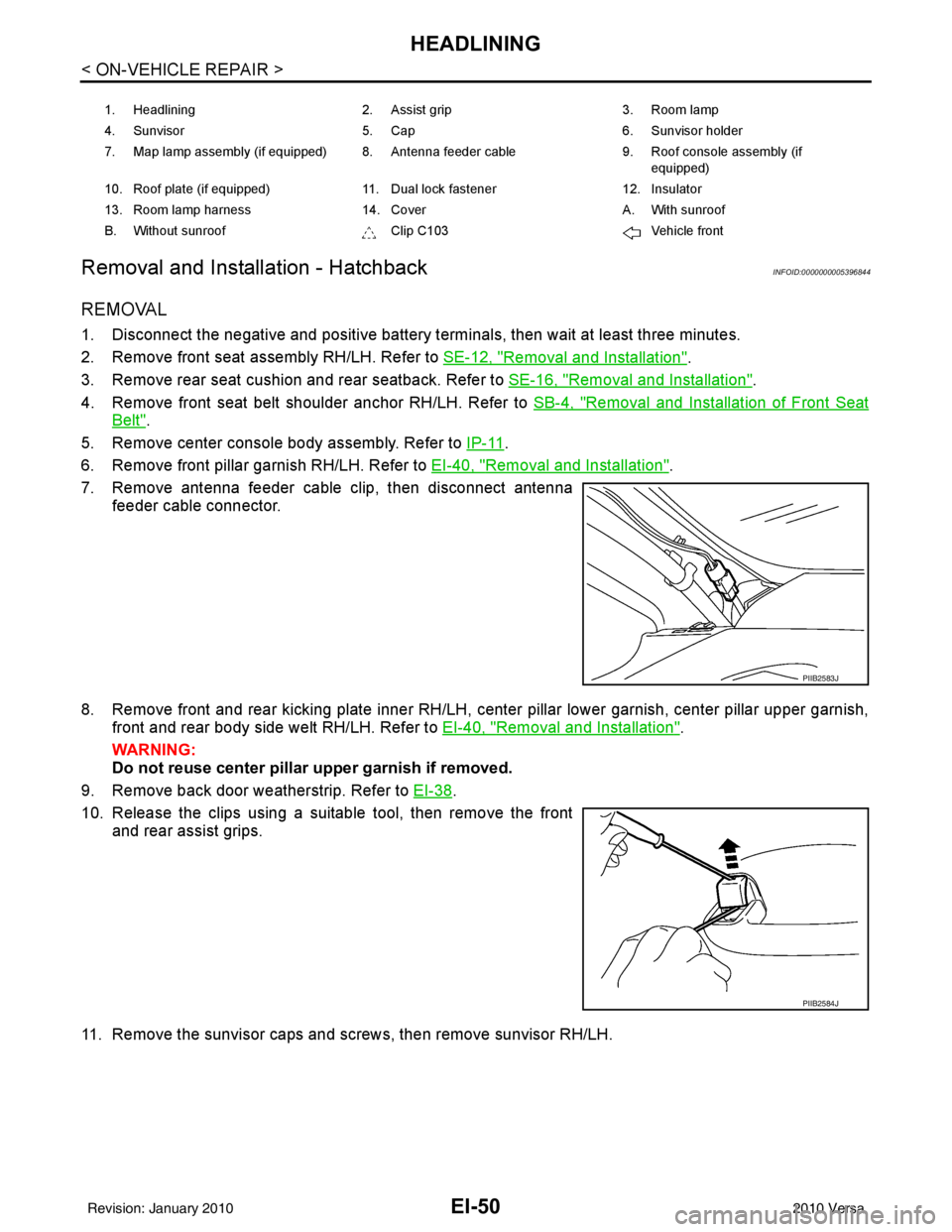

EI-50

< ON-VEHICLE REPAIR >

HEADLINING

Removal and Installation - Hatchback

INFOID:0000000005396844

REMOVAL

1. Disconnect the negative and positive battery termi nals, then wait at least three minutes.

2. Remove front seat assembly RH/LH. Refer to SE-12, "

Removal and Installation".

3. Remove rear seat cushion and rear seatback. Refer to SE-16, "

Removal and Installation".

4. Remove front seat belt shoulder anchor RH/LH. Refer to SB-4, "

Removal and Installation of Front Seat

Belt".

5. Remove center console body assembly. Refer to IP-11

.

6. Remove front pillar garnish RH/LH. Refer to EI-40, "

Removal and Installation".

7. Remove antenna feeder cable clip, then disconnect antenna feeder cable connector.

8. Remove front and rear kicking plate inner RH/LH, center pillar lower garnish, center pillar upper garnish, front and rear body side welt RH/LH. Refer to EI-40, "

Removal and Installation".

WARNING:

Do not reuse center pillar upper garnish if removed.

9. Remove back door weatherstrip. Refer to EI-38

.

10. Release the clips using a suitable tool, then remove the front and rear assist grips.

11. Remove the sunvisor caps and screws, then remove sunvisor RH/LH.

1. Headlining 2. Assist grip 3. Room lamp

4. Sunvisor 5. Cap 6. Sunvisor holder

7. Map lamp assembly (if equipped) 8. Antenna feeder cable 9. Roof console assembly (if

equipped)

10. Roof plate (if equipped) 11. Dual lock fastener 12. Insulator

13. Room lamp harness 14. Cover A. With sunroof

B. Without sunroof Clip C103Vehicle front

PIIB2583J

PIIB2584J

Revision: January 20102010 Versa