Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2352 of 3745

HEADLININGEI-51

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

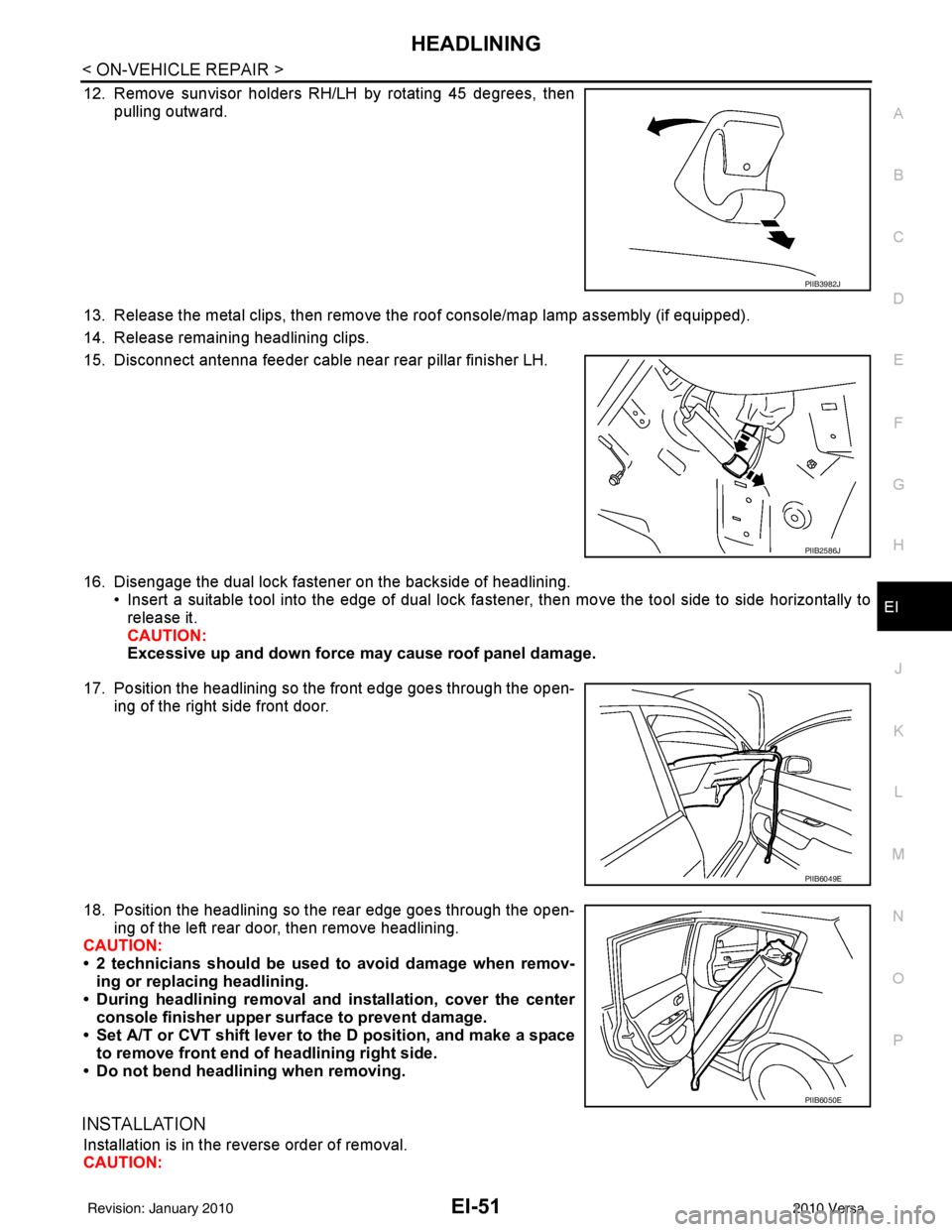

12. Remove sunvisor holders RH/LH by rotating 45 degrees, then pulling outward.

13. Release the metal clips, then remove the roof console/map lamp assembly (if equipped).

14. Release remaining headlining clips.

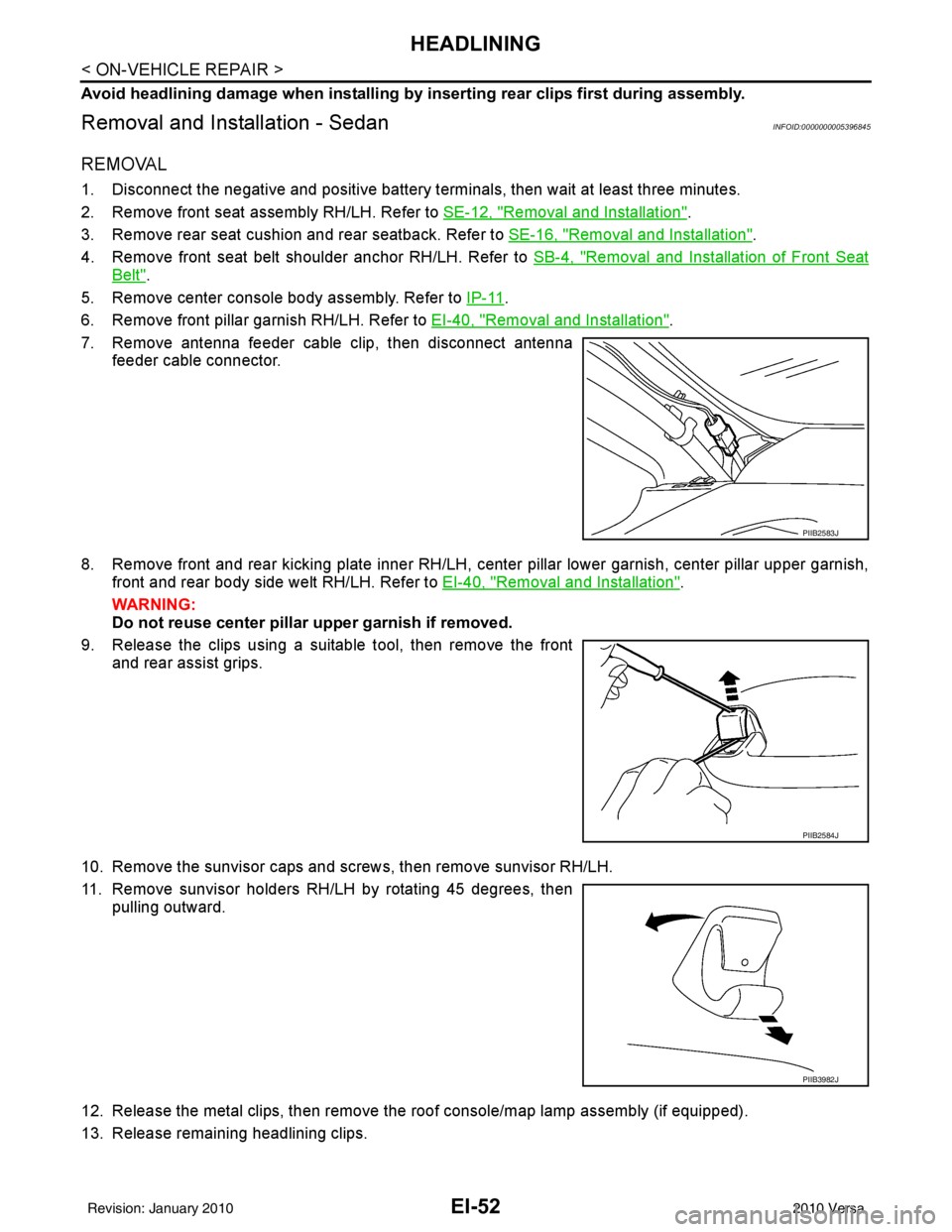

15. Disconnect antenna feeder cable near rear pillar finisher LH.

16. Disengage the dual lock fastener on the backside of headlining. • Insert a suitable tool into the edge of dual lock fa stener, then move the tool side to side horizontally to

release it.

CAUTION:

Excessive up and down force may cause roof panel damage.

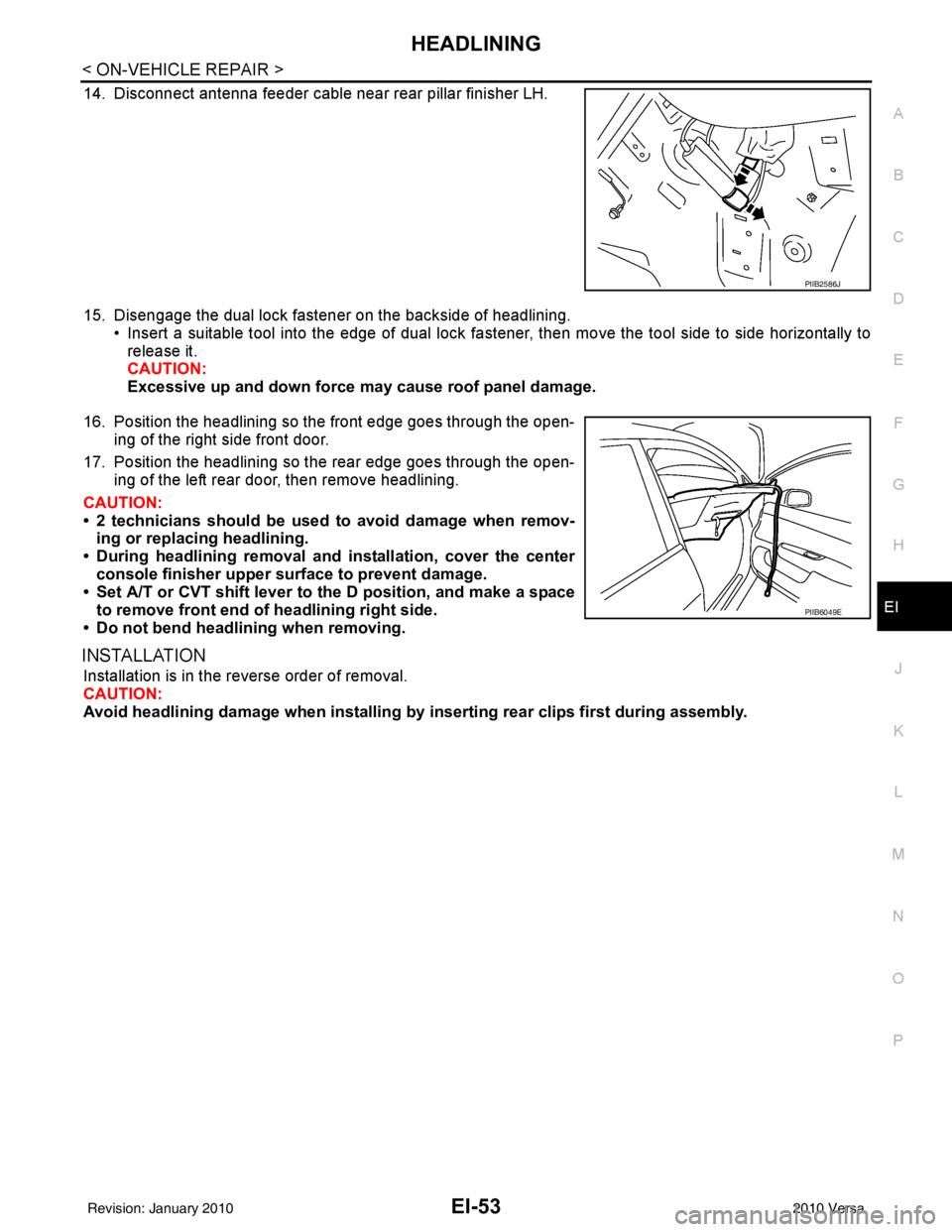

17. Position the headlining so the front edge goes through the open- ing of the right side front door.

18. Position the headlining so the rear edge goes through the open- ing of the left rear door, then remove headlining.

CAUTION:

• 2 technicians should be used to avoid damage when remov-

ing or replacing headlining.

• During headlining removal and installation, cover the center

console finisher upper surface to prevent damage.

• Set A/T or CVT shift lever to the D position, and make a space

to remove front end of headlining right side.

• Do not bend headlining when removing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

PIIB3982J

PIIB2586J

PIIB6049E

PIIB6050E

Revision: January 20102010 Versa

Page 2353 of 3745

EI-52

< ON-VEHICLE REPAIR >

HEADLINING

Avoid headlining damage when installing by inserting rear clips first during assembly.

Removal and Installation - SedanINFOID:0000000005396845

REMOVAL

1. Disconnect the negative and positive battery terminals, then wait at least three minutes.

2. Remove front seat assembly RH/LH. Refer to SE-12, "

Removal and Installation".

3. Remove rear seat cushion and rear seatback. Refer to SE-16, "

Removal and Installation".

4. Remove front seat belt shoulder anchor RH/LH. Refer to SB-4, "

Removal and Installation of Front Seat

Belt".

5. Remove center console body assembly. Refer to IP-11

.

6. Remove front pillar garnish RH/LH. Refer to EI-40, "

Removal and Installation".

7. Remove antenna feeder cable clip, then disconnect antenna feeder cable connector.

8. Remove front and rear kicking plate inner RH/LH, center pillar lower garnish, center pillar upper garnish, front and rear body side welt RH/LH. Refer to EI-40, "

Removal and Installation".

WARNING:

Do not reuse center pillar upper garnish if removed.

9. Release the clips using a suitable tool, then remove the front and rear assist grips.

10. Remove the sunvisor caps and scr ews, then remove sunvisor RH/LH.

11. Remove sunvisor holders RH/LH by rotating 45 degrees, then pulling outward.

12. Release the metal clips, then remove the roof console/map lamp assembly (if equipped).

13. Release remaining headlining clips.

PIIB2583J

PIIB2584J

PIIB3982J

Revision: January 20102010 Versa

Page 2354 of 3745

HEADLININGEI-53

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

14. Disconnect antenna feeder cable near rear pillar finisher LH.

15. Disengage the dual lock fastener on the backside of headlining. • Insert a suitable tool into the edge of dual lock fa stener, then move the tool side to side horizontally to

release it.

CAUTION:

Excessive up and down force may cause roof panel damage.

16. Position the headlining so the front edge goes through the open- ing of the right side front door.

17. Position the headlining so the rear edge goes through the open- ing of the left rear door, then remove headlining.

CAUTION:

• 2 technicians should be used to avoid damage when remov-

ing or replacing headlining.

• During headlining removal and installation, cover the center

console finisher upper surface to prevent damage.

• Set A/T or CVT shift lever to the D position, and make a space

to remove front end of headlining right side.

• Do not bend headlining when removing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Avoid headlining damage when installing by inserting rear clips first during assembly.

PIIB2586J

PIIB6049E

Revision: January 20102010 Versa

Page 2355 of 3745

EI-54

< ON-VEHICLE REPAIR >

LUGGAGE FLOOR TRIM

LUGGAGE FLOOR TRIM

Removal and InstallationINFOID:0000000005396846

REMOVAL

CAUTION:

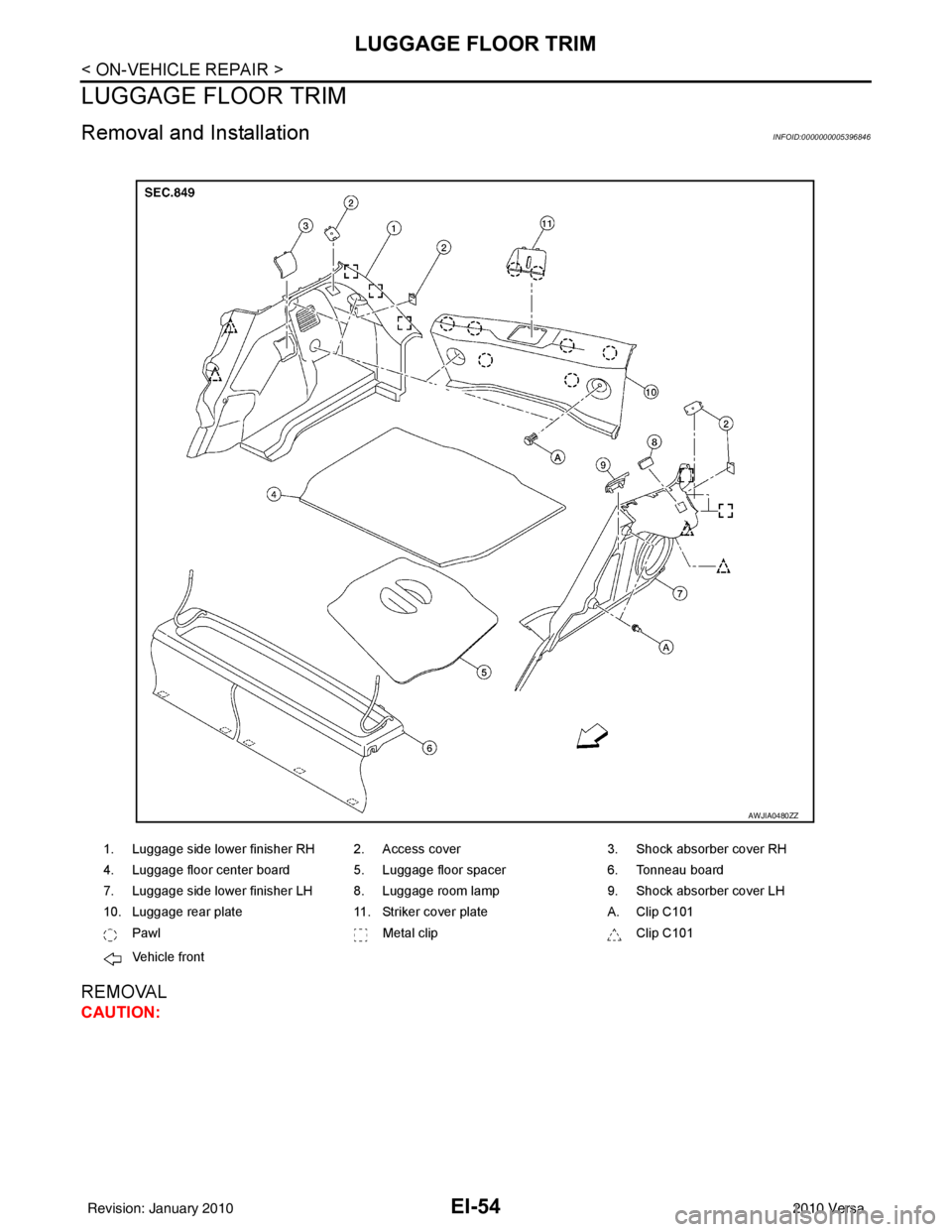

1. Luggage side lower finisher RH 2. Access cover3. Shock absorber cover RH

4. Luggage floor center board 5. Luggage floor spacer 6. Tonneau board

7. Luggage side lower finisher LH 8. Luggage room lamp 9. Shock absorber cover LH

10. Luggage rear plate 11. Striker cover plate A. Clip C101

Pawl Metal clip Clip C101

Vehicle front

AWJIA0480ZZ

Revision: January 20102010 Versa

Page 2356 of 3745

LUGGAGE FLOOR TRIMEI-55

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

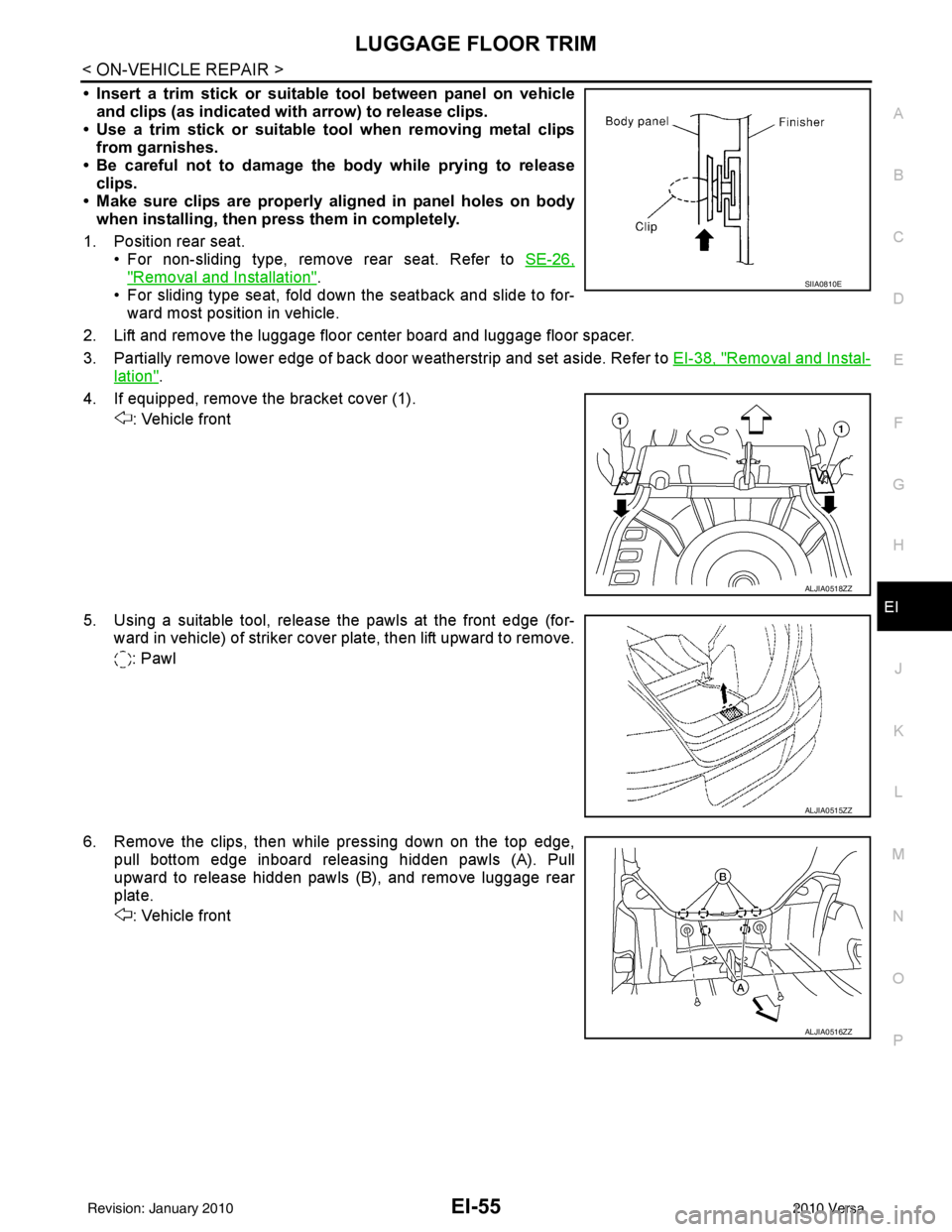

• Insert a trim stick or suitable tool between panel on vehicle and clips (as indicated with arrow) to release clips.

• Use a trim stick or suitable tool when removing metal clips

from garnishes.

• Be careful not to damage the body while prying to release clips.

• Make sure clips are properly al igned in panel holes on body

when installing, then press them in completely.

1. Position rear seat. • For non-sliding type, remove rear seat. Refer to SE-26,

"Removal and Installation".

• For sliding type seat, fold down the seatback and slide to for- ward most position in vehicle.

2. Lift and remove the luggage floor center board and luggage floor spacer.

3. Partially remove lower edge of back door weatherstrip and set aside. Refer to EI-38, "

Removal and Instal-

lation".

4. If equipped, remove the bracket cover (1). : Vehicle front

5. Using a suitable tool, release the pawls at the front edge (for- ward in vehicle) of striker cover plate, then lift upward to remove.

: Pawl

6. Remove the clips, then while pressing down on the top edge, pull bottom edge inboard releasing hidden pawls (A). Pull

upward to release hidden pawls (B), and remove luggage rear

plate.

: Vehicle front

SIIA0810E

ALJIA0518ZZ

ALJIA0515ZZ

ALJIA0516ZZ

Revision: January 20102010 Versa

Page 2357 of 3745

EI-56

< ON-VEHICLE REPAIR >

LUGGAGE FLOOR TRIM

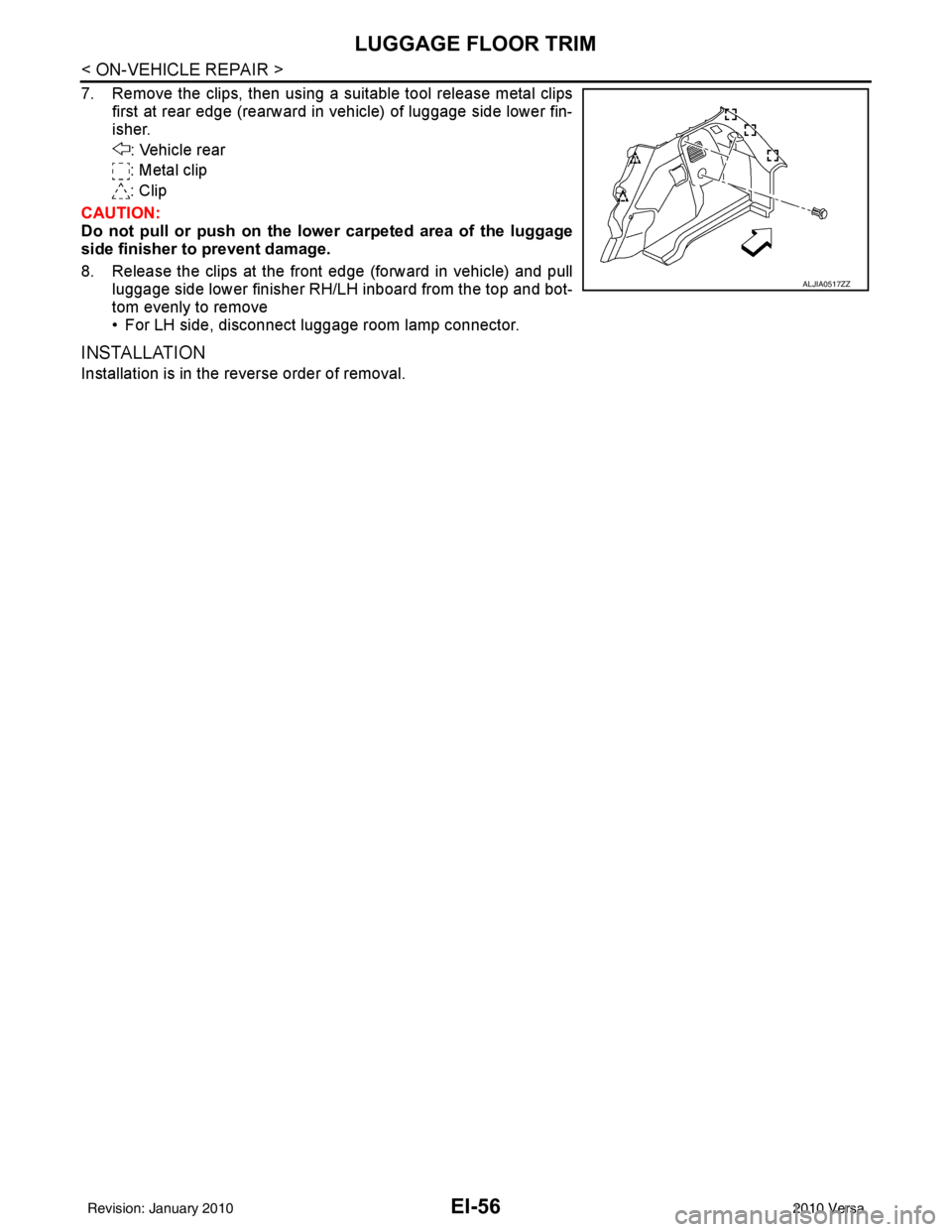

7. Remove the clips, then using a suitable tool release metal clipsfirst at rear edge (rearward in vehicle) of luggage side lower fin-

isher.

: Vehicle rear

: Metal clip

: Clip

CAUTION:

Do not pull or push on the lower carpeted area of the luggage

side finisher to prevent damage.

8. Release the clips at the front edge (forward in vehicle) and pull luggage side lower finisher RH/LH inboard from the top and bot-

tom evenly to remove

• For LH side, disconnect luggage room lamp connector.

INSTALLATION

Installation is in the reverse order of removal.

ALJIA0517ZZ

Revision: January 20102010 Versa

Page 2358 of 3745

TRUNK ROOM TRIM & TRUNK LID FINISHEREI-57

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

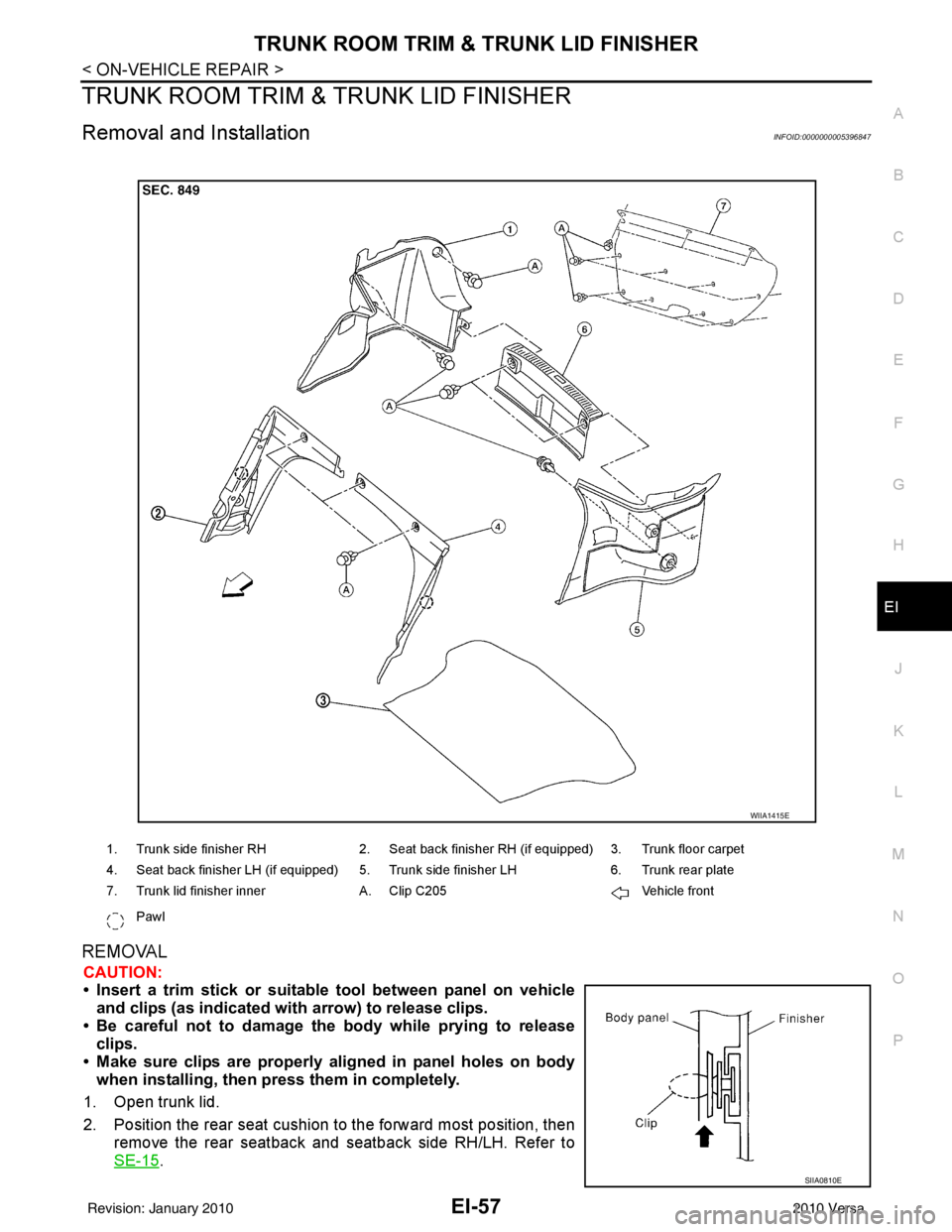

TRUNK ROOM TRIM & TRUNK LID FINISHER

Removal and InstallationINFOID:0000000005396847

REMOVAL

CAUTION:

• Insert a trim stick or suitable tool between panel on vehicle and clips (as indicated with arrow) to release clips.

• Be careful not to damage the body while prying to release clips.

• Make sure clips are properly al igned in panel holes on body

when installing, then press them in completely.

1. Open trunk lid.

2. Position the rear seat cushion to the forward most position, then remove the rear seatback and seatback side RH/LH. Refer to

SE-15

.

1. Trunk side finisher RH 2. Seat back finisher RH (if equipped) 3. Trunk floor carpet

4. Seat back finisher LH (if equipped) 5. Trunk side finisher LH 6. Trunk rear plate

7. Trunk lid finisher inner A. Clip C205 Vehicle front

Pawl

WIIA1415E

SIIA0810E

Revision: January 20102010 Versa

Page 2361 of 3745

EM-2

Removal and Installation ........................................42

IGNITION COIL, SPARK PLUG AND ROCK-

ER COVER .........................................................

46

Exploded View ........................................................46

Removal and Installation ........................................46

TIMING CHAIN ............................................... ...49

Exploded View ..................................................... ...49

Removal and Installation ........................................49

Inspection ...............................................................57

CAMSHAFT .......................................................59

Exploded View ..................................................... ...59

Removal and Installation ........................................59

Inspection ...............................................................65

OIL SEAL ...........................................................70

VALVE OIL SEAL .................................................. ...70

VALVE OIL SEAL : Removal and Installation .........70

FRONT OIL SEAL .................................................. ...70

FRONT OIL SEAL : Removal and Installation ........71

REAR OIL SEAL .................................................... ...71

REAR OIL SEAL : Removal and Installation ..........71

CYLINDER HEAD ........................................... ...73

Removal and Installation ..................................... ...73

Disassembly and Assembly ....................................76

REMOVAL AND INSTALLATION ...............82

ENGINE ASSEMBLY ...................................... ...82

Exploded View ..................................................... ...82

Removal and Installation ........................................82

Inspection ...............................................................85

DISASSEMBLY AND ASSEMBLY .............87

ENGINE STAND SETTING ............................. ...87

Setting ................................................................. ...87

ENGINE UNIT ....................................................88

Disassembly ........................................................ ...88

Assembly ................................................................88

CYLINDER BLOCK ...........................................89

Exploded View ..................................................... ...89

Disassembly and Assembly ....................................90

Inspection ...............................................................97

HOW TO SELECT PISTON AND BEARING ...106

Description ........................................................... ..106

Connecting Rod Bearing .......................................106

Main Bearing .........................................................108

SERVICE DATA AND SPECIFICATIONS

(SDS) ........................................................ ..

111

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

111

General Specification ........................................... .111

Drive Belts .............................................................111

Spark Plug ............................................................112

Exhaust Manifold ..................................................112

Camshaft ...............................................................112

Cylinder Head .......................................................114

Cylinder Block .......................................................116

Connecting Rod Bearing .......................................119

Main Bearing .........................................................120

MR18DE

SERVICE INFORMATION .. .......................

122

PRECAUTIONS .............................................. ..122

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

122

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

122

Precaution for Procedure without Cowl Top Cover .123

Precaution for Drain Coolant .................................123

Precaution for Disconnecting Fuel Piping ............ .123

Precaution for Removal and Disassembly ............123

Precaution for Inspection, Repair and Replace-

ment ......................................................................

123

Precaution for Assembly and Installation ............. .123

Parts Requiring Angular Tightening ......................124

Precaution for Liquid Gasket .................................124

PREPARATION ................................................126

Special Service Tool ............................................ .126

Commercial Service Tool ......................................128

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

130

NVH Troubleshooting - Engine Noise .................. .130

Use the Chart Below to Help You Find the Cause

of the Symptom .................................................... .

131

DRIVE BELTS ..................................................132

Component .......................................................... .132

Checking Drive Belts .............................................132

Tension Adjustment ..............................................132

Removal and Installation .......................................132

Component .......................................................... .133

Removal and Installation of Drive Belt Auto Ten-

sioner ....................................................................

133

AIR CLEANER AND AIR DUCT .......................135

Component .......................................................... .135

Removal and Installation .......................................135

Changing Air Cleaner Filter ...................................136

INTAKE MANIFOLD ....................................... ..137

Component .......................................................... .137

Removal and Installation .......................................137

EXHAUST MANIFOLD ................................... ..140

Component .......................................................... .140

Removal and Installation .......................................140

Revision: January 20102010 Versa

Page 2362 of 3745

EM-3

C

DE

F

G H

I

J

K L

M

EM A

N

O P

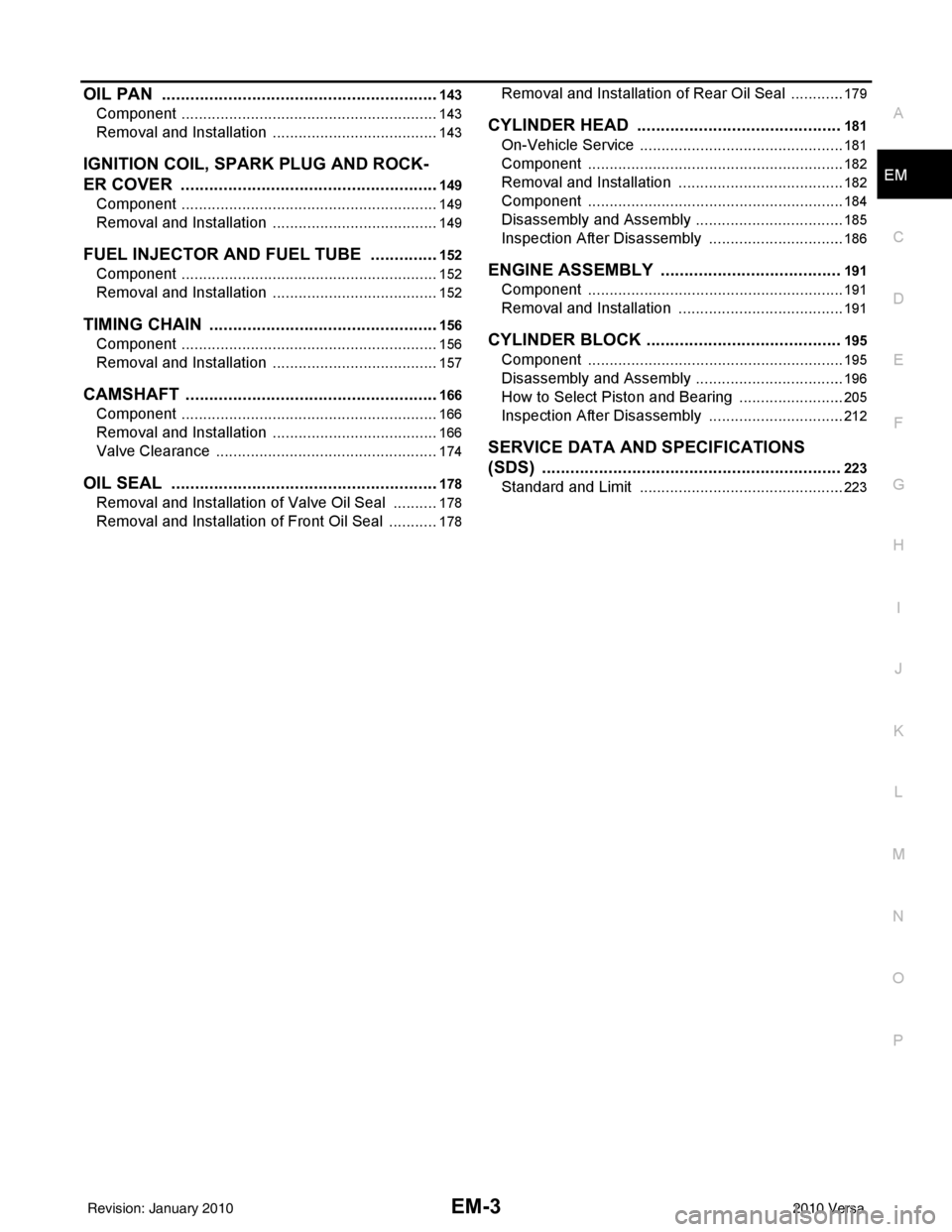

OIL PAN ...........................................................143

Component .......................................................... ..143

Removal and Installation .......................................143

IGNITION COIL, SPARK PLUG AND ROCK-

ER COVER .......................................................

149

Component .......................................................... ..149

Removal and Installation .......................................149

FUEL INJECTOR AND FUEL TUBE ............. ..152

Component .......................................................... ..152

Removal and Installation .......................................152

TIMING CHAIN .................................................156

Component .......................................................... ..156

Removal and Installation .......................................157

CAMSHAFT .................................................... ..166

Component .......................................................... ..166

Removal and Installation .......................................166

Valve Clearance .................................................. ..174

OIL SEAL .........................................................178

Removal and Installation of Valve Oil Seal ...........178

Removal and Installation of Front Oil Seal ............178

Removal and Installation of Rear Oil Seal .............179

CYLINDER HEAD ...........................................181

On-Vehicle Service .............................................. ..181

Component ............................................................182

Removal and Installation .......................................182

Component ............................................................184

Disassembly and Assembly ...................................185

Inspection After Disassembly ................................186

ENGINE ASSEMBLY ......................................191

Component .......................................................... ..191

Removal and Installation .......................................191

CYLINDER BLOCK .........................................195

Component ............................................................195

Disassembly and Assembly ...................................196

How to Select Piston and Bearing ....................... ..205

Inspection After Disassembly .............................. ..212

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

223

Standard and Limit ................................................223

Revision: January 20102010 Versa

Page 2363 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005398023

The Supplemental Res NISSAN TIIDA 2010 Service Repair Manual EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005398023

The Supplemental Res](/img/5/57397/w960_57397-2362.png)

EM-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005398023

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005398024

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa