Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2304 of 3745

PRECAUTIONSEI-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714352

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005396814

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2309 of 3745

EI-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005396819

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

Revision: January 20102010 Versa

Page 2310 of 3745

SQUEAK AND RATTLE TROUBLE DIAGNOSISEI-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: January 20102010 Versa

Page 2316 of 3745

FRONT BUMPEREI-15

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

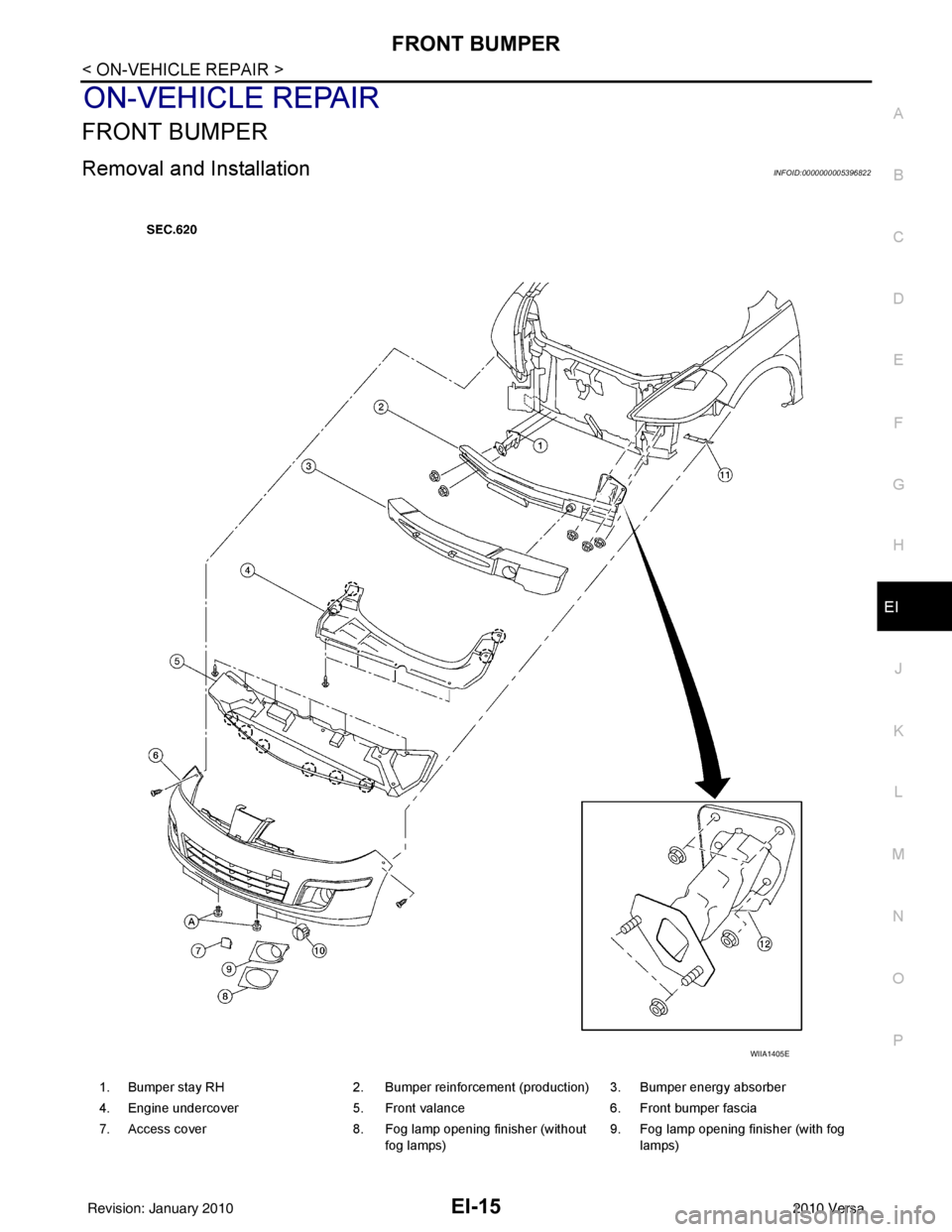

ON-VEHICLE REPAIR

FRONT BUMPER

Removal and InstallationINFOID:0000000005396822

1. Bumper stay RH 2. Bumper reinforcement (production) 3. Bumper energy absorber

4. Engine undercover 5. Front valance 6. Front bumper fascia

7. Access cover 8. Fog lamp opening finisher (without

fog lamps) 9. Fog lamp opening finisher (with fog

lamps)

WIIA1405E

Revision: January 20102010 Versa

Page 2317 of 3745

EI-16

< ON-VEHICLE REPAIR >

FRONT BUMPER

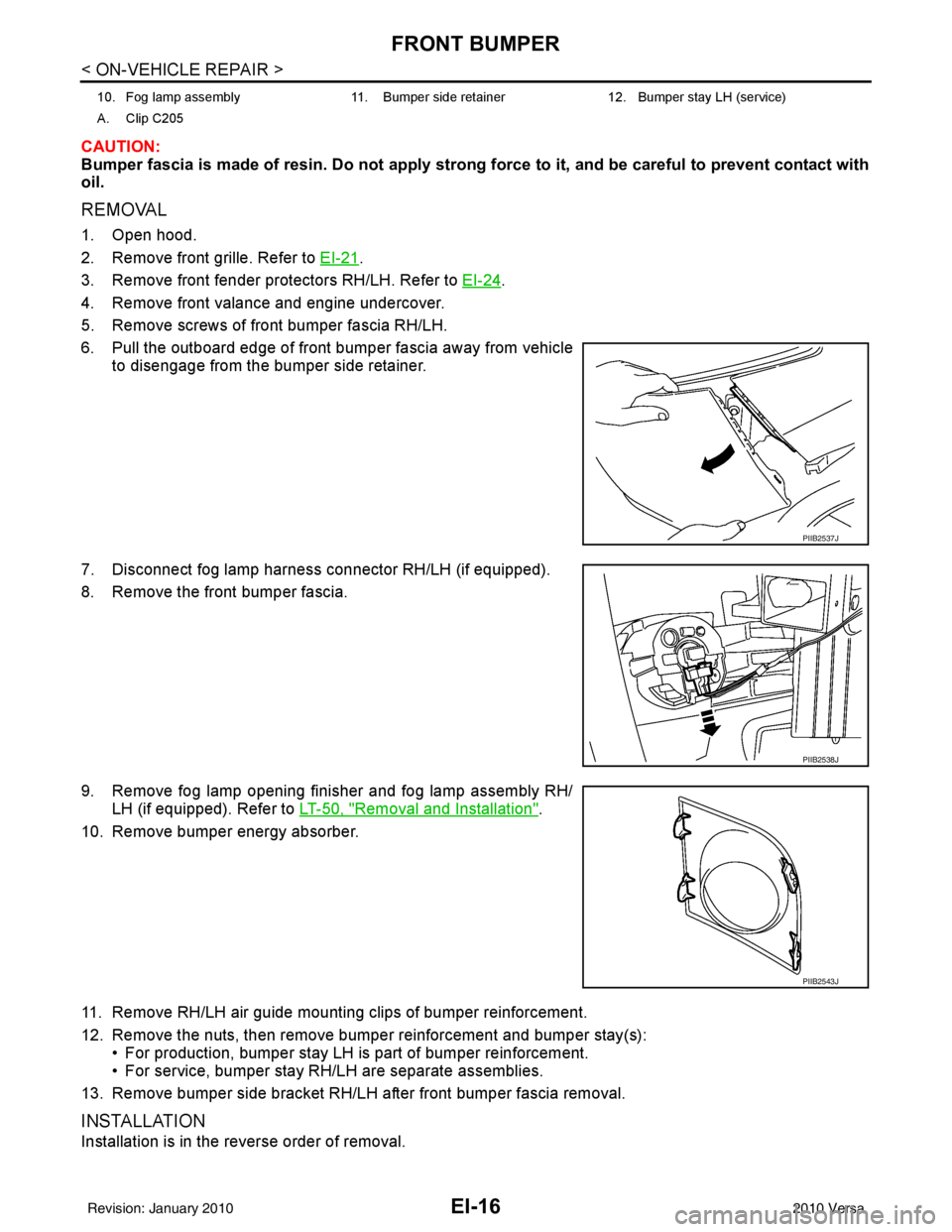

CAUTION:

Bumper fascia is made of resin. Do not apply strong force to it, and be careful to prevent contact with

oil.

REMOVAL

1. Open hood.

2. Remove front grille. Refer to EI-21

.

3. Remove front fender protectors RH/LH. Refer to EI-24

.

4. Remove front valance and engine undercover.

5. Remove screws of front bumper fascia RH/LH.

6. Pull the outboard edge of front bumper fascia away from vehicle to disengage from the bumper side retainer.

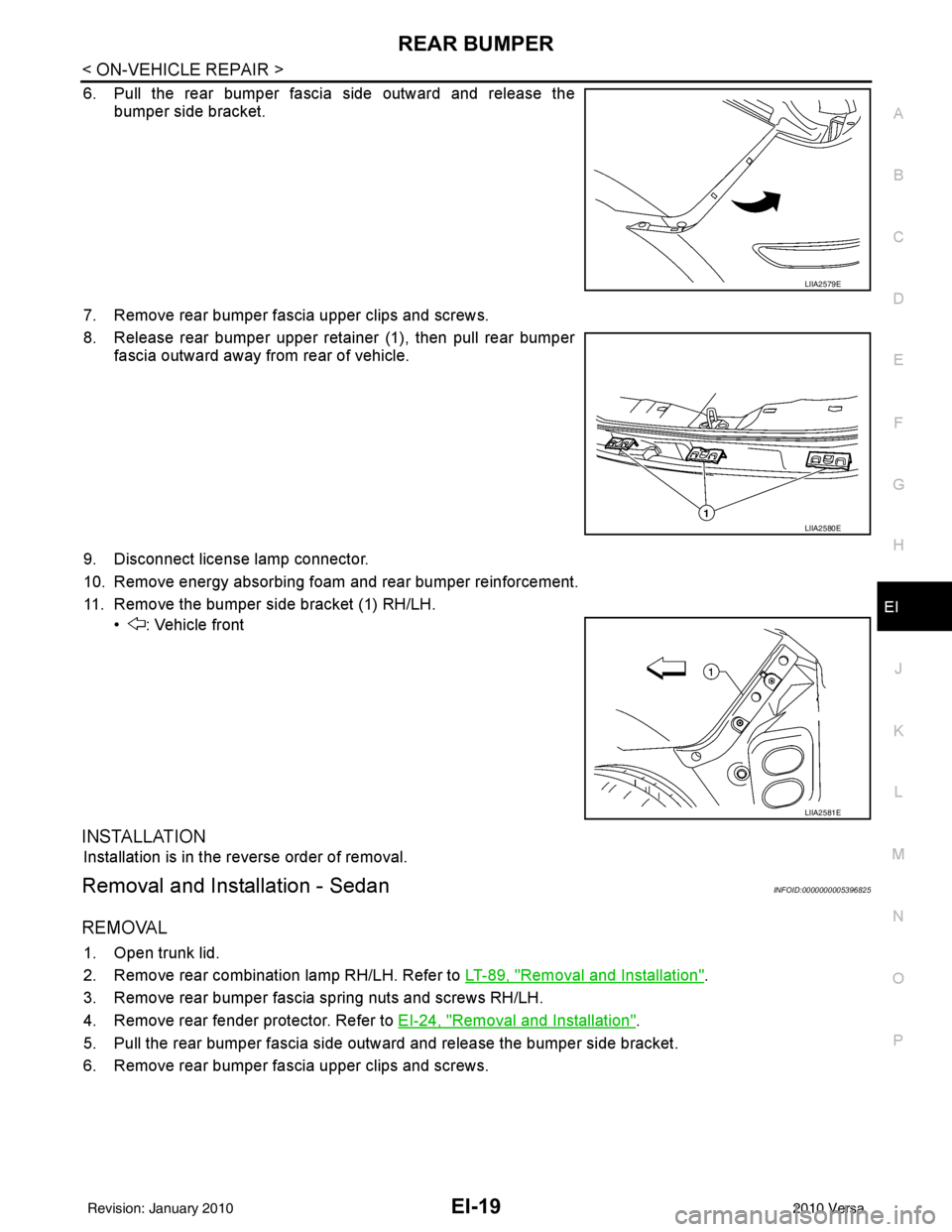

7. Disconnect fog lamp harness connector RH/LH (if equipped).

8. Remove the front bumper fascia.

9. Remove fog lamp opening finisher and fog lamp assembly RH/ LH (if equipped). Refer to LT-50, "

Removal and Installation".

10. Remove bumper energy absorber.

11. Remove RH/LH air guide mounting clips of bumper reinforcement.

12. Remove the nuts, then remove bumper reinforcement and bumper stay(s): • For production, bumper stay LH is part of bumper reinforcement.

• For service, bumper stay RH/LH are separate assemblies.

13. Remove bumper side bracket RH/LH after front bumper fascia removal.

INSTALLATION

Installation is in the reverse order of removal.

10. Fog lamp assembly 11. Bumper side retainer 12. Bumper stay LH (service)

A. Clip C205

PIIB2537J

PIIB2538J

PIIB2543J

Revision: January 20102010 Versa

Page 2320 of 3745

REAR BUMPEREI-19

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

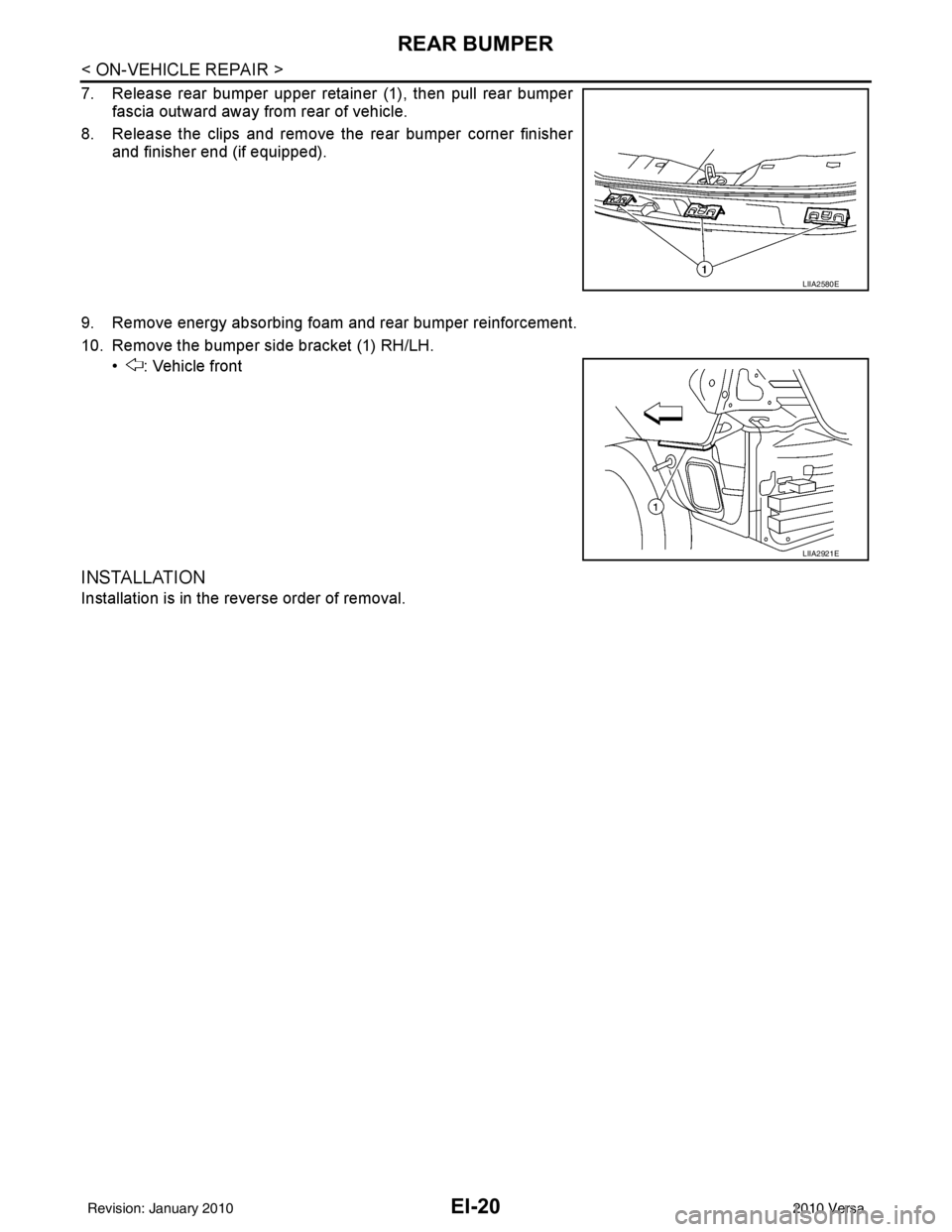

6. Pull the rear bumper fascia side outward and release the bumper side bracket.

7. Remove rear bumper fascia upper clips and screws.

8. Release rear bumper upper retainer (1), then pull rear bumper fascia outward away from rear of vehicle.

9. Disconnect license lamp connector.

10. Remove energy absorbing foam and rear bumper reinforcement.

11. Remove the bumper side bracket (1) RH/LH. • : Vehicle front

INSTALLATION

Installation is in the reverse order of removal.

Removal and Installation - SedanINFOID:0000000005396825

REMOVAL

1. Open trunk lid.

2. Remove rear combination lamp RH/LH. Refer to LT-89, "

Removal and Installation".

3. Remove rear bumper fascia spring nuts and screws RH/LH.

4. Remove rear fender protector. Refer to EI-24, "

Removal and Installation".

5. Pull the rear bumper fascia side outward and release the bumper side bracket.

6. Remove rear bumper fascia upper clips and screws.

LIIA2579E

LIIA2580E

LIIA2581E

Revision: January 20102010 Versa

Page 2321 of 3745

EI-20

< ON-VEHICLE REPAIR >

REAR BUMPER

7. Release rear bumper upper retainer (1), then pull rear bumperfascia outward away from rear of vehicle.

8. Release the clips and remove the rear bumper corner finisher and finisher end (if equipped).

9. Remove energy absorbing foam and rear bumper reinforcement.

10. Remove the bumper side bracket (1) RH/LH. • : Vehicle front

INSTALLATION

Installation is in the reverse order of removal.

LIIA2580E

LIIA2921E

Revision: January 20102010 Versa

Page 2322 of 3745

FRONT GRILLEEI-21

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

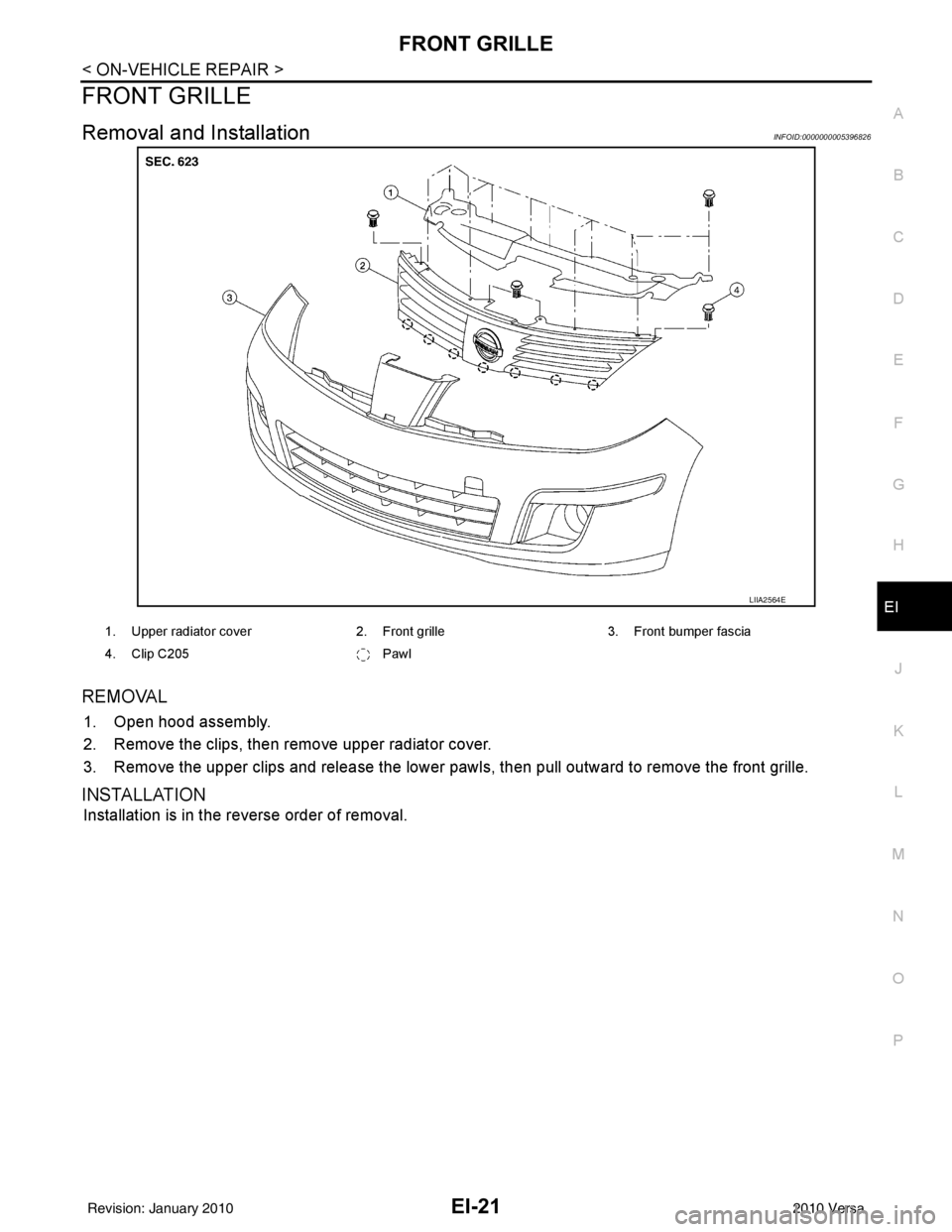

FRONT GRILLE

Removal and InstallationINFOID:0000000005396826

REMOVAL

1. Open hood assembly.

2. Remove the clips, then remove upper radiator cover.

3. Remove the upper clips and release the lower pawls, then pull outward to remove the front grille.

INSTALLATION

Installation is in the reverse order of removal.

LIIA2564E

1. Upper radiator cover2. Front grille3. Front bumper fascia

4. Clip C205 Pawl

Revision: January 20102010 Versa

Page 2323 of 3745

EI-22

< ON-VEHICLE REPAIR >

COWL TOP

COWL TOP

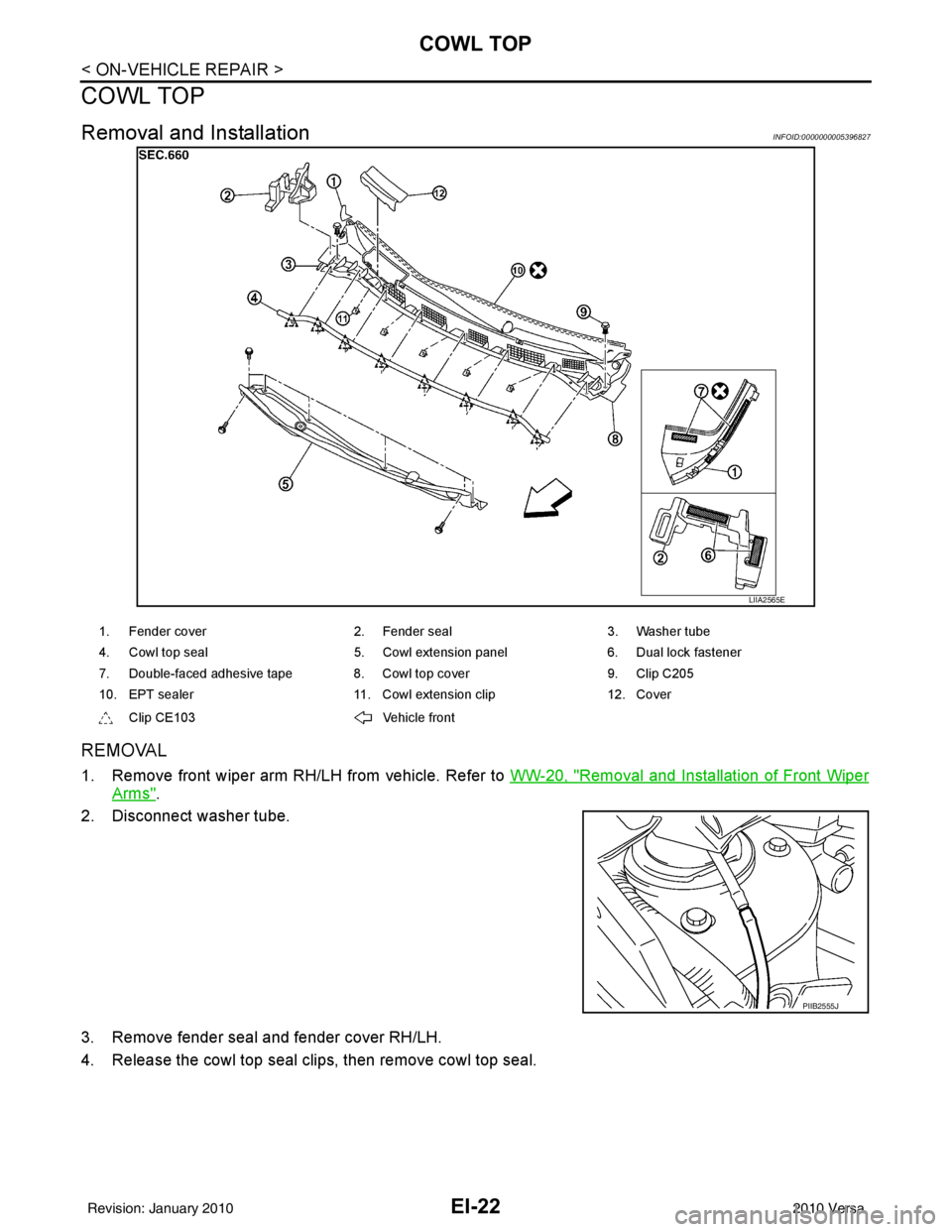

Removal and InstallationINFOID:0000000005396827

REMOVAL

1. Remove front wiper arm RH/LH from vehicle. Refer to WW-20, "Removal and Installation of Front Wiper

Arms".

2. Disconnect washer tube.

3. Remove fender seal and fender cover RH/LH.

4. Release the cowl top seal clips, then remove cowl top seal.

LIIA2565E

1. Fender cover 2. Fender seal3. Washer tube

4. Cowl top seal 5. Cowl extension panel6. Dual lock fastener

7. Double-faced adhesive tape 8. Cowl top cover 9. Clip C205

10. EPT sealer 11. Cowl extension clip12. Cover

Clip CE103 Vehicle front

PIIB2555J

Revision: January 20102010 Versa

Page 2324 of 3745

COWL TOPEI-23

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

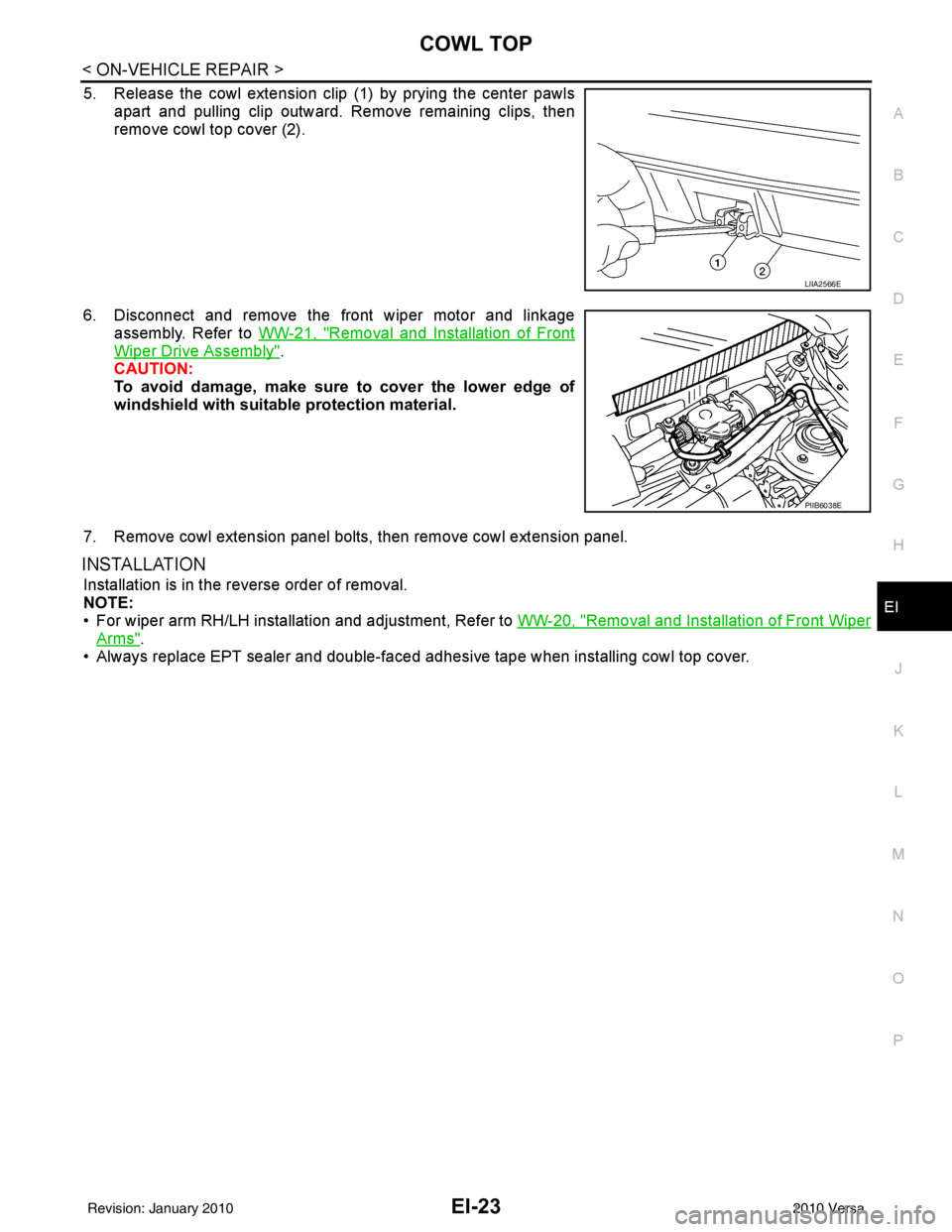

5. Release the cowl extension clip (1) by prying the center pawls apart and pulling clip outward. Remove remaining clips, then

remove cowl top cover (2).

6. Disconnect and remove the front wiper motor and linkage assembly. Refer to WW-21, "

Removal and Installation of Front

Wiper Drive Assembly".

CAUTION:

To avoid damage, make sure to cover the lower edge of

windshield with suitable protection material.

7. Remove cowl extension panel bolts, then remove cowl extension panel.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

• For wiper arm RH/LH installation and adjustment, Refer to WW-20, "

Removal and Installation of Front Wiper

Arms".

• Always replace EPT sealer and double-faced adhesive tape when installing cowl top cover.

LIIA2566E

PIIB6038E

Revision: January 20102010 Versa