Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3437 of 3745

PG-54

< SERVICE INFORMATION >

HARNESS

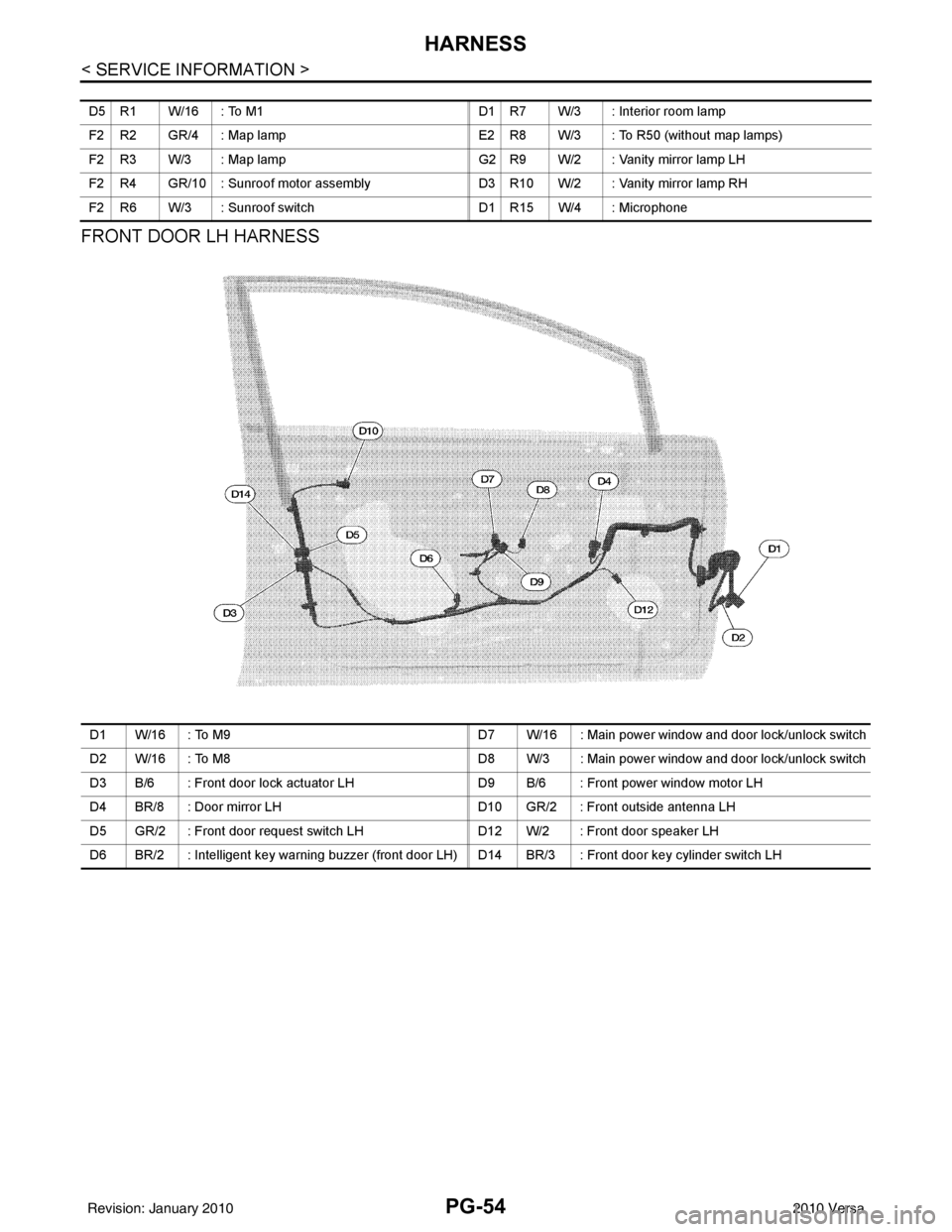

FRONT DOOR LH HARNESS

D5 R1 W/16 : To M1 D1 R7 W/3 : Interior room lamp

F2 R2 GR/4 : Map lamp E2 R8 W/3 : To R50 (without map lamps)

F2 R3 W/3 : Map lamp G2 R9 W/2 : Vanity mirror lamp LH

F2 R4 GR/10 : Sunroof motor assembly D3 R10 W/2 : Vanity mirror lamp RH

F2 R6 W/3 : Sunroof switch D1 R15 W/4 : Microphone

D1 W/16 : To M9D7 W/16 : Main power window and door lock/unlock switch

D2 W/16 : To M8 D8 W/3 : Main power window and door lock/unlock switch

D3 B/6 : Front door lock actuator LH D9 B/6 : Front power window motor LH

D4 BR/8 : Door mirror LH D10 GR/2 : Front outside antenna LH

D5 GR/2 : Front door request switch LH D12 W/2 : Front door speaker LH

D6 BR/2 : Intelligent key warning buzzer (front door LH) D14 BR/3 : Front door key cylinder switch LH

Revision: January 20102010 Versa

Page 3438 of 3745

HARNESSPG-55

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

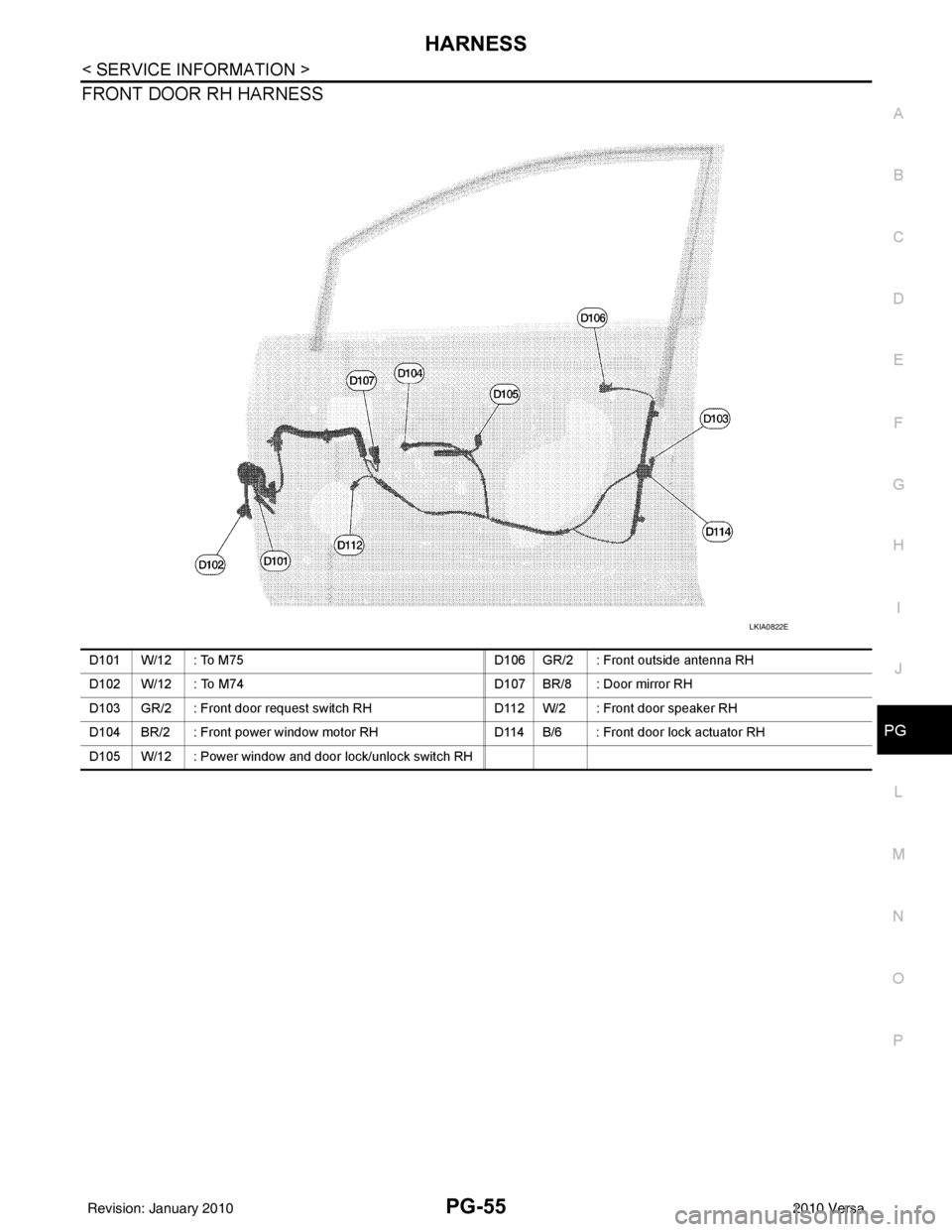

FRONT DOOR RH HARNESS

LKIA0822E

D101 W/12 : To M75 D106 GR/2 : Front outside antenna RH

D102 W/12 : To M74 D107 BR/8 : Door mirror RH

D103 GR/2 : Front door request switch RH D112 W/2 : Front door speaker RH

D104 BR/2 : Front power window motor RH D114 B/6 : Front door lock actuator RH

D105 W/12 : Power window and door lock/unlock switch RH

Revision: January 20102010 Versa

Page 3442 of 3745

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

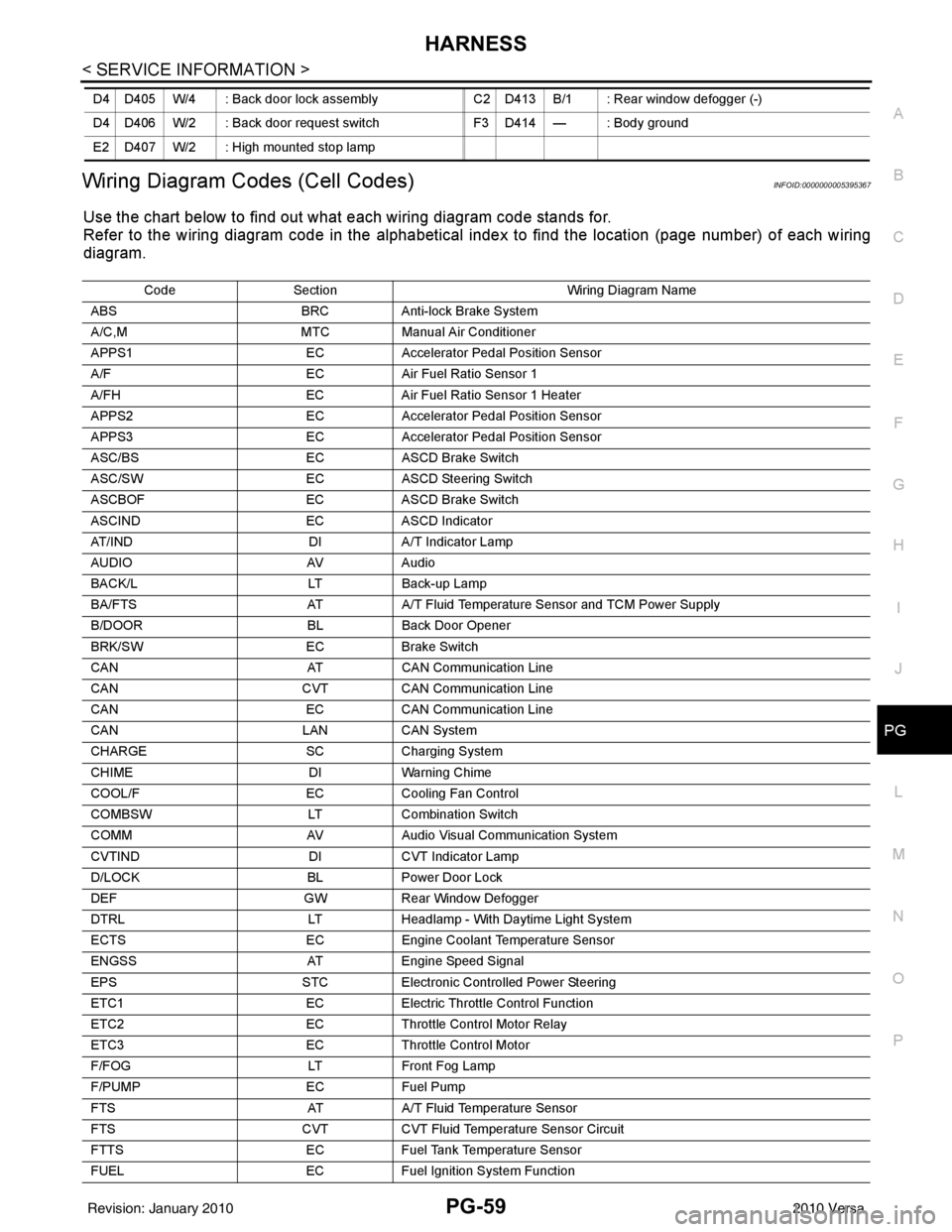

Wiring Diagram Codes (Cell Codes)INFOID:0000000005395367

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

Revision: January 20102010 Versa

Page 3444 of 3745

HARNESSPG-61

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

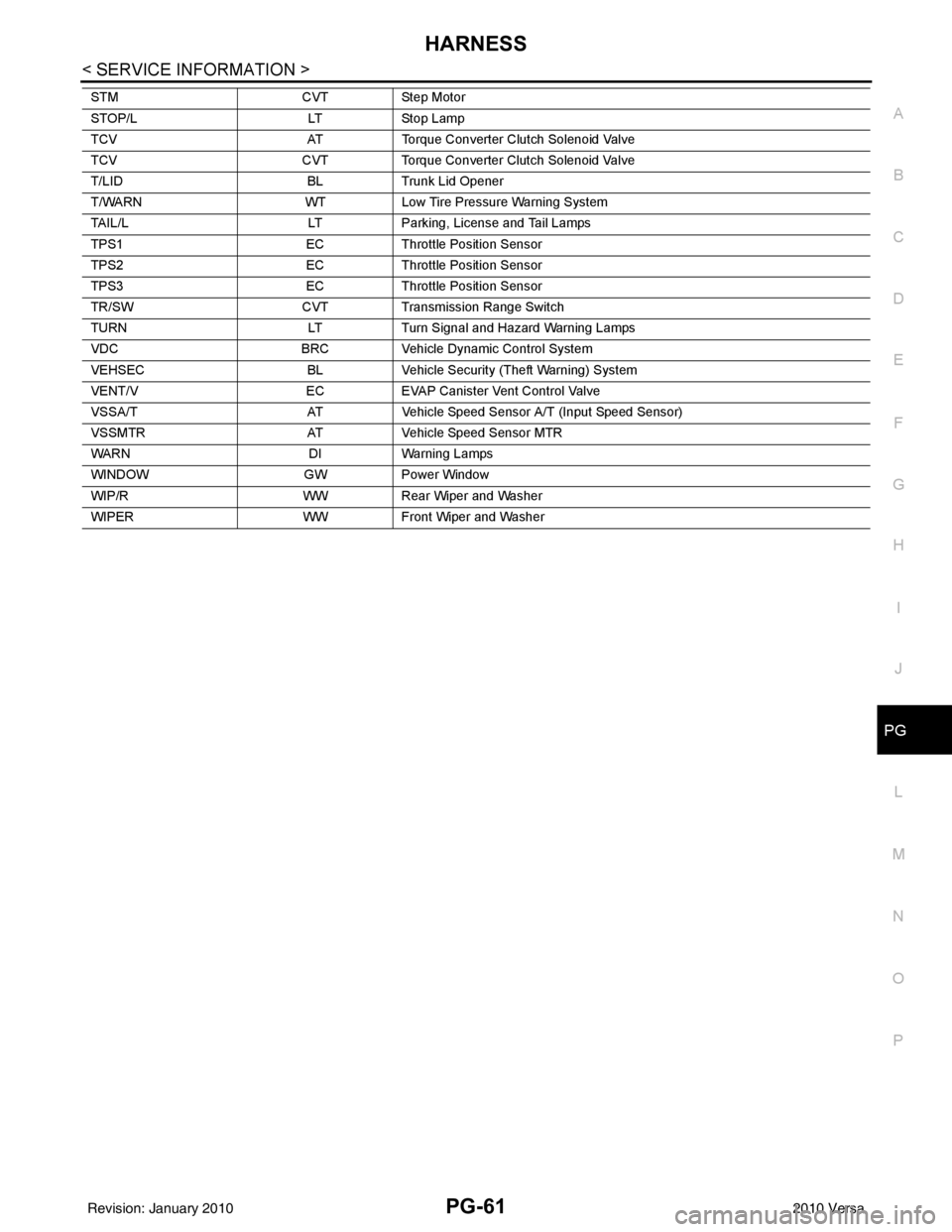

STM CVT Step Motor

STOP/L LT Stop Lamp

TCV AT Torque Converter Clutch Solenoid Valve

TCV CVT Torque Converter Clutch Solenoid Valve

T/LID BL Trunk Lid Opener

T/WARN WT Low Tire Pressure Warning System

TAIL/L LT Parking, License and Tail Lamps

TPS1 EC Throttle Position Sensor

TPS2 EC Throttle Position Sensor

TPS3 EC Throttle Position Sensor

TR/SW CVT Transmission Range Switch

TURN LT Turn Signal and Hazard Warning Lamps

VDC BRC Vehicle Dynamic Control System

VEHSEC BL Vehicle Security (Theft Warning) System

VENT/V EC EVAP Canister Vent Control Valve

VSSA/T AT Vehicle Speed Sensor A/T (Input Speed Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN DI Warning Lamps

WINDOW GW Power Window

WIP/R WW Rear Wiper and Washer

WIPER WW Front Wiper and Washer

Revision: January 20102010 Versa

Page 3460 of 3745

PS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713822

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005396929

NOTE:

• This procedure is applied only to models with Intel ligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition switch in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3464 of 3745

PS-6

< SERVICE INFORMATION >

STEERING WHEEL

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000005396934

CHECKING CONDITION OF INSTALLATION

• Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check steering gear assembly mounting bolts and nuts for looseness. Refer to PS-12, "

Removal and Instal-

lation".

CHECKING STEERING WHEEL PLAY

• Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on the

outer circumference.

• When the measurement value is outside the standard val ue, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

• Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the correct position.

• Perform neutral position inspection after wheel alignment. Refer to SRS-2, "

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"".

• Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

• Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steer-

ing wheel is not in the neutral position.

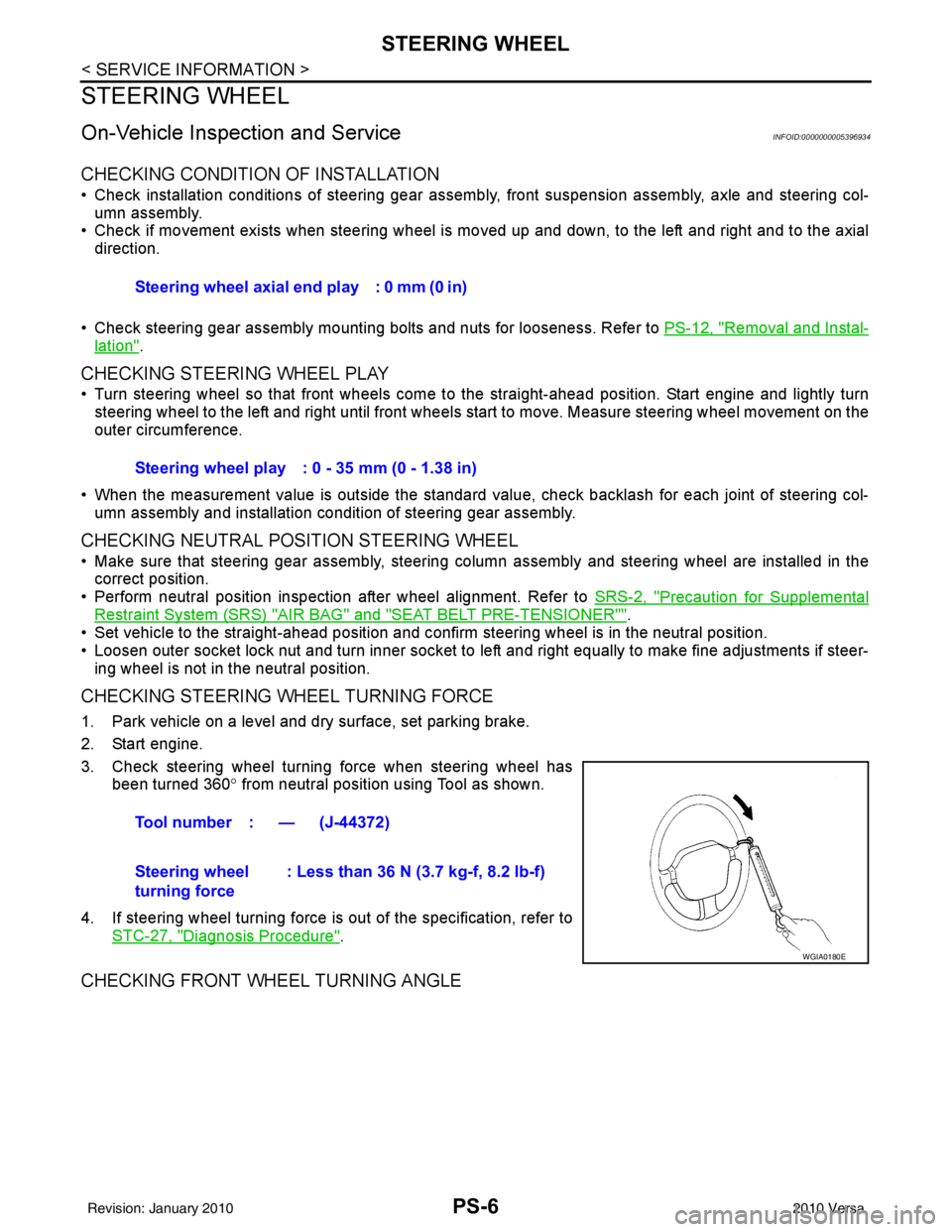

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Check steering wheel turning force when steering wheel has

been turned 360 ° from neutral position using Tool as shown.

4. If steering wheel turning force is out of the specification, refer to STC-27, "

Diagnosis Procedure".

CHECKING FRONT WHEEL TURNING ANGLE

Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Tool number : — (J-44372)

Steering wheel

turning force : Less than 36 N (3.7 kg-f, 8.2 lb-f)

WGIA0180E

Revision: January 20102010 Versa

Page 3465 of 3745

STEERING WHEELPS-7

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

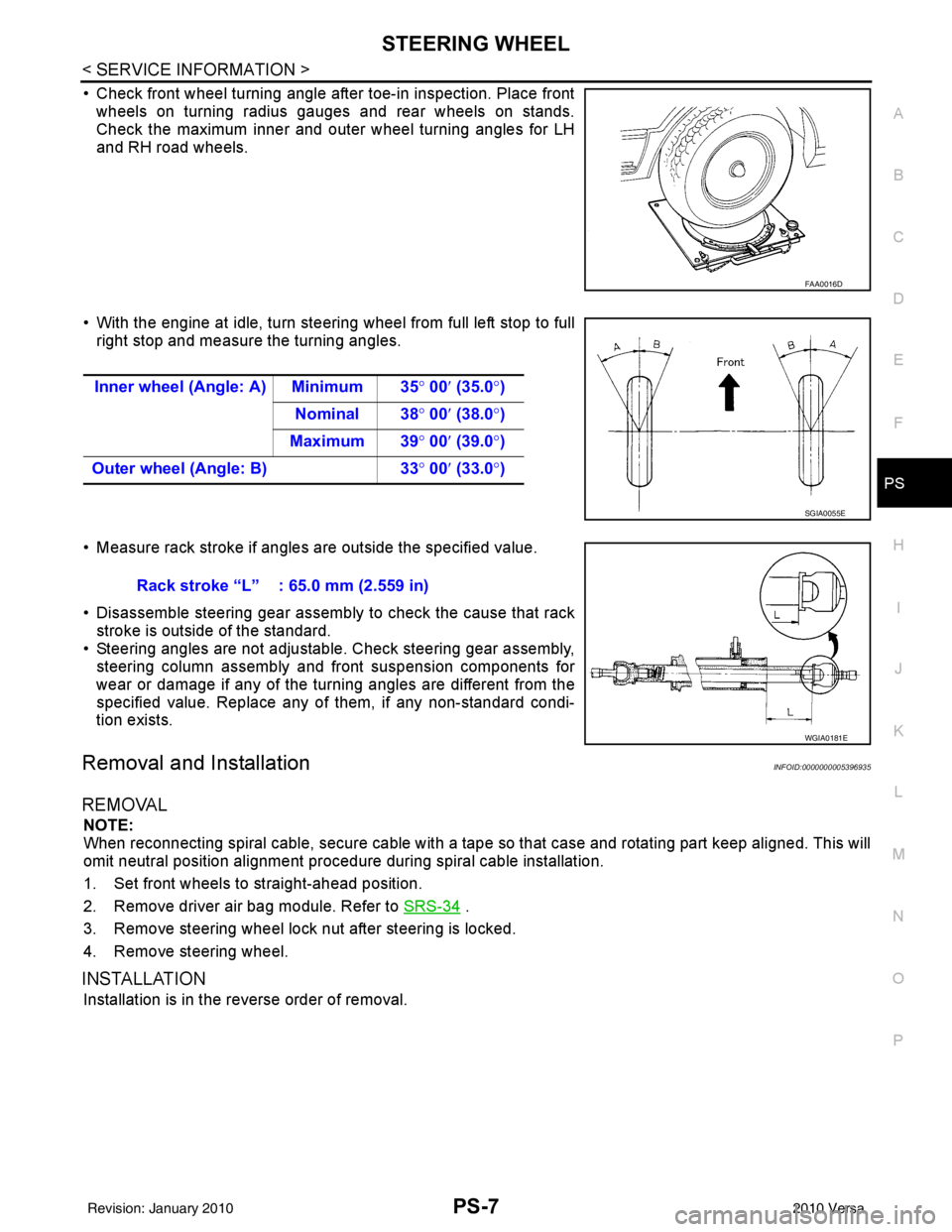

• Check front wheel turning angle after toe-in inspection. Place front wheels on turning radius gauges and rear wheels on stands.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

• With the engine at idle, turn steering wheel from full left stop to full right stop and measure the turning angles.

• Measure rack stroke if angles are outside the specified value.

• Disassemble steering gear assembly to check the cause that rack stroke is outside of the standard.

• Steering angles are not adjustable. Check steering gear assembly, steering column assembly and front suspension components for

wear or damage if any of the turning angles are different from the

specified value. Replace any of them, if any non-standard condi-

tion exists.

Removal and InstallationINFOID:0000000005396935

REMOVAL

NOTE:

When reconnecting spiral cable, secure cable with a tape so that case and rotating part keep aligned. This will

omit neutral position alignment procedure during spiral cable installation.

1. Set front wheels to straight-ahead position.

2. Remove driver air bag module. Refer to SRS-34

.

3. Remove steering wheel lock nut after steering is locked.

4. Remove steering wheel.

INSTALLATION

Installation is in the reverse order of removal.

FAA0016D

Inner wheel (Angle: A) Minimum 35 ° 00 ′ (35.0 °)

Nominal 38° 00′ (38.0 °)

Maximum 39 ° 00 ′ (39.0 °)

Outer wheel (Angle: B) 33° 00 ′ (33.0 °)

SGIA0055E

Rack stroke “L” : 65.0 mm (2.559 in)

WGIA0181E

Revision: January 20102010 Versa

Page 3467 of 3745

STEERING COLUMNPS-9

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

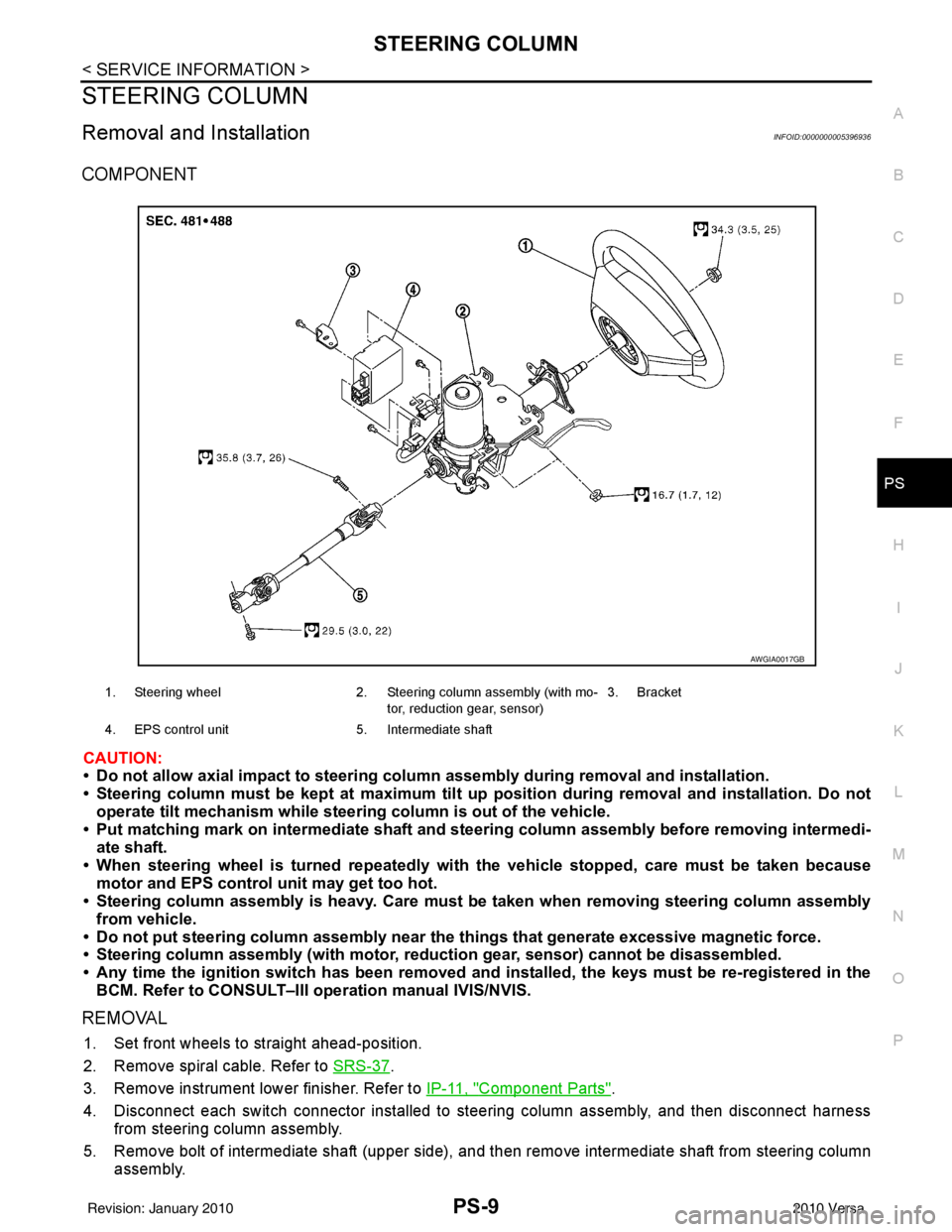

STEERING COLUMN

Removal and InstallationINFOID:0000000005396936

COMPONENT

CAUTION:

• Do not allow axial impact to steering colu mn assembly during removal and installation.

• Steering column must be kept at maximum tilt up position during removal and installation. Do not

operate tilt mechanism while steeri ng column is out of the vehicle.

• Put matching mark on intermediate shaft and st eering column assembly before removing intermedi-

ate shaft.

• When steering wheel is turned re peatedly with the vehicle stopped, care must be taken because

motor and EPS control unit may get too hot.

• Steering column assembly is heavy. Care must be taken when removing steering column assembly

from vehicle.

• Do not put steering column assem bly near the things that generate excessive magnetic force.

• Steering column assembly (with motor, reduc tion gear, sensor) cannot be disassembled.

• Any time the ignition switch h as been removed and installed, the keys must be re-registered in the

BCM. Refer to CONSULT–III ope ration manual IVIS/NVIS.

REMOVAL

1. Set front wheels to straight ahead-position.

2. Remove spiral cable. Refer to SRS-37

.

3. Remove instrument lower finisher. Refer to IP-11, "

Component Parts".

4. Disconnect each switch connector installed to steering column assembly, and then disconnect harness from steering column assembly.

5. Remove bolt of intermediate shaft (upper side), and then remove intermediate shaft from steering column assembly.

1. Steering wheel 2. Steering column assembly (with mo-

tor, reduction gear, sensor) 3. Bracket

4. EPS control unit 5. Intermediate shaft

AWGIA0017GB

Revision: January 20102010 Versa

Page 3470 of 3745

PS-12

< SERVICE INFORMATION >

POWER STEERING GEAR

POWER STEERING GEAR

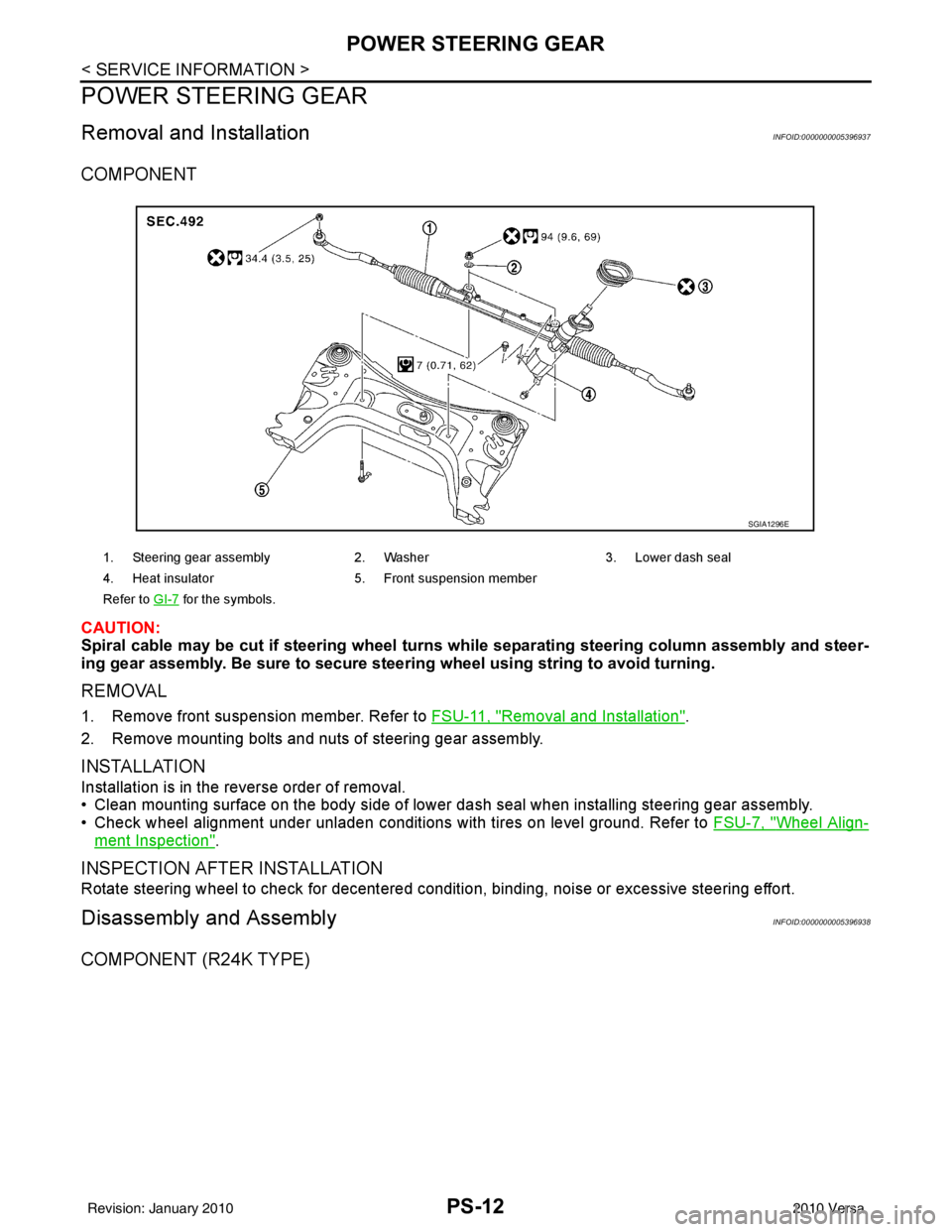

Removal and InstallationINFOID:0000000005396937

COMPONENT

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

REMOVAL

1. Remove front suspension member. Refer to FSU-11, "Removal and Installation".

2. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Clean mounting surface on the body side of lower dash seal when installing steering gear assembly.

• Check wheel alignment under unladen conditions with tires on level ground. Refer to FSU-7, "

Wheel Align-

ment Inspection".

INSPECTION AFTER INSTALLATION

Rotate steering wheel to check for decentered condition, binding, noise or excessive steering effort.

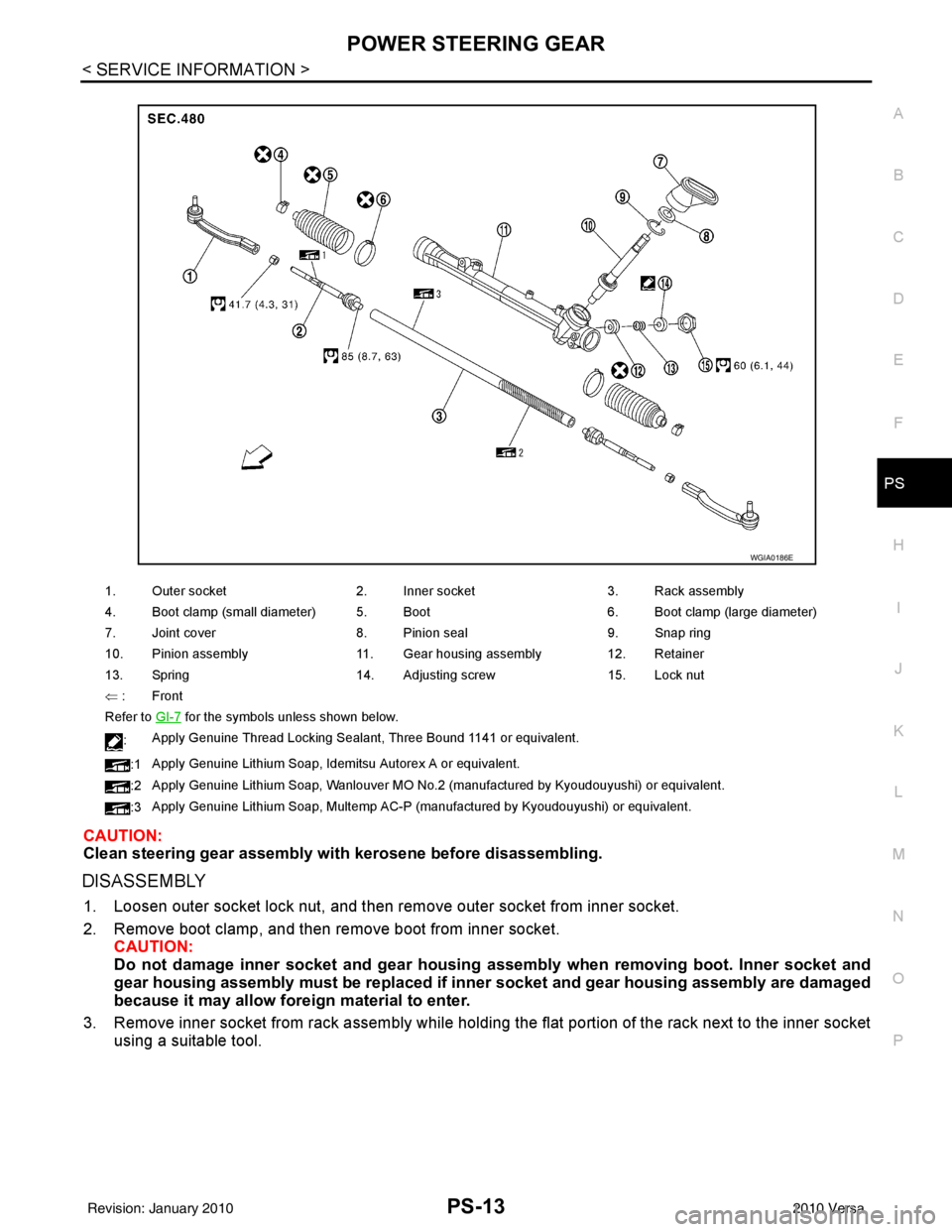

Disassembly and AssemblyINFOID:0000000005396938

COMPONENT (R24K TYPE)

1. Steering gear assembly2. Washer 3. Lower dash seal

4. Heat insulator 5. Front suspension member

Refer to GI-7

for the symbols.

SGIA1296E

Revision: January 20102010 Versa

Page 3471 of 3745

POWER STEERING GEARPS-13

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

CAUTION:

Clean steering gear assembly with kerosene before disassembling.

DISASSEMBLY

1. Loosen outer socket lock nut, and then re move outer socket from inner socket.

2. Remove boot clamp, and then remove boot from inner socket. CAUTION:

Do not damage inner socket an d gear housing assembly when re moving boot. Inner socket and

gear housing assembly must be replaced if inne r socket and gear housing assembly are damaged

because it may allow foreign material to enter.

3. Remove inner socket from rack assembly while holdi ng the flat portion of the rack next to the inner socket

using a suitable tool.

1. Outer socket 2. Inner socket 3. Rack assembly

4. Boot clamp (small diameter) 5. Boot 6. Boot clamp (large diameter)

7. Joint cover 8. Pinion seal 9. Snap ring

10. Pinion assembly 11. Gear housing assembly 12. Retainer

13. Spring 14. Adjusting screw 15. Lock nut

⇐ :Front

Refer to GI-7

for the symbols unless shown below.

: Apply Genuine Thread Locking Sealant, Three Bound 1141 or equivalent.

:1 Apply Genuine Lithium Soap, Idemitsu Autorex A or equivalent.

:2 Apply Genuine Lithium Soap, Wanlouver MO No.2 (manufactured by Kyoudouyushi) or equivalent.

:3 Apply Genuine Lithium Soap, Multemp AC-P (manufactured by Kyoudouyushi) or equivalent.

WGIA0186E

Revision: January 20102010 Versa