Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3324 of 3745

TROUBLE DIAGNOSISMTC-45

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

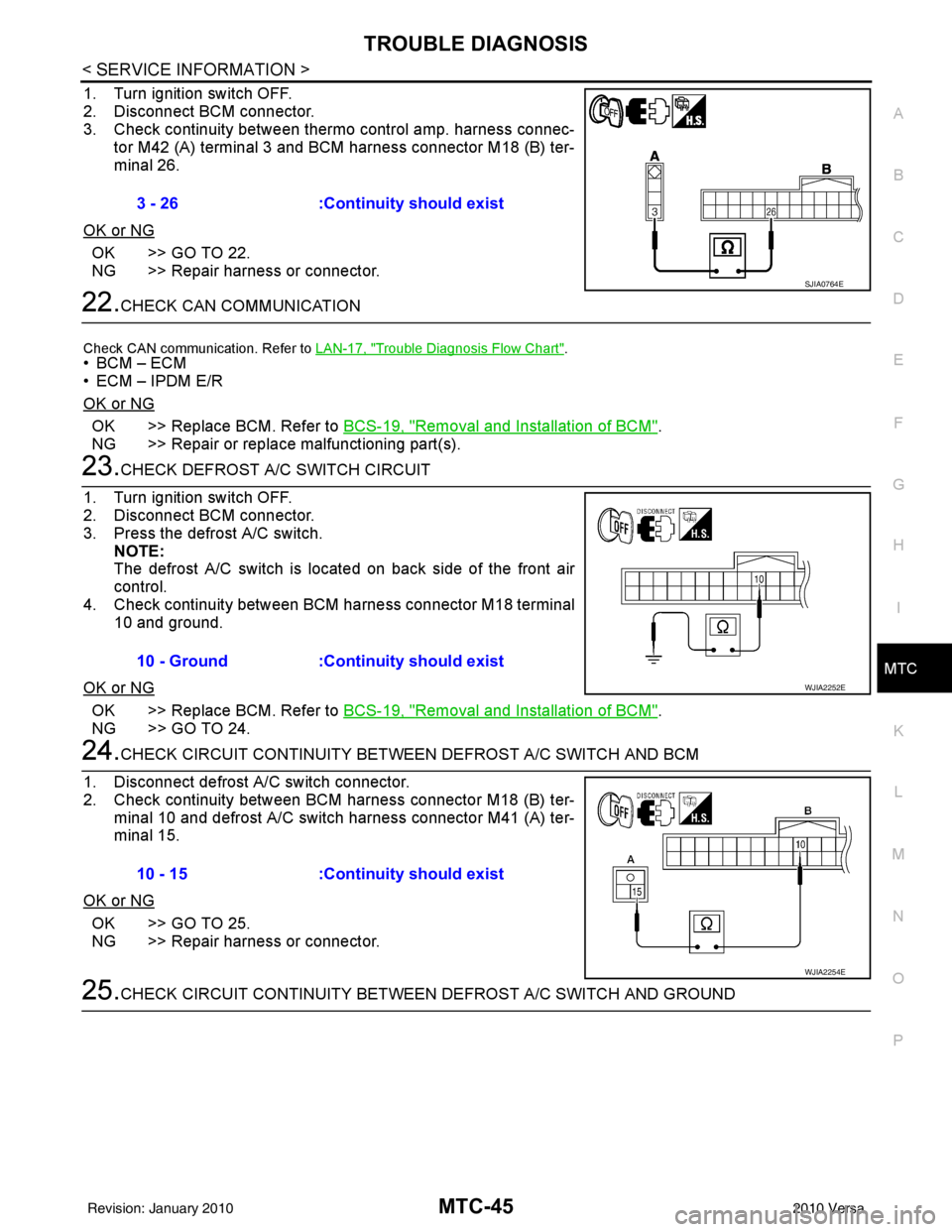

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between thermo control amp. harness connec- tor M42 (A) terminal 3 and BCM harness connector M18 (B) ter-

minal 26.

OK or NG

OK >> GO TO 22.

NG >> Repair harness or connector.

22.CHECK CAN COMMUNICATION

Check CAN communication. Refer to LAN-17, "Trouble Diagnosis Flow Chart".

•BCM – ECM

• ECM – IPDM E/R

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> Repair or replace malfunctioning part(s).

23.CHECK DEFROST A/C SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Press the defrost A/C switch. NOTE:

The defrost A/C switch is located on back side of the front air

control.

4. Check continuity between BCM harness connector M18 terminal 10 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> GO TO 24.

24.CHECK CIRCUIT CONTINUITY BETWEE N DEFROST A/C SWITCH AND BCM

1. Disconnect defrost A/C switch connector.

2. Check continuity between BCM harness connector M18 (B) ter- minal 10 and defrost A/C switch harness connector M41 (A) ter-

minal 15.

OK or NG

OK >> GO TO 25.

NG >> Repair harness or connector.

25.CHECK CIRCUIT CONTINUITY BETWEE N DEFROST A/C SWITCH AND GROUND

3 - 26

:Continuity should exist

SJIA0764E

10 - Ground :Continuity should exist

WJIA2252E

10 - 15:Continuity should exist

WJIA2254E

Revision: January 20102010 Versa

Page 3328 of 3745

TROUBLE DIAGNOSISMTC-49

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

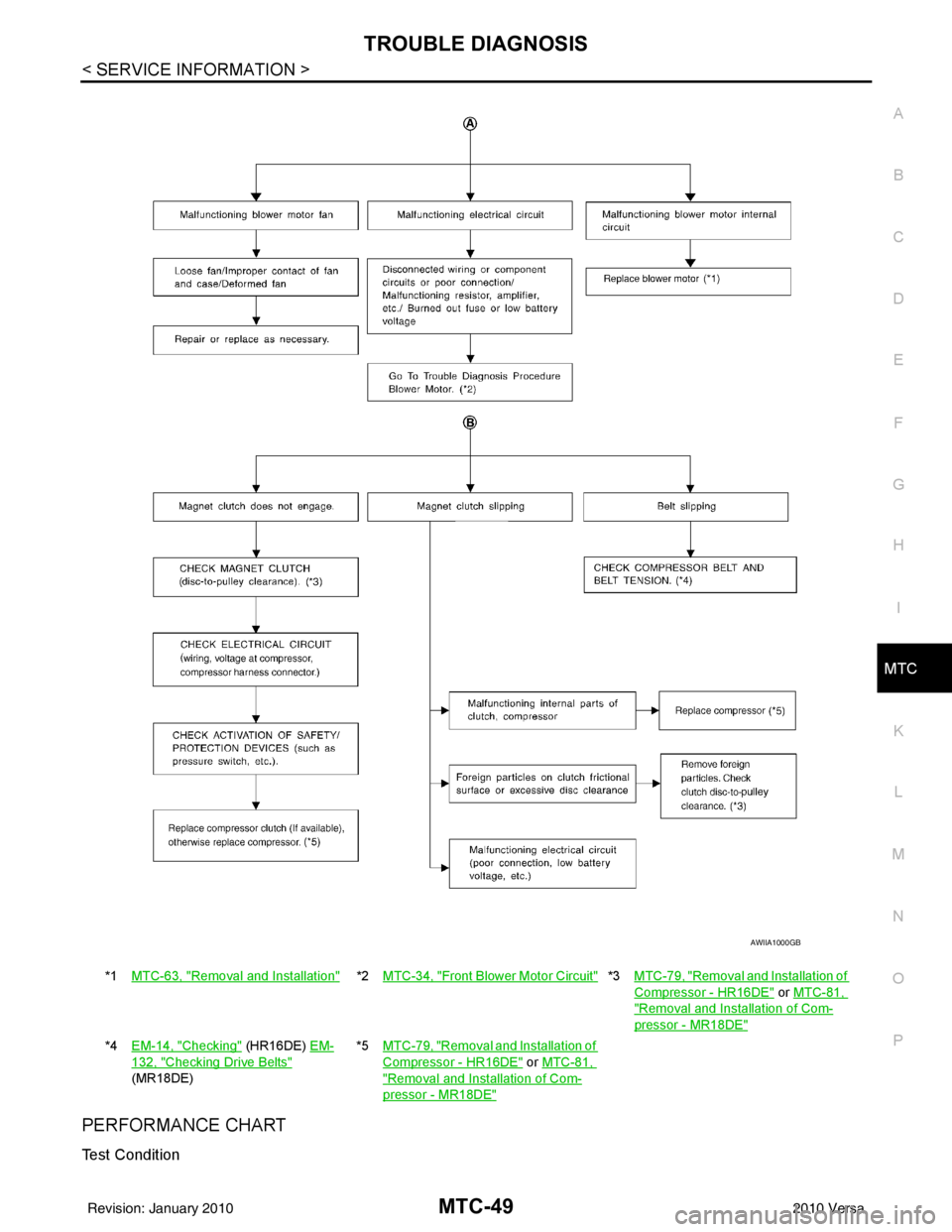

PERFORMANCE CHART

Test Condition

*1 MTC-63, "Removal and Installation"*2MTC-34, "Front Blower Motor Circuit"*3 MTC-79, "Removal and Installation of

Compressor - HR16DE" or MTC-81,

"Removal and Installation of Com-

pressor - MR18DE"

*4 EM-14, "Checking" (HR16DE) EM-

132, "Checking Drive Belts"

(MR18DE) *5

MTC-79, "

Removal and Installation of

Compressor - HR16DE" or MTC-81,

"Removal and Installation of Com-

pressor - MR18DE"

AWIIA1000GB

Revision: January 20102010 Versa

Page 3331 of 3745

MTC-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

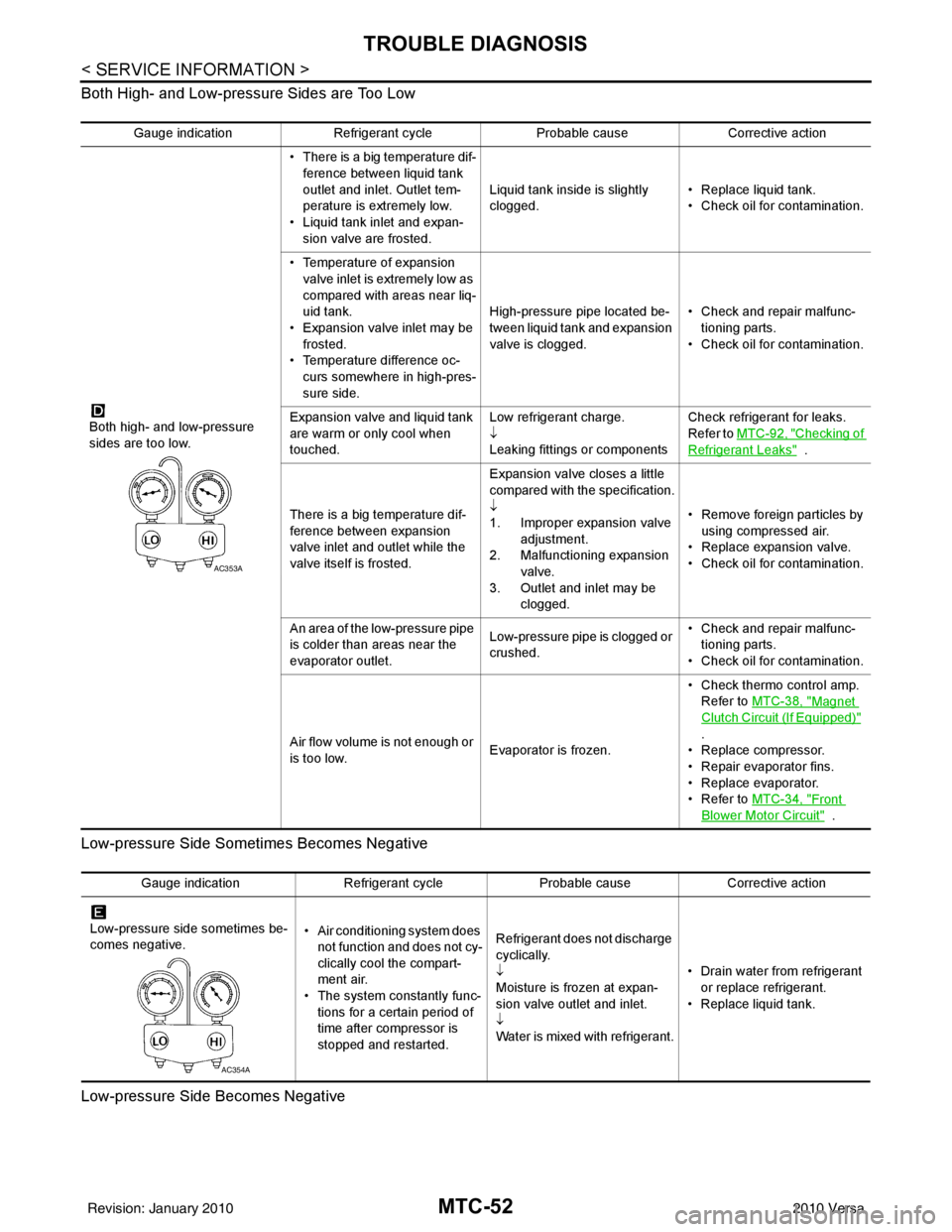

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too low. • There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged.

• Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low as

compared with areas near liq-

uid tank.

• Expansion valve inlet may be

frosted.

• Temperature difference oc- curs somewhere in high-pres-

sure side. High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged.

• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched. Low refrigerant charge.

↓

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to

MTC-92, "

Checking of

Refrigerant Leaks" .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Replace expansion valve.

• Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet. Low-pressure pipe is clogged or

crushed.• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is not enough or

is too low. Evaporator is frozen.• Check thermo control amp.

Refer to MTC-38, "

Magnet

Clutch Circuit (If Equipped)"

.

• Replace compressor.

• Repair evaporator fins.

• Replace evaporator.

•Refer to MTC-34, "

Front

Blower Motor Circuit" .

AC353A

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side sometimes be-

comes negative. • Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted. Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

Revision: January 20102010 Versa

Page 3332 of 3745

TROUBLE DIAGNOSISMTC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Insufficient HeatingINFOID:0000000005396504

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check" .

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to CO-12, "

Inspection" (HR16DE) or CO-36, "Inspection" (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-15, "

Checking Radiator Cap" HR16DE or CO-39, "Checking Radiator

Cap" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

OK or NG

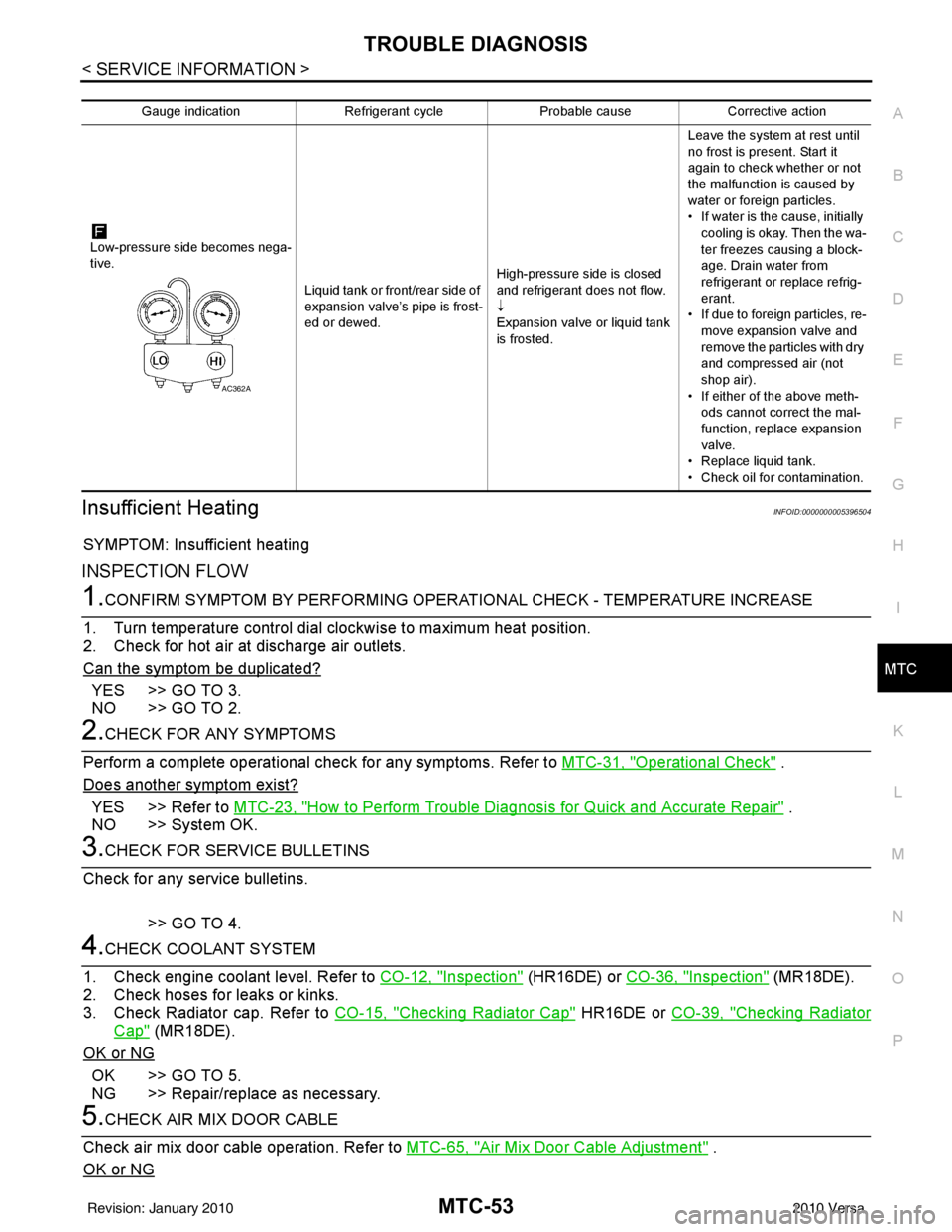

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: January 20102010 Versa

Page 3350 of 3745

DUCTS AND GRILLESMTC-71

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

CENTER VENTILATOR GRILLES

Removal

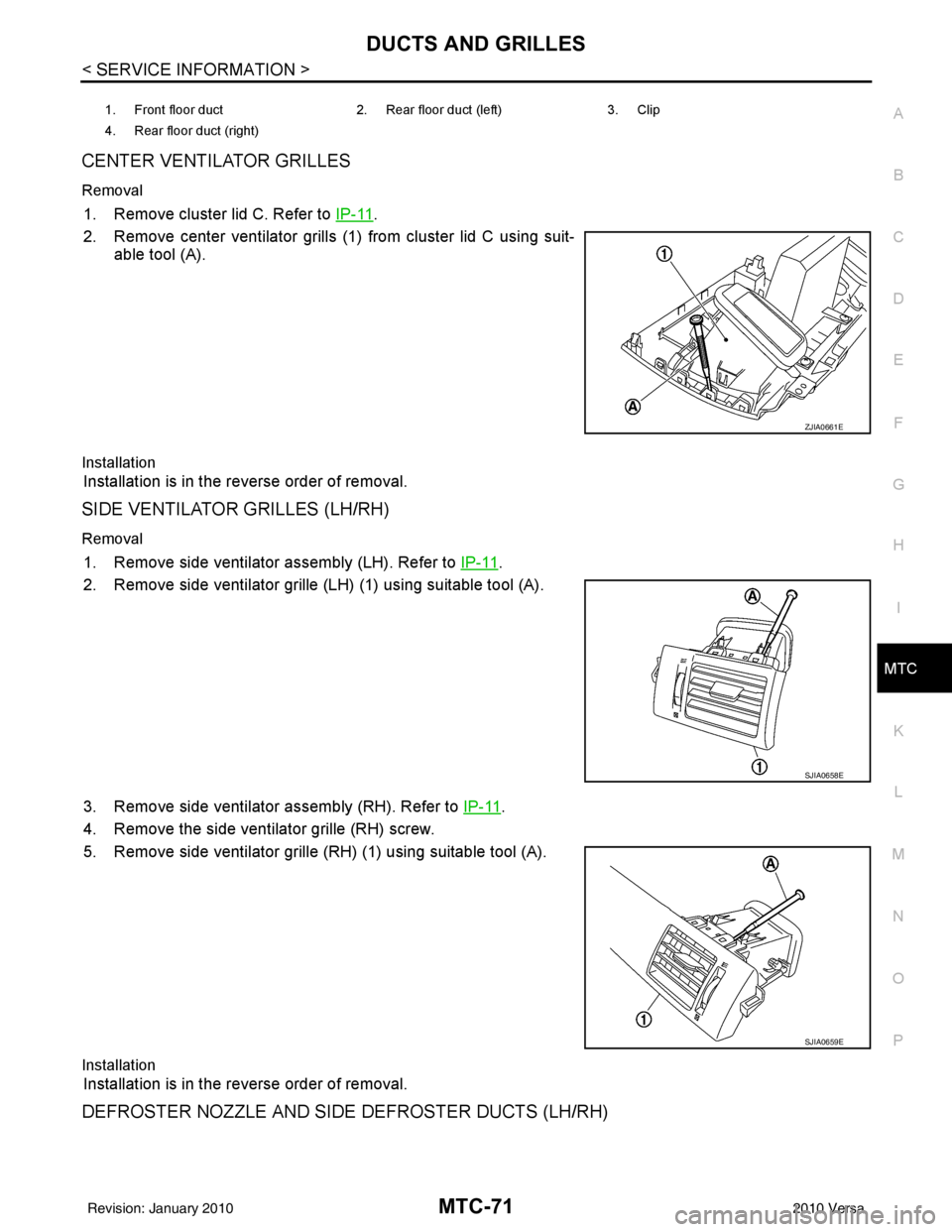

1. Remove cluster lid C. Refer to IP-11.

2. Remove center ventilator grills (1) from cluster lid C using suit- able tool (A).

Installation

Installation is in the reverse order of removal.

SIDE VENTILATOR GRILLES (LH/RH)

Removal

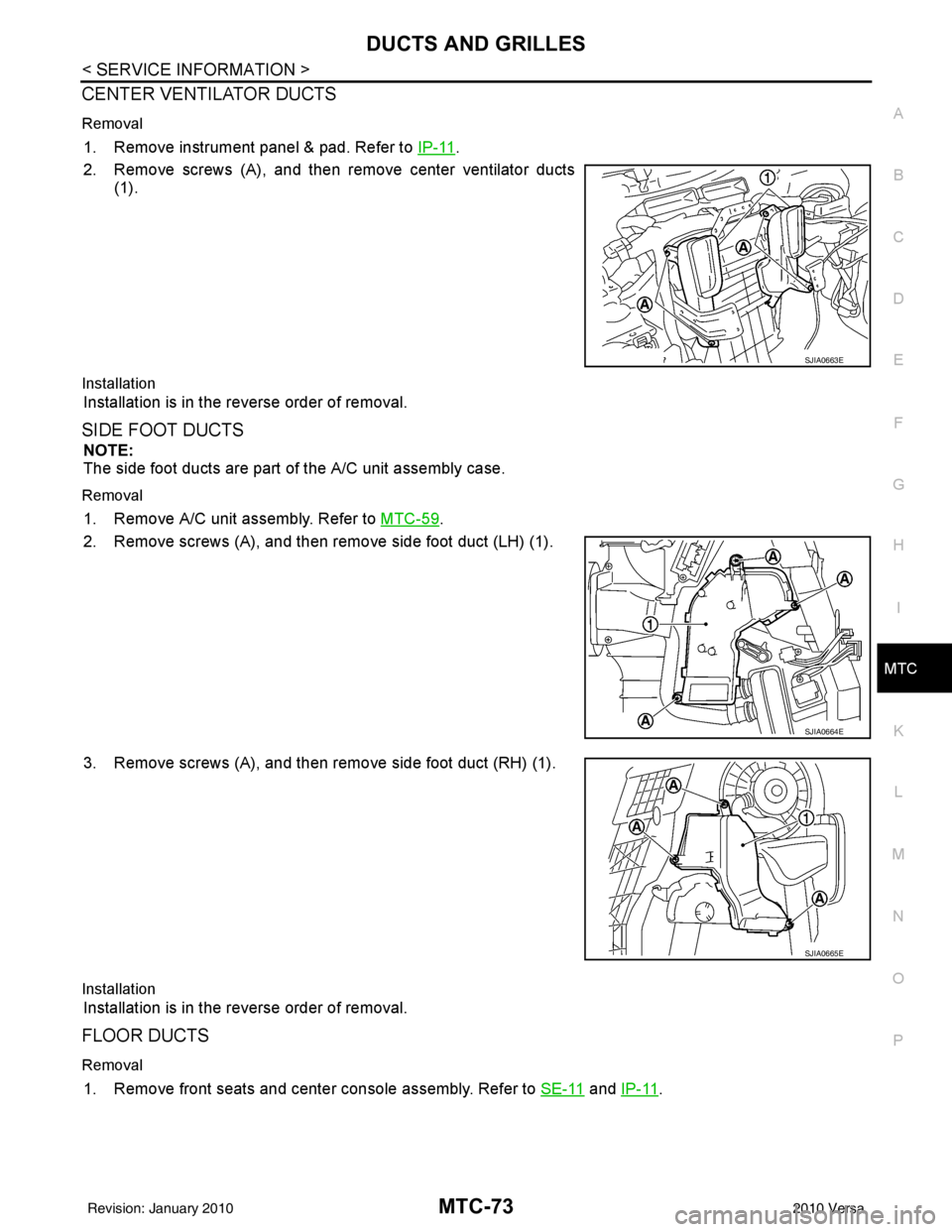

1. Remove side ventilator assembly (LH). Refer to IP-11.

2. Remove side ventilator grille (LH) (1) using suitable tool (A).

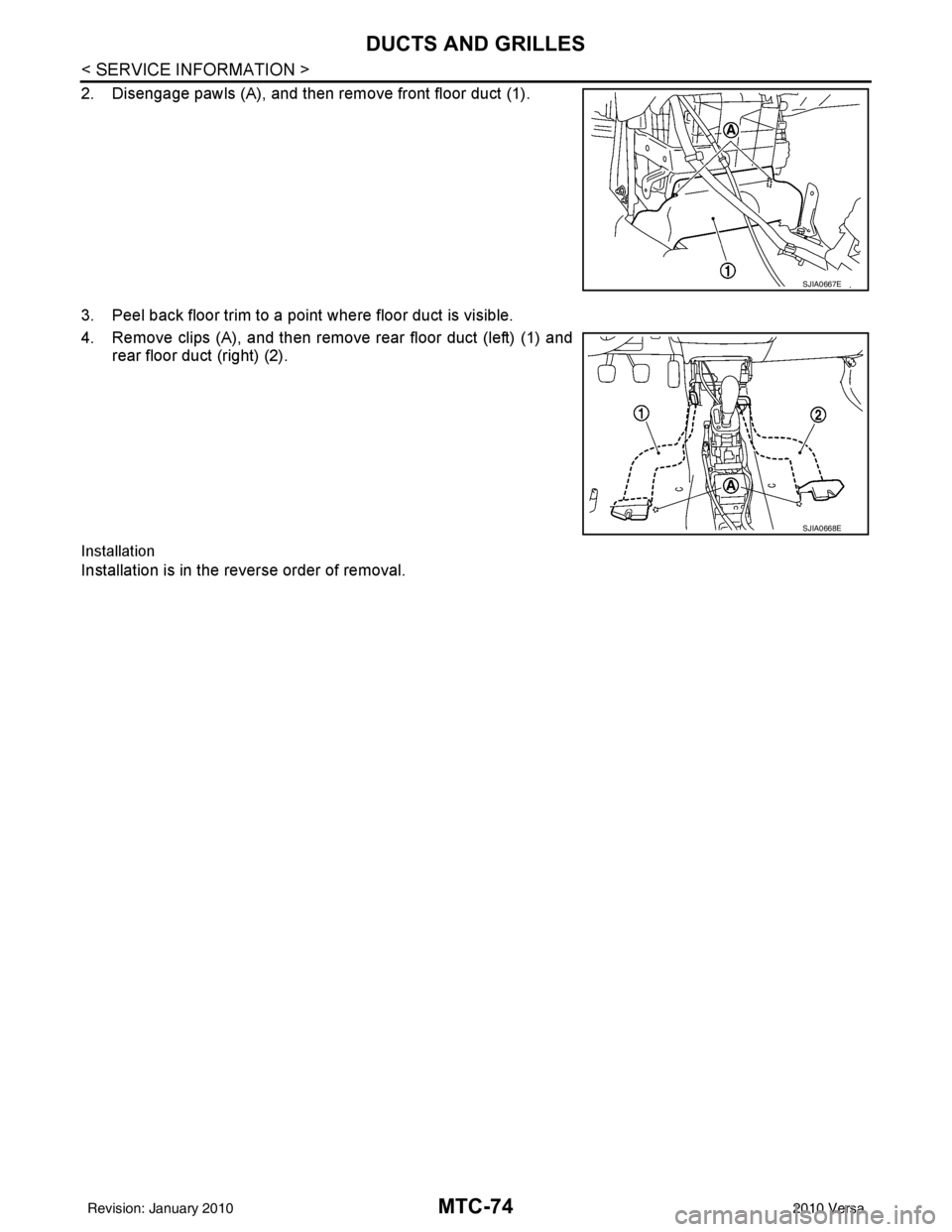

3. Remove side ventilator assembly (RH). Refer to IP-11

.

4. Remove the side ventilator grille (RH) screw.

5. Remove side ventilator grille (RH) (1) using suitable tool (A).

Installation

Installation is in the reverse order of removal.

DEFROSTER NOZZLE AND SIDE DEFROSTER DUCTS (LH/RH)

1. Front floor duct 2. Rear floor duct (left)3. Clip

4. Rear floor duct (right)

ZJIA0661E

SJIA0658E

SJIA0659E

Revision: January 20102010 Versa

Page 3352 of 3745

DUCTS AND GRILLESMTC-73

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

CENTER VENTILATOR DUCTS

Removal

1. Remove instrument panel & pad. Refer to IP-11.

2. Remove screws (A), and then remove center ventilator ducts (1).

Installation

Installation is in the reverse order of removal.

SIDE FOOT DUCTS

NOTE:

The side foot ducts are part of the A/C unit assembly case.

Removal

1. Remove A/C unit assembly. Refer to MTC-59.

2. Remove screws (A), and then remove side foot duct (LH) (1).

3. Remove screws (A), and then remove side foot duct (RH) (1).

Installation

Installation is in the reverse order of removal.

FLOOR DUCTS

Removal

1. Remove front seats and center console assembly. Refer to SE-11 and IP-11.

SJIA0663E

SJIA0664E

SJIA0665E

Revision: January 20102010 Versa

Page 3353 of 3745

MTC-74

< SERVICE INFORMATION >

DUCTS AND GRILLES

2. Disengage pawls (A), and then remove front floor duct (1).

3. Peel back floor trim to a point where floor duct is visible.

4. Remove clips (A), and then remove rear floor duct (left) (1) andrear floor duct (right) (2).

Installation

Installation is in the reverse order of removal.

SJIA0667E

SJIA0668E

Revision: January 20102010 Versa

Page 3362 of 3745

REFRIGERANT LINESMTC-83

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

INSPECTION AFTER REMOVAL

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the cont act surface of the pulley shows signs of excessive

grooving, replace the clutch disc and pulley. The c ontact surfaces of the pulley assembly should be cleaned

with a suitable solvent before installation.

Coil

Check the magnet coil for a loose connection or cracked insulation.

INSTALLATION

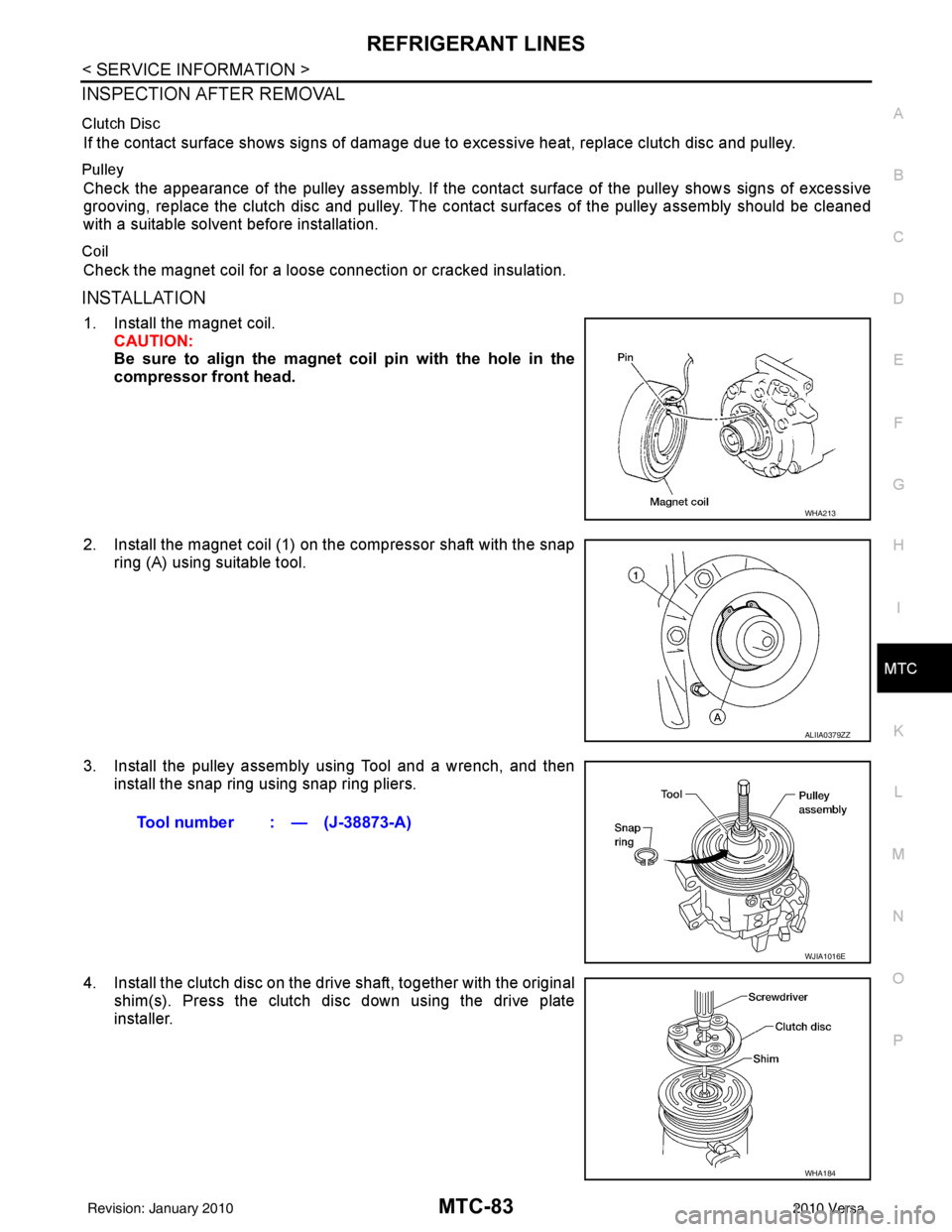

1. Install the magnet coil. CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

2. Install the magnet coil (1) on the compressor shaft with the snap ring (A) using suitable tool.

3. Install the pulley assembly using Tool and a wrench, and then install the snap ring using snap ring pliers.

4. Install the clutch disc on the drive shaft, together with the original shim(s). Press the clutch disc down using the drive plate

installer.

WHA213

ALIIA0379ZZ

Tool number : — (J-38873-A)

WJIA1016E

WHA184

Revision: January 20102010 Versa

Page 3364 of 3745

REFRIGERANT LINESMTC-85

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

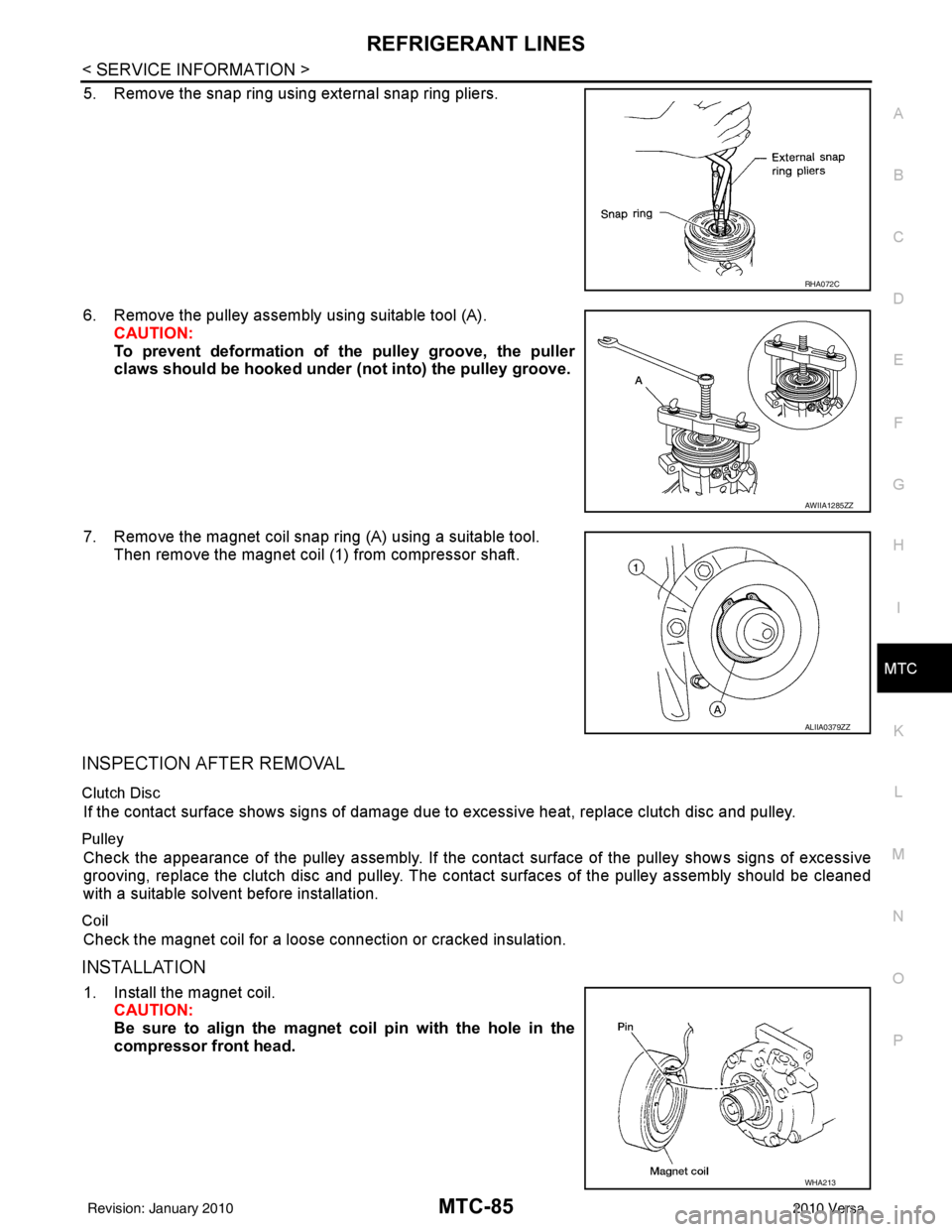

5. Remove the snap ring using external snap ring pliers.

6. Remove the pulley assembly using suitable tool (A). CAUTION:

To prevent deformation of the pulley groove, the puller

claws should be hooked under (not into) the pulley groove.

7. Remove the magnet coil snap ring (A) using a suitable tool. Then remove the magnet coil (1) from compressor shaft.

INSPECTION AFTER REMOVAL

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the cont act surface of the pulley shows signs of excessive

grooving, replace the clutch disc and pulley. The c ontact surfaces of the pulley assembly should be cleaned

with a suitable solvent before installation.

Coil

Check the magnet coil for a loose connection or cracked insulation.

INSTALLATION

1. Install the magnet coil. CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

RHA072C

AWIIA1285ZZ

ALIIA0379ZZ

WHA213

Revision: January 20102010 Versa

Page 3377 of 3745

PB-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005397013

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005397014

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa