srs NISSAN TIIDA 2010 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3280 of 3745

MTC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION MTC

A

B

MTC

N

O P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Oil Precaution ............................................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ......7

Precaution for Service Equipment ....................... ......8

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................11

HFC-134a (R-134a) Service Tool and Equipment ....11

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................15

Refrigerant Cycle ................................................ ....15

Refrigerant System Protection ................................15

Component Part Location ................................... ....16

OIL ......................................................................17

Maintenance of Oil Quantity in Compressor ....... ....17

AIR CONDITIONER CONTROL .........................19

Control Operation ................................................ ....19

Discharge Air Flow ..................................................20

System Description .................................................20

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ............................. ....22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

23

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

23

Schematic ...............................................................26

Wiring Diagram - Heater - .......................................27

Wiring Diagram - A/C,M - .................................... ....28

Operational Check ...................................................31

Mode Door ...............................................................32

Air Mix Door .............................................................33

Intake Door ..............................................................34

Front Blower Motor Circuit .......................................34

Magnet Clutch Circuit (If Equipped) ..................... ....38

Insufficient Cooling ..................................................46

Insufficient Heating ..................................................53

Noise .......................................................................54

CONTROLLER ..................................................56

Removal and Installation .........................................56

Disassembly and Assembly .....................................57

THERMO CONTROL AMPLIFIER ....................58

Removal and Installation .........................................58

A/C UNIT ASSEMBLY ......................................59

Removal and Installation .........................................59

Disassembly and Assembly .....................................61

BLOWER MOTOR ............................................63

Removal and Installation .........................................63

INTAKE DOOR ..................................................64

Intake Door Cable Adjustment .................................64

AIR MIX DOOR .................................................65

Air Mix Door Cable Adjustment ...............................65

MODE DOOR ....................................................66

Mode Door Cable Adjustment .................................66

BLOWER FAN RESISTOR ...............................67

Removal and Installation .........................................67

HEATER CORE .................................................68

Removal and Installation .........................................68

AIR CONDITIONER FILTER .............................69

Removal and Installation .........................................69

Revision: January 20102010 Versa

Page 3282 of 3745

PRECAUTIONSMTC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006022079

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005396473

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3376 of 3745

PB-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION PB

A

B

PB

N

O P

CONTENTS

PARKING BRAKE SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Commercial Service Tool .................................... .....4

PARKING BRAKE CONTROL ...........................5

On-Vehicle Service ...................................................5

Component ...............................................................6

Removal and Installation ..........................................6

SERVICE DATA AND SPECIFICATIONS

(SDS) ..................................................................

8

Parking Brake Control ..............................................8

Revision: January 20102010 Versa

Page 3377 of 3745

PB-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005397013

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005397014

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3384 of 3745

PG-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION PG

A

B

PG

N

O P

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

POWER SUPPLY ROUTING CIRCUIT ...............4

Schematic ........................................................... ......4

Wiring Diagram - POWER - ......................................6

Fuse ........................................................................16

Fusible Link .............................................................16

Circuit Breaker (Built Into BCM) ..............................16

Circuit Breaker ........................................................16

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

System Description ............................................. ....17

CAN Communication System Description ...............18

Function of Detecting Ignition Relay Malfunction ....18

CONSULT-III Function (IPDM E/R) ..................... ....18

Auto Active Test ......................................................20

IPDM E/R Terminal Arrangement - Type A .............23

IPDM E/R Terminal Arrangement - Type B .............24

Terminal and Reference Value for IPDM E/R .........25

IPDM E/R Power/Ground Circuit Inspection ...........27

Inspection with CONSULT-III (Self-Diagnosis) .......28

Removal and Installation of IPDM E/R ................ ....28

GROUND CIRCUIT ...........................................30

Ground Distribution .............................................. ....30

HARNESS .........................................................39

Harness Layout ................................................... ....39

Wiring Diagram Codes (Cell Codes) .......................59

ELECTRICAL UNITS LOCATION ....................62

Electrical Units Location ..........................................62

HARNESS CONNECTOR .................................66

Description ...............................................................66

ELECTRICAL UNITS ........................................69

Terminal Arrangement .............................................69

STANDARDIZED RELAY .................................70

Description ...............................................................70

SUPER MULTIPLE JUNCTION (SMJ) .............72

Terminal Arrangement .............................................72

FUSE BLOCK-JUNCTION BOX (J/B) ..............74

Terminal Arrangement .............................................74

FUSE AND FUSIBLE LINK BOX ......................75

Terminal Arrangement .............................................75

Revision: January 20102010 Versa

Page 3385 of 3745

PG-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005395347

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005995526

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3443 of 3745

PG-60

< SERVICE INFORMATION >

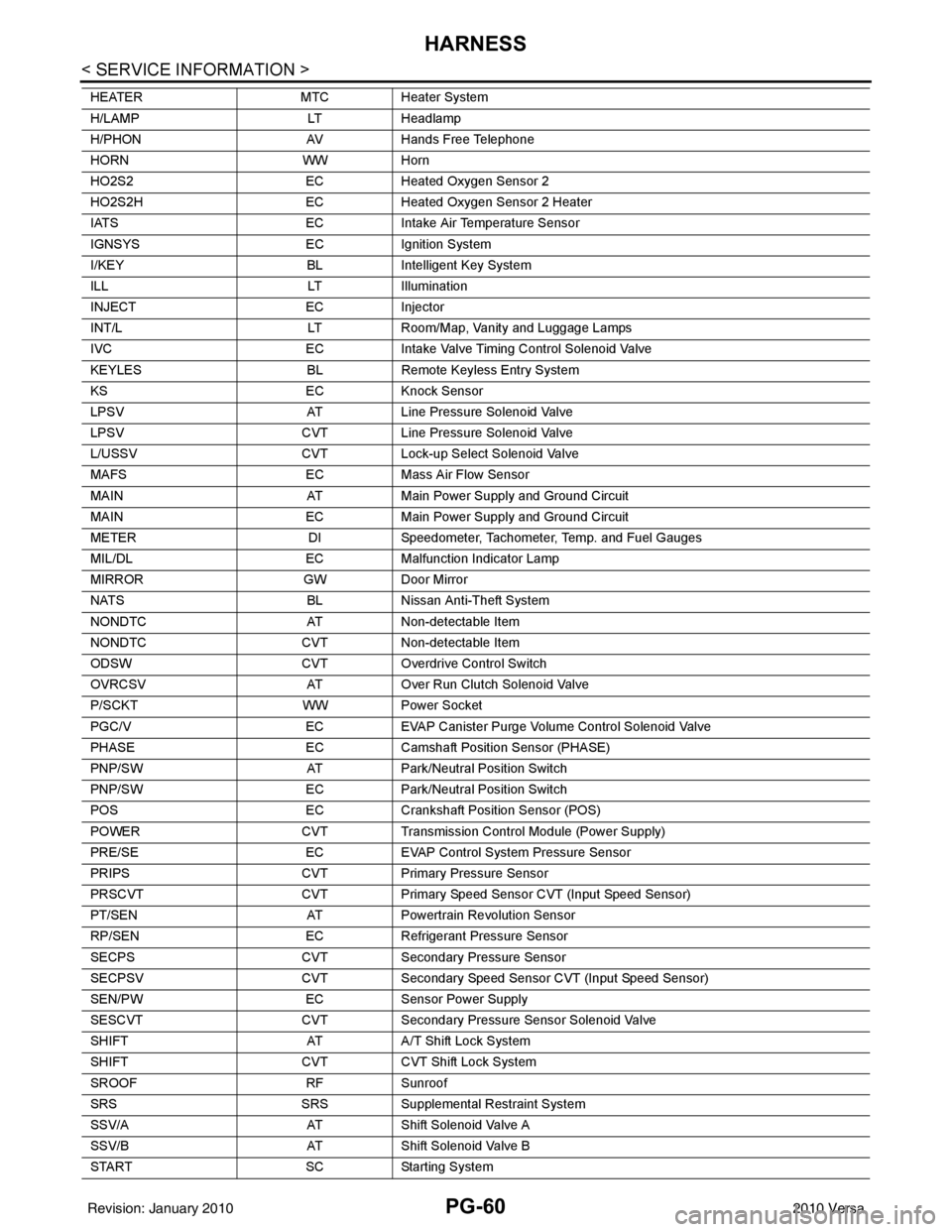

HARNESS

HEATERMTC Heater System

H/LAMP LT Headlamp

H/PHON AV Hands Free Telephone

HORN WW Horn

HO2S2 EC Heated Oxygen Sensor 2

HO2S2H EC Heated Oxygen Sensor 2 Heater

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

I/KEY BL Intelligent Key System

ILL LT Illumination

INJECT EC Injector

INT/L LT Room/Map, Vanity and Luggage Lamps

IVC EC Intake Valve Timing Control Solenoid Valve

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

LPSV AT Line Pressure Solenoid Valve

LPSV CVT Line Pressure Solenoid Valve

L/USSV CVT Lock-up Select Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp

MIRROR GW Door Mirror

NATS BL Nissan Anti-Theft System

NONDTC AT Non-detectable Item

NONDTC CVT Non-detectable Item

ODSW CVT Overdrive Control Switch

OVRCSV AT Over Run Clutch Solenoid Valve

P/SCKT WW Power Socket

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW AT Park/Neutral Position Switch

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER CVT Transmission Control Module (Power Supply)

PRE/SE EC EVAP Control System Pressure Sensor

PRIPS CVT Primary Pressure Sensor

PRSCVT CVT Primary Speed Sensor CVT (Input Speed Sensor)

PT/SEN AT Powertrain Revolution Sensor

RP/SEN EC Refrigerant Pressure Sensor

SECPS CVT Secondary Pressure Sensor

SECPSV CVT Secondary Speed Sensor CVT (Input Speed Sensor)

SEN/PW EC Sensor Power Supply

SESCVT CVT Secondary Pressu re Sensor Solenoid Valve

SHIFT AT A/T Shift Lock System

SHIFT CVT CVT Shift Lock System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

Revision: January 20102010 Versa

Page 3451 of 3745

PG-68

< SERVICE INFORMATION >

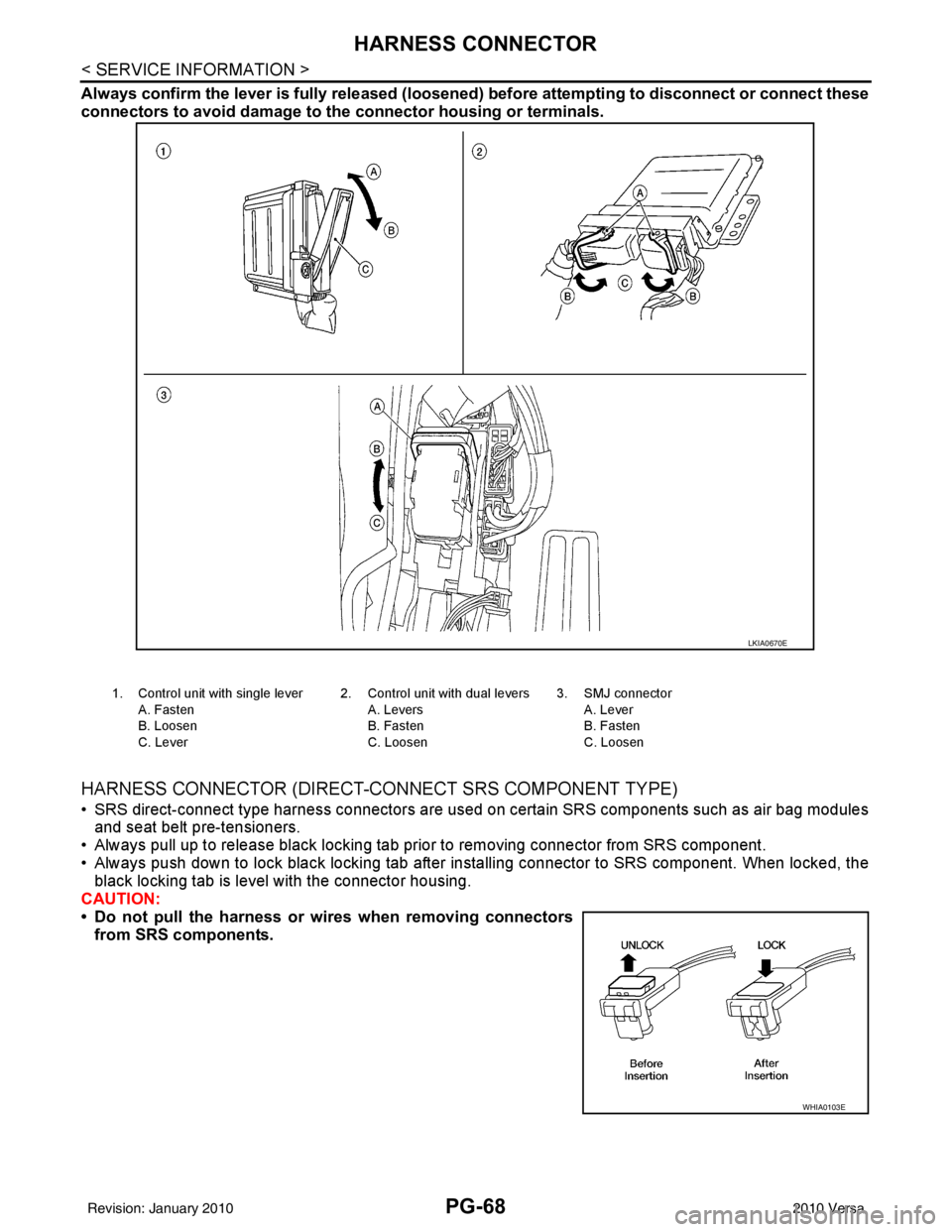

HARNESS CONNECTOR

Always confirm the lever is fully released (loosened) before attempti ng to disconnect or connect these

connectors to avoid damage to th e connector housing or terminals.

HARNESS CONNECTOR (DIRECT-CONNECT SRS COMPONENT TYPE)

• SRS direct-connect type harness connectors are used on certain SRS components such as air bag modules

and seat belt pre-tensioners.

• Always pull up to release black locking tab prior to removing connector from SRS component.

• Always push down to lock black locking tab after installing connector to SRS component. When locked, the

black locking tab is level with the connector housing.

CAUTION:

• Do not pull the harness or wi res when removing connectors

from SRS components.

LKIA0670E

1. Control unit with single lever

A. Fasten

B. Loosen

C. Lever 2. Control unit with dual levers

A. Levers

B. Fasten

C. Loosen 3. SMJ connector

A. Lever

B. Fasten

C. Loosen

WHIA0103E

Revision: January 20102010 Versa

Page 3459 of 3745

PS-1

STEERING

C

DE

F

H I

J

K L

M

SECTION PS

A

B

PS

N

O P

CONTENTS

POWER STEERING SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Steering System .......................... ......3

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

STEERING WHEEL ...........................................6

On-Vehicle Inspection and Service ..................... .....6

Removal and Installation ..........................................7

STEERING COLUMN .........................................9

Removal and Installation ..........................................9

POWER STEERING GEAR ..............................12

Removal and Installation .........................................12

Disassembly and Assembly .....................................12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Steering Wheel ........................................................17

Steering Angle .........................................................17

Steering Column ......................................................17

Steering Outer Socket and Inner Socket .................17

Steering Gear ...................................................... ....18

Revision: January 20102010 Versa

Page 3460 of 3745

PS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713822

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005396929

NOTE:

• This procedure is applied only to models with Intel ligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition switch in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa