Anchor NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 259 of 3745

AT-242

< SERVICE INFORMATION >

OVERHAUL

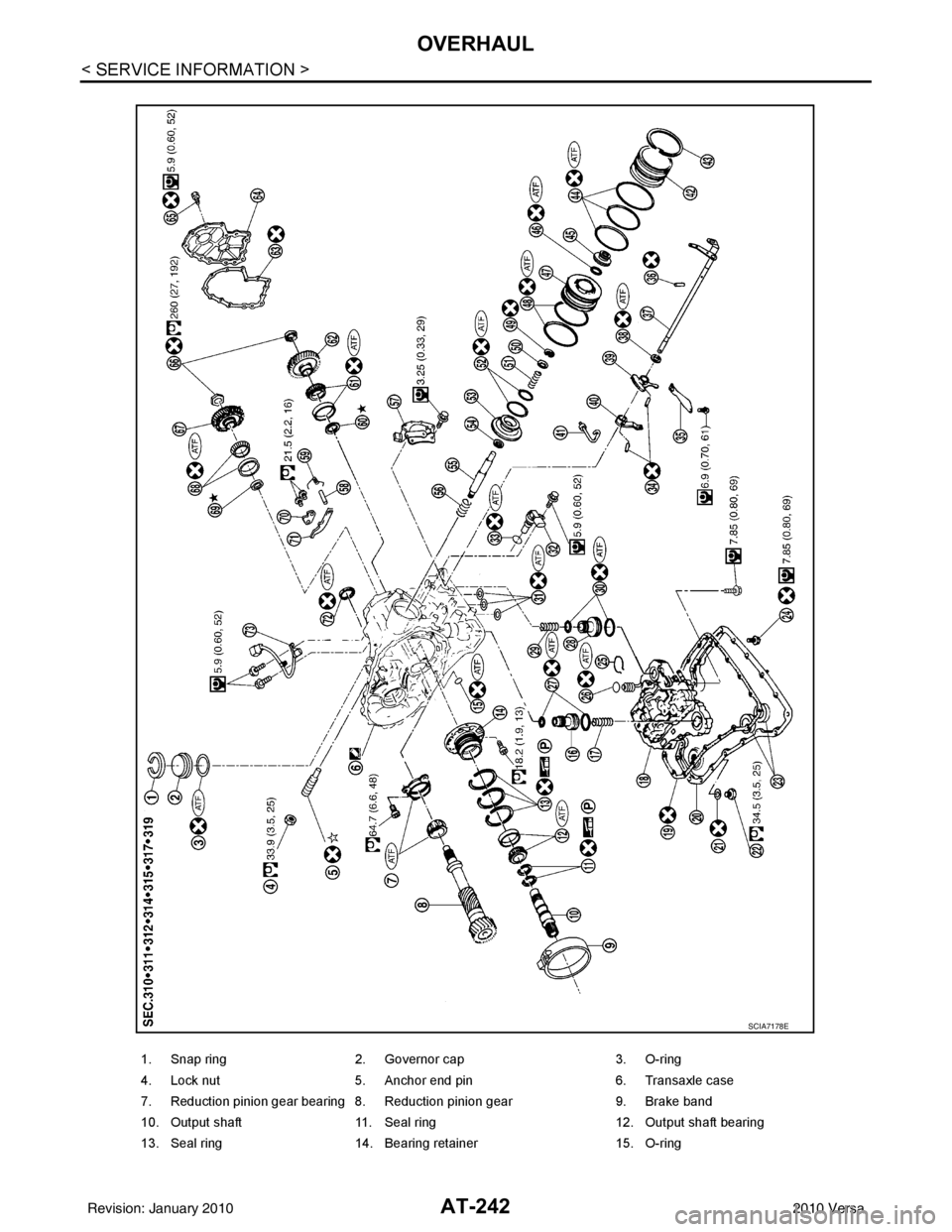

1. Snap ring2. Governor cap 3. O-ring

4. Lock nut 5. Anchor end pin 6. Transaxle case

7. Reduction pinion gear bearing 8. Reduction pinion gear 9. Brake band

10. Output shaft 11. Seal ring 12. Output shaft bearing

13. Seal ring 14. Bearing retainer 15. O-ring

SCIA7178E

Revision: January 20102010 Versa

Page 266 of 3745

OVERHAULAT-249

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

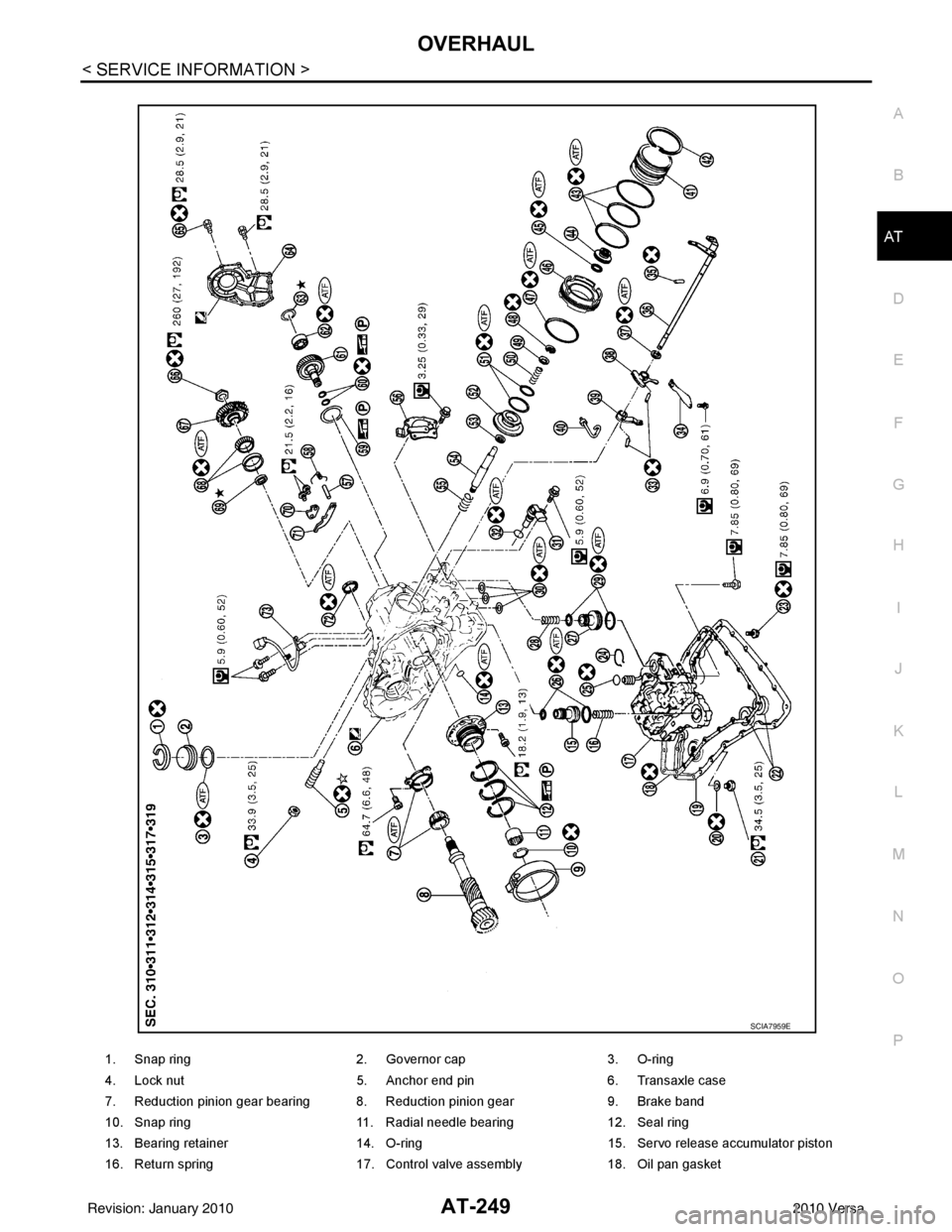

1. Snap ring 2. Governor cap3. O-ring

4. Lock nut 5. Anchor end pin6. Transaxle case

7. Reduction pinion gear bearing 8. Reduction pinion gear 9. Brake band

10. Snap ring 11. Radial needle bearing12. Seal ring

13. Bearing retainer 14. O-ring15. Servo release accumulator piston

16. Return spring 17. Control valve assembly18. Oil pan gasket

SCIA7959E

Revision: January 20102010 Versa

Page 281 of 3745

AT-264

< SERVICE INFORMATION >

DISASSEMBLY

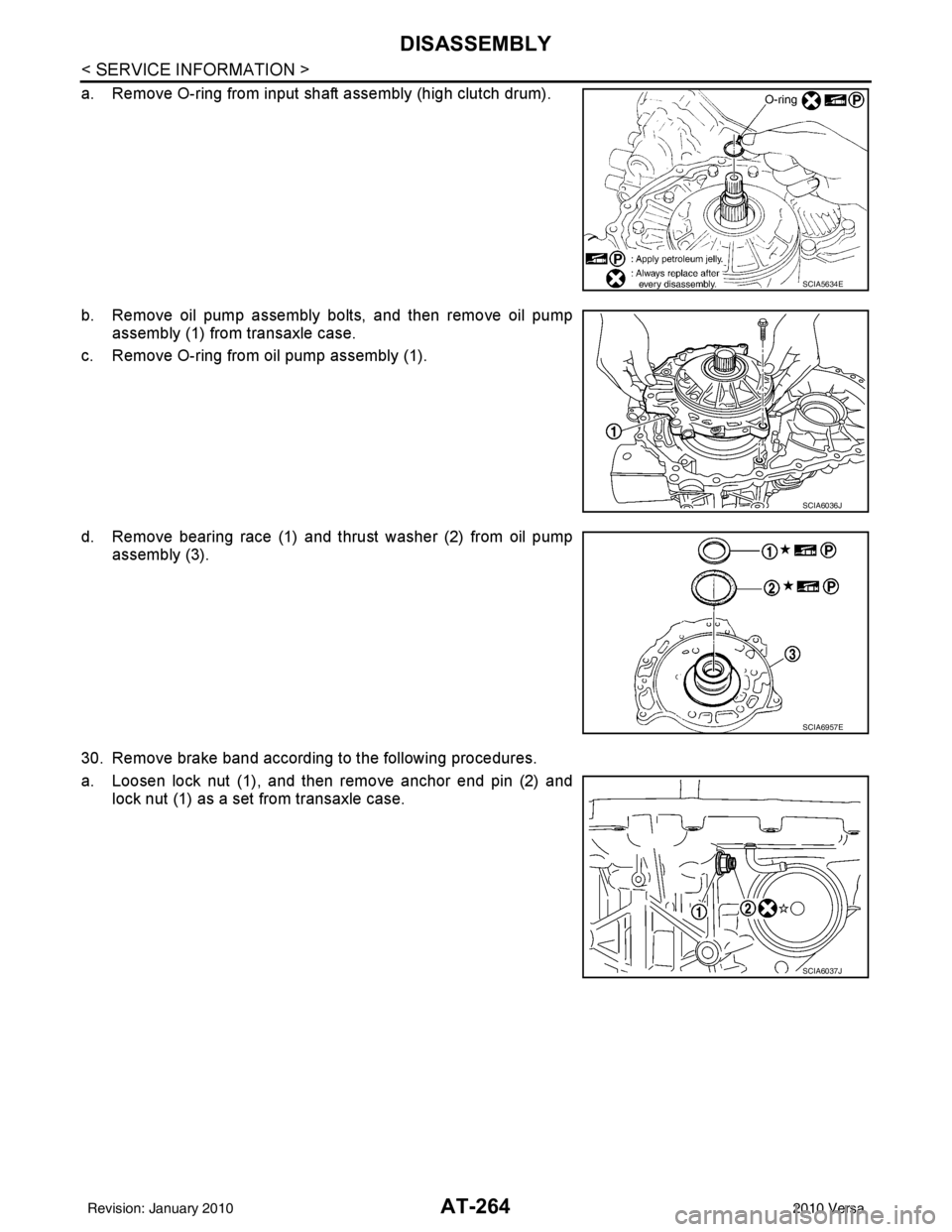

a. Remove O-ring from input shaft assembly (high clutch drum).

b. Remove oil pump assembly bolts, and then remove oil pumpassembly (1) from transaxle case.

c. Remove O-ring from oil pump assembly (1).

d. Remove bearing race (1) and thrust washer (2) from oil pump assembly (3).

30. Remove brake band according to the following procedures.

a. Loosen lock nut (1), and then remove anchor end pin (2) and lock nut (1) as a set from transaxle case.

SCIA5634E

SCIA6036J

SCIA6957E

SCIA6037J

Revision: January 20102010 Versa

Page 348 of 3745

REPAIR FOR COMPONENT PARTSAT-331

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

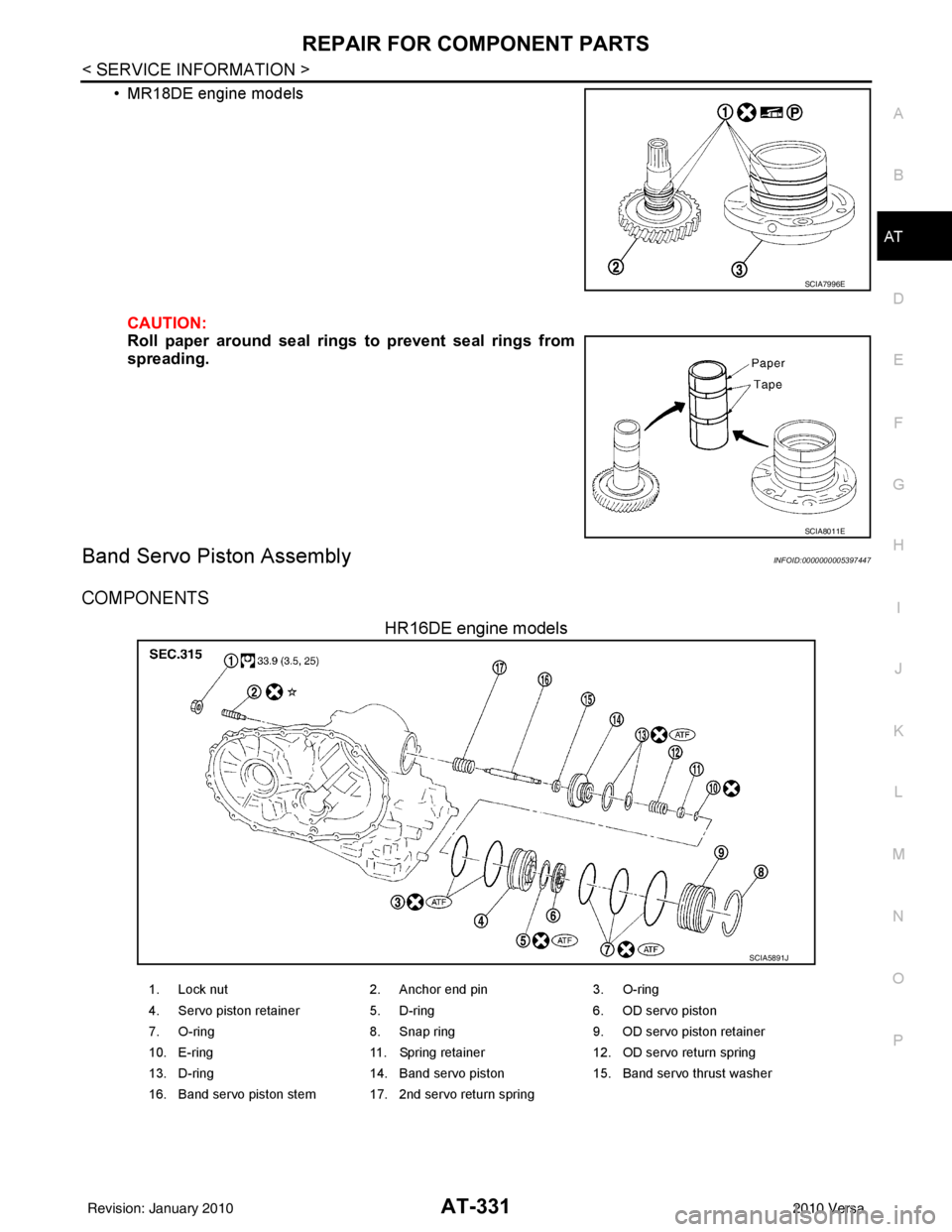

• MR18DE engine models

CAUTION:

Roll paper around seal ring s to prevent seal rings from

spreading.

Band Servo Piston AssemblyINFOID:0000000005397447

COMPONENTS

HR16DE engine models

SCIA7996E

SCIA8011E

SCIA5891J

1. Lock nut 2. Anchor end pin 3. O-ring

4. Servo piston retainer 5. D-ring 6. OD servo piston

7. O-ring 8. Snap ring 9. OD servo piston retainer

10. E-ring 11. Spring retainer 12. OD servo return spring

13. D-ring 14. Band servo piston 15. Band servo thrust washer

16. Band servo piston stem 17. 2nd servo return spring

Revision: January 20102010 Versa

Page 349 of 3745

AT-332

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

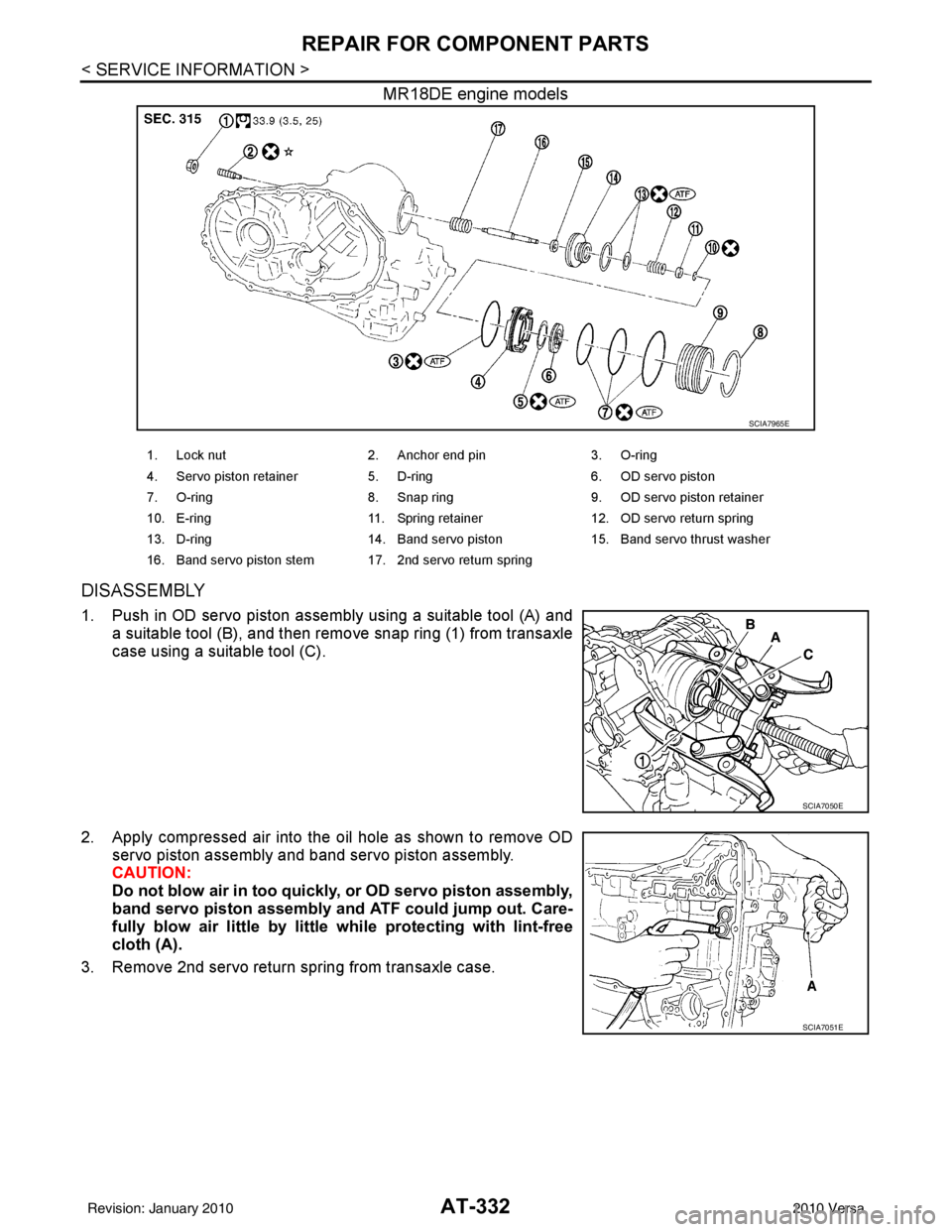

MR18DE engine models

DISASSEMBLY

1. Push in OD servo piston assembly using a suitable tool (A) anda suitable tool (B), and then remove snap ring (1) from transaxle

case using a suitable tool (C).

2. Apply compressed air into the oil hole as shown to remove OD servo piston assembly and band servo piston assembly.

CAUTION:

Do not blow air in too quickly, or OD servo piston assembly,

band servo piston assembly and ATF could jump out. Care-

fully blow air little by little while protecting with lint-free

cloth (A).

3. Remove 2nd servo return spring from transaxle case.

SCIA7965E

1. Lock nut 2. Anchor end pin 3. O-ring

4. Servo piston retainer 5. D-ring 6. OD servo piston

7. O-ring 8. Snap ring 9. OD servo piston retainer

10. E-ring 11. Spring retainer 12. OD servo return spring

13. D-ring 14. Band servo piston 15. Band servo thrust washer

16. Band servo piston stem 17. 2nd servo return spring

SCIA7050E

SCIA7051E

Revision: January 20102010 Versa

Page 381 of 3745

AT-364

< SERVICE INFORMATION >

ASSEMBLY

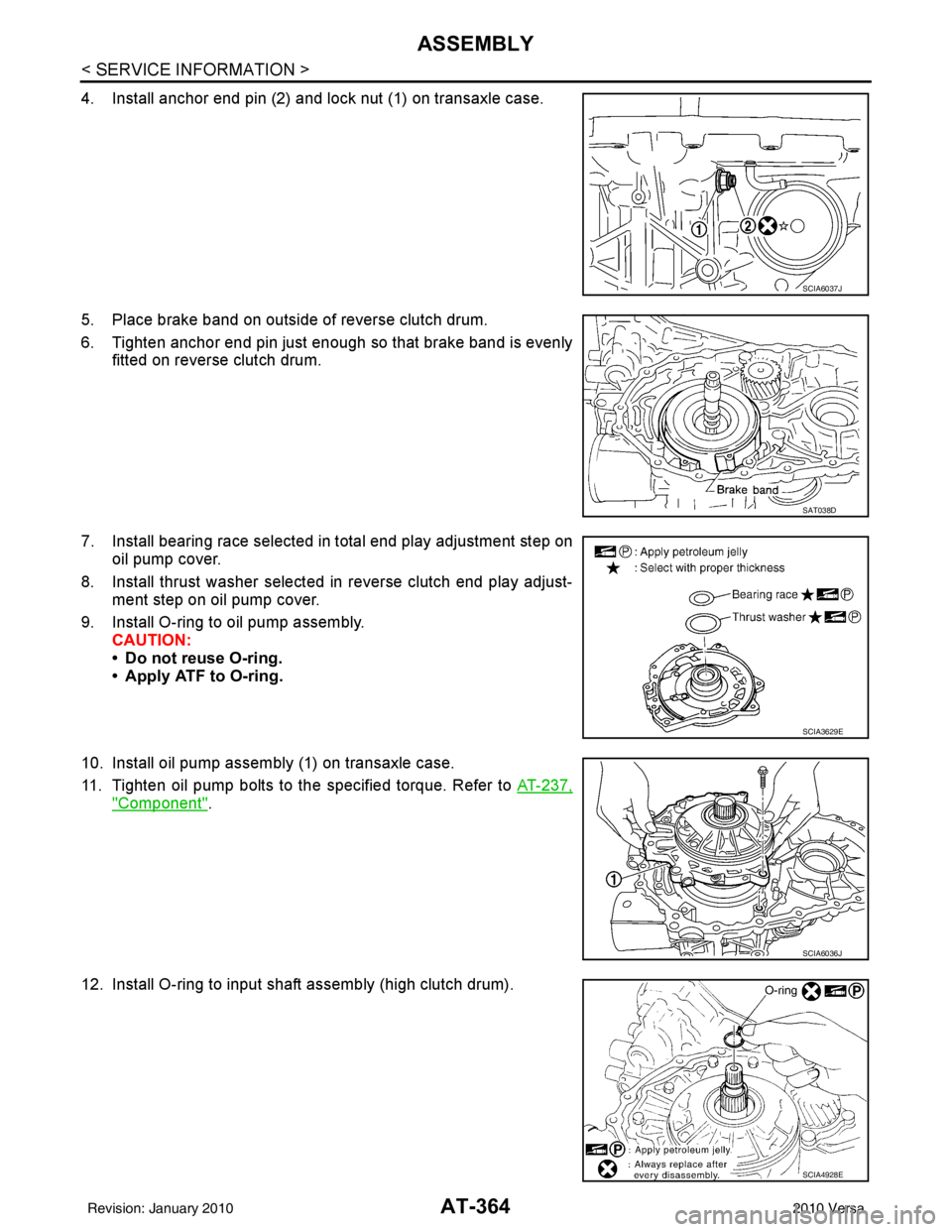

4. Install anchor end pin (2) and lock nut (1) on transaxle case.

5. Place brake band on outside of reverse clutch drum.

6. Tighten anchor end pin just enough so that brake band is evenlyfitted on reverse clutch drum.

7. Install bearing race selected in total end play adjustment step on oil pump cover.

8. Install thrust washer selected in reverse clutch end play adjust- ment step on oil pump cover.

9. Install O-ring to oil pump assembly. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

10. Install oil pump assembly (1) on transaxle case.

11. Tighten oil pump bolts to the specified torque. Refer to AT-237,

"Component".

12. Install O-ring to input shaft assembly (high clutch drum).

SCIA6037J

SAT038D

SCIA3629E

SCIA6036J

SCIA4928E

Revision: January 20102010 Versa

Page 382 of 3745

ASSEMBLYAT-365

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

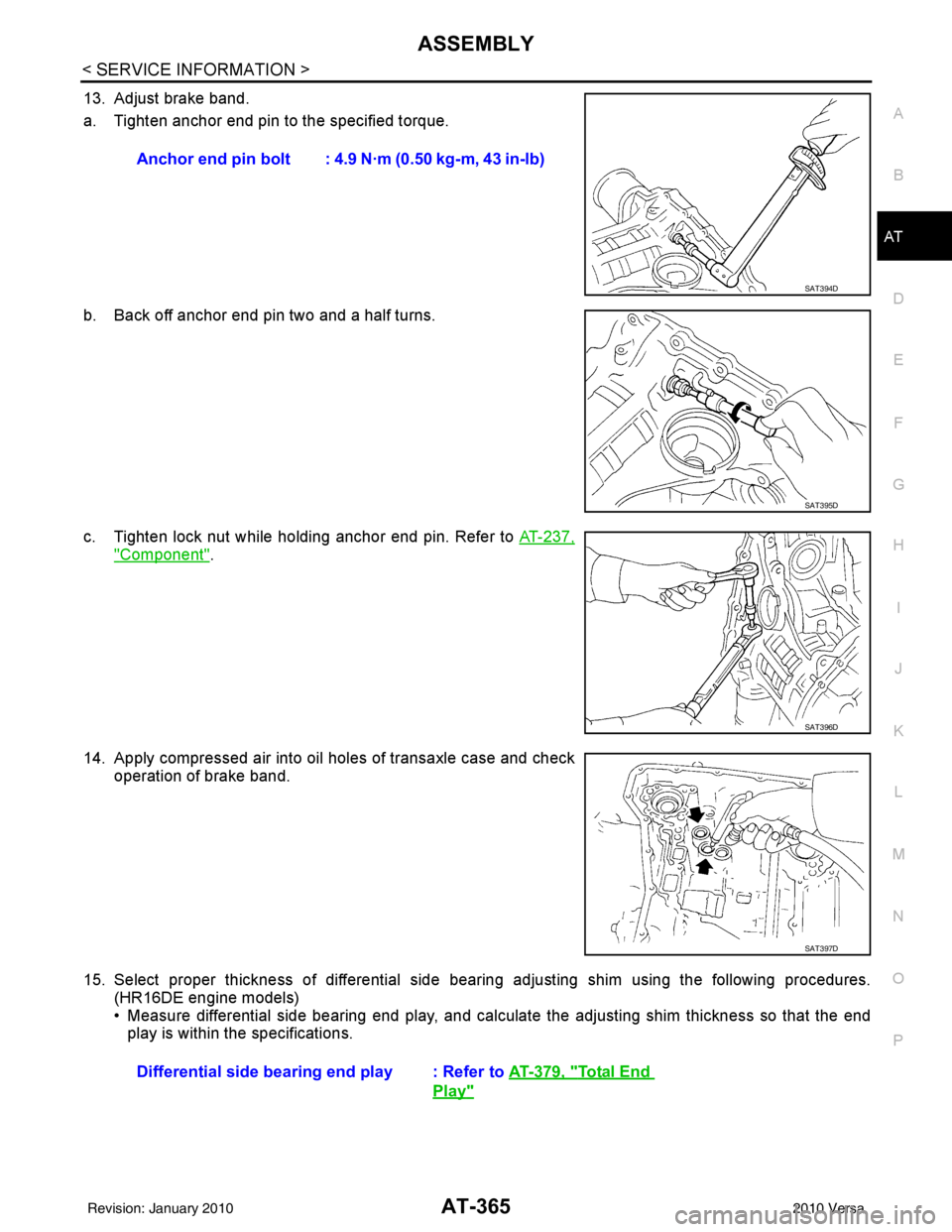

13. Adjust brake band.

a. Tighten anchor end pin to the specified torque.

b. Back off anchor end pin two and a half turns.

c. Tighten lock nut while holding anchor end pin. Refer to AT-237,

"Component".

14. Apply compressed air into oil holes of transaxle case and check operation of brake band.

15. Select proper thickness of differential side bear ing adjusting shim using the following procedures.

(HR16DE engine models)

• Measure differential side bearing end play, and calculat e the adjusting shim thickness so that the end

play is within the specifications. Anchor end pin bolt : 4.9 N·m (0.50 kg-m, 43 in-lb)

SAT394D

SAT395D

SAT396D

SAT397D

Differential side bearin

g end play : Refer to AT-379, "Total End

Play"

Revision: January 20102010 Versa

Page 394 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)AT-377

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

HIGH CLUTCH

FORWARD CLUTCH

OVERRUN CLUTCH

LOW & REVERSE BRAKE

BRAKE BAND

Applied model HR16DE engineMR18DE engine

Number of drive plates 34

Number of driven plates 57 (1

*1 + 6*2)

Drive plate thickness [mm (in)] Standard

1.6 (0.063) 1.6 (0.063)

Allowable limit 1.4 (0.055) 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

*1*2

2.0 (0.079) 1.5 (0.059)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094) 2.6 (0.102)

Number of drive plates 5

Number of driven plates 5

Drive plate thickness [mm (in)] Standard

1.8 (0.071)

Allowable limit 1.6 (0.063)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

0.45 - 0.85 (0.0177 - 0.0335)

Allowable limit 1.85 (0.0728)

Number of drive plates 3

Number of driven plates 4

Drive plate thickness [mm (in)] Standard

1.6 (0.063)

Allowable limit 1.4 (0.055)

Driven plate thickness [mm (in)] Standard 2.0 (0.079)

Clearance [mm (in)] Standard

1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Applied model HR16DE engineMR18DE engine

Number of drive plates 45

Number of driven plates 45

Drive plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Allowable limit 1.8 (0.071)1.8 (0.071)

Driven plate thickness [mm

(in)] Standard

2.0 (0.079)2.0 (0.079)

Clearance [mm (in)] Standard

1.4 - 1.8 (0.055 - 0.071) 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.6 (0.102)2.8 (0.110)

Anchor end pin tightening torque [N·m (kg-m, in-lb)] 4.9 (0.50, 43)

Number of returning revolutions for anchor end pin 2.5

Lock nut tightening torque [N·m (kg-m, ft-lb)] 33.9 (3.5, 25)

Revision: January 20102010 Versa

Page 2344 of 3745

BODY SIDE TRIMEI-43

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

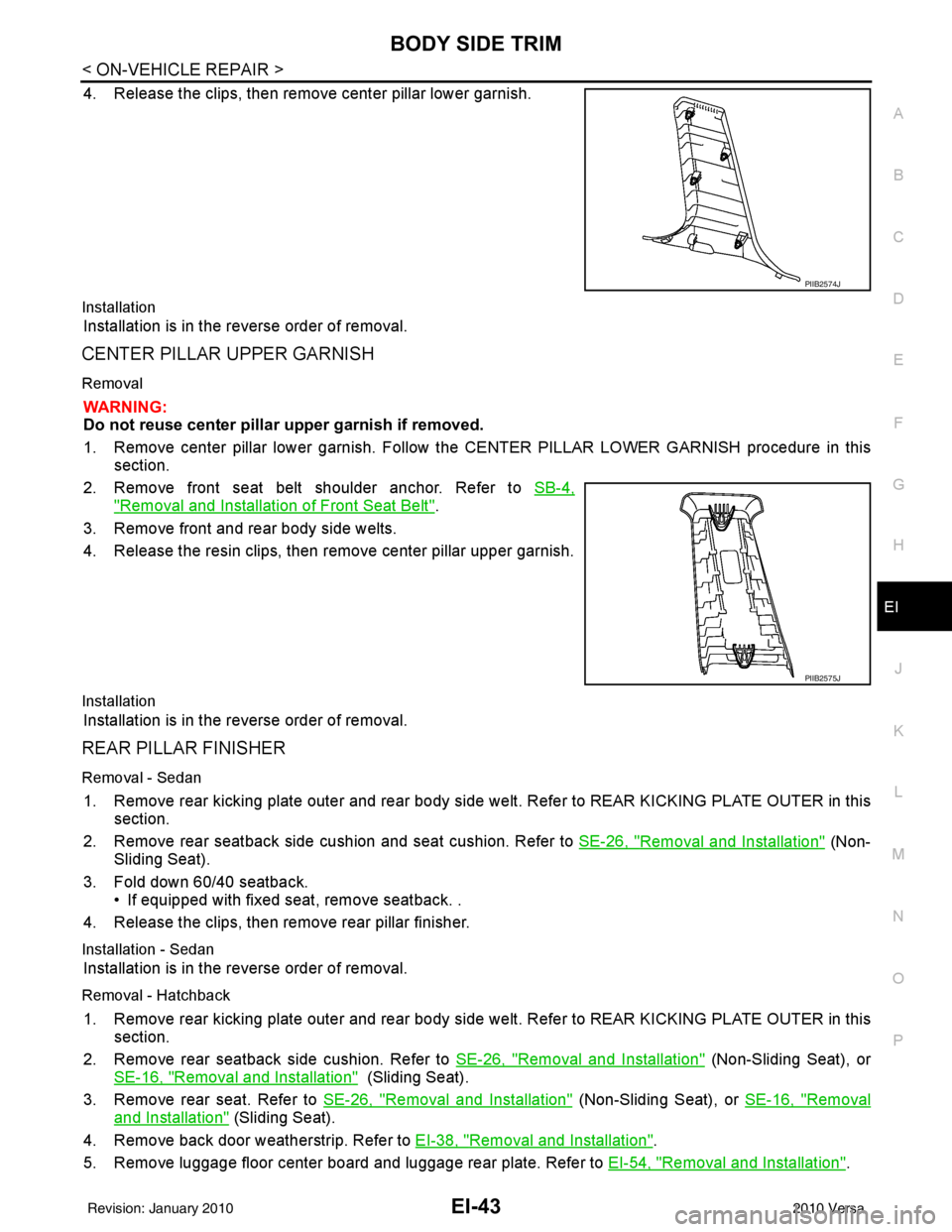

4. Release the clips, then remove center pillar lower garnish.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR UPPER GARNISH

Removal

WARNING:

Do not reuse center pillar upper garnish if removed.

1. Remove center pillar lower garnish. Follow t he CENTER PILLAR LOWER GARNISH procedure in this

section.

2. Remove front seat belt shoulder anchor. Refer to SB-4,

"Removal and Installation of Front Seat Belt".

3. Remove front and rear body side welts.

4. Release the resin clips, then remove center pillar upper garnish.

Installation

Installation is in the reverse order of removal.

REAR PILLAR FINISHER

Removal - Sedan

1. Remove rear kicking plate outer and rear body side welt. Refer to REAR KICKING PLATE OUTER in this

section.

2. Remove rear seatback side cushion and seat cushion. Refer to SE-26, "

Removal and Installation" (Non-

Sliding Seat).

3. Fold down 60/40 seatback. • If equipped with fixed seat, remove seatback. .

4. Release the clips, then remove rear pillar finisher.

Installation - Sedan

Installation is in the reverse order of removal.

Removal - Hatchback

1. Remove rear kicking plate outer and rear body side welt. Refer to REAR KICKING PLATE OUTER in this

section.

2. Remove rear seatback side cushion. Refer to SE-26, "

Removal and Installation" (Non-Sliding Seat), or

SE-16, "

Removal and Installation" (Sliding Seat).

3. Remove rear seat. Refer to SE-26, "

Removal and Installation" (Non-Sliding Seat), or SE-16, "Removal

and Installation" (Sliding Seat).

4. Remove back door weatherstrip. Refer to EI-38, "

Removal and Installation".

5. Remove luggage floor center board and luggage rear plate. Refer to EI-54, "

Removal and Installation".

PIIB2574J

PIIB2575J

Revision: January 20102010 Versa

Page 2345 of 3745

EI-44

< ON-VEHICLE REPAIR >

BODY SIDE TRIM

6. Remove luggage side lower finisher. Refer to EI-54, "Removal and Installation".

7. Remove rear seat belt outer anchor bolt. Refer to SB-6, "

Removal and Installation of Rear Seat Belt".

8. Release the clips, then remove rear pillar finisher.

Installation - Hatchback

Installation is in the reverse order of removal.

Revision: January 20102010 Versa