air conditioning NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 11 of 3745

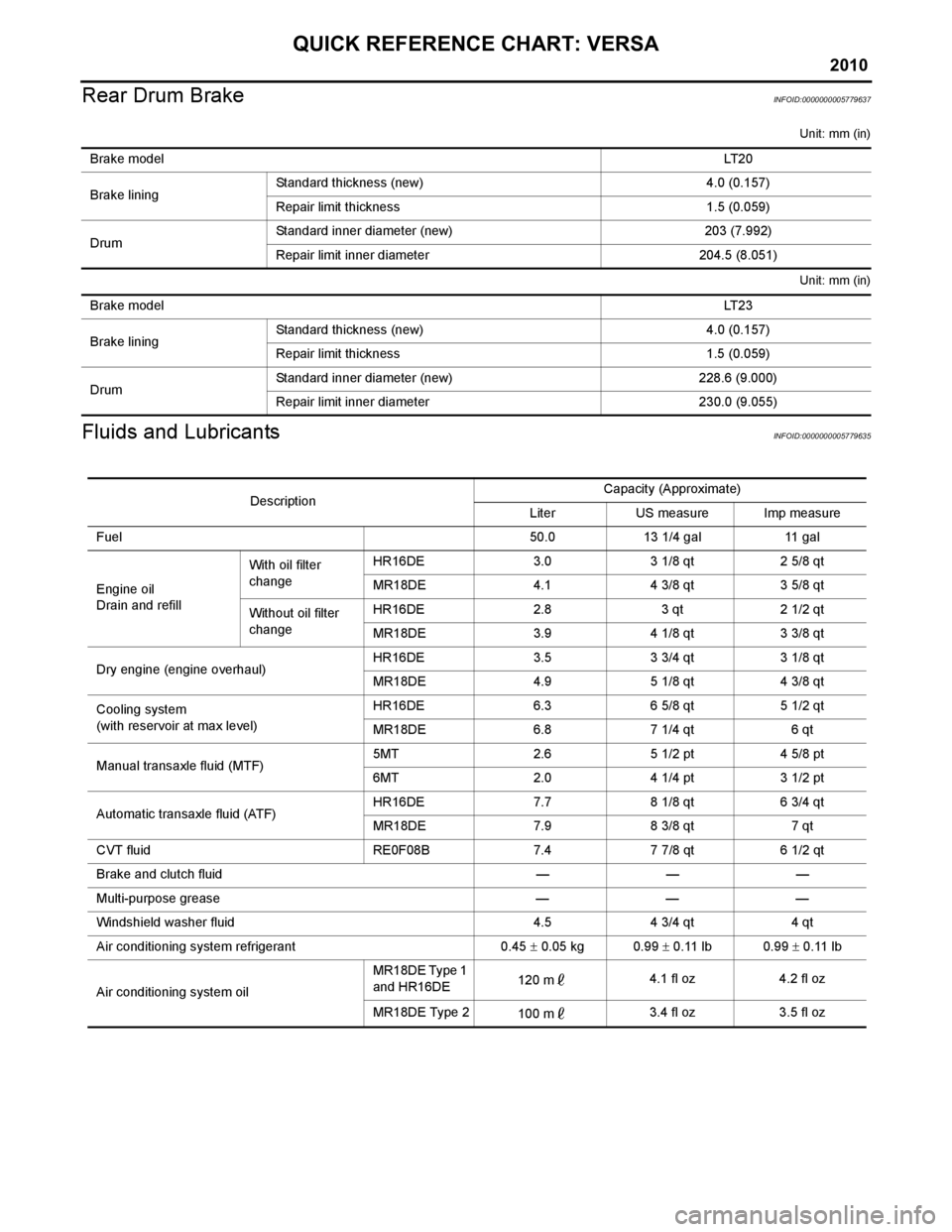

QUICK REFERENCE CHART: VERSA

2010

Rear Drum BrakeINFOID:0000000005779637

Unit: mm (in)

Unit: mm (in)

Fluids and LubricantsINFOID:0000000005779635

Brake modelLT 2 0

Brake lining Standard thickness (new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new) 203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model

LT 2 3

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new) 228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

Description Capacity (Approximate)

Liter US measure Imp measure

Fuel 50.0 13 1/4 gal 11 gal

Engine oil

Drain and refill With oil filter

change

HR16DE 3.0 3 1/8 qt 2 5/8 qt

MR18DE 4.1 4 3/8 qt 3 5/8 qt

Without oil filter

change HR16DE 2.8 3 qt 2 1/2 qt

MR18DE 3.9 4 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE 3.5 3 3/4 qt 3 1/8 qt

MR18DE 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE 6.3 6 5/8 qt 5 1/2 qt

MR18DE 6.8 7 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT 2.6 5 1/2 pt 4 5/8 pt

6MT 2.0 4 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) HR16DE 7.7 8 1/8 qt 6 3/4 qt

MR18DE 7.9 8 3/8 qt 7 qt

CVT fluid RE0F08B 7.4 7 7/8 qt 6 1/2 qt

Brake and clutch fluid — — —

Multi-purpose grease — — —

Windshield washer fluid 4.5 4 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil MR18DE Type 1

and HR16DE

120 m

4.1 fl oz 4.2 fl oz

MR18DE Type 2 100 m3.4 fl oz 3.5 fl oz

Page 1266 of 3745

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

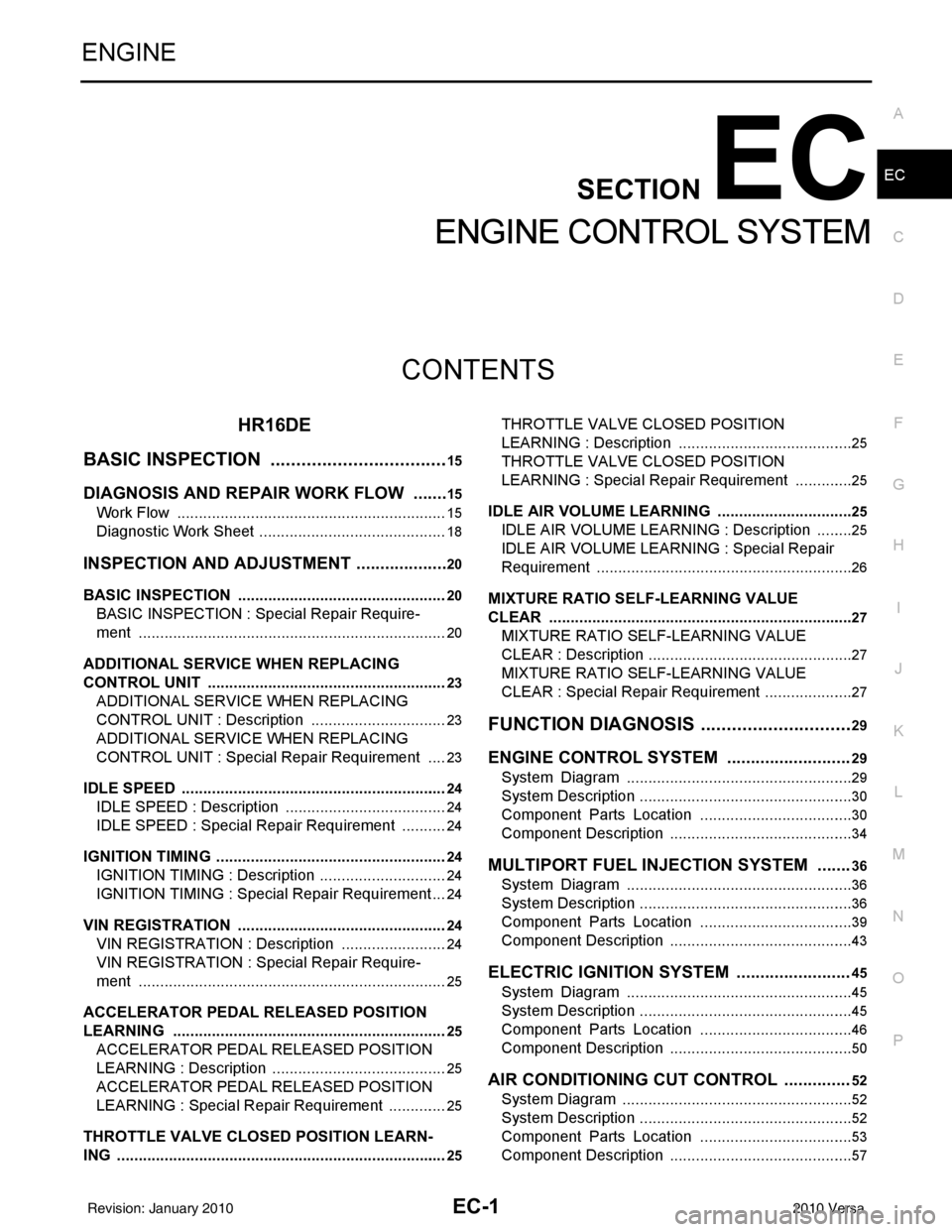

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

BASIC INSPECTION ....... ............................

15

DIAGNOSIS AND REPAIR WORK FLOW .... ....15

Work Flow ........................................................... ....15

Diagnostic Work Sheet ............................................18

INSPECTION AND ADJUSTMENT ....................20

BASIC INSPECTION .................................................20

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ....

20

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

23

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

23

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

23

IDLE SPEED .......................................................... ....24

IDLE SPEED : Description ........................ ..............24

IDLE SPEED : Special R epair Requirement ...........24

IGNITION TIMING .................................................. ....24

IGNITION TIMING : Description ..............................24

IGNITION TIMING : Special Repair Requirement ....24

VIN REGISTRATION ............................................. ....24

VIN REGISTRATION : Description .........................24

VIN REGISTRATION : Special Repair Require-

ment ........................................................................

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING ............................................................ ....

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description .........................................

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement ..............

25

THROTTLE VALVE CLOSED POSITION LEARN-

ING ......................................................................... ....

25

THROTTLE VALVE CLOSED POSITION

LEARNING : Description .........................................

25

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement ..............

25

IDLE AIR VOLUME LEARNING ............................ ....25

IDLE AIR VOLUME LEARNING : Description .........25

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

26

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

27

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ................................................

27

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement .....................

27

FUNCTION DIAGNOSIS ..............................29

ENGINE CONTRO L SYSTEM ..........................29

System Diagram ................................................. ....29

System Description ..................................................30

Component Parts Location ....................................30

Component Description ...........................................34

MULTIPORT FUEL INJECTION SYSTEM .......36

System Diagram .....................................................36

System Description ..................................................36

Component Parts Location ....................................39

Component Description ...........................................43

ELECTRIC IGNITION SYSTEM ........................45

System Diagram .....................................................45

System Description ..................................................45

Component Parts Location ....................................46

Component Description ...........................................50

AIR CONDITIONING CUT CONTROL ..............52

System Diagram ......................................................52

System Description ..................................................52

Component Parts Location ....................................53

Component Description ...........................................57

Revision: January 20102010 Versa

Page 1272 of 3745

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

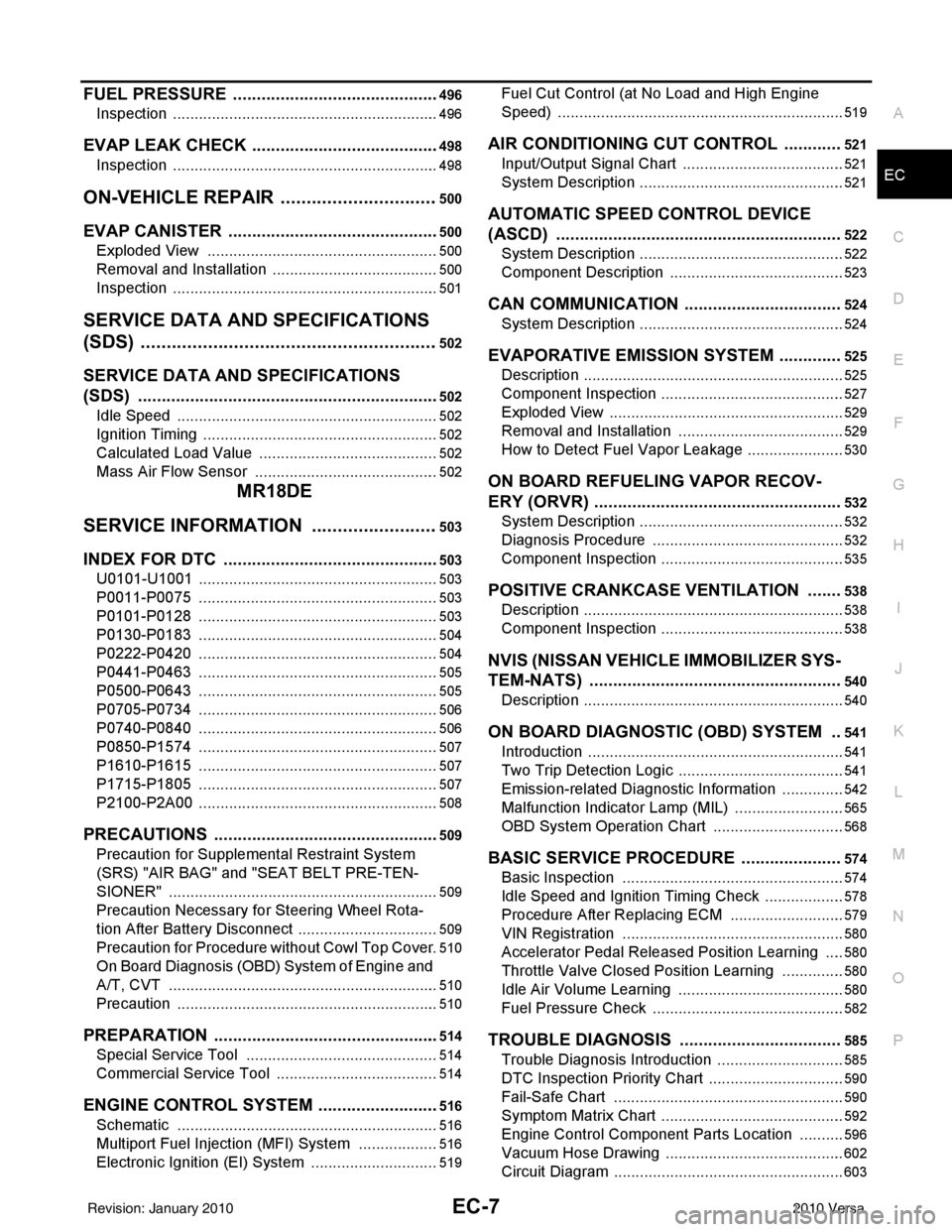

FUEL PRESSURE .......................................... ..496

Inspection ............................................................ ..496

EVAP LEAK CHECK ........................................498

Inspection ............................................................ ..498

ON-VEHICLE REPAIR ...............................500

EVAP CANISTER .............................................500

Exploded View .................................................... ..500

Removal and Installation .......................................500

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

502

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

502

Idle Speed ........................................................... ..502

Ignition Timing .......................................................502

Calculated Load Value ..........................................502

Mass Air Flow Sensor ...........................................502

MR18DE

SERVICE INFORMATION .. .......................

503

INDEX FOR DTC ............................................ ..503

U0101-U1001 ...................................................... ..503

P0011-P0075 ........................................................503

P0101-P0128 ........................................................503

P0130-P0183 ........................................................504

P0222-P0420 ........................................................504

P0441-P0463 ........................................................505

P0500-P0643 ........................................................505

P0705-P0734 ........................................................506

P0740-P0840 ........................................................506

P0850-P1574 ........................................................507

P1610-P1615 ........................................................507

P1715-P1805 ........................................................507

P2100-P2A00 ........................................................508

PRECAUTIONS ................................................509

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

509

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

509

Precaution for Procedure without Cowl Top Cover ..510

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ...............................................................

510

Precaution .............................................................510

PREPARATION ................................................514

Special Service Tool ........................................... ..514

Commercial Service Tool ......................................514

ENGINE CONTROL SYSTEM ..........................516

Schematic ........................................................... ..516

Multiport Fuel Injection (MFI) System ...................516

Electronic Ignition (EI) System ..............................519

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

519

AIR CONDITIONING CUT CONTROL ............521

Input/Output Signal Chart ......................................521

System Description ................................................521

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

522

System Description ................................................522

Component Description .........................................523

CAN COMMUNICATION .................................524

System Description ................................................524

EVAPORATIVE EMISSION SYSTEM .............525

Description .............................................................525

Component Inspection ...........................................527

Exploded View .......................................................529

Removal and Installation .......................................529

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Idle Air Volume Learning .......................................580

Fuel Pressure Check .............................................582

TROUBLE DIAGNOSIS ..................................585

Trouble Diagnosis Introduction ..............................585

DTC Inspection Priority Chart ................................590

Fail-Safe Chart ......................................................590

Symptom Matrix Chart ...........................................592

Engine Control Component Parts Location ...........596

Vacuum Hose Drawing ..........................................602

Circuit Diagram ......................................................603

Revision: January 20102010 Versa

Page 1291 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO NISSAN TIIDA 2010 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO](/img/5/57397/w960_57397-1290.png)

EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING

: Special Repair RequirementINFOID:0000000005398245

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (A/T), Neutral (M/T)

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- A/T models

• With CONSULT-III: Drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “TRANSMISSION”

system indicates less than 0.9 V.

• Without CONSULT-III: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

Revision: January 20102010 Versa

Page 1317 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-52

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000005398260

System DescriptionINFOID:0000000005398261

INPUT/OUTPUT SIGNAL CHART NISSAN TIIDA 2010 Service Repair Manual EC-52

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000005398260

System DescriptionINFOID:0000000005398261

INPUT/OUTPUT SIGNAL CHART](/img/5/57397/w960_57397-1316.png)

EC-52

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000005398260

System DescriptionINFOID:0000000005398261

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operati

on when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperat ure becomes excessively high.

JMBIA2195GB

Sensor Input Signal to ECMECM functionActuator

Air conditioner switch*

1Air conditioner ON signal

Air conditioner

cut controlIPDM E/R

↓

Air conditio

ner relay

↓

Compressor

Accelerator pedal position sensor

Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

2

Engine coolant temperature sensor

Engine coolant temperature

Battery Battery voltage*

2

Refrigerant pressure sensorRefrigerant pressure

EPS control unit Power steering operation

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Combination meter

BCM Air conditioner ON signal*

1

Revision: January 20102010 Versa

Page 1318 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-53

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-53

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed](/img/5/57397/w960_57397-1317.png)

AIR CONDITIONING CUT CONTROLEC-53

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Component Parts LocationINFOID:0000000005398262

1. Ignition coil (with power transistor)

and spark plug 2. Intake valve timing control solenoid

valve 3. Refrigerant pressure sensor

4. Knock sensor 5. Fuel injector6. Cooling fan motor

7. Camshaft position sensor (PHASE) 8. IPDM E/R 9. ECM

10. Mass air flow sensor (with intake air temperature sensor) 11. Engine coolant temperature sensor 12. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor)

13. EVAP canister purge volume control solenoid valve

PBIB2939E

Revision: January 20102010 Versa

Page 1319 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-54

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actuato NISSAN TIIDA 2010 Service Repair Manual EC-54

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actuato](/img/5/57397/w960_57397-1318.png)

EC-54

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Mass air flow sensor

(with intake air temperature sensor) 2. Engine coolant temperature sensor 3. Electric throttle control actuator

4. Camshaft position sensor (PHASE) 5. Ignition coil (with power transistor) 6. Fuel injector

7. EVAP canister purge volume control solenoid valve

Vehicle front

PBIB2940E

Revision: January 20102010 Versa

Page 1320 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-55

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. ECM harness connectors

2. ECM3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve timing control sol NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-55

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. ECM harness connectors

2. ECM3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve timing control sol](/img/5/57397/w960_57397-1319.png)

AIR CONDITIONING CUT CONTROLEC-55

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. ECM harness connectors

2. ECM3. IPDM E/R

4. Fuel pump fuse (15A) 5. Intake valve timing control solenoid

valve 6. Knock sensor

7. Refrigerant pressure sensor 8. PCV valve Vehicle front

PBIB2941E

Revision: January 20102010 Versa

Page 1321 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-56

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Air fuel ratio (A/F) sensor 1 2. Three way catalyst (Manifold) 3. Heated oxygen sensor 2

4. Three way catalyst (Under floor) 5. Muf NISSAN TIIDA 2010 Service Repair Manual EC-56

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Air fuel ratio (A/F) sensor 1 2. Three way catalyst (Manifold) 3. Heated oxygen sensor 2

4. Three way catalyst (Under floor) 5. Muf](/img/5/57397/w960_57397-1320.png)

EC-56

< FUNCTION DIAGNOSIS >[HR16DE]

AIR CONDITIONING CUT CONTROL

1. Air fuel ratio (A/F) sensor 1 2. Three way catalyst (Manifold) 3. Heated oxygen sensor 2

4. Three way catalyst (Under floor) 5. Muffler

Vehicle front

1. Exhaust manifold 2. Air fuel ratio (A/F) sensor 1 3. Heated oxygen sensor 2

4. Heated oxygen sensor 2 harness connector

Vehicle front

JMBIA2192ZZ

PBIB2943E

Revision: January 20102010 Versa

Page 1322 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-57

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000005398263

1. Cooling fan motor harness connec-

tor 2. Crankshaft po NISSAN TIIDA 2010 Service Repair Manual AIR CONDITIONING CUT CONTROLEC-57

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000005398263

1. Cooling fan motor harness connec-

tor 2. Crankshaft po](/img/5/57397/w960_57397-1321.png)

AIR CONDITIONING CUT CONTROLEC-57

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000005398263

1. Cooling fan motor harness connec-

tor 2. Crankshaft position sensor 3. Stop lamp switch

4. Brake pedal 5. Accelerator pedal position sensor

harness connector 6. Accelerator pedal position sensor

7. Accelerator pedal 8. Fuel level sensor unit and fuel pump

harness connector (view with in-

spection hole cover removed) 9. Fuel pressure regulator

10. Fuel pump

AWBIA0044ZZ

Component Reference

Accelerator pedal position sensor EC-392, "

Description"

Camshaft position sensor (PHASE)EC-262, "Description"

Crankshaft position sensor (POS)EC-257, "Description"

Revision: January 20102010 Versa