change time NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2 of 3745

-2

This manual contains maintenance and repair procedures for the

2010 NISSAN VERSA.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifi-

cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 127 of 3745

AT-110

< SERVICE INFORMATION >

P0731 1GR INCORRECT RATIO

5. Accelerate vehicle to 20 to 25 km/h (12 to 16 MPH) under the following conditions and release the accel-erator pedal completely.

THROTTLE POSI: Less than 1.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

- Make sure that “GEAR” shows “2” after releasing pedal.

6. Depress accelerator pedal to WOT (more than 7.0/8 of “THROTTLE POSI”) quickly from a speed of 20 to

25 km/h (12 to 16 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETED”. (It will take

approximately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-110, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT- III screen, go to the following step.

- Make sure that “GEAR” shows “1” wh en depressing accelerator pedal to WOT.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0731 1GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Funct ion (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-110, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397293

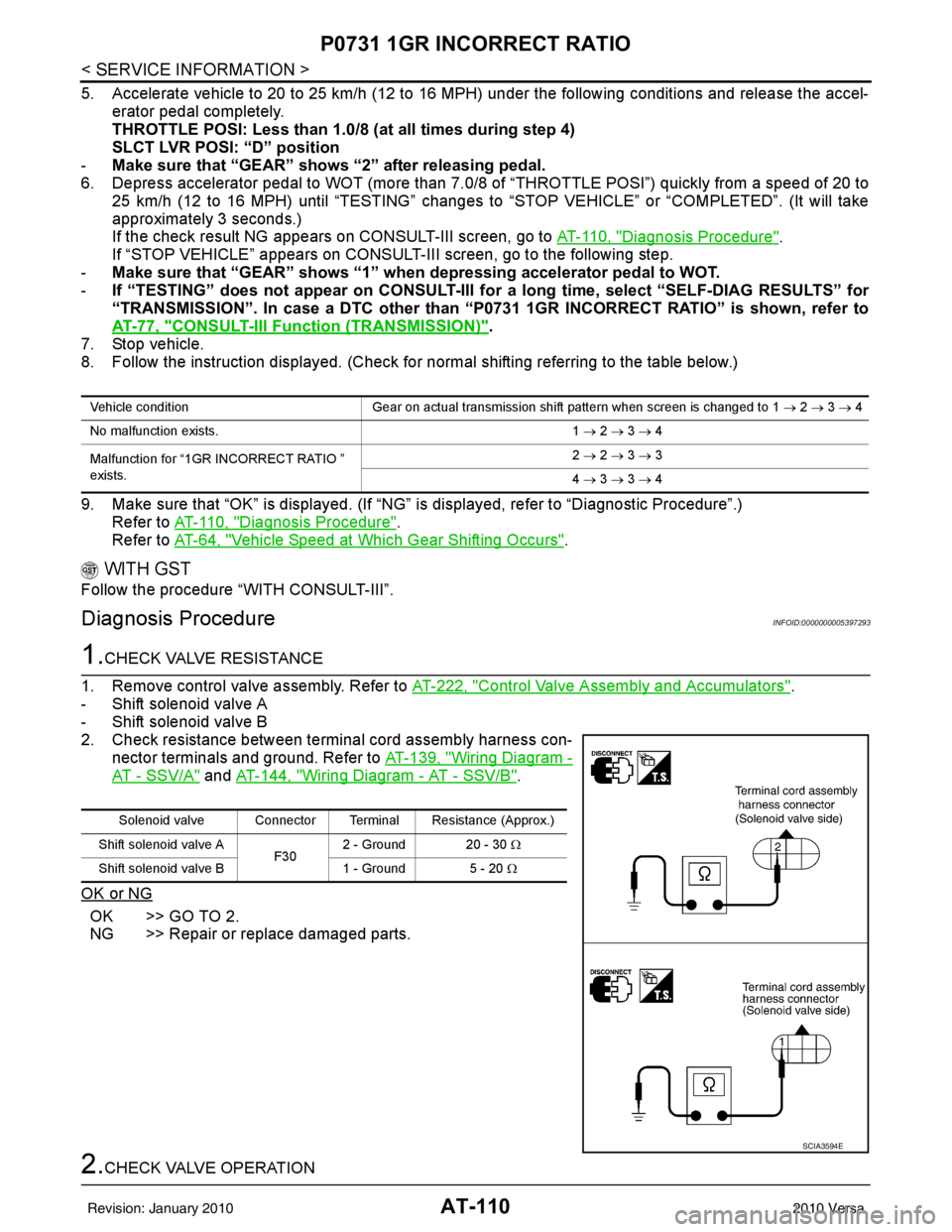

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK VALVE OPERATION

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists. 1 → 2 → 3 → 4

Malfunction for “1GR INCORRECT RATIO ”

exists. 2

→ 2 → 3 → 3

4 → 3 → 3 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

Revision: January 20102010 Versa

Page 130 of 3745

P0732 2GR INCORRECT RATIOAT-113

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

- Make sure that “GEAR” shows “3” or “4” after releasing pedal.

6. Depress accelerator pedal to WOT (more than 7.0/8 of “THROTTLE POSI”) quickly from a speed of 45 to 50 km/h (28 to 31 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETE”. (It will take

approximately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-113, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “2” when depressing accelerator pedal to WOT.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0732 2GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-113, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397298

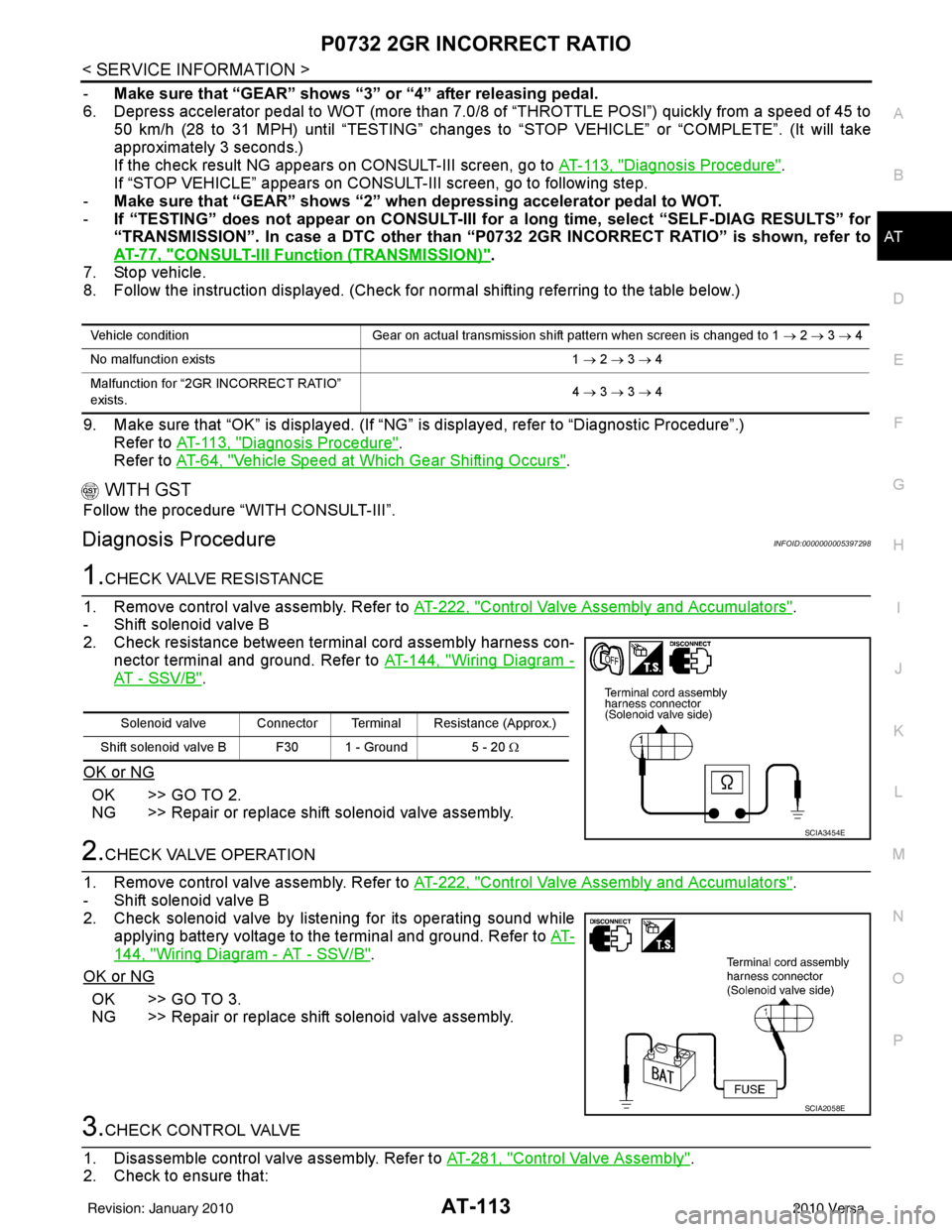

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminal and ground. Refer to AT-144, "

Wiring Diagram -

AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while applying battery voltage to the terminal and ground. Refer to AT-

144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3.CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-281, "

Control Valve Assembly".

2. Check to ensure that:

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “2GR INCORRECT RATIO”

exists. 4

→ 3 → 3 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve B F30 1 - Ground 5 - 20 Ω

SCIA3454E

SCIA2058E

Revision: January 20102010 Versa

Page 133 of 3745

AT-116

< SERVICE INFORMATION >

P0733 3GR INCORRECT RATIO

-Make sure that “GEAR” shows “4” after releasing pedal.

6. Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of “THROTTLE POSI” from a speed of 60 to 75 km/h (37 to 47 MPH) until “TESTING” changes to “STOP VEHICLE” or “COMPLETED”. (It will take approxi-

mately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-116, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSUL T-III screen, go to following step.

- Make sure that “GEAR” shows “3” when depressing accelerator pedal with 3.5/8 - 4.5/8 of

“THROTTLE POSI”.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0733 3GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Funct ion (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-116, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397303

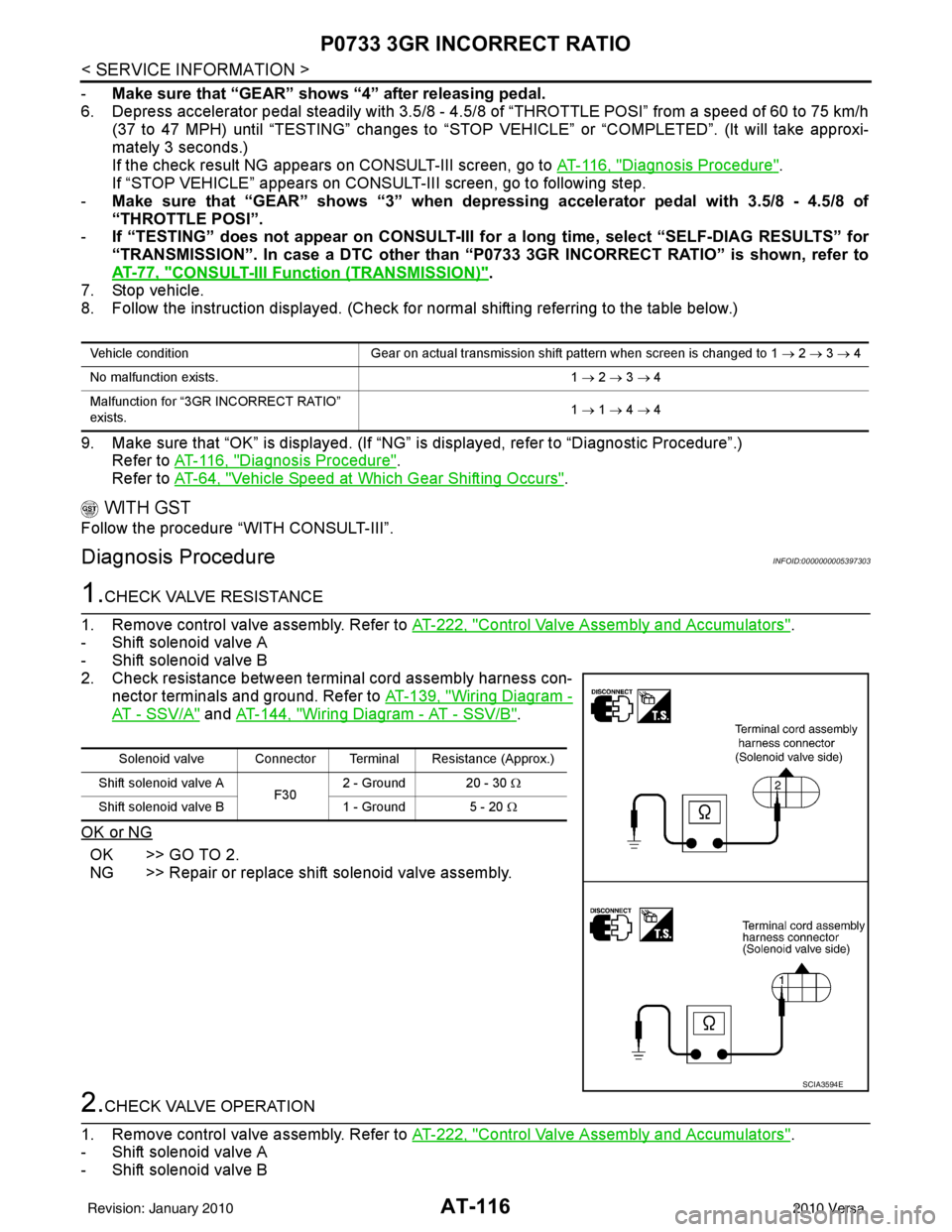

1.CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con- nector terminals and ground. Refer to AT-139, "

Wiring Diagram -

AT - SSV/A" and AT-144, "Wiring Diagram - AT - SSV/B".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2.CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators".

- Shift solenoid valve A

- Shift solenoid valve B

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists. 1 → 2 → 3 → 4

Malfunction for “3GR INCORRECT RATIO”

exists. 1

→ 1 → 4 → 4

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F302 - Ground 20 - 30

Ω

Shift solenoid valve B 1 - Ground 5 - 20 Ω

SCIA3594E

Revision: January 20102010 Versa

Page 136 of 3745

P0734 4GR INCORRECT RATIOAT-119

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “4TH GR FNCTN P0734” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

5. Accelerate vehicle to 55 to 65 km/h (34 to 40 MPH) under the following conditions and release the accel-

erator pedal completely.

THROTTLE POSI: Less th an 5.5/8 (at all times during step 4)

SLCT LVR POSI: “D” position

- Make sure that “GEAR” shows “3” after releasing pedal.

6. Depress accelerator pedal steadily with 1.0/8 - 2.0/ 8 of “THROTTLE POSI” from a speed of 55 to 65 km/h

(34 to 40 MPH) until “TESTING” has turned to “STO P VEHICLE” or “COMPLETED”. (It will take approxi-

mately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-119, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “4” when depressing accelerator pedal with 1.0/8 - 2.0/8 of

“THROTTLE POSI”.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0734 4GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-119, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397309

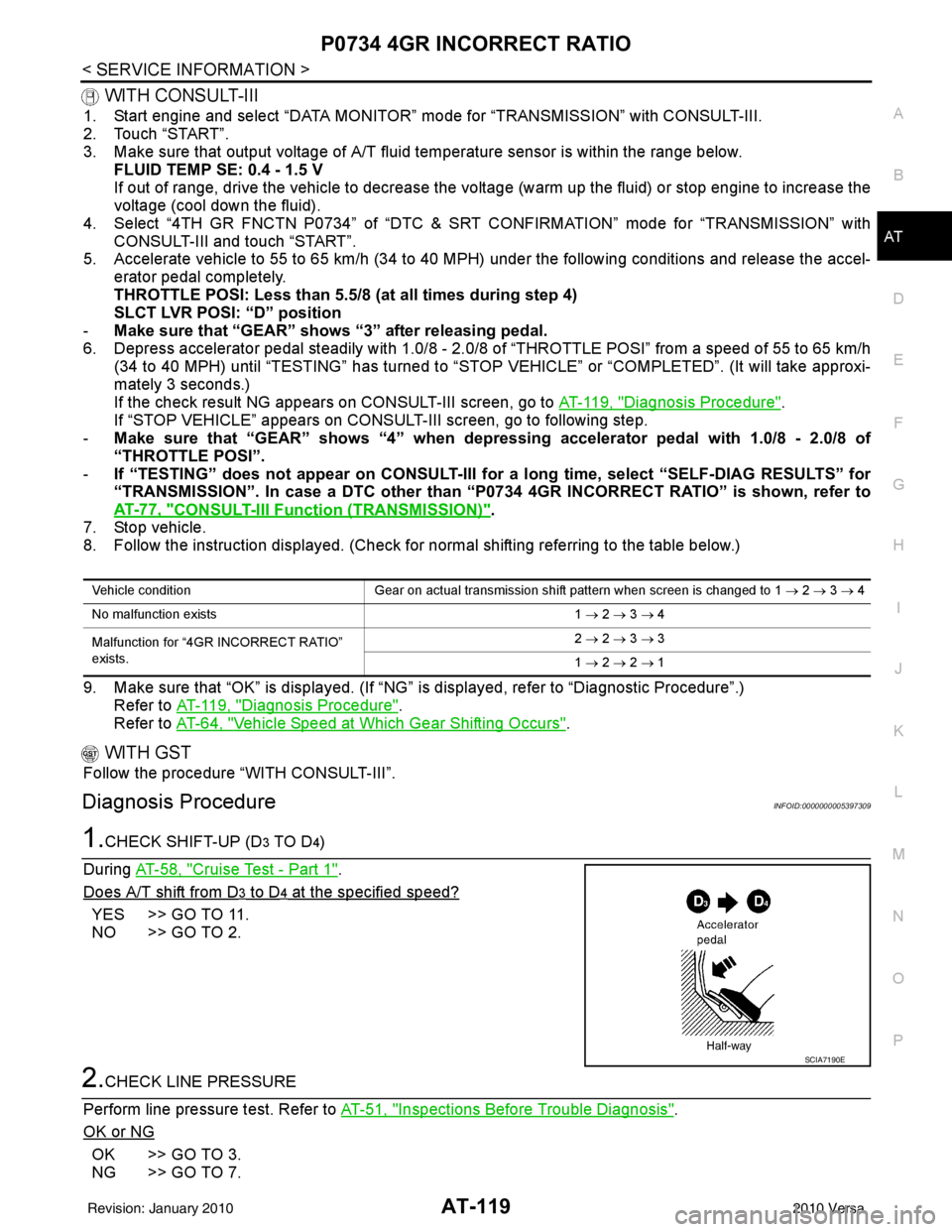

1.CHECK SHIFT-UP (D3 TO D4)

During AT-58, "

Cruise Test - Part 1".

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-51, "

Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “4GR INCORRECT RATIO”

exists. 2

→ 2 → 3 → 3

1 → 2 → 2 → 1

SCIA7190E

Revision: January 20102010 Versa

Page 404 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-7

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

• through 10A fuse (No. 20, located in the fuse and fusible link box)

• to audio unit terminal 7.

Grou NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-7

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

• through 10A fuse (No. 20, located in the fuse and fusible link box)

• to audio unit terminal 7.

Grou](/img/5/57397/w960_57397-403.png)

AUDIOAV-7

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

• through 10A fuse (No. 20, located in the fuse and fusible link box)

• to audio unit terminal 7.

Ground is supplied through the case of the audio unit.

Then audio signals are supplied

• through audio unit terminals 2, 3, 4, 5, 11, 12, 13 and 14

• to terminals + and - of front door speaker LH and RH and

• to terminals + and - of rear door speaker LH and RH.

PREMIUM SYSTEM

Refer to Owner's Manual for audio system operating instructions.

Power is supplied at all times

• through 20A fuse (No. 27, located in the fuse and fusible link box)

• to audio unit terminal 19.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse (No. 20, located in the fuse and fusible link box)

• to audio unit terminal 7.

Ground is supplied

• to audio unit terminals 20 and 61

• through body grounds M57 and M61.

Then audio signals are supplied

• through audio unit terminals 2, 3, 4, 5, 11, 12, 13, and 14

• to terminals + and - of front door speaker LH and RH and

• to terminals + and - of tweeter LH and RH and

• to terminals + and - of rear door speaker LH and RH.

Steering Wheel Audio Contro l Switches (with Bluetooth)

When one of steering wheel audio control switches is pus hed, the resistance in steering switch circuit changes

depending on which button is pushed.

SPEED SENSITIVE VOLUME SYSTEM (PREMIUM SYSTEM)

Volume level of this system goes up and down automatica lly in proportion to the vehicle speed. The control

level can be selected by the customer. Refer to Owner's Manual for operating instructions.

Revision: January 20102010 Versa

Page 418 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or e NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or e](/img/5/57397/w960_57397-417.png)

AUDIOAV-21

< SERVICE INFORMATION > [AUDIO WITHOUT NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or external noise

from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the antenna at a different time from the waves t hat reflect off of mountains or buildings.

Noise InspectionINFOID:0000000005395318

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

TYPE OF NOISE AND POSSIBLE CAUSE

No sound can be heard from one or several speakers. • Open or short in audio signal circuit between audio unit and front

speaker. Refer to AV- 2 4 , "

Sound Is Not Heard from Front Door

Speaker (Base System)" or AV- 2 6 , "Sound Is Not Heard from

Front Door Speaker or Tweeter (Premium System)" .

• Front speaker. Refer to AV- 2 4 , "

Sound Is Not Heard from Front

Door Speaker (Base System)" or AV- 2 6 , "Sound Is Not Heard

from Front Door Speaker or Tweeter (Premium System)" .

• Open or short in audio signal circuit between audio unit and rear

speaker. Refer to AV- 2 5 , "

Sound Is Not Heard from Rear Door

Speaker (Base System)" or AV- 2 7 , "Sound Is Not Heard from

Rear Door Speaker (Premium System)" .

• Rear speaker. Refer to AV- 2 5 , "

Sound Is Not Heard from Rear

Door Speaker (Base System)" or AV- 2 7 , "Sound Is Not Heard

from Rear Door Speaker (Premium System)" .

• Tweeter (mid level and premium system) AV- 2 6 , "

Sound Is Not

Heard from Front Door Speaker or Tweeter (Premium System)"

or AV- 2 7 , "

Sound Is Not Heard from Rear Door Speaker (Premi-

um System)" .

• Audio unit. Refer to AV- 2 9 , "

Removal and Installation" .

No sound can be heard from radio or noise is heard. • Antenna feeder. Refer to

AV- 3 3

.

• Antenna. Refer to AV- 3 3

.

• Audio unit. Refer to AV- 2 9 , "

Removal and Installation" .

Symptom

Check item

Occurrence condition Possible cause

Occurs only when engine is ON. A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.

Ignition components

A whistling noise occurs while the engine speed is

high. A booming noise occurs while the engine is

running and the lighting switch is ON. Generator

Noise only occurs when various

electrical components are oper-

ating. A cracking or snapping sound occurs with the op-

eration of various switches.

Relay malfunction, radio malfunction

The noise occurs when various motors are operat-

ing. • Motor case ground

•Motor

The noise occurs constantly, not just under certain conditions. • Rear defogger coil malfunction

• Open circuit in printed heater

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. • Ground wire of body parts.

• Ground due to improper part installation

• Wiring connections or a short circuit

Revision: January 20102010 Versa

Page 450 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-53

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

System DescriptionINFOID:0000000005988543

AUDIO SYSTEM

Refer to Owners Manual for audio system operating in NISSAN TIIDA 2010 Service Repair Manual AUDIOAV-53

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

System DescriptionINFOID:0000000005988543

AUDIO SYSTEM

Refer to Owners Manual for audio system operating in](/img/5/57397/w960_57397-449.png)

AUDIOAV-53

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

System DescriptionINFOID:0000000005988543

AUDIO SYSTEM

Refer to Owner's Manual for audio system operating instructions.

Navigation is built into AV control unit.

This navigation has the following functions.

• Full support for playback of music from iPod

® and USB device.

• High resolution full color touch panel 5 “WQVGA” display.

• FM/AM twin digital tuner.

• USB mass storage.

• XM traffic.

• POI Support is included. User POI download.

Power is supplied at all times

• through 20A fuse (No. 27, located in the fuse and fusible link box)

• to AV control unit terminal 19.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in the fuse block (J/B)]

• to AV control unit terminal 7.

Ground is supplied to

• to AV control unit terminals 20 and 32

• through grounds M57 and M61.

Then audio signals are supplied

• through AV control unit terminals 2, 3, 4, 5, 11, 12, 13 and 14

• to terminals + and - of front door speaker LH and RH

• to terminals + and - of front tweeter LH and RH and

• to terminals + and - of rear door speaker LH and RH.

STEERING WHEEL AUDIO CONTROL SWITCHES

When one of steering wheel audio control switches is pus hed, the resistance in steering switch circuit changes

depending on which button is pushed.

AWNIA2215GB

Revision: January 20102010 Versa

Page 463 of 3745

![NISSAN TIIDA 2010 Service Repair Manual AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunction CD, electromagnetic

interference, etc.). Check the s NISSAN TIIDA 2010 Service Repair Manual AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunction CD, electromagnetic

interference, etc.). Check the s](/img/5/57397/w960_57397-462.png)

AV-66

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

AUDIO

• The majority of the audio malfunctions are the result of outside causes (Malfunction CD, electromagnetic

interference, etc.). Check the symptoms below to diagnose the malfunction.

• The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and oper-

ation of each piece of electrical equipment, and then determine the cause.

NOTE:

• CD-R is not guaranteed to play because they can contain compressed audio (MP3, WMA) or could be

incorrectly mastered by the customer on a computer.

• Check if the CDs have the Compact Disc logo. If not , the disc is not mastered to the “red book” Compact

Disc standard and may not play.

NOTE:

Noise resulting from variations in field strength, such as fading noise and multi-path noise, or external noise

from trains and other sources, is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun- tains or buildings blocking the signal.

• Multi-path noise: This noise results from a time di fference between the broadcast waves directly from the

station arriving at the antenna and the waves reflected by mountains or buildings.

MALFUNCTION WITH USB

NOTE:

Check that there is no malfunction of USB equi pment main body before performing a diagnosis.

Symptom Probable malfunction location

Audio system does not work normally. • AV control unit power supply and ground circuit. Refer to

AV- 6 7

.

• AV control unit. Refer to AV- 6 7

.

Audio steering wheel switch does not operate proper-

ly. • Remote control signal circuit between steering switch and AV control unit.

Refer to AV- 6 8

.

• Steering wheel audio control switch. Refer to AV- 7 2

.

• AV control unit. Refer to AV- 7 2

.

No sound can be heard from any speakers. • Speaker circuit shorted to ground. Refer to AV- 5 5

.

• AV control unit. Refer to AV- 7 2

.

No sound can be heard from front speakers. • Audio signal circuit between AV control unit and front speakers. Refer to

AV- 6 9

.

• Front speaker. Refer to AV- 7 2

.

• Front tweeter. Refer to AV- 7 2

.

• AV control unit. Refer to AV- 7 2

.

No sound can be heard from rear speakers. • Audio signal circuit between AV control unit and rear speakers. Refer to

AV- 7 1

.

• Rear speaker. Refer to AV- 7 2

.

• AV control unit. Refer to AV- 7 2

.

No sound can be heard from radio or noise is heard. • Antenna feeder. Refer to AV- 9 0

.

• Roof antenna. Refer to AV- 9 0

.

• AV control unit. Refer to AV- 7 2

.

Speed dependent volume system does not function. • Vehicle speed signal circuit between combination meter and AV control

unit. Refer to DI-16

.

• AV control unit. Refer to AV- 7 2

.

• Combination meter. Refer to DI-20

.

There is no sound from the iPod

® or Aux jack. •iPod

® sound signal circuit between AV control unit and Auxiliary jack as-

sembly. Refer to AV- 8 9

.

• AV control unit. Refer to AV- 7 2

.

Revision: January 20102010 Versa

Page 493 of 3745

BCS-4

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE)

System DescriptionINFOID:0000000005395103

BCM (body control module) controls the operation of various electrical units installed on the vehicle.

BCM FUNCTION

BCM has a combination switch reading function for reading the operation of combination switches (light, wiper,

washer, turn signal) in addition to the function for cont rolling the operation of various electrical components.

Also, it functions as an interface that receives signal s from the front air control, and sends signals to ECM

using CAN communication.

COMBINATION SWITCH READING FUNCTION

1. Description • BCM reads combination switch (light, wiper) status, and controls various electrical components accord-

ing to the results.

• BCM reads information of a maximum of 20 switches by combining five output terminals (OUTPUT 1-5)

and five input terminals (INPUT 1-5).

2. Operation description • BCM activates transistors of output terminals (OUTPU T 1-5) periodically and allows current to flow in

turn.

• If any (1 or more) of the switches are turned ON, circuit of output terminals (OUTPUT 1-5) and input ter- minals (INPUT 1-5) becomes active.

• At this time, transistors of output terminals (OUTPUT 1-5) are activated to allow current to flow. When

voltage of input terminals (INPUT 1-5) corresponding to that switch changes, interface in BCM detects

voltage change and BCM determines that switch is ON.

3. BCM - Operation table of combination switch • BCM reads operation status of combination switch by the combination shown in the following table.

SKIB7592E

Revision: January 20102010 Versa