system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2805 of 3787

REAR WINDOW DEFOGGERGW-51

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

REAR WINDOW DEFOGGER

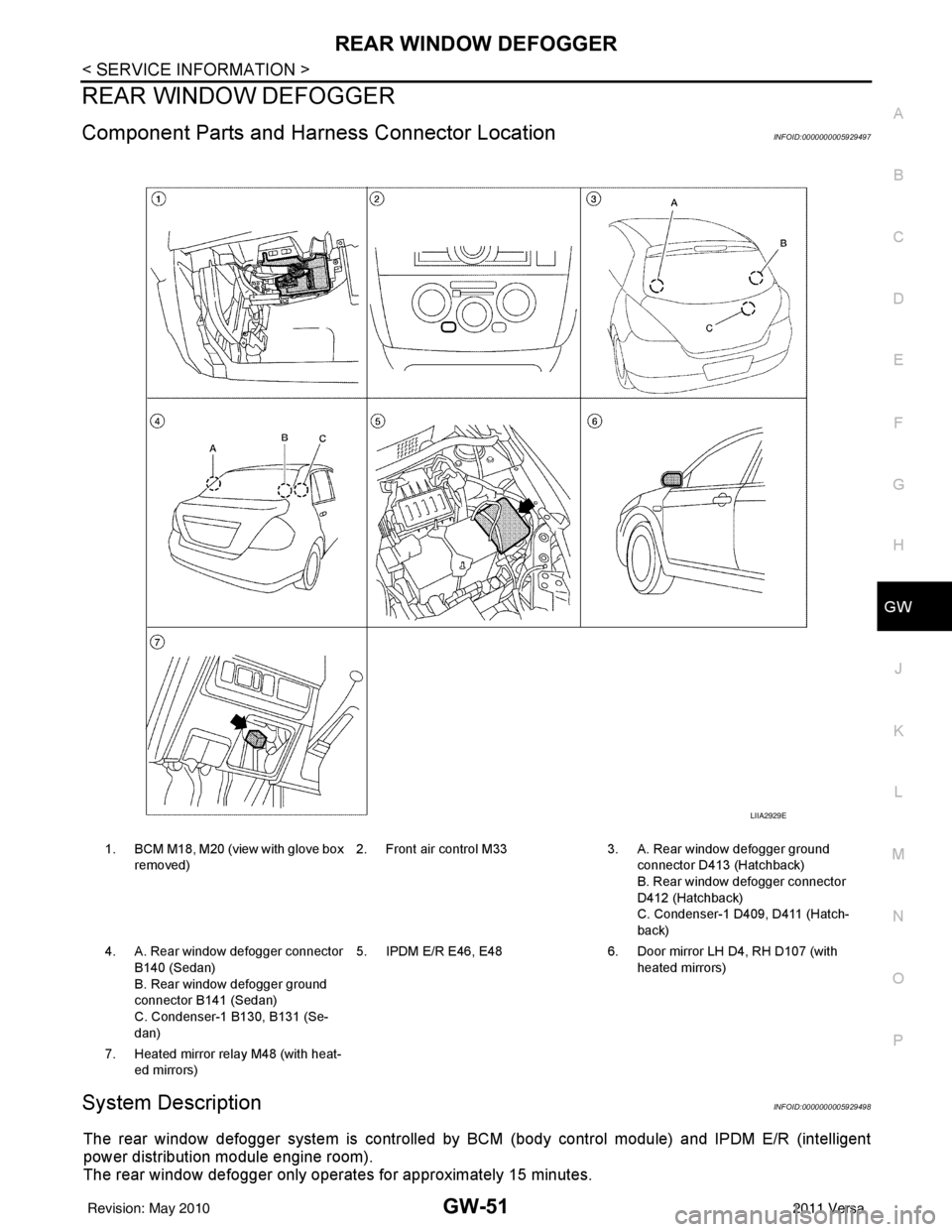

Component Parts and Har ness Connector LocationINFOID:0000000005929497

System DescriptionINFOID:0000000005929498

The rear window defogger system is controlled by BCM (body control module) and IPDM E/R (intelligent

power distribution module engine room).

The rear window defogger only operates for approximately 15 minutes.

1. BCM M18, M20 (view with glove box

removed) 2. Front air control M33 3. A. Rear window defogger ground

connector D413 (Hatchback)

B. Rear window defogger connector

D412 (Hatchback)

C. Condenser-1 D409, D411 (Hatch-

back)

4. A. Rear window defogger connector B140 (Sedan)

B. Rear window defogger ground

connector B141 (Sedan)

C. Condenser-1 B130, B131 (Se-

dan) 5. IPDM E/R E46, E48

6. Door mirror LH D4, RH D107 (with

heated mirrors)

7. Heated mirror relay M48 (with heat- ed mirrors)

LIIA2929E

Revision: May 2010 2011 Versa

Page 2806 of 3787

GW-52

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Power is supplied at all times

• through 15A fuses (No. 46 and 47, located in the IPDM E/R)

• to rear window defogger relay

• through 10A fuse [No. 5 (with heated mirrors), located in the fuse block (J/B)]

• to heated mirror relay terminal 3

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition relay

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to front air control terminal 8

• through body grounds M57 and M61

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

When front air control (rear window defogger switch) is turned to ON, ground is supplied

• to BCM terminal 9

• through front air control terminal 3

• through front air control terminal 8

• through body grounds M57 and M61.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via CAN communication (CAN-H, CAN-L).

When IPDM E/R receives rear window defogger switch signals, ground is supplied

• to rear window defogger relay (located in the IPDM E/R)

• through IPDM E/R terminals 39 and 59

• through body grounds E15 and E24

Then rear window defogger relay is energized.

With power and ground supplied, rear window def ogger filaments heat and defog the rear window.

When rear window defogger relay is turned to ON (with heated mirrors), power is supplied

• through heated mirror relay terminal 5

• to door mirror (LH and RH) terminal 1.

Door mirror (LH and RH) is grounded through body grounds M57 and M61.

With power and ground supplied, rear window defogger filaments heat and defog the rear window and door

mirror filaments heat and defog the mirrors.

CAN Communication System DescriptionINFOID:0000000005929499

Refer to LAN-7, "System Description".

Revision: May 2010 2011 Versa

Page 2809 of 3787

REAR WINDOW DEFOGGERGW-55

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

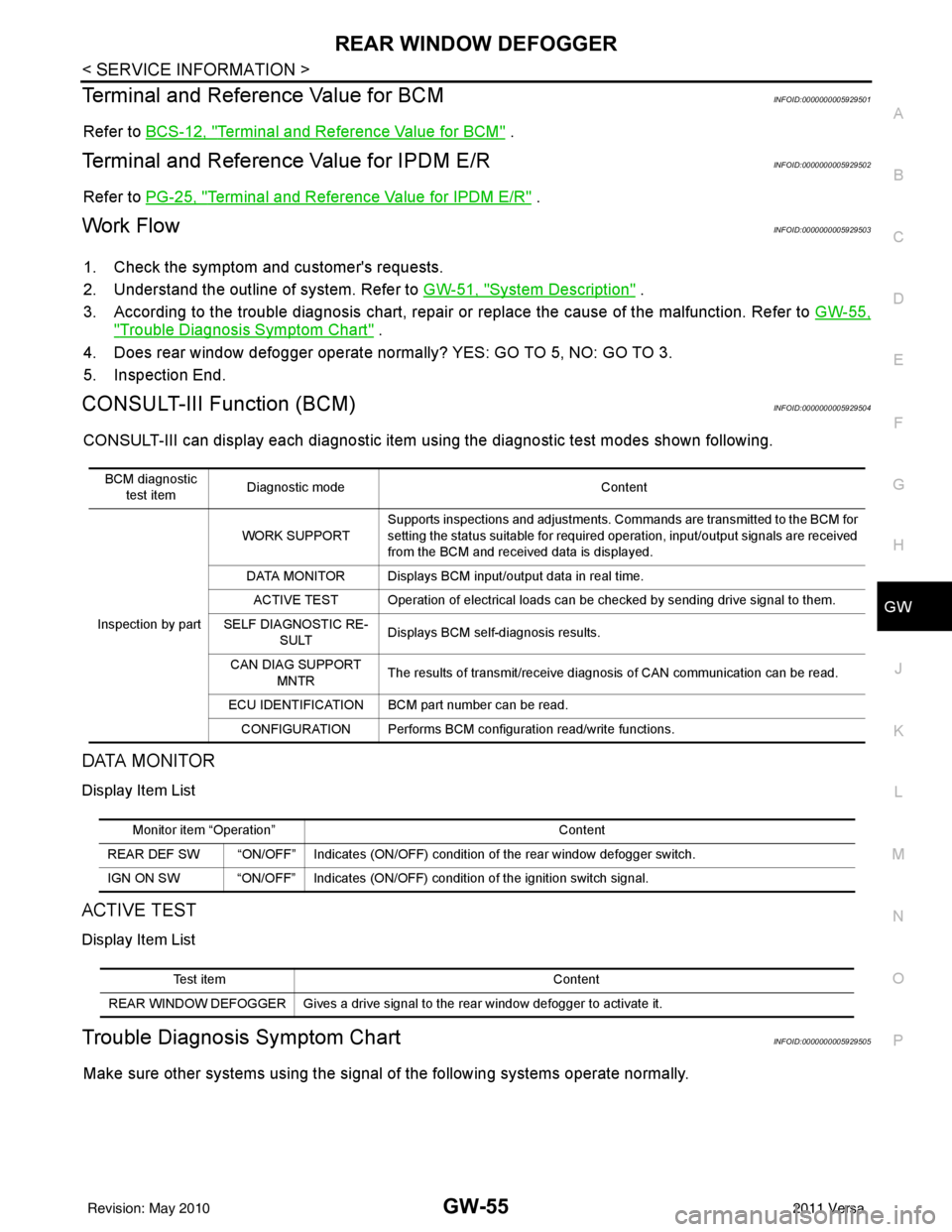

Terminal and Reference Value for BCMINFOID:0000000005929501

Refer to BCS-12, "Terminal and Reference Value for BCM" .

Terminal and Reference Value for IPDM E/RINFOID:0000000005929502

Refer to PG-25, "Terminal and Reference Value for IPDM E/R" .

Work FlowINFOID:0000000005929503

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-51, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to GW-55,

"Trouble Diagnosis Symptom Chart" .

4. Does rear window defogger operate normally? YES: GO TO 5, NO: GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005929504

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

Trouble Diagnosis Symptom ChartINFOID:0000000005929505

Make sure other systems using the signal of the following systems operate normally.

BCM diagnostic

test item Diagnostic mode

Content

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RE- SULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ECU IDENTIFICATION BCM part number can be read. CONFIGURATION Performs BCM configuration read/write functions.

Monitor item “Operation” Content

REAR DEF SW “ON/OFF” Indicates (ON/OFF) condition of the rear window defogger switch.

IGN ON SW “ON/OFF” Indicates (ON/OFF) condition of the ignition switch signal.

Test item Content

REAR WINDOW DEFOGGER Gives a drive signal to the rear window defogger to activate it.

Revision: May 2010 2011 Versa

Page 2822 of 3787

IP-1

BODY

C

DE

F

G H

J

K L

M

SECTION IP

A

B

IP

N

O P

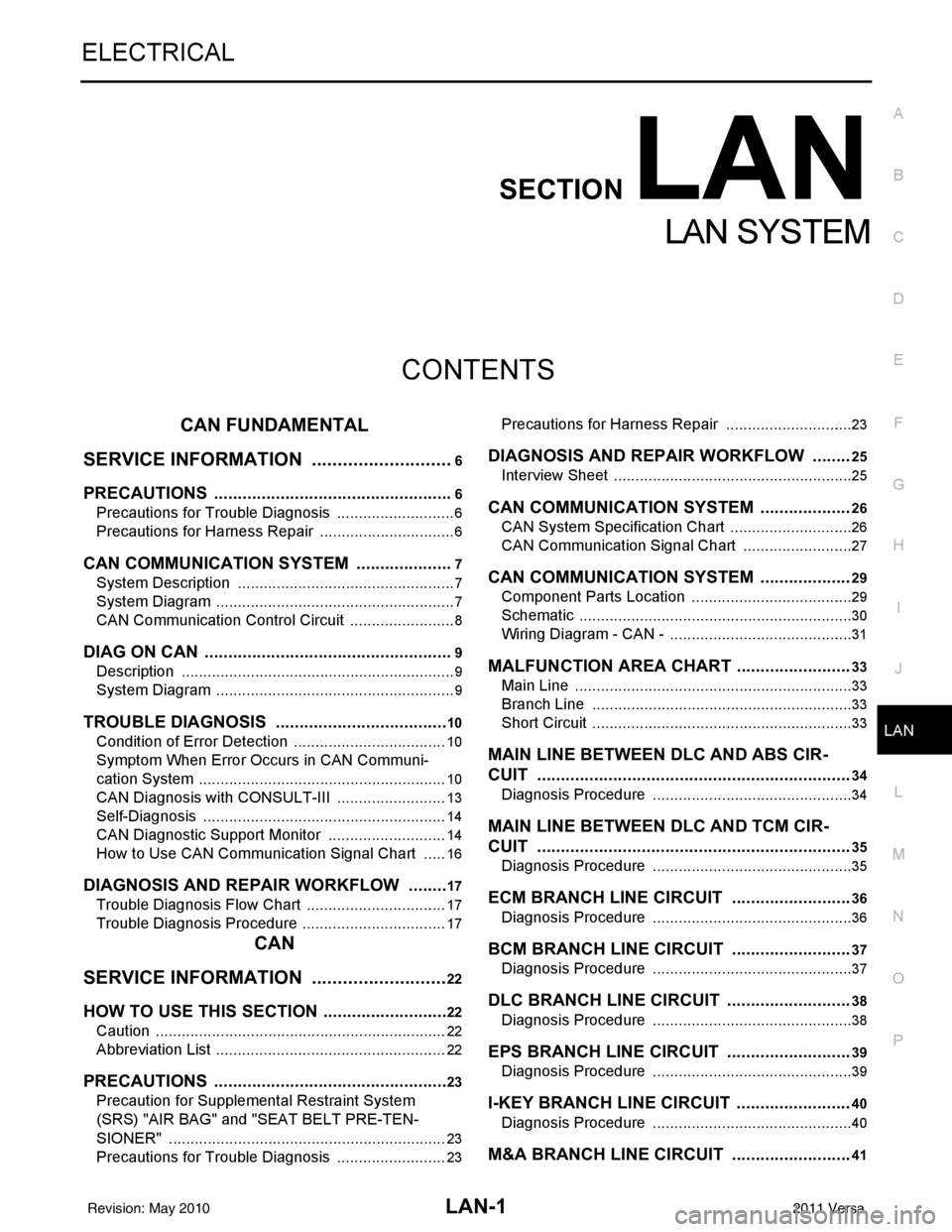

CONTENTS

INSTRUMENT PANEL

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution .................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ...............................................................

5

Work Flow ............................................................ .....5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

ON-VEHICLE REPAIR .................................11

INSTRUMENT PANEL ASSEMBLY .................11

Component Parts ................................................. ....11

Removal and Installation .........................................12

Disassembly and Assembly .....................................23

Revision: May 2010 2011 Versa

Page 2823 of 3787

IP-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929584

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929585

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 2824 of 3787

PRECAUTIONSIP-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

PrecautionINFOID:0000000005929586

• Disconnect both battery terminals in advance.

• Disconnect air bag system line in advance.

• Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

• Be careful not to scratch pad and other parts.

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts, protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an non-reusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

Revision: May 2010 2011 Versa

Page 2847 of 3787

LAN-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LAN

A

B

LAN

N

O P

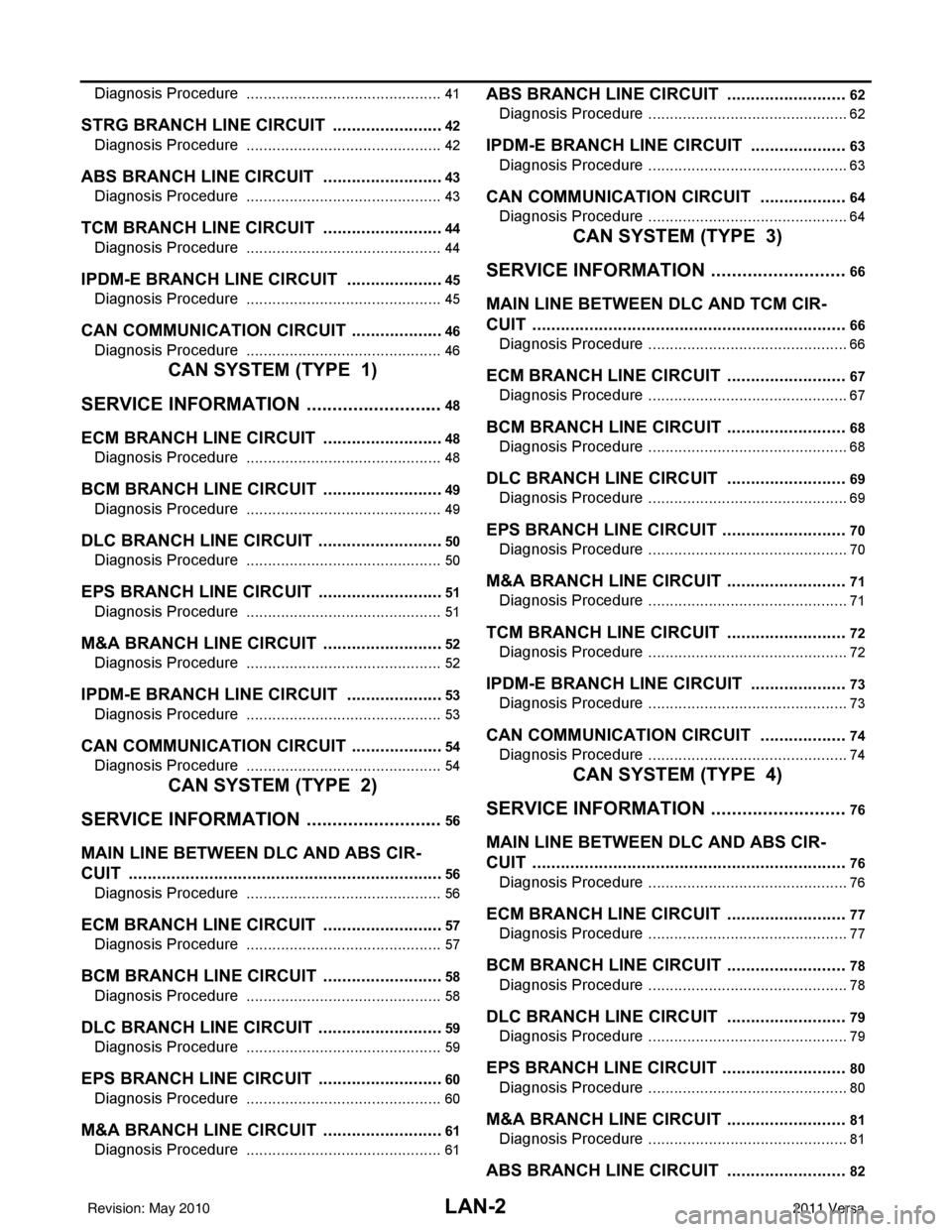

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

SERVICE INFORMATION .. ..........................

6

PRECAUTIONS .............................................. .....6

Precautions for Trouble Diagnosis ...................... ......6

Precautions for Harness Repair ................................6

CAN COMMUNICATION SYSTEM ................ .....7

System Description ............................................. ......7

System Diagram ........................................................7

CAN Communication Control Circuit .........................8

DIAG ON CAN .....................................................9

Description .......................................................... ......9

System Diagram ........................................................9

TROUBLE DIAGNOSIS .....................................10

Condition of Error Detection ................................ ....10

Symptom When Error Occurs in CAN Communi-

cation System ...................................................... ....

10

CAN Diagnosis with CONSULT-III ..........................13

Self-Diagnosis .........................................................14

CAN Diagnostic Support Monitor ............................14

How to Use CAN Communication Signal Chart ......16

DIAGNOSIS AND REPAIR WORKFLOW .........17

Trouble Diagnosis Flow Chart ............................. ....17

Trouble Diagnosis Procedure ..................................17

CAN

SERVICE INFORMATION .. .........................

22

HOW TO USE THIS SECTION ....................... ....22

Caution ................................................................ ....22

Abbreviation List ......................................................22

PRECAUTIONS ..................................................23

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

23

Precautions for Trouble Diagnosis ..........................23

Precautions for Harness Repair .......................... ....23

DIAGNOSIS AND REPAIR WORKFLOW ........25

Interview Sheet ........................................................25

CAN COMMUNICATION SYSTEM ...................26

CAN System Specification Chart .............................26

CAN Communication Signal Chart ..........................27

CAN COMMUNICATION SYSTEM ...................29

Component Parts Location ......................................29

Schematic ................................................................30

Wiring Diagram - CAN - ...........................................31

MALFUNCTION AREA CHART ........................33

Main Line .................................................................33

Branch Line .............................................................33

Short Circuit .............................................................33

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ..................................................................

34

Diagnosis Procedure ...............................................34

MAIN LINE BETWEEN DLC AND TCM CIR-

CUIT ..................................................................

35

Diagnosis Procedure ...............................................35

ECM BRANCH LINE CIRCUIT .........................36

Diagnosis Procedure ...............................................36

BCM BRANCH LINE CIRCUIT .........................37

Diagnosis Procedure ...............................................37

DLC BRANCH LINE CIRCUIT ..........................38

Diagnosis Procedure ...............................................38

EPS BRANCH LINE CIRCUIT ..........................39

Diagnosis Procedure ...............................................39

I-KEY BRANCH LINE CIRCUIT ........................40

Diagnosis Procedure ...............................................40

M&A BRANCH LINE CIRCUIT .........................41

Revision: May 2010 2011 Versa

Page 2848 of 3787

LAN-2

Diagnosis Procedure ..............................................41

STRG BRANCH LINE CIRCUIT ........................42

Diagnosis Procedure ........................................... ...42

ABS BRANCH LINE CIRCUIT ..........................43

Diagnosis Procedure ........................................... ...43

TCM BRANCH LINE CIRCUIT ..........................44

Diagnosis Procedure ........................................... ...44

IPDM-E BRANCH LINE CIRCUIT .....................45

Diagnosis Procedure ........................................... ...45

CAN COMMUNICATION CIRCUIT ....................46

Diagnosis Procedure ........................................... ...46

CAN SYSTEM (TYPE 1)

SERVICE INFORMATION ...........................

48

ECM BRANCH LINE CIRCUIT ....................... ...48

Diagnosis Procedure ........................................... ...48

BCM BRANCH LINE CIRCUIT ..........................49

Diagnosis Procedure ........................................... ...49

DLC BRANCH LINE CIRCUIT ...........................50

Diagnosis Procedure ........................................... ...50

EPS BRANCH LINE CIRCUIT ...........................51

Diagnosis Procedure ........................................... ...51

M&A BRANCH LINE CIRCUIT ..........................52

Diagnosis Procedure ........................................... ...52

IPDM-E BRANCH LINE CIRCUIT .....................53

Diagnosis Procedure ........................................... ...53

CAN COMMUNICATION CIRCUIT ....................54

Diagnosis Procedure ........................................... ...54

CAN SYSTEM (TYPE 2)

SERVICE INFORMATION ...........................

56

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ ...

56

Diagnosis Procedure ........................................... ...56

ECM BRANCH LINE CIRCUIT ..........................57

Diagnosis Procedure ........................................... ...57

BCM BRANCH LINE CIRCUIT ..........................58

Diagnosis Procedure ........................................... ...58

DLC BRANCH LINE CIRCUIT ...........................59

Diagnosis Procedure ........................................... ...59

EPS BRANCH LINE CIRCUIT ...........................60

Diagnosis Procedure ........................................... ...60

M&A BRANCH LINE CIRCUIT ..........................61

Diagnosis Procedure ........................................... ...61

ABS BRANCH LINE CIRCUIT ..........................62

Diagnosis Procedure ............................................ ...62

IPDM-E BRANCH LINE CIRCUIT .....................63

Diagnosis Procedure ............................................ ...63

CAN COMMUNICATION CIRCUIT ...................64

Diagnosis Procedure ............................................ ...64

CAN SYSTEM (TYPE 3)

SERVICE INFORMATION .. ........................

66

MAIN LINE BETWEEN DLC AND TCM CIR-

CUIT ................................................................ ...

66

Diagnosis Procedure ............................................ ...66

ECM BRANCH LINE CIRCUIT ..........................67

Diagnosis Procedure ............................................ ...67

BCM BRANCH LINE CIRCUIT ..........................68

Diagnosis Procedure ............................................ ...68

DLC BRANCH LINE CIRCUIT ..........................69

Diagnosis Procedure ............................................ ...69

EPS BRANCH LINE CIRCUIT ...........................70

Diagnosis Procedure ............................................ ...70

M&A BRANCH LINE CIRCUIT ..........................71

Diagnosis Procedure ............................................ ...71

TCM BRANCH LINE CIRCUIT ..........................72

Diagnosis Procedure ............................................ ...72

IPDM-E BRANCH LINE CIRCUIT .....................73

Diagnosis Procedure ............................................ ...73

CAN COMMUNICATION CIRCUIT ...................74

Diagnosis Procedure ............................................ ...74

CAN SYSTEM (TYPE 4)

SERVICE INFORMATION .. ........................

76

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ ...

76

Diagnosis Procedure ............................................ ...76

ECM BRANCH LINE CIRCUIT ..........................77

Diagnosis Procedure ............................................ ...77

BCM BRANCH LINE CIRCUIT ..........................78

Diagnosis Procedure ............................................ ...78

DLC BRANCH LINE CIRCUIT ..........................79

Diagnosis Procedure ............................................ ...79

EPS BRANCH LINE CIRCUIT ...........................80

Diagnosis Procedure ............................................ ...80

M&A BRANCH LINE CIRCUIT ..........................81

Diagnosis Procedure ............................................ ...81

ABS BRANCH LINE CIRCUIT ..........................82

Revision: May 2010 2011 Versa

Page 2849 of 3787

LAN-3

C

DE

F

G H

I

J

L

M A

B

LAN

N

O P

Diagnosis Procedure ...........................................

....

82

TCM BRANCH LINE CIRCUIT ...........................83

Diagnosis Procedure ........................................... ....83

IPDM-E BRANCH LINE CIRCUIT ......................84

Diagnosis Procedure ........................................... ....84

CAN COMMUNICATION CIRCUIT ....................85

Diagnosis Procedure ........................................... ....85

CAN SYSTEM (TYPE 5)

SERVICE INFORMATION .. .........................

87

ECM BRANCH LINE CIRCUIT ....................... ....87

Diagnosis Procedure ........................................... ....87

BCM BRANCH LINE CIRCUIT ..........................88

Diagnosis Procedure ........................................... ....88

DLC BRANCH LINE CIRCUIT ...........................89

Diagnosis Procedure ........................................... ....89

EPS BRANCH LINE CIRCUIT ...........................90

Diagnosis Procedure ........................................... ....90

M&A BRANCH LINE CIRCUIT ..........................91

Diagnosis Procedure ........................................... ....91

IPDM-E BRANCH LINE CIRCUIT ......................92

Diagnosis Procedure ........................................... ....92

CAN COMMUNICATION CIRCUIT ....................93

Diagnosis Procedure ........................................... ....93

CAN SYSTEM (TYPE 6)

SERVICE INFORMATION .. .........................

95

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ ....

95

Diagnosis Procedure ........................................... ....95

ECM BRANCH LINE CIRCUIT ...........................96

Diagnosis Procedure ........................................... ....96

BCM BRANCH LINE CIRCUIT ..........................97

Diagnosis Procedure ........................................... ....97

DLC BRANCH LINE CIRCUIT ...........................98

Diagnosis Procedure ........................................... ....98

EPS BRANCH LINE CIRCUIT ...........................99

Diagnosis Procedure ........................................... ....99

M&A BRANCH LINE CIRCUIT ........................100

Diagnosis Procedure ........................................... ..100

ABS BRANCH LINE CIRCUIT .........................101

Diagnosis Procedure ........................................... ..101

IPDM-E BRANCH LINE CIRCUIT ....................102

Diagnosis Procedure ........................................... ..102

CAN COMMUNICATION CIRCUIT .................103

Diagnosis Procedure ........................................... ..103

CAN SYSTEM (TYPE 7)

SERVICE INFORMATION .. .......................

105

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................

105

Diagnosis Procedure ........................................... ..105

ECM BRANCH LINE CIRCUIT .......................106

Diagnosis Procedure .............................................106

BCM BRANCH LINE CIRCUIT .......................107

Diagnosis Procedure .............................................107

DLC BRANCH LINE CIRCUIT ........................108

Diagnosis Procedure .............................................108

EPS BRANCH LINE CIRCUIT ........................109

Diagnosis Procedure .............................................109

M&A BRANCH LINE CIRCUIT .......................110

Diagnosis Procedure .............................................110

STRG BRANCH LINE CIRCUIT .....................111

Diagnosis Procedure .............................................111

ABS BRANCH LINE CIRCUIT ........................112

Diagnosis Procedure .............................................112

IPDM-E BRANCH LINE CIRCUIT ...................113

Diagnosis Procedure .............................................113

CAN COMMUNICATION CIRCUIT .................114

Diagnosis Procedure .............................................114

CAN SYSTEM (TYPE 8)

SERVICE INFORMATION .. .......................

116

MAIN LINE BETWEEN DLC AND TCM CIR-

CUIT ................................................................

116

Diagnosis Procedure ........................................... ..116

ECM BRANCH LINE CIRCUIT .......................117

Diagnosis Procedure .............................................117

BCM BRANCH LINE CIRCUIT .......................118

Diagnosis Procedure .............................................118

DLC BRANCH LINE CIRCUIT ........................119

Diagnosis Procedure .............................................119

EPS BRANCH LINE CIRCUIT ........................120

Diagnosis Procedure .............................................120

M&A BRANCH LINE CIRCUIT .......................121

Diagnosis Procedure .............................................121

TCM BRANCH LINE CIRCUIT ........................122

Diagnosis Procedure .............................................122

IPDM-E BRANCH LINE CIRCUIT ...................123

Revision: May 2010 2011 Versa

Page 2850 of 3787

LAN-4

Diagnosis Procedure .............................................123

CAN COMMUNICATION CIRCUIT ..................124

Diagnosis Procedure ........................................... ..124

CAN SYSTEM (TYPE 9)

SERVICE INFORMATION ..........................

126

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ .

126

Diagnosis Procedure ........................................... ..126

ECM BRANCH LINE CIRCUIT ........................127

Diagnosis Procedure ........................................... ..127

BCM BRANCH LINE CIRCUIT ........................128

Diagnosis Procedure ........................................... ..128

DLC BRANCH LINE CIRCUIT .........................129

Diagnosis Procedure ........................................... ..129

EPS BRANCH LINE CIRCUIT .........................130

Diagnosis Procedure ........................................... ..130

M&A BRANCH LINE CIRCUIT ........................131

Diagnosis Procedure ........................................... ..131

ABS BRANCH LINE CIRCUIT ........................132

Diagnosis Procedure ........................................... ..132

TCM BRANCH LINE CIRCUIT ........................133

Diagnosis Procedure ........................................... ..133

IPDM-E BRANCH LINE CIRCUIT ...................134

Diagnosis Procedure ........................................... ..134

CAN COMMUNICATION CIRCUIT ..................135

Diagnosis Procedure ........................................... ..135

CAN SYSTEM (TYPE 10)

SERVICE INFORMATION ..........................

137

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ .

137

Diagnosis Procedure ........................................... ..137

ECM BRANCH LINE CIRCUIT ........................138

Diagnosis Procedure ........................................... ..138

BCM BRANCH LINE CIRCUIT ........................139

Diagnosis Procedure ........................................... ..139

DLC BRANCH LINE CIRCUIT .........................140

Diagnosis Procedure ........................................... ..140

EPS BRANCH LINE CIRCUIT .........................141

Diagnosis Procedure ........................................... ..141

M&A BRANCH LINE CIRCUIT ........................142

Diagnosis Procedure ........................................... ..142

STRG BRANCH LINE CIRCUIT ......................143

Diagnosis Procedure ........................................... ..143

ABS BRANCH LINE CIRCUIT .........................144

Diagnosis Procedure ............................................ .144

TCM BRANCH LINE CIRCUIT .........................145

Diagnosis Procedure ............................................ .145

IPDM-E BRANCH LINE CIRCUIT ....................146

Diagnosis Procedure ............................................ .146

CAN COMMUNICATION CIRCUIT ..................147

Diagnosis Procedure ............................................ .147

CAN SYSTEM (TYPE 11)

SERVICE INFORMATION .. .......................

149

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ ..

149

Diagnosis Procedure ............................................ .149

ECM BRANCH LINE CIRCUIT .........................150

Diagnosis Procedure ............................................ .150

BCM BRANCH LINE CIRCUIT .........................151

Diagnosis Procedure ............................................ .151

DLC BRANCH LINE CIRCUIT .........................152

Diagnosis Procedure ............................................ .152

EPS BRANCH LINE CIRCUIT ..........................153

Diagnosis Procedure ............................................ .153

I-KEY BRANCH LINE CIRCUIT .......................154

Diagnosis Procedure ............................................ .154

M&A BRANCH LINE CIRCUIT .........................155

Diagnosis Procedure ............................................ .155

STRG BRANCH LINE CIRCUIT .......................156

Diagnosis Procedure ............................................ .156

ABS BRANCH LINE CIRCUIT .........................157

Diagnosis Procedure ............................................ .157

TCM BRANCH LINE CIRCUIT .........................158

Diagnosis Procedure ............................................ .158

IPDM-E BRANCH LINE CIRCUIT ....................159

Diagnosis Procedure ............................................ .159

CAN COMMUNICATION CIRCUIT ..................160

Diagnosis Procedure ............................................ .160

CAN SYSTEM (TYPE 12)

SERVICE INFORMATION .. .......................

162

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ................................................................ ..

162

Diagnosis Procedure ............................................ .162

ECM BRANCH LINE CIRCUIT .........................163

Diagnosis Procedure ............................................ .163

BCM BRANCH LINE CIRCUIT .........................164

Revision: May 2010 2011 Versa