system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2733 of 3787

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

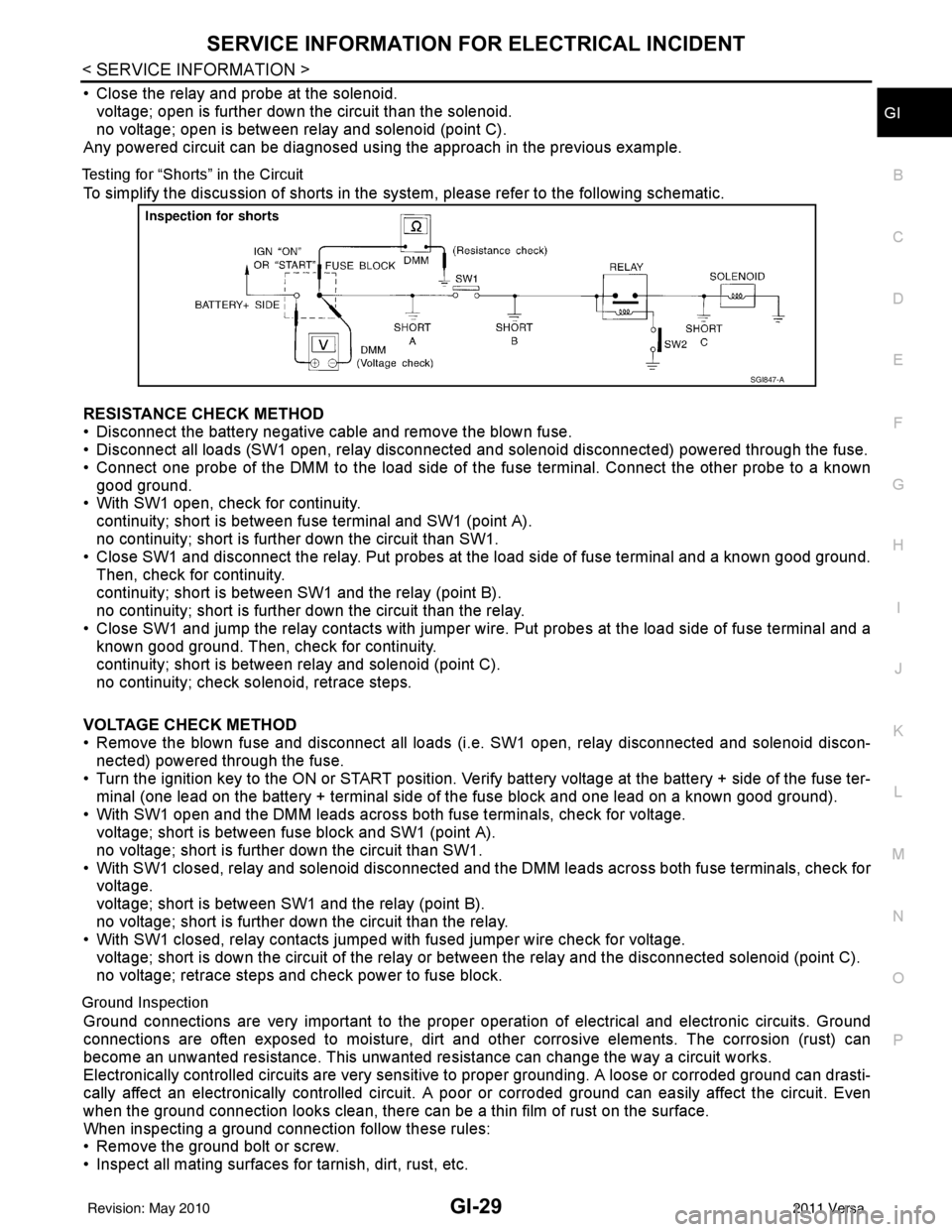

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

• With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground.

Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

• Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper oper ation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

SGI847-A

Revision: May 2010 2011 Versa

Page 2735 of 3787

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

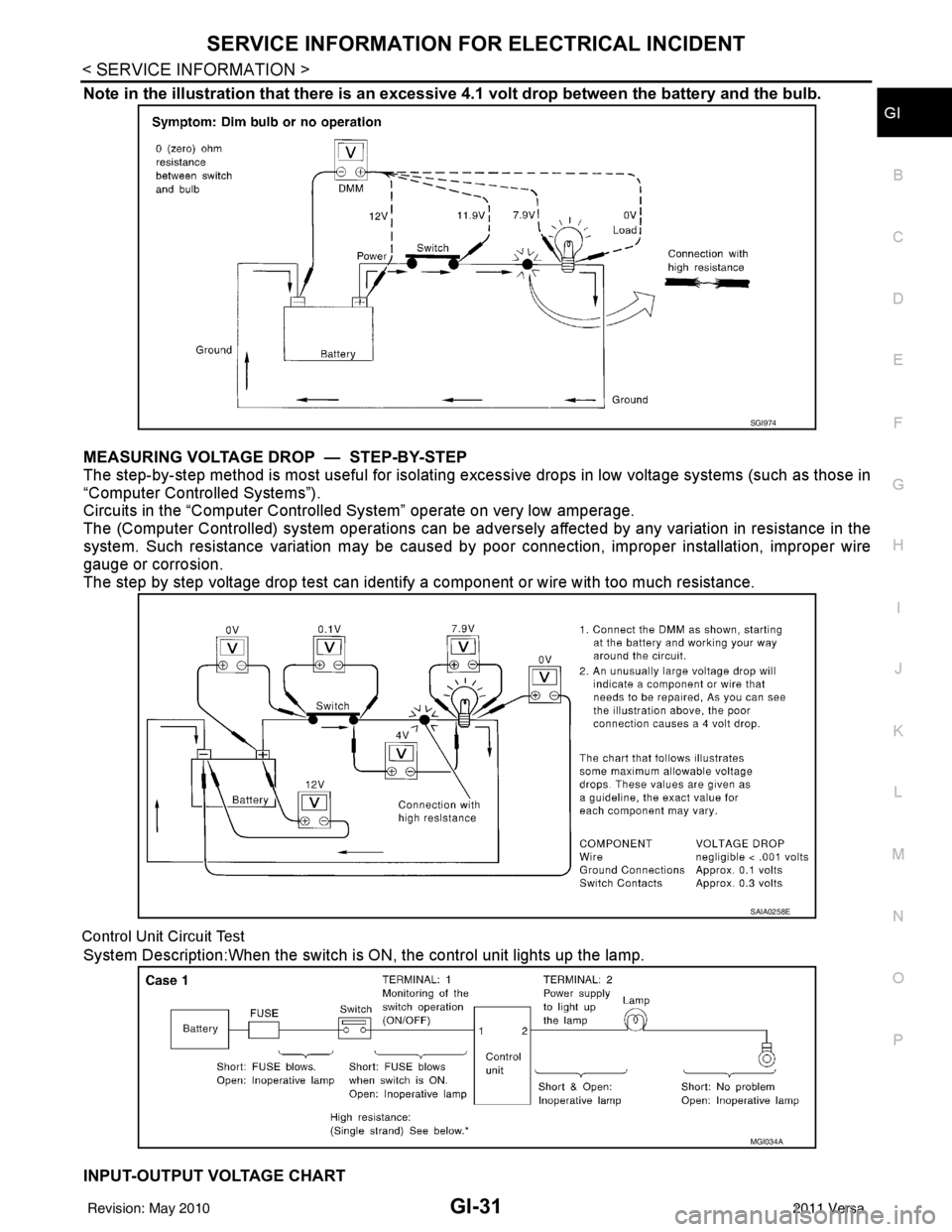

Note in the illustration that there is an excessi ve 4.1 volt drop between the battery and the bulb.

MEASURING VOLTAGE DRO P — STEP-BY-STEP

The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system oper ations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

Control Unit Circuit Test

System Description:When the switch is ON, the control unit lights up the lamp.

INPUT-OUTPUT VOLTAGE CHART

SGI974

SAIA0258E

MGI034A

Revision: May 2010 2011 Versa

Page 2739 of 3787

CONSULT-III CHECKING SYSTEMGI-35

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PCONSULT-III CHECKING SYSTEM

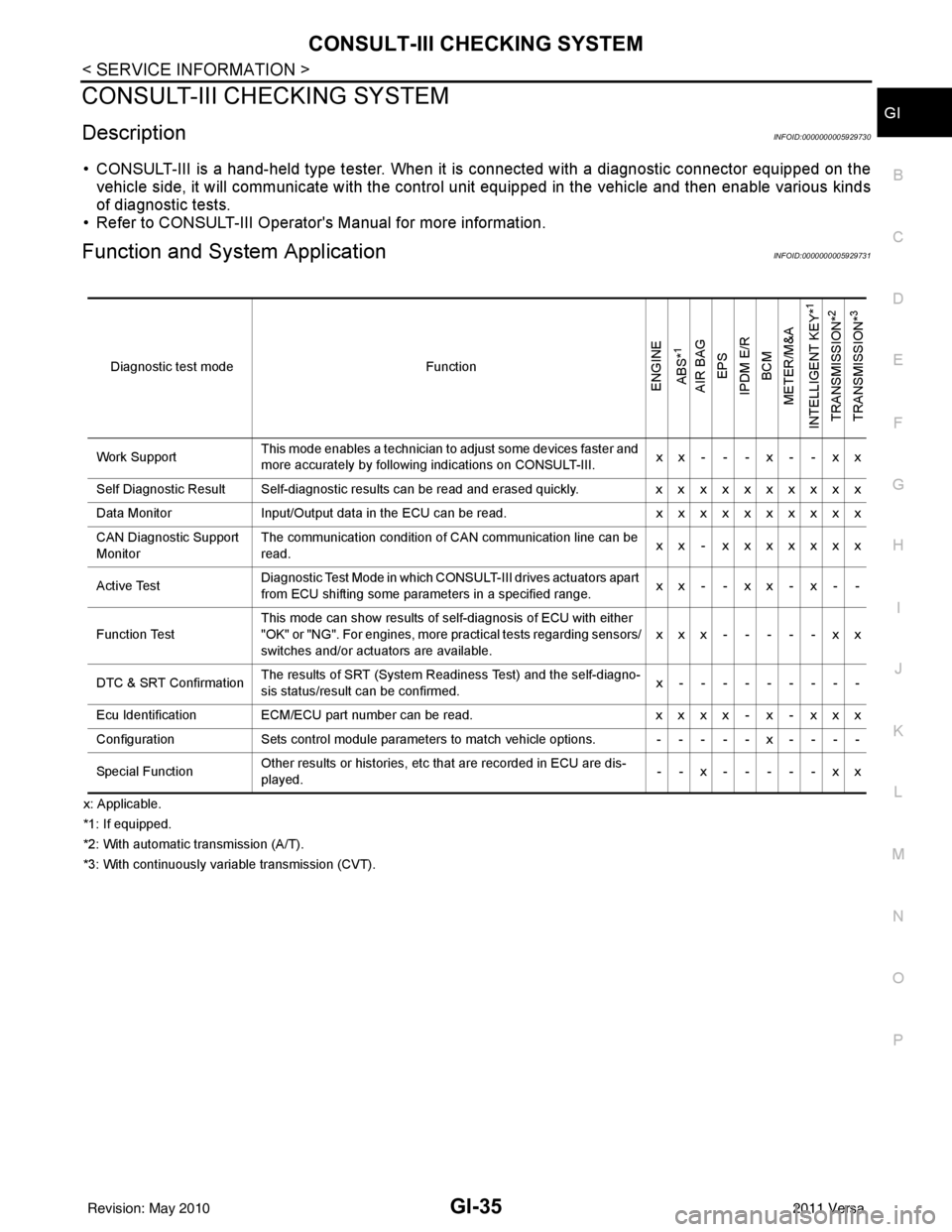

DescriptionINFOID:0000000005929730

• CONSULT-III is a hand-held type tester. When it is connected with a diagnostic connector equipped on the vehicle side, it will communicate with the contro l unit equipped in the vehicle and then enable various kinds

of diagnostic tests.

• Refer to CONSULT-III Operator's Manual for more information.

Function and System ApplicationINFOID:0000000005929731

x: Applicable.

*1: If equipped.

*2: With automatic transmission (A/T).

*3: With continuously variable transmission (CVT). Diagnostic test mode

Function

ENGINE

ABS*

1

AIR BAG EPS

IPDM E/R BCM

METER/M&A

INTELLIGENT KEY*

1

TRANSMISSION*

2

TRANSMISSION*

3

Work Support This mode enables a technician to adjust some devices faster and

more accurately by following indications on CONSULT-III. xx - - - x - - xx

Self Diagnostic Result Self-diagnostic results can be read and erased quickly. x x x x x x x x x x

Data Monitor Input/Output data in the ECU can be read. x x x x x x x x x x

CAN Diagnostic Support

Monitor The communication condition of CAN communication line can be

read.

xx - xxxxxxx

Active Test Diagnostic Test Mode in which CONSULT-III drives actuators apart

from ECU shifting some parameters in a specified range. xx - - xx - x - -

Function Test This mode can show results of self-diagnosis of ECU with either

"OK" or "NG". For engines, more practical tests regarding sensors/

switches and/or actuators are available. xxx - - - - - xx

DTC & SRT Confirmation The results of SRT (System Readiness Test) and the self-diagno-

sis status/result can be confirmed. x---------

Ecu Identification ECM/ECU part number can be read. x x x x - x - x x x

Configuration Sets control module parameters to match vehicle options. - - - - - x - - - -

Special Function Other results or histories, etc that are recorded in ECU are dis-

played. --x-----xx

Revision: May 2010

2011 Versa

Page 2740 of 3787

GI-36

< SERVICE INFORMATION >

CONSULT-III CHECKING SYSTEM

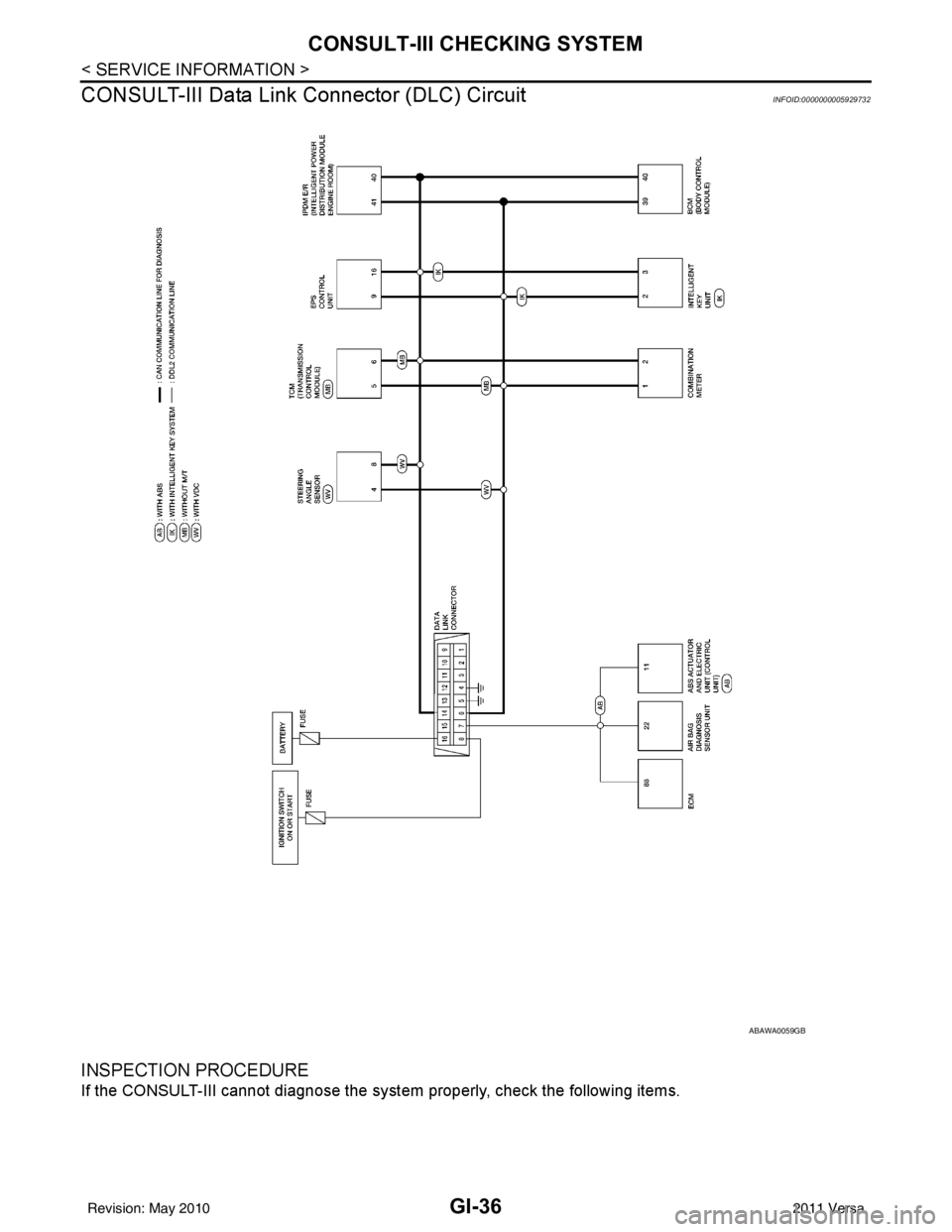

CONSULT-III Data Link Connector (DLC) Circuit

INFOID:0000000005929732

INSPECTION PROCEDURE

If the CONSULT-III cannot diagnose the syst em properly, check the following items.

ABAWA0059GB

Revision: May 2010 2011 Versa

Page 2741 of 3787

CONSULT-III CHECKING SYSTEMGI-37

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

NOTE:

The DDL1 and DDL2 circuits from DLC pins 6, 7 and 14 may be connected to more than one system. A short

in a DDL circuit connected to a control unit in one syst em may affect CONSULT-III access to other systems.

Symptom Check item

CONSULT-III cannot access

any system. • CONSULT-III DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4). For detailed cir-

cuit, refer to LAN-31, "

Wiring Diagram - CAN -".

CONSULT-III cannot access in-

dividual system. (Other sys-

tems can be accessed.) • Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wiring

diagram for each system).

• Open or short circuit between the system and CONSULT-III DLC (For detailed circuit, refer to wiring diagram for each system).

• Open or short circuit CAN communication line. Refer to LAN-31, "

Wiring Diagram - CAN -" .

Revision: May 2010 2011 Versa

Page 2744 of 3787

GI-40

< SERVICE INFORMATION >

TOW TRUCK TOWING

TOW TRUCK TOWING

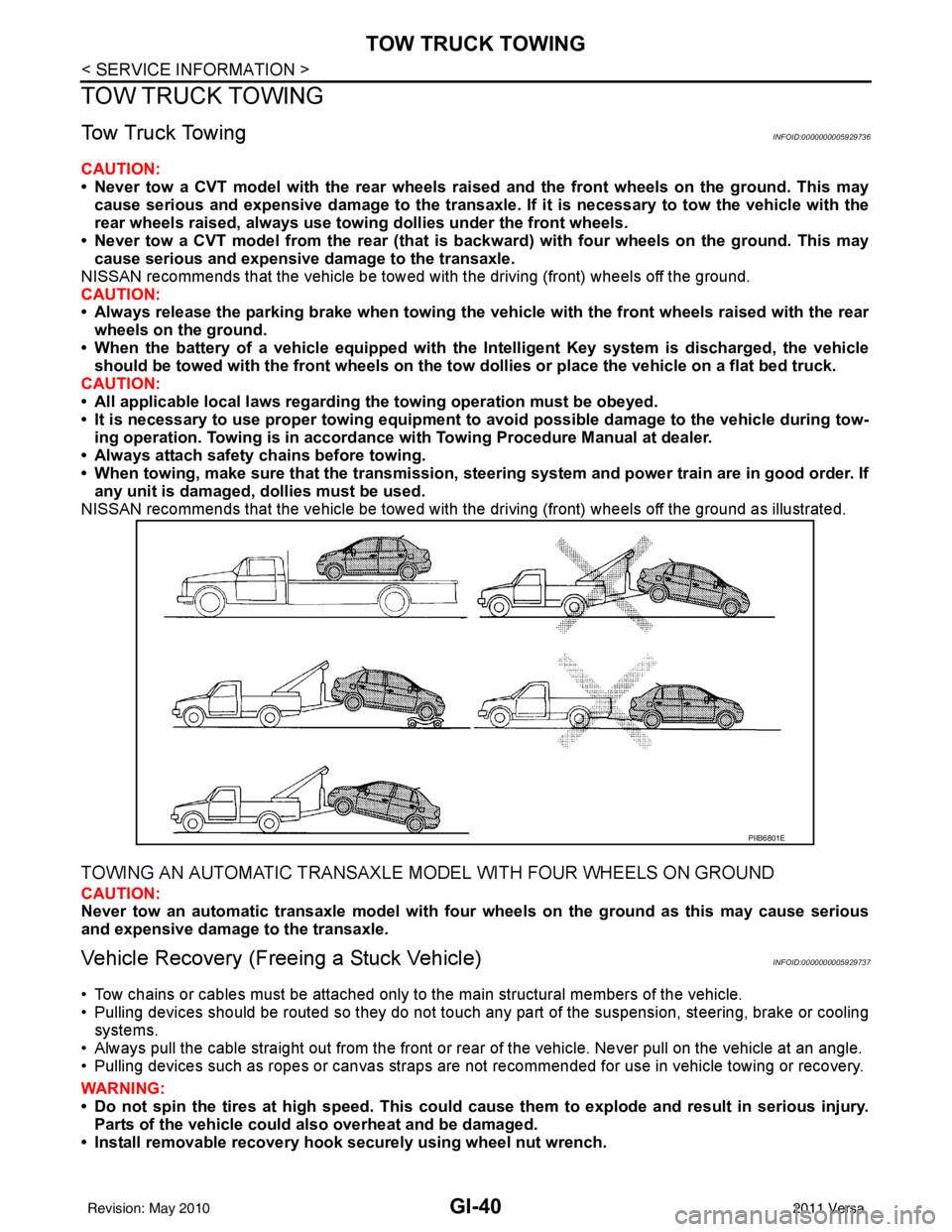

Tow Truck TowingINFOID:0000000005929736

CAUTION:

• Never tow a CVT model with the rear wheels raised and the front wheels on the ground. This may

cause serious and expensive damage to the transaxle. If it is necessary to tow the vehicle with the

rear wheels raised, always use towi ng dollies under the front wheels.

• Never tow a CVT model from the rear (that is backw ard) with four wheels on the ground. This may

cause serious and expensive damage to the transaxle.

NISSAN recommends that the vehicle be towed with the driving (front) wheels off the ground.

CAUTION:

• Always release the parking brake when towing the veh icle with the front wheels raised with the rear

wheels on the ground.

• When the battery of a vehicle equipped with th e Intelligent Key system is discharged, the vehicle

should be towed with the front wheels on the tow dollies or place the vehicle on a flat bed truck.

CAUTION:

• All applicable local laws regarding the towing operation must be obeyed.

• It is necessary to use proper towi ng equipment to avoid possible damage to the vehicle during tow-

ing operation. To wing is in accordance with Towing Procedure Manual at dealer.

• Always attach safety chains before towing.

• When towing, make sure that the transmission, steering system and power train are in good order. If

any unit is damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving (front) wheels off the ground as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

CAUTION:

Never tow an automatic transaxle model with four wheels on the ground as this may cause serious

and expensive damage to the transaxle.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000005929737

• Tow chains or cables must be attached only to the main structural members of the vehicle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or cooling

systems.

• Always pull the cable straight out from the front or r ear of the vehicle. Never pull on the vehicle at an angle.

• Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or recovery.

WARNING:

• Do not spin the tires at high sp eed. This could cause them to explode and result in serious injury.

Parts of the vehicle could also overheat and be damaged.

• Install removable recovery hook securely using wheel nut wrench.

PIIB6801E

Revision: May 2010 2011 Versa

Page 2748 of 3787

GI-44

< SERVICE INFORMATION >

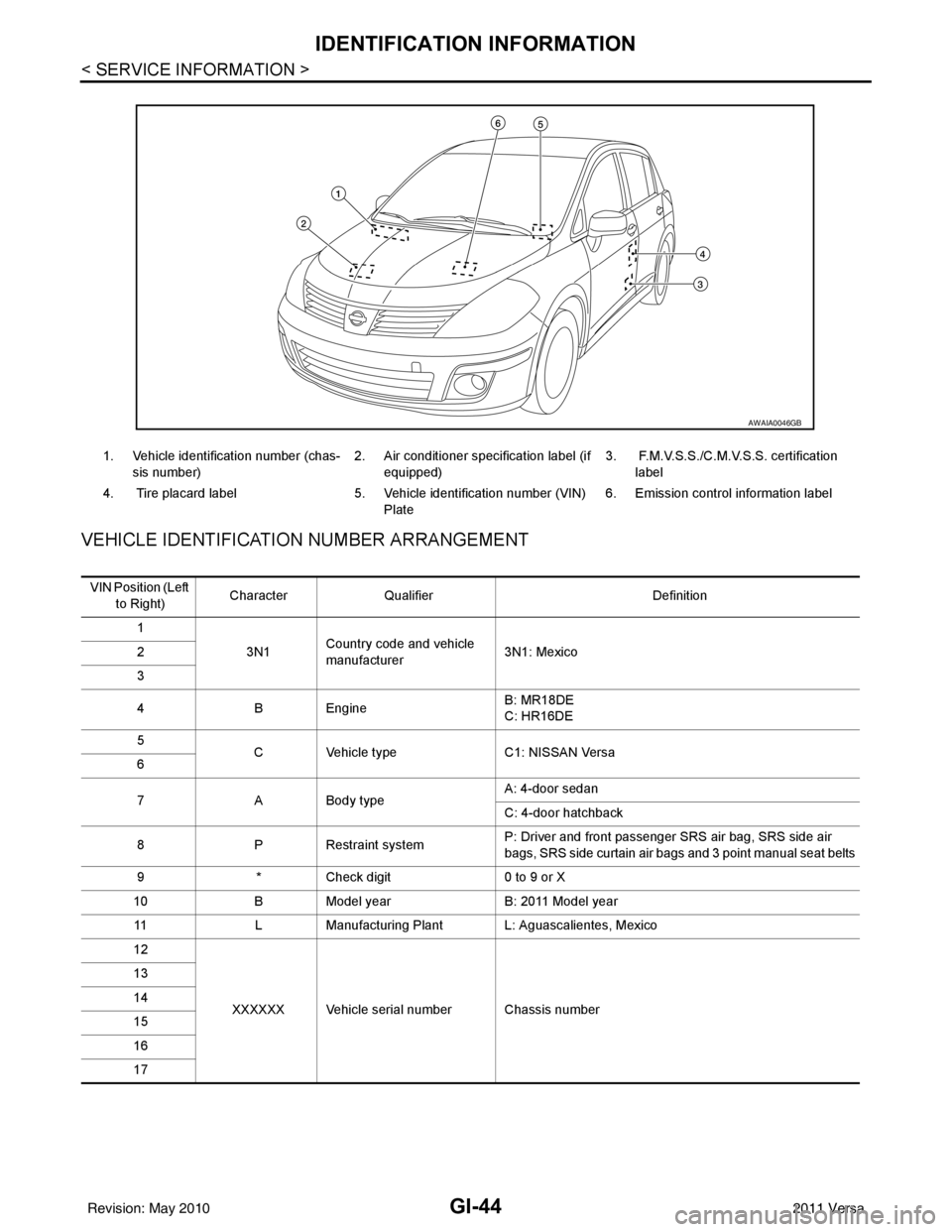

IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Vehicle identification number (chas-

sis number) 2. Air conditioner specification label (if

equipped) 3. F.M.V.S.S./C.M.V.S.S. certification

label

4. Tire placard label 5. Vehicle identification number (VIN)

Plate 6. Emission control information label

AWAIA0046GB

VIN Position (Left

to Right) Character

Qualifier Definition

1 3N1Country code and vehicle

manufacturer

3N1: Mexico

2

3

4 B Engine B: MR18DE

C: HR16DE

5 C Vehicle type C1: NISSAN Versa

6

7 A Body type A: 4-door sedan

C: 4-door hatchback

8 P Restraint system P: Driver and front passenger SRS air bag, SRS side air

bags, SRS side curtain air bags and 3 point manual seat belts

9 * Check digit 0 to 9 or X

10 B Model year B: 2011 Model year

11 L Manufacturing Plant L: Aguascalientes, Mexico

12

XXXXXX Vehicle serial number Chassis number

13

14

15

16

17

Revision: May 2010

2011 Versa

Page 2751 of 3787

TERMINOLOGYGI-47

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PTERMINOLOGY

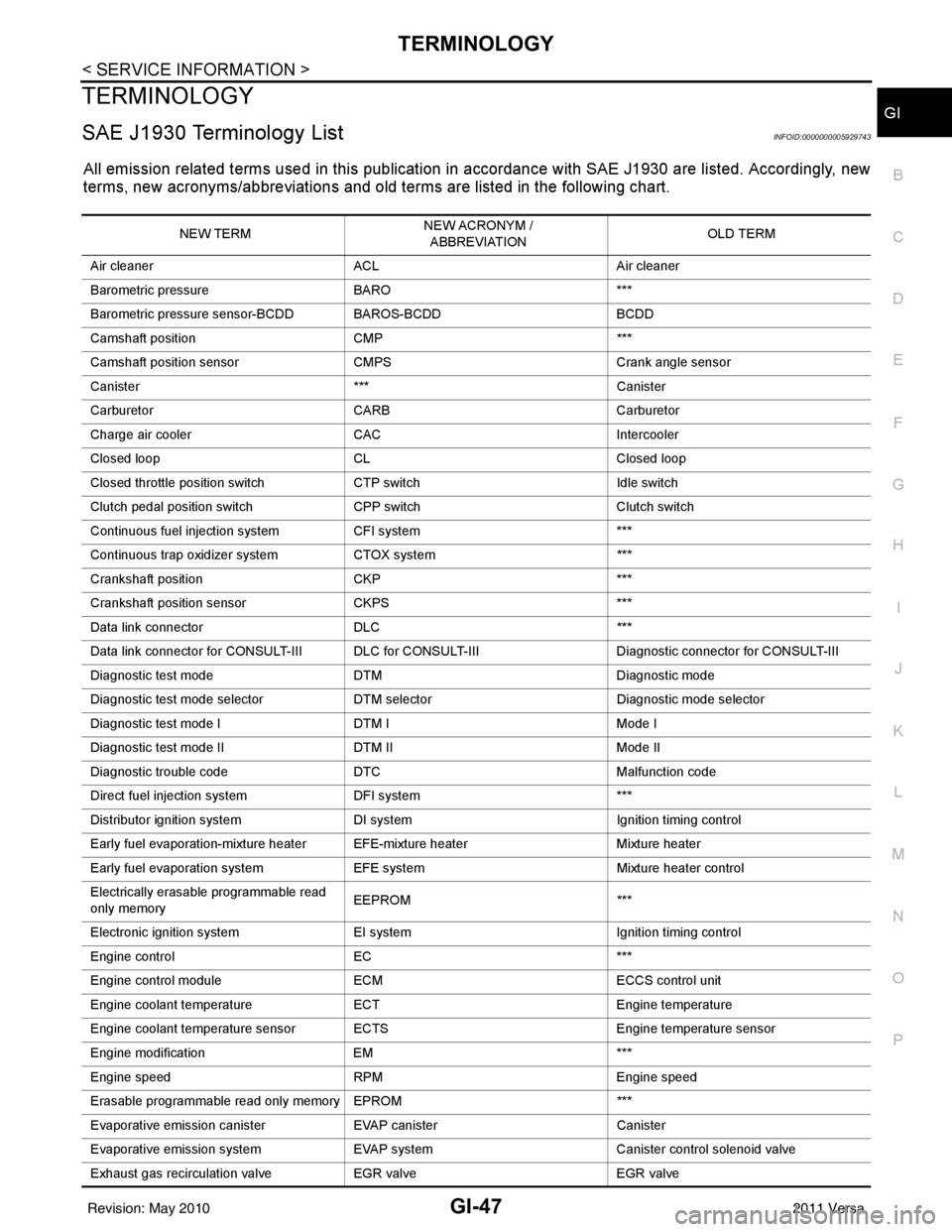

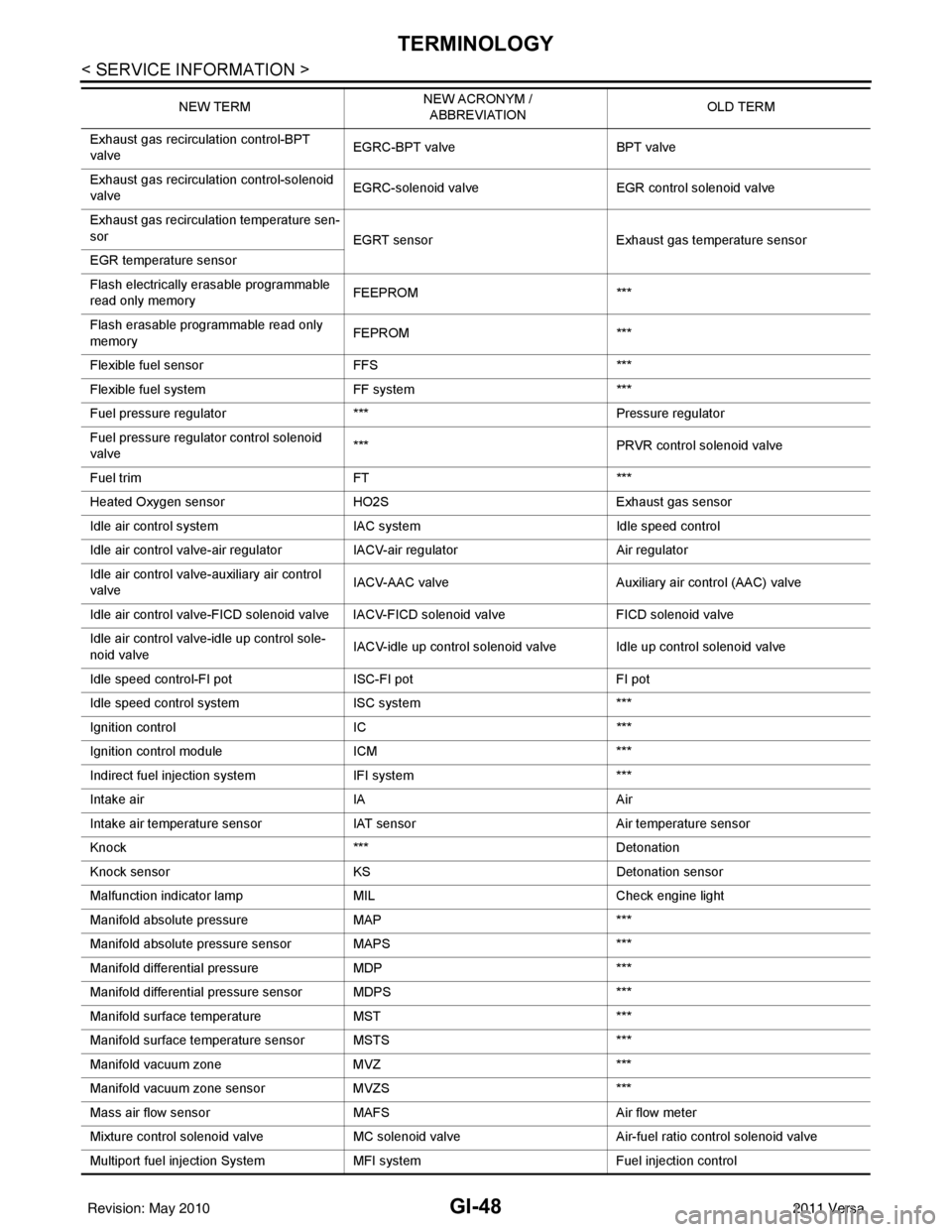

SAE J1930 Terminology ListINFOID:0000000005929743

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERM NEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP***

Camshaft position sensor CMPSCrank angle sensor

Canister ***Canister

Carburetor CARB Carburetor

Charge air cooler CACIntercooler

Closed loop CLClosed loop

Closed throttle position switch CTP switchIdle switch

Clutch pedal position switch CPP switchClutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC***

Data link connector fo r CONSULT-III DLC for CONSULT-III Diagnostic connector for CONSULT-III

Diagnostic test mode DTMDiagnostic mode

Diagnostic test mode selector DTM selectorDiagnostic mode selector

Diagnostic test mode I DTM IMode I

Diagnostic test mode II DTM IIMode II

Diagnostic trouble code DTCMalfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE systemMixture heater control

Electrically erasable programmable read

only memory EEPROM

***

Electronic ignition system EI systemIgnition timing control

Engine control EC ***

Engine control module ECMECCS control unit

Engine coolant temperature ECTEngine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPMEngine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canisterCanister

Evaporative emission system EVAP systemCanister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Revision: May 2010 2011 Versa

Page 2752 of 3787

GI-48

< SERVICE INFORMATION >

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve

BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve

EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensorExhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM

***

Flash erasable programmable read only

memory FEPROM

***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulato r*** Pressure regulator

Fuel pressure regulator control solenoid

valve ***

PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve- air regulator IACV-air regulator Air regulator

Idle air control valve- auxiliary air control

valve IACV-AAC valve

Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI potFI pot

Idle speed control system ISC system ***

Ignition control IC***

Ignition control module ICM***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valveAir-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection control

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: May 2010

2011 Versa

Page 2753 of 3787

TERMINOLOGYGI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

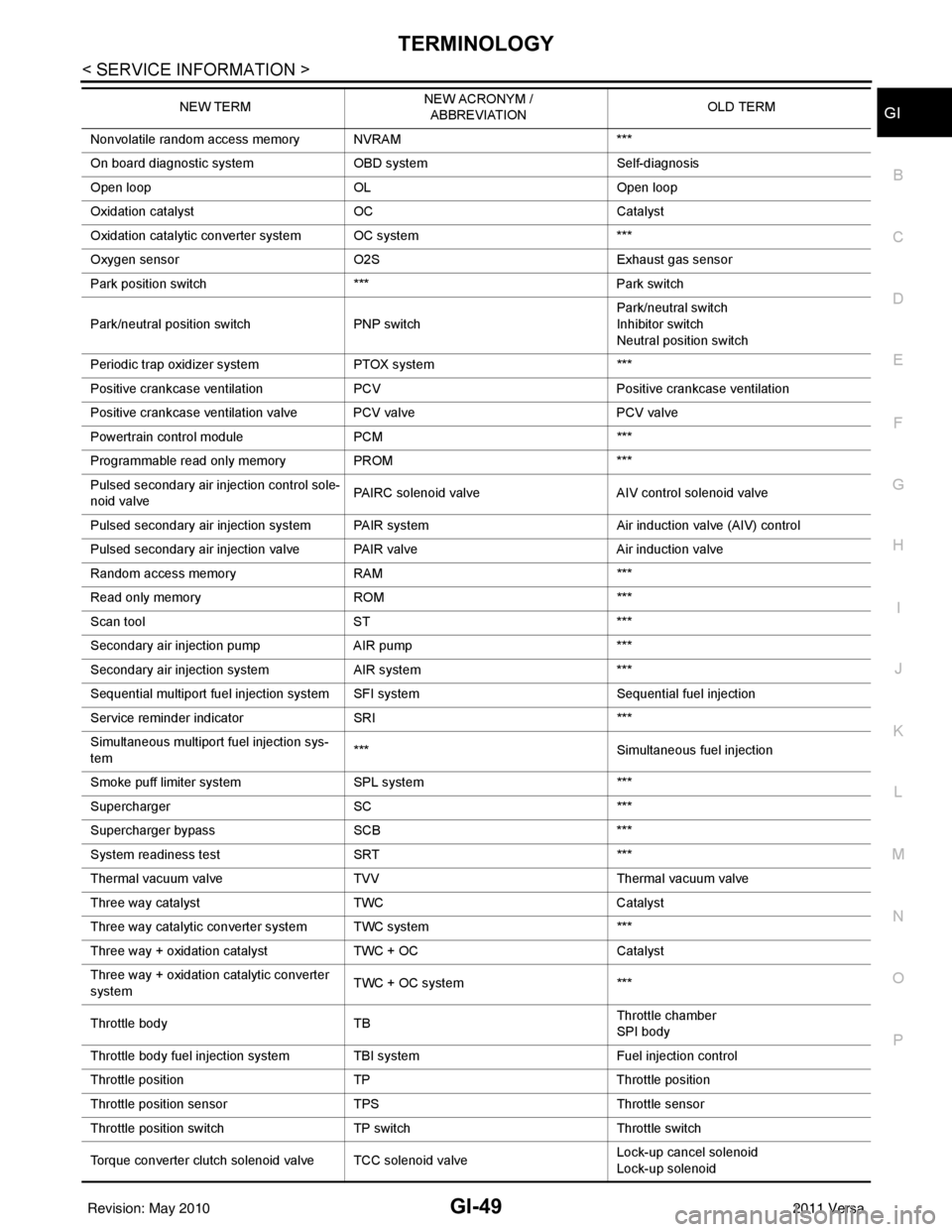

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OLOpen loop

Oxidation catalyst OCCatalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch ***Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain cont rol module PCM ***

Programmable read only memory PROM***

Pulsed secondary air injection control sole-

noid valve PAIRC solenoid valve

AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM***

Read only memory ROM***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI***

Simultaneous multiport fuel injection sys-

tem ***

Simultaneous fuel injection

Smoke puff limiter system SPL system***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

system TWC + OC system

***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switchThrottle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: May 2010

2011 Versa