audio NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3142 of 3787

LT-110

< SERVICE INFORMATION >

ILLUMINATION

• to hazard switch terminal 4

• to combination meter terminal 13

• to door mirror remote control switch terminal 15

• to combination switch (spiral cable) terminal 27 (with steering wheel audio control switches)

• to steering wheel audio control switches through combination switch (spiral cable) terminal 21 (with steeringwheel audio control switches).

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-74, "System Description".

CAN Communication System DescriptionINFOID:0000000005929151

Refer to LAN-7, "System Description" .

Revision: May 2010 2011 Versa

Page 3460 of 3787

PG-40

< SERVICE INFORMATION >

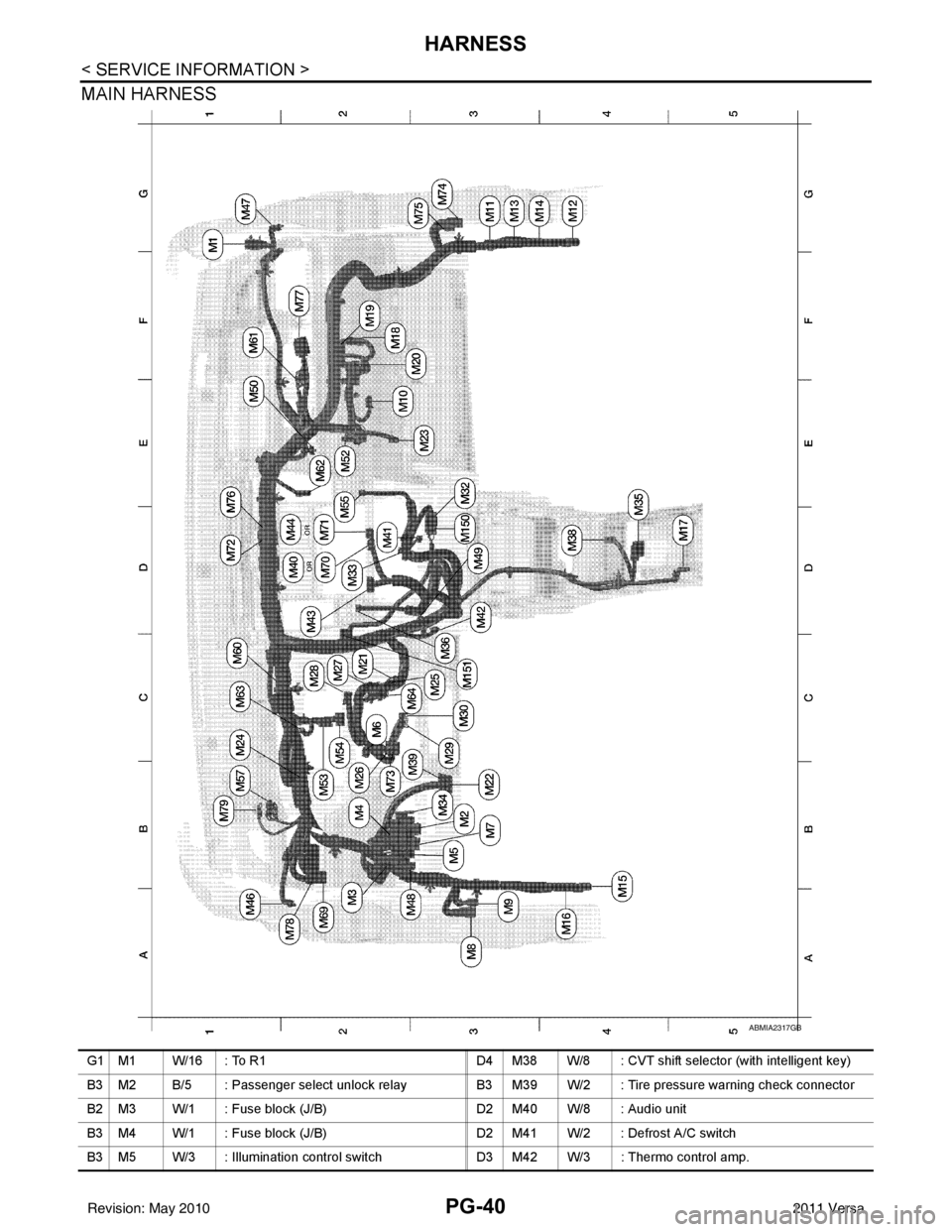

HARNESS

MAIN HARNESS

ABMIA2317GB

G1 M1 W/16 : To R1D4 M38 W/8 : CVT shift selector (with intelligent key)

B3 M2 B/5 : Passenger select unlock relay B3 M39 W/2 : Tire pressure warning check connector

B2 M3 W/1 : Fuse block (J/B) D2 M40 W/8 : Audio unit

B3 M4 W/1 : Fuse block (J/B) D2 M41 W/2 : Defrost A/C switch

B3 M5 W/3 : Illumination control switch D3 M42 W/3 : Thermo control amp.

Revision: May 2010 2011 Versa

Page 3461 of 3787

HARNESSPG-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

C2 M6 W/4 : Steering lock solenoid D2 M43 W/20 : Audio unit

B3 M7 W/16 : Door mirror re mote control switch D2 M44 W/16 : Audio unit

A3 M8 W/16 : To D2 D2 M45 W/12 : Audio unit

A3 M9 W/16 : To D1 A1 M46 BR/2 : Front tweeter LH

E2 M10 GR/2 : Instrument panel antenna G1 M47 BR/2 : Front tweeter RH

G3 M11 W/4 : To B106 B2 M48 L/4 : Heated mirror relay

G4 M12 W/16 : To B101 D3 M49 W/24 : iPod ® adapter

G3 M13 W/24 : To B102 E1 M50 GR/16 : iPod ® side

G3 M14 W/24 : To B120 E2 M52 W/40 : Intelligent key unit

B4 M15 W/16 : To B23 B2 M53 W/16 : EPS control unit

B4 M16 W/24 : To B24 B3 M54 B/2 : EPS control unit

D5 M17 B/1 : Parking brake switch D2 M55 W/4 : Hazard switch

F2 M18 W/40 : BCM (body control module) B2 M57 — : Body ground

F2 M19 W/15 : BCM (body control module) C1 M60 L/2 : EPS control unit

F3 M20 B/15 : BCM (body control module) F1 M61 — : Body ground

C2 M21 W/4 : NATS antenna amp. E2 M62 W/2 : Front blower motor

B3 M22 W/16 : Data link connector C1 M63 W/4 : Torque sensor

E3 M23 W/4 : Remote keyless entry receiver C3 M64 W/8 : Steering angle sensor

C1 M24 W/40 : Combination meter A2 M69 SMJ : To E7

C3 M25 /2 : Diode-1 D2 M70 W/24 : AV control unit

B2 M26 W/6 : Ignition switch D2 M71 W/9 : AV control unit

C2 M27 GR/6 : Key switch and key lock solenoid D1 M72 B/5 : USB interface and aux jack

C2 M28 W/16 : Combination switch B2 M73 GR/6 : Key switch and ignition knob switch

C3 M29 Y/6 : Combination switch G3 M74 W/12 : To D102

C3 M30 GR/8 : Combination switch G3 M75 W/12 : To D101

E3 M32 W/4 : To M150 E1 M76 B/4 : USB interface and aux jack

D2 M33 B/15 : Front air control F2 M77 Y/4 : Front passenger air bag module

B3 M34 GR/6 : VDC OFF switch A2 M78 B/2 : To E11

D4 M35 Y/28 : Air bag diagnosis sensor unit B1 M79 — : Body ground

C3 M36 W/3 : Front passenger air bag OFF indicator D3 M150 W/4 : To M32

D4 M38 W/6 : A/T shift selector (with A/T) C3 M151 W/4 : Front blower motor resistor

D4 M38 W/6 : CVT shift selector (without intelligent

key)

Revision: May 2010

2011 Versa

Page 3478 of 3787

PG-58

< SERVICE INFORMATION >

HARNESS

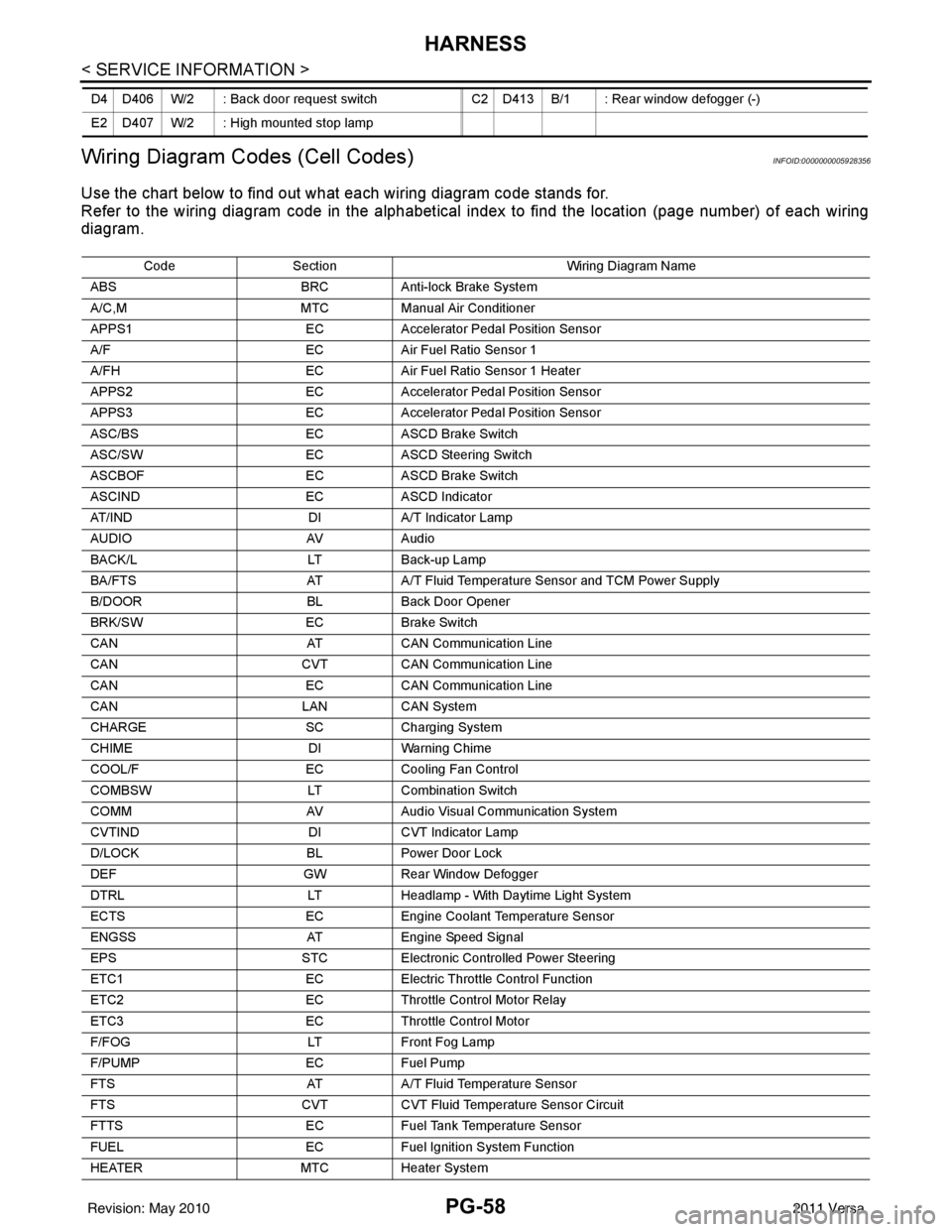

Wiring Diagram Codes (Cell Codes)

INFOID:0000000005928356

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D406 W/2 : Back door request switch C2 D413 B/1 : Rear window defogger (-)

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

HEATER MTC Heater System

Revision: May 2010 2011 Versa

Page 3530 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929522

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: May 2010 2011 Versa

Page 3586 of 3787

SC-8

< SERVICE INFORMATION >

BATTERY

INSTALLATION (All except MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

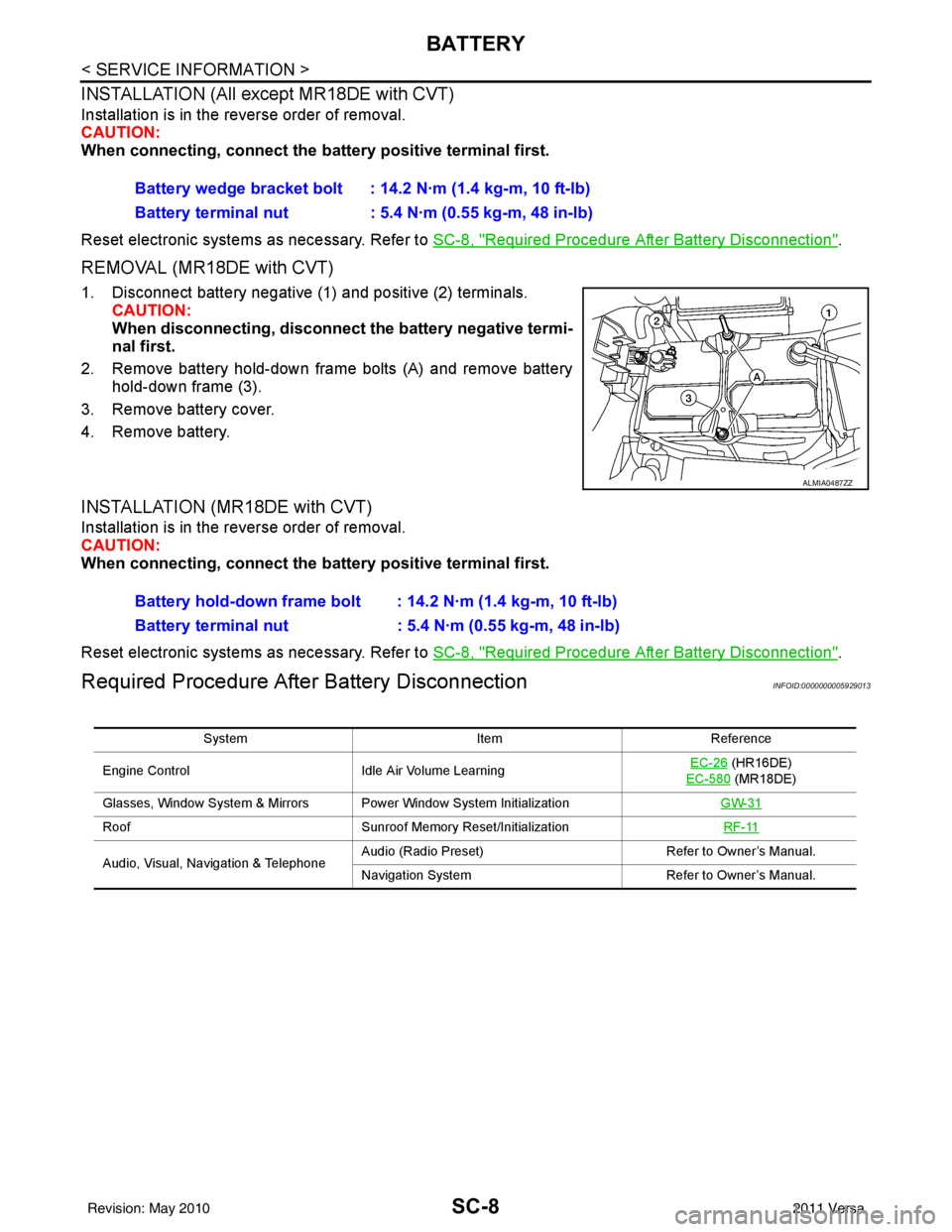

REMOVAL (MR18DE with CVT)

1. Disconnect battery negative (1) and positive (2) terminals.

CAUTION:

When disconnecting, disconnect the battery negative termi-

nal first.

2. Remove battery hold-down frame bolts (A) and remove battery hold-down frame (3).

3. Remove battery cover.

4. Remove battery.

INSTALLATION (MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

Required Procedure After Battery DisconnectionINFOID:0000000005929013

Battery wedge bracket bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

ALMIA0487ZZ

Battery hold-down frame bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

System ItemReference

Engine Control Idle Air Volume Learning EC-26

(HR16DE)

EC-580

(MR18DE)

Glasses, Window System & Mirrors Power Window System Initialization GW-31

RoofSunroof Memory Reset/Initialization RF-11

Audio, Visual, Navigation & TelephoneAudio (Radio Preset)

Refer to Owner’s Manual.

Navigation System Refer to Owner’s Manual.

Revision: May 2010 2011 Versa

Page 3612 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-7

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929602

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: May 2010 2011 Versa