system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 491 of 3787

BCS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION BCS

A

B

BCS

N

O P

CONTENTS

BODY CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

BCM (BODY CONTROL MODULE) ....................4

System Description ............................................. ......4

CAN Communication System Description .................8

Schematic ............................................................ .....9

BCM Terminal Arrangement ....................................11

Terminal and Reference Value for BCM ..................12

BCM Power Supply and Ground Circuit Inspection

....

16

CONSULT-III Function (BCM) .................................17

CAN Communication Inspection Using CON-

SULT-III (Self-Diagnosis) ..................................... ....

18

Configuration ...........................................................19

Removal and Installation of BCM ............................19

Revision: May 2010 2011 Versa

Page 492 of 3787

BCS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929254

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006413290

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 494 of 3787

BCS-4

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE)

System DescriptionINFOID:0000000005929255

BCM (body control module) controls the operation of various electrical units installed on the vehicle.

BCM FUNCTION

BCM has a combination switch reading function for reading the operation of combination switches (light, wiper,

washer, turn signal) in addition to the function for cont rolling the operation of various electrical components.

Also, it functions as an interface that receives signal s from the front air control, and sends signals to ECM

using CAN communication.

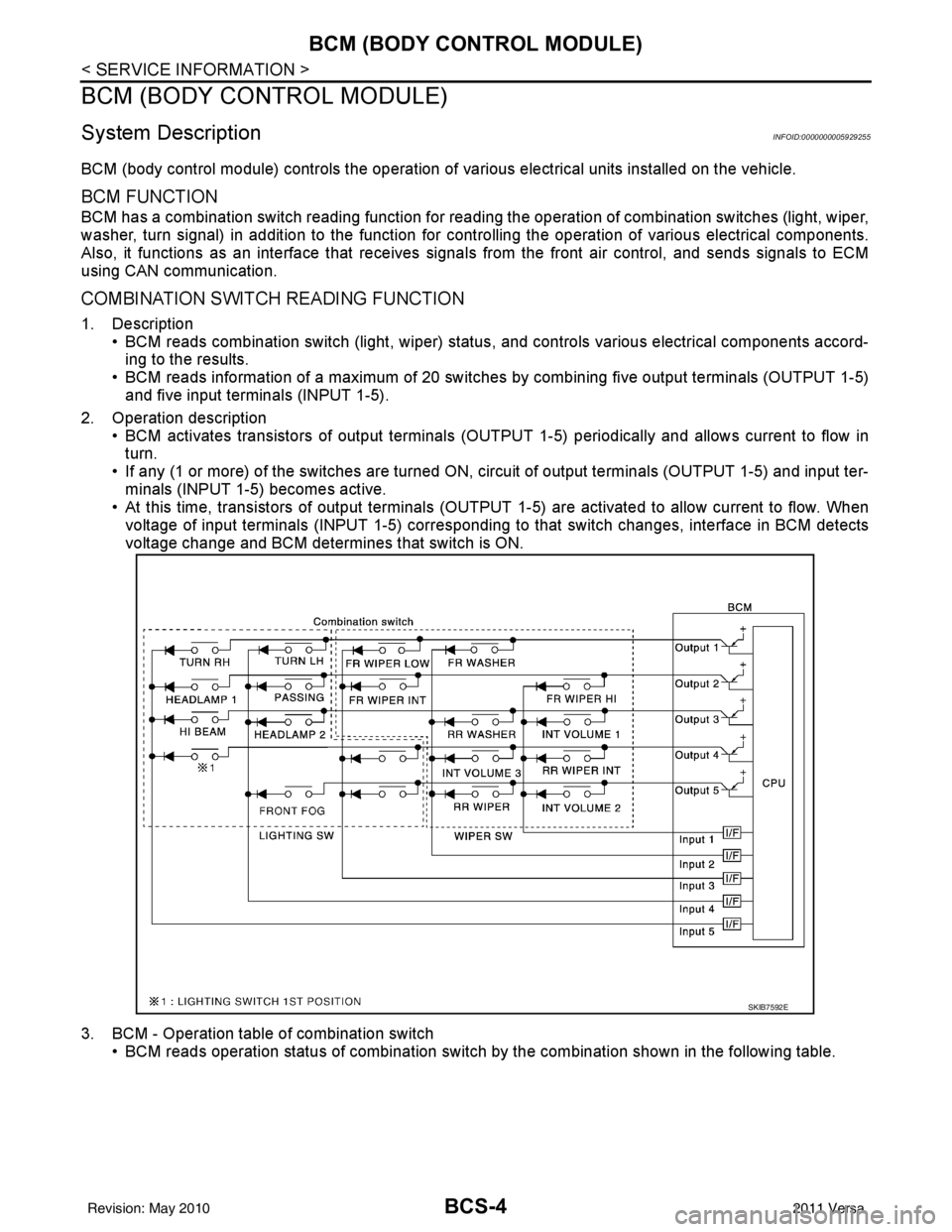

COMBINATION SWITCH READING FUNCTION

1. Description • BCM reads combination switch (light, wiper) status, and controls various electrical components accord-

ing to the results.

• BCM reads information of a maximum of 20 switches by combining five output terminals (OUTPUT 1-5)

and five input terminals (INPUT 1-5).

2. Operation description • BCM activates transistors of output terminals (OUTPU T 1-5) periodically and allows current to flow in

turn.

• If any (1 or more) of the switches are turned ON, circuit of output terminals (OUTPUT 1-5) and input ter- minals (INPUT 1-5) becomes active.

• At this time, transistors of output terminals (OUTPUT 1-5) are activated to allow current to flow. When

voltage of input terminals (INPUT 1-5) corresponding to that switch changes, interface in BCM detects

voltage change and BCM determines that switch is ON.

3. BCM - Operation table of combination switch • BCM reads operation status of combination switch by the combination shown in the following table.

SKIB7592E

Revision: May 2010 2011 Versa

Page 495 of 3787

BCM (BODY CONTROL MODULE)BCS-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

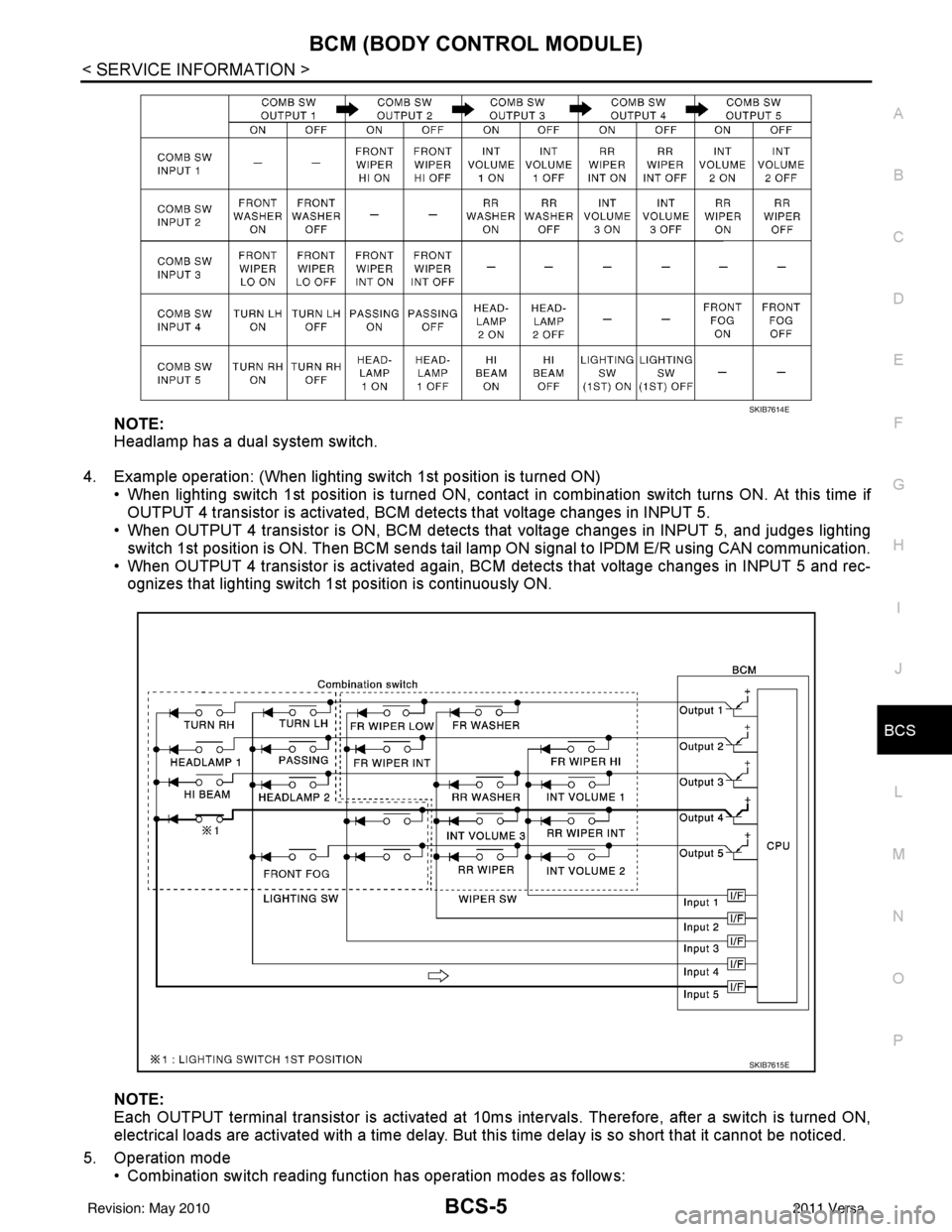

NOTE:

Headlamp has a dual system switch.

4. Example operation: (When lighting switch 1st position is turned ON) • When lighting switch 1st position is turned ON, contact in combination switch turns ON. At this time ifOUTPUT 4 transistor is activated, BCM detects that voltage changes in INPUT 5.

• When OUTPUT 4 transistor is ON, BCM detects that voltage changes in INPUT 5, and judges lighting

switch 1st position is ON. Then BCM sends tail lamp ON signal to IPDM E/R using CAN communication.

• When OUTPUT 4 transistor is activated again, BC M detects that voltage changes in INPUT 5 and rec-

ognizes that lighting switch 1st position is continuously ON.

NOTE:

Each OUTPUT terminal transistor is activated at 10ms intervals. Therefore, after a switch is turned ON,

electrical loads are activated with a time delay. But this time delay is so short that it cannot be noticed.

5. Operation mode • Combination switch reading functi on has operation modes as follows:

SKIB7614E

SKIB7615E

Revision: May 2010 2011 Versa

Page 496 of 3787

BCS-6

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

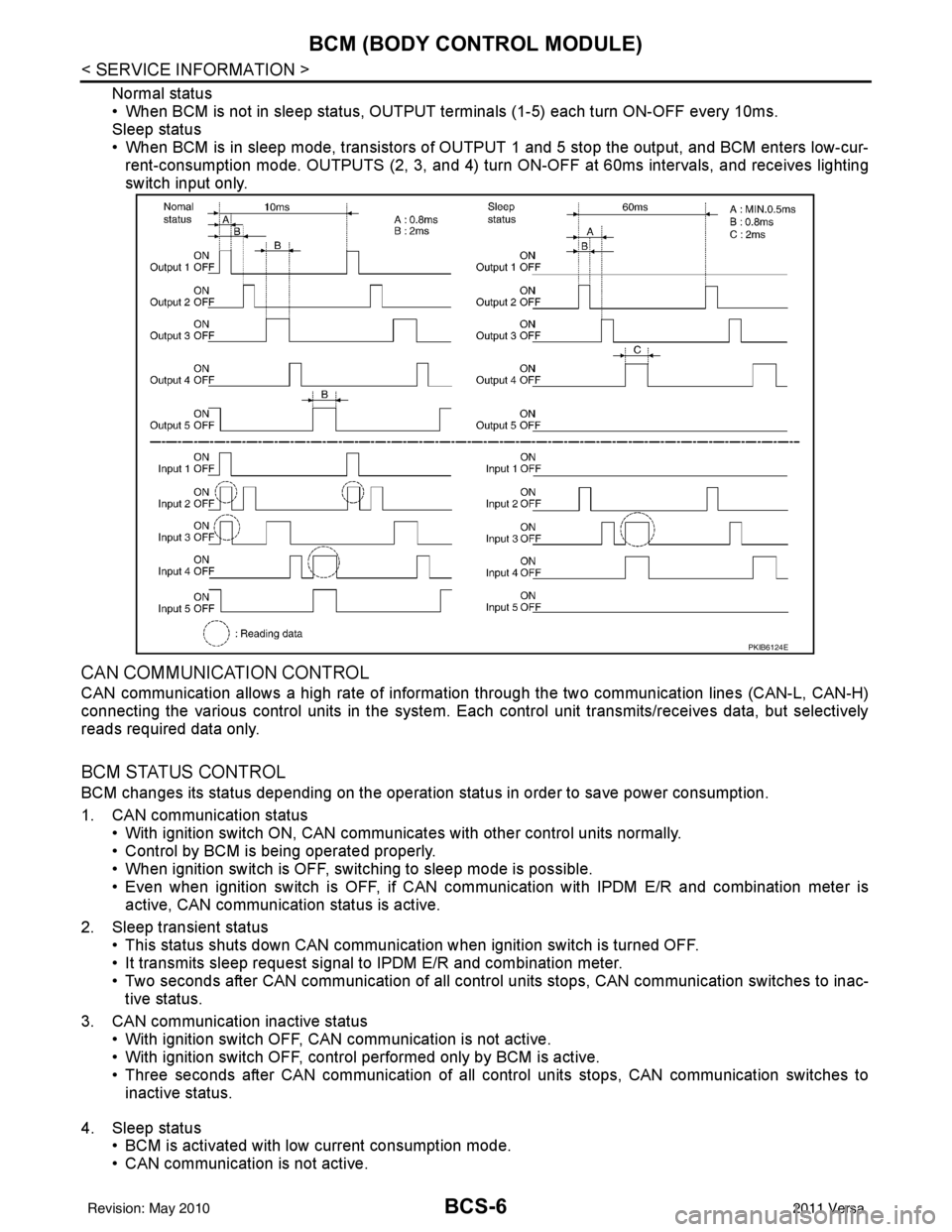

Normal status

• When BCM is not in sleep status, OUTPUT terminals (1-5) each turn ON-OFF every 10ms.

Sleep status

• When BCM is in sleep mode, transistors of OUTPUT 1 and 5 stop the output, and BCM enters low-cur-

rent-consumption mode. OUTPUTS (2, 3, and 4) turn ON-OFF at 60ms intervals, and receives lighting

switch input only.

CAN COMMUNICATION CONTROL

CAN communication allows a high rate of information through the two communication lines (CAN-L, CAN-H)

connecting the various control units in the system. Each control unit transmits/receives data, but selectively

reads required data only.

BCM STATUS CONTROL

BCM changes its status depending on the operation stat us in order to save power consumption.

1. CAN communication status • With ignition switch ON, CAN communicates with other control units normally.

• Control by BCM is being operated properly.

• When ignition switch is OFF, switching to sleep mode is possible.

• Even when ignition switch is OFF, if CAN communication with IPDM E/R and combination meter isactive, CAN communication status is active.

2. Sleep transient status • This status shuts down CAN communication when ignition switch is turned OFF.

• It transmits sleep request signal to IPDM E/R and combination meter.

• Two seconds after CAN communication of all control units stops, CAN communication switches to inac-tive status.

3. CAN communication inactive status • With ignition switch OFF, CAN communication is not active.

• With ignition switch OFF, control performed only by BCM is active.

• Three seconds after CAN communication of all control units stops, CAN communication switches to

inactive status.

4. Sleep status • BCM is activated with low current consumption mode.

• CAN communication is not active.

PKIB6124E

Revision: May 2010 2011 Versa

Page 497 of 3787

BCM (BODY CONTROL MODULE)BCS-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes , it switches to CAN communication state:

- Ignition switch

- Key switch (without Intelligent Key)

- Key switch and ignition knob switch (with Intelligent Key)

- Hazard switch

- Door lock/unlock switch (with power door locks)

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back door lock assembly (Hatchback)

- Trunk key cylinder switch (Sedan)

- Trunk lamp switch and trunk release solenoid (Sedan)

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal) (with power door locks)

- Front door key cylinder switch LH

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system (with power door locks). Refer to BL-23, "System Description" .

• Remote keyless entry system. Refer to BL-58, "

System Description" .

• Power window system (with power windows). Refer to GW-19, "

System Description" . NOTE

• Sunroof system (with sunroof). Refer to RF-11, "System Description". NOTE

• Room lamp timer. Refer to LT-93, "System Description" .

• Rear wiper and washer system (Hatchback). Refer to WW-27, "

System Description" .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, "System Description" .

• Vehicle security (theft warning) system. Refer to BL-218, "

System Description" .

• NVIS(NATS) system. Refer to BL-246, "

System Description" .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-74, "

System Description", LT- 5 , "System

Description" or LT-27, "System Description" .

• Front fog lamp (with front fog lamps). Refer to LT-41, "

System Description" .

• Front wiper and washer system. Refer to WW-5, "

System Description" .

• Rear window defogger system. Refer to GW-51, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-43, "System Description" .

• Turn signal and hazard warning lamps. Refer to LT-50, "

System Description" .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, "System Description" .

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob)• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH)

All door locking actuators

Power supply (IGN /RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply

Power supply to power window and sunroof system

Revision: May 2010 2011 Versa

Page 498 of 3787

BCS-8

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

CAN Communication System Description

INFOID:0000000005929256

Refer to LAN-7, "System Description".

Panic alarm •Key switch

•KeyfobIPDM E/R

Vehicle security system • All door switches

•Keyfob

• Door lock/unlock switch

• Trunk key cylinder switch (Se-

dan)

• Front door key cylinder switch LH • IPDM/ER

• Security indicator lamp

Battery save r control • Ignition switch

• Combination switch

IPDM E/R

Headlamp Combination switch IPDM E/R

Tail lamp Combination switchIPDM E/R

Front fog lamp (with front fog lamps) Combination switch IPDM E/R

Turn signal lamp Combination switch• Turn signal lamp

• Combination meter

Hazard lamp Hazard switch• Turn signal lamp

• Combination meter

Room lamp timer •Key switch

•Keyfob

• Main power window and door

lock/unlock switch

• Front door switch LH

• All door switch Interior room lamp

Back door switch signal (Hatchback) Back door lock assembly Luggage room lamp

Back door lock signal (Hatchback) Back door lock assembly Back door opener

Trunk lamp switch signal (Sedan) Trunk lamp switch and trunk re-

lease solenoidLuggage room lamp

Trunk lid opener signal (Sedan) Trunk lamp switch and trunk re-

lease solenoid

Trunk lid opener

Key warning chime •Key switch

• Front door switch LHCombination meter (warning buzzer)

Light warning chime • Combination switch

•Key switch

• Front door switch LHCombination meter (warning buzzer)

Seat belt warning chime • Seat belt buckle switch LH

• Ignition switch

Combination meter (warning buzzer)

Front wiper and washer system • Combination switch

• Ignition switchIPDM E/R

Rear window defogger Rear window defogger switch IPDM E/R

Rear wiper and washer system

(Hatchback) • Combination switch

• Ignition switch

Rear wiper motor

A/C switch signal Front air controlECM

Blower fan switch signal Front air controlECM

A/C indicator signal Front air controlA/C indicator

Low tire pressure warning system Remote keyless entry receiver Combination meter System

Input Output

Revision: May 2010 2011 Versa

Page 507 of 3787

BCM (BODY CONTROL MODULE)BCS-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

OK or NG

OK >> GO TO 3.

NG >> Repair or replace the harness.

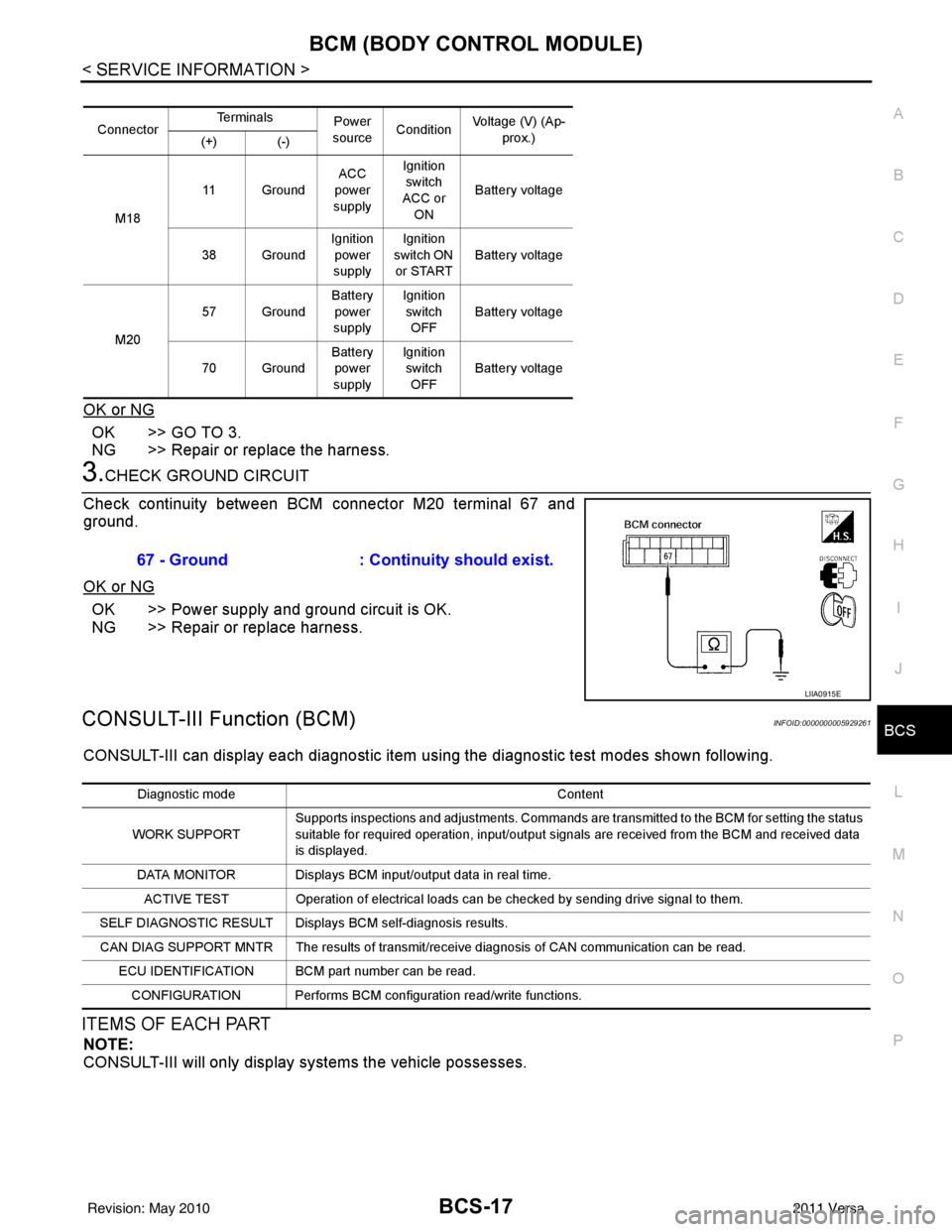

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

OK or NG

OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

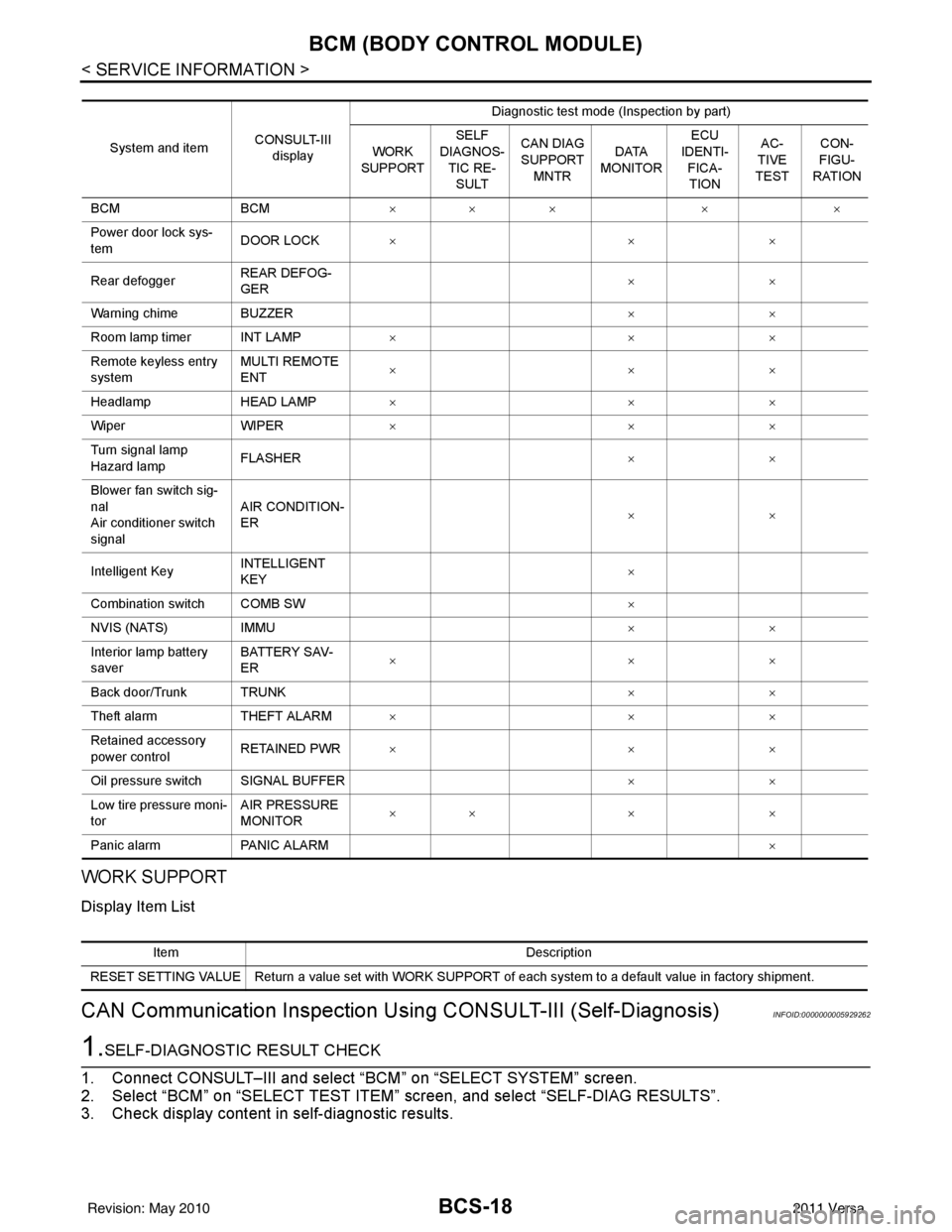

CONSULT-III Function (BCM)INFOID:0000000005929261

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses.

Connector Te r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

67 - Ground

: Continuity should exist.

LIIA0915E

Diagnostic mode Content

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the status

suitable for required operation, input/output signals are received from the BCM and received data

is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 508 of 3787

BCS-18

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

WORK SUPPORT

Display Item List

CAN Communication Inspection Using CONSULT-III (Self-Diagnosis)INFOID:0000000005929262

1.SELF-DIAGNOSTIC RESULT CHECK

1. Connect CONSULT–III and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT TEST ITEM” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

System and item CONSULT-III

display Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

DIAGNOS- TIC RE-

SULT CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

IDENTI- FICA-

TION AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Remote keyless entry

system MULTI REMOTE

ENT

××

×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch sig-

nal

Air conditioner switch

signal AIR CONDITION-

ER

××

Intelligent Key INTELLIGENT

KEY ×

Combination switch COMB SW ×

NVIS (NATS) IMMU ××

Interior lamp battery

saver BATTERY SAV-

ER

××

×

Back door/Trunk TRUNK ××

Theft alarm THEFT ALARM×× ×

Retained accessory

power control RETAINED PWR

×× ×

Oil pressure swit ch SIGNAL BUFFER ××

Low tire pressure moni-

tor AIR PRESSURE

MONITOR

××

× ×

Panic alarm PANIC ALARM ×

ItemDescription

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

Revision: May 2010 2011 Versa

Page 509 of 3787

BCM (BODY CONTROL MODULE)BCS-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

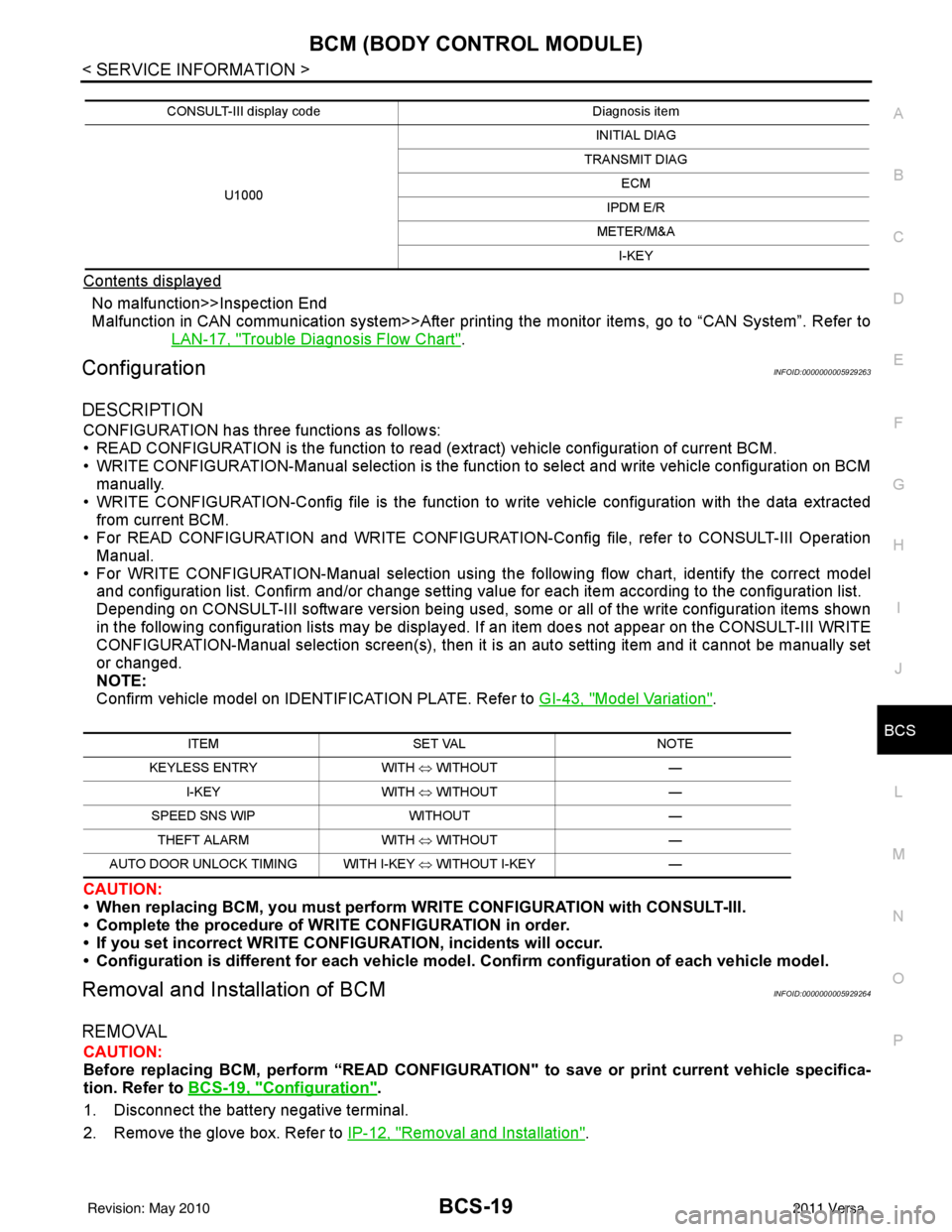

Contents displayed

No malfunction>>Inspection End

Malfunction in CAN communication system>>After printing the monitor items, go to “CAN System”. Refer to

LAN-17, "

Trouble Diagnosis Flow Chart".

ConfigurationINFOID:0000000005929263

DESCRIPTION

CONFIGURATION has three functions as follows:

• READ CONFIGURATION is the function to read (e xtract) vehicle configuration of current BCM.

• WRITE CONFIGURATION-Manual selection is the functi on to select and write vehicle configuration on BCM

manually.

• WRITE CONFIGURATION-Config file is the function to write vehicle configuration with the data extracted

from current BCM.

• For READ CONFIGURATION and WRITE CONFIGURATION -Config file, refer to CONSULT-III Operation

Manual.

• For WRITE CONFIGURATION-Manual selection using the following flow chart, identify the correct model

and configuration list. Confirm and/or change setting val ue for each item according to the configuration list.

Depending on CONSULT-III software version being used, some or all of the write configuration items shown

in the following configuration lists may be display ed. If an item does not appear on the CONSULT-III WRITE

CONFIGURATION-Manual selection screen(s), then it is an auto setting item and it cannot be manually set

or changed.

NOTE:

Confirm vehicle model on IDENTIFICATION PLATE. Refer to GI-43, "

Model Variation".

CAUTION:

• When replacing BCM, you must perform WRITE CONFIGURATION with CONSULT-III.

• Complete the procedure of WRITE CONFIGURATION in order.

• If you set incorrect WRITE CONF IGURATION, incidents will occur.

• Configuration is different for each vehicle model. Confirm conf iguration of each vehicle model.

Removal and Installation of BCMINFOID:0000000005929264

REMOVAL

CAUTION:

Before replacing BCM, perform “READ CONFIGURATI ON" to save or print current vehicle specifica-

tion. Refer to BCS-19, "

Configuration".

1. Disconnect the battery negative terminal.

2. Remove the glove box. Refer to IP-12, "

Removal and Installation".

CONSULT-III display code Diagnosis item

U1000 INITIAL DIAG

TRANSMIT DIAG ECM

IPDM E/R

METER/M&A I-KEY

ITEM SET VAL NOTE

KEYLESS ENTRY WITH ⇔ WITHOUT —

I-KEY WITH ⇔ WITHOUT —

SPEED SNS WIP WITHOUT —

THEFT ALARM WITH ⇔ WITHOUT —

AUTO DOOR UNLOCK TIMING WITH I-KEY ⇔ WITHOUT I-KEY —

Revision: May 2010 2011 Versa