system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 510 of 3787

BCS-20

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

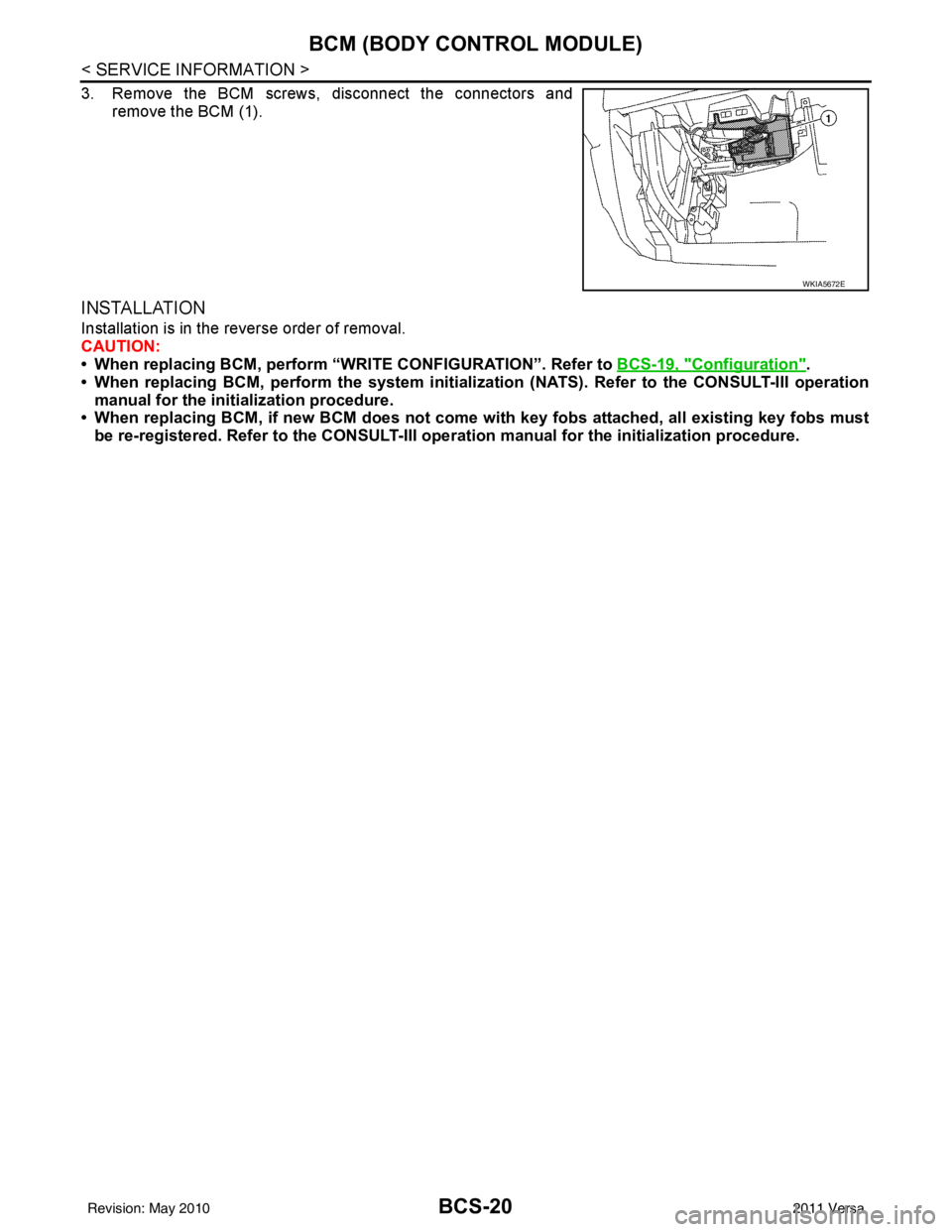

3. Remove the BCM screws, disconnect the connectors andremove the BCM (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing BCM, perform “WRI TE CONFIGURATION”. Refer to BCS-19, "

Configuration".

• When replacing BCM, perform the system initializati on (NATS). Refer to the CONSULT-III operation

manual for the initialization procedure.

• When replacing BCM, if new BCM does not come wi th key fobs attached, all existing key fobs must

be re-registered. Refer to the CONSULT-III oper ation manual for the initialization procedure.

WKIA5672E

Revision: May 2010 2011 Versa

Page 511 of 3787

BL-1

BODY

C

DE

F

G H

J

K L

M

SECTION BL

A

B

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspection .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ................................................21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description .................................................23

CAN Communication System Description ...............25

Schematic ...............................................................26

Wiring Diagram - D/LOCK - .....................................27

Schematic ...............................................................31

Wiring Diagram - D/LOCK - .....................................32

Terminal and Reference Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (BCM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection

....

43

Door Switch Check (Hatchback) ..............................44

Door Switch Check (Sedan) ....................................47

Key Switch (Insert) Check .......................................48

Door Lock and Unlock Switch Check ......................49

Front Door Lock Assembly LH (Actuator) Check .....52

Front Door Lock Assembly RH (Actuator) Check ....53

Rear Door Lock Actuator LH/RH Check .............. ....54

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

56

REMOTE KEYLESS ENTRY SYSTEM .............58

Component Parts and Harness Connector Loca-

tion ...........................................................................

58

System Description ..................................................58

CAN Communication System Description ...............60

Schematic ................................................................61

Wiring Diagram - KEYLES - ....................................62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ...................................................69

CONSULT-III Function (BCM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ..........................71

Keyfob Battery and Function Check ........................72

ACC Switch Circuit Check .......................................74

Door Switch Check (Hatchback) ..............................74

Door Switch Check (Sedan) ....................................76

Key Switch (Insert) Check .......................................78

Hazard Function Check ...........................................79

Horn Function Check ...............................................79

Interior Lamp and Ignition Keyhole Illumination

Function Check ........................................................

80

Remote Keyless Entry Receiver Check ...................80

Revision: May 2010 2011 Versa

Page 512 of 3787

BL-2

Keyfob Function (Lock) Check ...............................82

Keyfob Function (Unlock) Check ............................82

ID Code Entry Procedure .................................... ...83

Keyfob Battery Replacement ............................... ...85

Removal and Installation of Remote Keyless Entry

Receiver .............................................................. ...

85

INTELLIGENT KEY SYSTEM ............................86

Component Parts and Harness Connector Loca-

tion ....................................................................... ...

86

System Description .................................................88

CAN Communication System Description ..............95

Schematic ............................................................ ...96

Wiring Diagram - I/KEY - ..................................... ...98

Intelligent Key Unit Har ness Connector Terminal

Layout .................................................................. ..

108

Terminal and Reference Value for Intelligent Key

Unit ........................................................................

108

Steering Lock Solenoid Harness Connector Ter-

minal Layout ..........................................................

110

Terminal and Reference Value for Steering Lock

Solenoid .................................................................

110

Terminal and Reference Value for BCM ................111

Trouble Diagnosis Procedure ................................115

CONSULT-III Functions (INTELLIGENT KEY) ......117

CONSULT-III Application Item ............................. ..117

Trouble Diagnosis Symptom Chart ........................119

CAN Communication System Inspection ...............126

Power Supply and Ground Circuit Inspection ........126

Key Switch (Intelligent Key Unit Input) Check .......127

Key Switch (BCM Input) Check .............................128

Ignition Knob Switch Check ................................. ..129

Door Switch Check (Hatchback) ............................131

Door Switch Check (Sedan) ..................................134

Door Request Switch Check ..................................135

Back Door Request Switch Check (Hatchback) ....137

Trunk Opener Request Switch Check (Sedan) ... ..138

Unlock Sensor Check ............................................140

Intelligent Key Warning Buzzer(s) Check ..............142

Outside Key Antenna (Dri ver Side and Passenger

Side) Check ......................................................... ..

143

Outside Key Antenna (Rear Bumper) Check .........144

Inside Key Antenna Check ....................................146

Steering Lock Solenoid Check ............................ ..147

Key Interlock Solenoid (With M/T) Check ..............149

Ignition Switch Position Check ............................ ..150

Stop Lamp Switch Check (With CVT or A/T) ....... ..150

Stop Lamp Switch Check (With M/T) .....................152

CVT or A/T Shift Selector (Park Position Switch)

Check .................................................................. ..

153

"P-SHIFT" Warning Lamp (With CVT or A/T)

Check ....................................................................

154

"LOCK" Warning Lamp (With M/T) Check .............155

"KEY" Warning Lamp (RED) Check ......................155

"KEY" Warning Lamp (G REEN) Check .................155

Check Warning Chime in Combination Meter ........156

Hazard Function Check .........................................156

Horn Function Check .... .........................................157

Headlamp Function Chec k ....................................157

Intelligent Key Battery Re placement .....................158

Remote Keyless Entry Func tion ............................158

Removal and Installation of Intelligent Key Unit ... .158

DOOR ...............................................................160

Fitting Adjustment ................................................ .160

Removal and Installation .......................................163

Back Door Stay Disposal ..................................... .166

FRONT DOOR LOCK .......................................167

Component Parts Location .................................. .167

Removal and Installation .......................................167

REAR DOOR LOCK ....................................... ..170

Component Parts Location .................................. .170

Removal and Installation .......................................170

BACK DOOR LOCK ....................................... ..173

Component Parts and Harness Connector Loca-

tion ....................................................................... .

173

System Description ...............................................173

Wiring Diagram - B/DOOR - ..................................174

Terminal and Reference Value for BCM ...............176

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

180

CONSULT-III Function (BCM) ..............................182

Work Flow .............................................................183

Trouble Diagnosis Chart by Symptom ..................183

BCM Power Supply and Ground Circuit Inspection

.

183

Check Back Door Opener Switch Circuit (Without

Intelligent Key or Power Windows) ...................... .

184

Check Back Door Opener Switch Circuit (Without

Intelligent Key, with Power Windows) .................. .

187

Check Back Door Opener Switch Circuit (With In-

telligent Key) ........................................................ .

189

Check Back Door Lock Assembly (Actuator) Cir-

cuit ........................................................................

191

Removal and Installation .......................................193

TRUNK LID ..................................................... ..195

Fitting Adjustment ................................................ .195

Trunk Lid Assembly ..............................................195

Trunk Lid Lock ......................................................196

Trunk Lid Striker ....................................................196

TRUNK LID OPENER .......................................198

Component Parts and Harness Connector Loca-

tion ....................................................................... .

198

System Description ...............................................198

Wiring Diagram - TLID - ........................................199

Terminal and Reference Value for BCM ...............201

Terminal and Reference Value for Intelligent Key

Unit ....................................................................... .

205

CONSULT-III Function (BCM) ..............................207

Work Flow .............................................................208

Trouble Diagnosis Chart by Symptom ..................208

BCM Power Supply and Ground Circuit Inspection

.

208

Revision: May 2010 2011 Versa

Page 513 of 3787

BL-3

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Check Trunk Lid Opener S

witch Circuit (Without

Intelligent Key) .................................................... ..

209

Check Trunk Lid Opener Switch Circuit (With Intel-

ligent Key) ........................................................... ..

212

Check Trunk Release Solenoid Circuit .................214

FUEL FILLER LID OPENER ............................216

Removal and Installation of Fuel Filler Lid Opener ..216

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ...........................................................

217

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

217

System Description ...............................................218

CAN Communication System Description .............220

Schematic .............................................................221

Wiring Diagram - VEHSEC - .................................222

Terminal and Reference Value for BCM ...............226

Terminal and Reference Value for Intelligent Key

Unit ...................................................................... ..

230

CONSULT-III Function (BCM) ...............................232

Trouble Diagnosis .................................................234

Preliminary Check .................................................234

Symptom Chart .....................................................236

Diagnosis Procedure 1 ..........................................237

Diagnosis Procedure 2 ..........................................239

Diagnosis Procedure 3 ..........................................240

Diagnosis Procedure 4 ..........................................240

Diagnosis Procedure 5 ..........................................240

Diagnosis Procedure 6 ..........................................241

Diagnosis Procedure 7 ..........................................241

Diagnosis Procedure 8 ..........................................242

Diagnosis Procedure 9 ........................................ ..244

NATS (Nissan Anti-Theft System) ................246

Component Parts and Harness Connector Loca-

tion .........................................................................

246

System Description ................................................246

System Composition ..............................................247

ECM Re-communicating Function .........................247

Wiring Diagram - NATS - .......................................249

Terminal and Reference Value for BCM ................250

CONSULT-III Function ........................................ ..254

Trouble Diagnosis Procedure ................................255

Trouble Diagnosis ..................................................257

Diagnosis Procedure 1 ..........................................258

Diagnosis Procedure 2 ..........................................260

Diagnosis Procedure 3 ..........................................261

Diagnosis Procedure 4 ..........................................262

Diagnosis Procedure 5 ..........................................263

Diagnosis Procedure 6 ..........................................264

How to Replace NATS Antenna Amp ....................264

BODY REPAIR ................................................265

Body Exterior Paint Color ......................................265

Body Component Parts .........................................267

Corrosion Protection ..............................................272

Body Sealing .........................................................276

Body Construction .................................................282

Body Alignment .....................................................284

Handling Precaution for Plastics ............................301

Precaution in Repairing High Strength Steel .........305

Foam Repair ..........................................................308

Replacement Operation .........................................311

Revision: May 2010 2011 Versa

Page 514 of 3787

BL-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929267

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929268

NOTE:

• This procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnec ting both battery cables with the ignition in the ″LOCK ″

position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS /IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 532 of 3787

BL-22

< SERVICE INFORMATION >

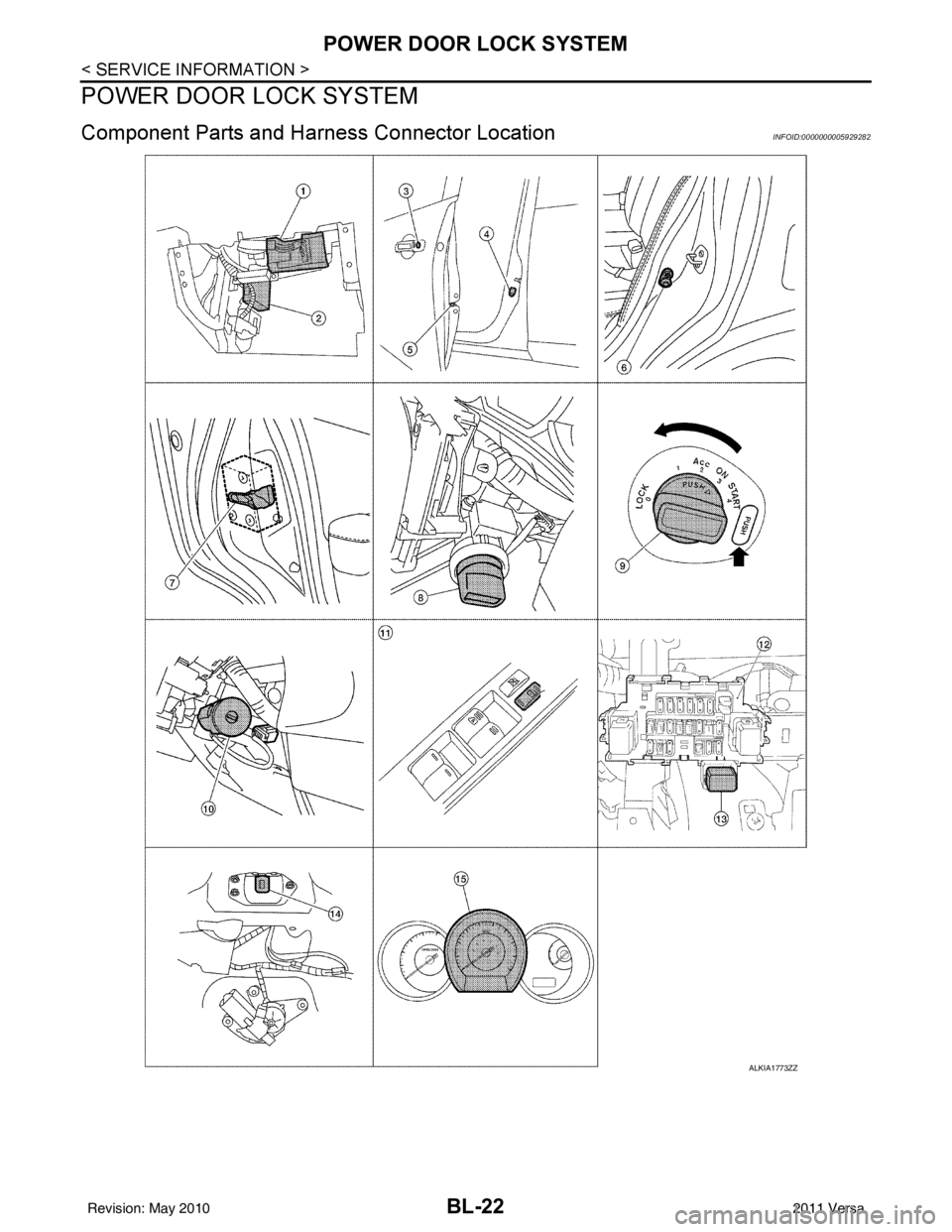

POWER DOOR LOCK SYSTEM

POWER DOOR LOCK SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000005929282

ALKIA1773ZZ

Revision: May 2010 2011 Versa

Page 533 of 3787

POWER DOOR LOCK SYSTEMBL-23

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

System DescriptionINFOID:0000000005929283

Power is supplied at all times

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to key switch terminal 2 (without Intelligent Key system)

• through 10A fuse [No. 31, located in the fuse block (J/B)]

• to key switch and ignition knob switch terminals 2 and 4 (with Intelligent Key system).

When key switch is ON (key is inserted in ignition key cylinder), power is supplied

• through key switch terminal 1 (without Intelligent Key system) or key switch and ignition knob terminal 1 (with Intelligent Key system)

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 67

• through body grounds M57 and M61.

LOCK OPERATION

When the door is locked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 45

• through main power window and door lock and unlock switch terminals 17 and 18

• through body grounds M57 and M61.

When the door is locked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 45

• through power window and door lock and unlock switch RH terminals 1 and 3

• through body grounds M57 and M61.

When the door is locked with front door lock assemb ly LH (key cylinder switch), ground is supplied

• to BCM terminal 8

• through front door lock assembly LH (key cylinder switch) terminals 4 and 6

• through body grounds M57 and M61.

UNLOCK OPERATION

When the door is unlocked with main power window and door lock/unlock switch, ground is supplied

• to BCM terminal 46

• through main power window and door lock/unlock switch terminals 6 and 17

• through body grounds M57 and M61.

When the door is unlocked with power window and door lock/unlock switch RH, ground is supplied

• to BCM terminal 46

• through power window and door lock and unlock switch RH terminals 2 and 3

• through body grounds M57 and M61.

When the door is unlocked with front door lock assemb ly LH (key cylinder switch), ground is supplied

• to BCM terminal 7

• through front door lock assembly LH (key cylinder switch) terminals 4 and 5

1. BCM M18, M19, M20

(view with glove box removed) 2. Intelligent Key unit M52

(if equipped) 3. Front door lock assembly LH (key cyl-

inder switch) D14

4. Front door switch LH B8, RH B108 5. Front door lock assembly LH (actuator) D14

Front door lock assembly RH (actuator)

D1146. Rear door switch LH B6, RH B116

7. Rear door lock actuator LH D205 RH D305 8. Key switch and ignition knob switch M73

(with A/T or CVT and Intelligent Key) 9. Key switch and ignition knob switch

M73 (with M/T and Intelligent Key)

10. Key switch and key lock solenoid M27 (without Intelligent key) 11. Main power window and door lock/un-

lock switch D7, D8

Power window and door lock/unlock

switch RH D105 12. Fuse block (with Intelligent Key)

(view with instrument panel LH re-

moved)

13. Passenger select unlock relay M2 (with Intelligent Key) 14. Back door lock assembly (back door

switch) D405 (hatchback view with back

door open) 15. Combination meter M24

Revision: May 2010

2011 Versa

Page 534 of 3787

BL-24

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• through body grounds M57 and M61.

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 1

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 1

• through rear door switch RH case ground.

When the back door lock assembly (back door switch) ( hatchback) is ON (back door is OPEN), ground is sup-

plied

• to BCM terminal 43

• through back door lock assembly (back door switch) terminals 3 and 4

• through body grounds B117, B132 and D402.

OUTLINE

Functions available by operating the inside door lock and unlock switches

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors are

locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors are

unlocked.

Functions available by operating the front door lock assembly LH (key cylinder switch)

• Interlocked with the locking operation of front door lock assembly LH (key cylinder switch), door lock actua-

tors of all doors are locked.

• When front door lock assembly LH (key cylinder switch) is unlocked, front door lock assembly LH (actuator)

is unlocked.

• When front door lock assembly LH (key cylinder swit ch) is unlocked for the second time within 5 seconds

after the first operation, front door lock assembly RH (actuator), rear door lock actuator LH and rear door

lock actuator RH are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key inserted in key cylinder and any

door open, all door lock actuators are locked and then unlocked.

AUTOMATIC DOOR LOCKS (LOCK OPERATION)

The interlock door lock function is the function that locks all doors linked with the vehicle speed.

Vehicle Speed Sensing Auto Door Lock*1

All doors are locked when the vehicle speed reaches 24 km/h (15 MPH) or more.

BCM outputs the lock signal to all door lock actuators when it detects that the ignition switch is turned ON, all

doors are closed and the vehicle speed received from the combination meter via CAN communication

becomes 15 MPH (24 km/h) or more.

If a door is opened and closed at any time during one ignition cycle (OFF → ON), even after initial auto door

lock has taken place, the BCM will relock all doors when the vehicle speed reaches 15 MPH (24 km/h) or more

again.

Setting change of Automatic Door Locks (LOCK) Function

The lock operation setting of the autom atic door locks function can be changed.

With CONSULT-III

The ON/OFF switching of the automatic door locks (LOC K) function and the type selection of the automatic

door locks (LOCK) function can be performed at the WO RK SUPPORT setting of CONSULT-III. Refer to BL-

41, "CONSULT-III Function (BCM)".

Without CONSULT- III

The automatic door locks (LOCK) function can be swit ched ON/OFF by performing the following operation.

Revision: May 2010 2011 Versa

Page 535 of 3787

POWER DOOR LOCK SYSTEMBL-25

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1. Close all doors (door switch OFF).

2. Turn ignition switch ON.

3. Within 20 seconds of turning the ignition switch ON, press and hold the door lock and unlock switch to the LOCK position for more than 5 seconds.

4. The switching is completed when the hazard lamps blink.

5. The ignition switch must be turned OFF and ON again between each setting change.

AUTOMATIC DOOR LOCKS (UNLOCK OPERATION)

The automatic door locks (UNLOCK) function is the function that unlocks all doors linked with the key position.

IGN OFF Interlock Door Unlock*1

For vehicles equipped with Intelligent Key system, all doors are unlocked when the power supply position is

changed from ON to OFF.

For vehicles not equipped with Intelligent Key system , all doors are unlocked when the mechanical key is

removed from the ignition key cylinder.

BCM outputs the unlock signal to all door lock actuator s when it detects that the power supply position is

changed from ignition switch ON to OFF (with Intelligent Key) or when the mechanical key is removed from the

ignition key cylinder (without Intelligent Key).

Setting change of Automatic Door Locks (UNLOCK) Function

The lock operation setting of the aut omatic door locks function can be changed.

With CONSULT-III

The ON/OFF switching of the automatic door locks (UNL OCK) function and the type selection of the automatic

door locks (UNLOCK) function can be performed at the WORK SUPPORT setting of CONSULT-III. Refer to

BL-41, "

CONSULT-III Function (BCM)".

Without CONSULT- III

The automatic door locks (UNLOCK) function can be sw itched ON/OFF by performing the following operation.

1. Close all doors (door switch OFF).

2. Turn ignition switch ON.

3. Within 20 seconds of turning the ignition switch ON, press and hold the door lock and unlock switch to the UNLOCK position for more than 5 seconds.

4. The switching is completed when the hazard lamps blink.

5. The ignition switch must be turned OFF and ON again between each setting change.

*1: This function is set to ON before delivery.

CAN Communication System DescriptionINFOID:0000000005929284

Refer to LAN-7 .

OFF → ON : 2 blinks

ON → OFF : 1 blink

OFF → ON : 2 blinks

ON → OFF : 1 blink

Revision: May 2010 2011 Versa

Page 536 of 3787

BL-26

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

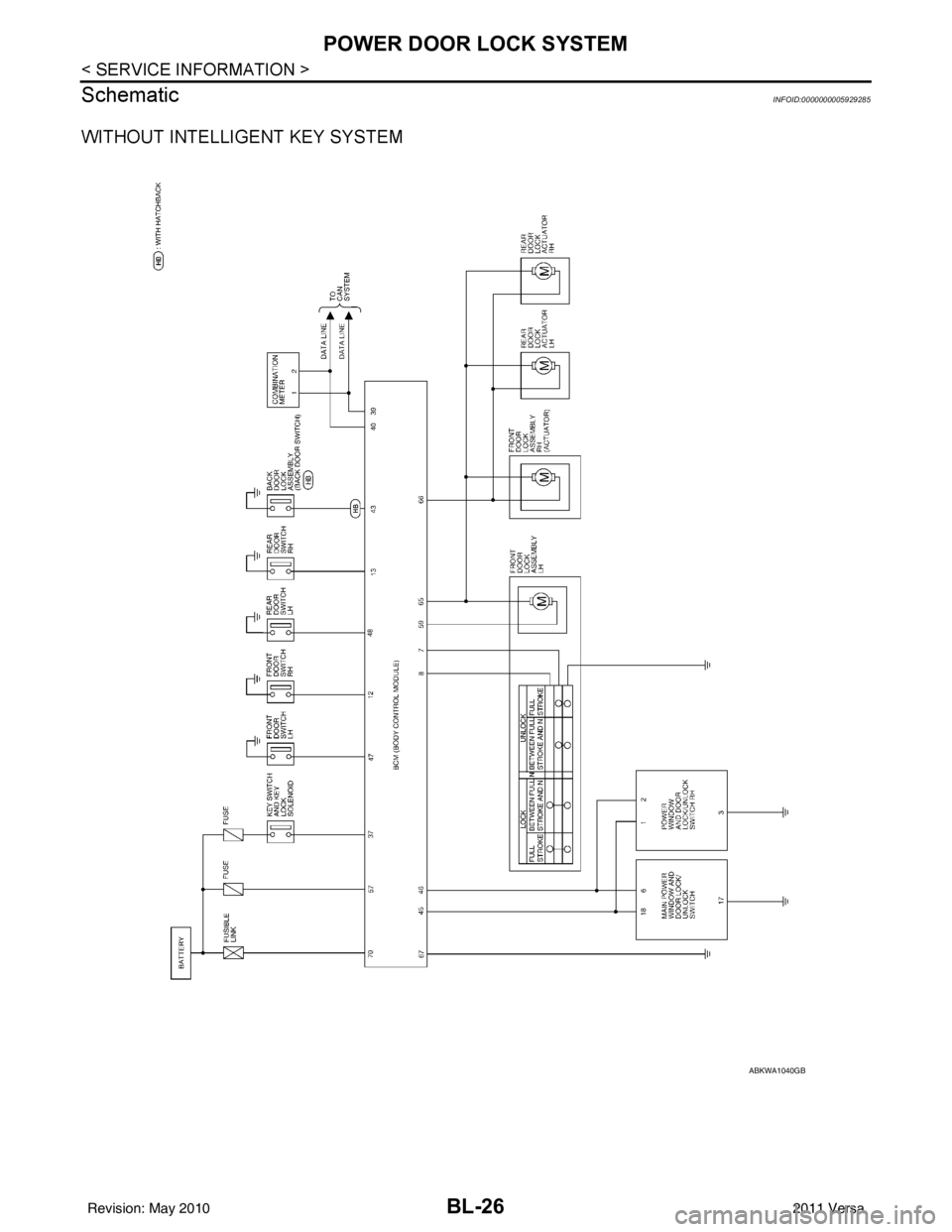

Schematic

INFOID:0000000005929285

WITHOUT INTELLIGENT KEY SYSTEM

ABKWA1040GB

Revision: May 2010 2011 Versa