Time NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1102 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISCVT-47

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

14 Y ROM assembly ——

15 G ROM assembly ——

18 GR P RANGE SW Selector lever in “P” po

sition. Ba NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISCVT-47

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

14 Y ROM assembly ——

15 G ROM assembly ——

18 GR P RANGE SW Selector lever in “P” po

sition. Ba](/img/5/57396/w960_57396-1101.png)

TROUBLE DIAGNOSISCVT-47

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

14 Y ROM assembly ——

15 G ROM assembly ——

18 GR P RANGE SW Selector lever in “P” po

sition. Battery voltage

Other than above position. 0 V

19 R Power supply —

Battery voltage

—0 V

20 W Step motor C Within 2 seconds after ignition switch ON, the time measurement by using the pulse width measurement function (Hi level) of CONSULT-III.*1

*1: A circuit tester cannot be used to test this item. 30.0 msec

21 P Step motor D 10.0 msec

22 BR R RANGE SW Selector lever in “R” position.

Battery voltage

Other than above position. 0 V

25 B Ground Always0 V

26 W N RANGE SW Selector lever in “N” position.

Battery voltage

Other than above position. 0 V

28 Y Power supply

(memory back-

up) Always

Battery voltage

29 R Secondary

speed sensor

When driving [“D” position, 20 km/h (12 MPH)].

570 Hz

30 Y Power supply

(memory back-

up) Always

Battery voltage

31 LG K-LINE ——

37 L Secondary pres-

sure sensor

and “N” position idle

1.0 V

38 V Primary speed

sensor When driving [“L” position, 20 km/h (12 MPH)].

1250 Hz

41* — —— ——

42 LG Sensor ground Always 0 V

43 SB D RANGE SW Selector lever in “D” position.

Battery voltage

Other than above position. 0 V

44 W L RANGE SW Selector lever in “” position.

Battery voltage

Other than above position. 0 V

Te r m i n a l

Wire

color Item

ConditionData (Approx.)

Revision: May 2010 2011 Versa

Page 1107 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-52

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*1: Refer to CVT-28, "Malfunction Indicator Lamp (MIL)" .

*2: Models without ABS does not indicate.

DATA MONITOR MODE

Display Items List

X: NISSAN TIIDA 2011 Service Repair Manual CVT-52

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*1: Refer to CVT-28, "Malfunction Indicator Lamp (MIL)" .

*2: Models without ABS does not indicate.

DATA MONITOR MODE

Display Items List

X:](/img/5/57396/w960_57396-1106.png)

CVT-52

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

*1: Refer to CVT-28, "Malfunction Indicator Lamp (MIL)" .

*2: Models without ABS does not indicate.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

VEHICLE

SPEED*2• CAN communication with the

ABS actuator and the electric

unit (control unit) is malfunctioning

• There is a great difference between the vehicle speed sig-

nal from the ABS actuator and the electric unit (control

unit), and the vehicle speed sensor signal P1722

—CVT-119

SPEED SENSOR A rotation sensor error is detected because the gear does not

change in accordance with the position of the stepping motor

CAUTION:

One of the “P0720”, the “P0715” or the “P0725“ is dis-

played with the DTC at the same time P1723

—CVT-121

THROTTLE CON-

TROL SIG The electronically controlled throttle for ECM is malfunction-

ing

P1726

—CVT-123

SLCT SOLENOID • Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor value P1740 P1740

CVT-124

LINE PRESS

CONTROLTCM detects the unexpected line pressure

P1745—CVT-128

STEP MOTOR Each coil of the step motor is not energized properly due to

an open or a short P1777 P1777

CVT-129

STEP MOTORThere is a great difference between the number of steps for

the stepping motor and for the actual gear ratio

P1778 P1778

CVT-133

NO DTC IS DE-

TECTED: FUR-

THER TESTING

MAY BE RE-

QUIREDNo NG item has been detected

XX —

Items (CONSULT-

III screen terms)

Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III

or GST

Monitored item (Unit) Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

VSP SENSOR (km/h or mph) X—

ESTM VSP SIG (km/h or mph) X— Models without ABS does not indicate.

PRI SPEED SEN (rpm) X—

ENG SPEED SIG (rpm) X—

SEC HYDR SEN (V) X—

PRI HYDR SEN (V) X—

ATF TEMP SEN (V) X— CVT fluid temperature sensor

VIGN SEN (V) X—

Revision: May 2010 2011 Versa

Page 1111 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-56

< SERVICE INFORMATION >[RE0F08B]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000005928762

CAN (Controller Area Network) is a serial communication line for real time appl NISSAN TIIDA 2011 Service Repair Manual CVT-56

< SERVICE INFORMATION >[RE0F08B]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000005928762

CAN (Controller Area Network) is a serial communication line for real time appl](/img/5/57396/w960_57396-1110.png)

CVT-56

< SERVICE INFORMATION >[RE0F08B]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000005928762

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehi

cle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN-H line, CAN-L li ne) allowing a high rate of information transmission

with less wiring. Each control unit transmits/recei ves data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000005928763

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “U1000” with CONSULT-III is detected when TCM cannot communicate to other

control units.

Possible CauseINFOID:0000000005928764

Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928765

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode fo r “TRANSMISSION” with CONSULT-III.

3. Start engine and wait for at least 6 seconds.

4. If DTC is detected, go to CVT-58, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Revision: May 2010 2011 Versa

Page 1114 of 3787

![NISSAN TIIDA 2011 Service Repair Manual U1010 CONTROL UNIT (CAN)CVT-59

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

U1010 CONTROL UNIT (CAN)

DescriptionINFOID:0000000005928768

CAN (Controller Area Network) is a serial NISSAN TIIDA 2011 Service Repair Manual U1010 CONTROL UNIT (CAN)CVT-59

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

U1010 CONTROL UNIT (CAN)

DescriptionINFOID:0000000005928768

CAN (Controller Area Network) is a serial](/img/5/57396/w960_57396-1113.png)

U1010 CONTROL UNIT (CAN)CVT-59

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

U1010 CONTROL UNIT (CAN)

DescriptionINFOID:0000000005928768

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communica tion speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000005928769

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “U1010” with CONSULT-III is detected when TCM cannot communicate to other control units.

Possible CauseINFOID:0000000005928770

Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928771

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and wait for at least 6 seconds.

4. If DTC is detected, go to CVT-59, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005928772

1.CHECK DTC

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “ERASE”.

4. Turn ignition switch OFF and wait for at least 10 seconds.

5. Perform “DTC confirmation procedure”. Refer to CVT-59, "

DTC Confirmation Procedure".

Is any malfunction of the

“U1010” indicated?

YES >> Replace the TCM. Refer to CVT-159, "Removal and Installation".

NO >> INSPECTION END

Revision: May 2010 2011 Versa

Page 1176 of 3787

![NISSAN TIIDA 2011 Service Repair Manual P1723 SPEED SENSORCVT-121

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1723 SPEED SENSOR

DescriptionINFOID:0000000005928900

• The primary speed sensor is included in the cont NISSAN TIIDA 2011 Service Repair Manual P1723 SPEED SENSORCVT-121

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1723 SPEED SENSOR

DescriptionINFOID:0000000005928900

• The primary speed sensor is included in the cont](/img/5/57396/w960_57396-1175.png)

P1723 SPEED SENSORCVT-121

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1723 SPEED SENSOR

DescriptionINFOID:0000000005928900

• The primary speed sensor is included in the control valve assembly.

• The secondary speed sensor detects the revolution of the idler gear and generates a pulse signal. The pulse signal is sent to the TCM, which converts it into vehicle speed.

• The primary speed sensor detects the primary pul ley revolution speed and sends a signal to the TCM.

On Board Diagnosis LogicINFOID:0000000005928901

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1723” with CONSULT-III is det ected when there is a great difference between the

vehicle speed signal and the secondary speed sensor signal.

CAUTION:

One of the “P0720”, the “P0715” or the “P0725“ is displayed with the DTC at the same time.

Possible CauseINFOID:0000000005928902

• Harness or connectors

(Sensor circuit is open or shorted.)

• Secondary speed sensor

• Primary speed sensor

• Engine speed signal system

DTC Confirmation ProcedureINFOID:0000000005928903

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED SE: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

3. If DTC is detected, go to CVT-121, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005928904

1.CHECK STEP MOTOR FUNCTION

Perform the self-diagnosis check. Refer to CVT-48, "

CONSULT-III Function (TRANSMISSION)".

Is a malfunction in the step motor function indicated in the results?

YES >> Repair or replace damaged parts. (C heck the step motor function. Refer to CVT-133.)

NO >> GO TO 2.

2.CHECK SECONDARY SPEED SENSOR SYSTEM AND PRIMARY SPEED SENSOR SYSTEM

Check secondary speed sensor system and primary speed sensor system. Refer to CVT-76

, CVT-72.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK ENGINE SPEED SIGNAL SYSTEM

Revision: May 2010 2011 Versa

Page 1179 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CVT-124

< SERVICE INFORMATION >[RE0F08B]

P1740 SELECT SOLENOID

P1740 SELECT SOLENOID

DescriptionINFOID:0000000005928910

• The lock-up select solenoid valve is included in the control valve assembly. NISSAN TIIDA 2011 Service Repair Manual CVT-124

< SERVICE INFORMATION >[RE0F08B]

P1740 SELECT SOLENOID

P1740 SELECT SOLENOID

DescriptionINFOID:0000000005928910

• The lock-up select solenoid valve is included in the control valve assembly.](/img/5/57396/w960_57396-1178.png)

CVT-124

< SERVICE INFORMATION >[RE0F08B]

P1740 SELECT SOLENOID

P1740 SELECT SOLENOID

DescriptionINFOID:0000000005928910

• The lock-up select solenoid valve is included in the control valve assembly.

• The lock-up select solenoid valve controls lock-up clutch pressure or forward clutch pressure (reverse brake

pressure).

• When controlling lock-up clutch, the valve is turned OFF. When controlling forward clutch, it is turned ON.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928911

On Board Diagn osis LogicINFOID:0000000005928912

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1740” with CONSULT-III is detected under the following conditions.

- When TCM compares target value with monitor value and detects an irregularity.

Possible CauseINFOID:0000000005928913

• Lock-up select solenoid valve

• Harness or connectors

(Solenoid circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928914

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode fo r “TRANSMISSION” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 5 consecutive seconds. RANGE: “D” position and “N” position

(At each time, wait for 5 seconds.)

4. If DTC is detected, go to CVT-126, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value

LUSEL SOL OUT Selector lever in “P

” and “N” positions on

Wait at least for 5 seconds with the selector lever

in “R”, “D” and “L” positions off

Revision: May 2010

2011 Versa

Page 1241 of 3787

DI-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006412029

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006412030

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 1242 of 3787

PRECAUTIONDI-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Revision: May 2010 2011 Versa

Page 1243 of 3787

DI-4

< SERVICE INFORMATION >

COMBINATION METERS

COMBINATION METERS

Component Parts and Harness Connector LocationINFOID:0000000005929159

System DescriptionINFOID:0000000005929160

UNIFIED METER CONTROL UNIT

• Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signals drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

(⇐: Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

WKIA5450E

Revision: May 2010 2011 Versa

Page 1251 of 3787

DI-12

< SERVICE INFORMATION >

COMBINATION METERS

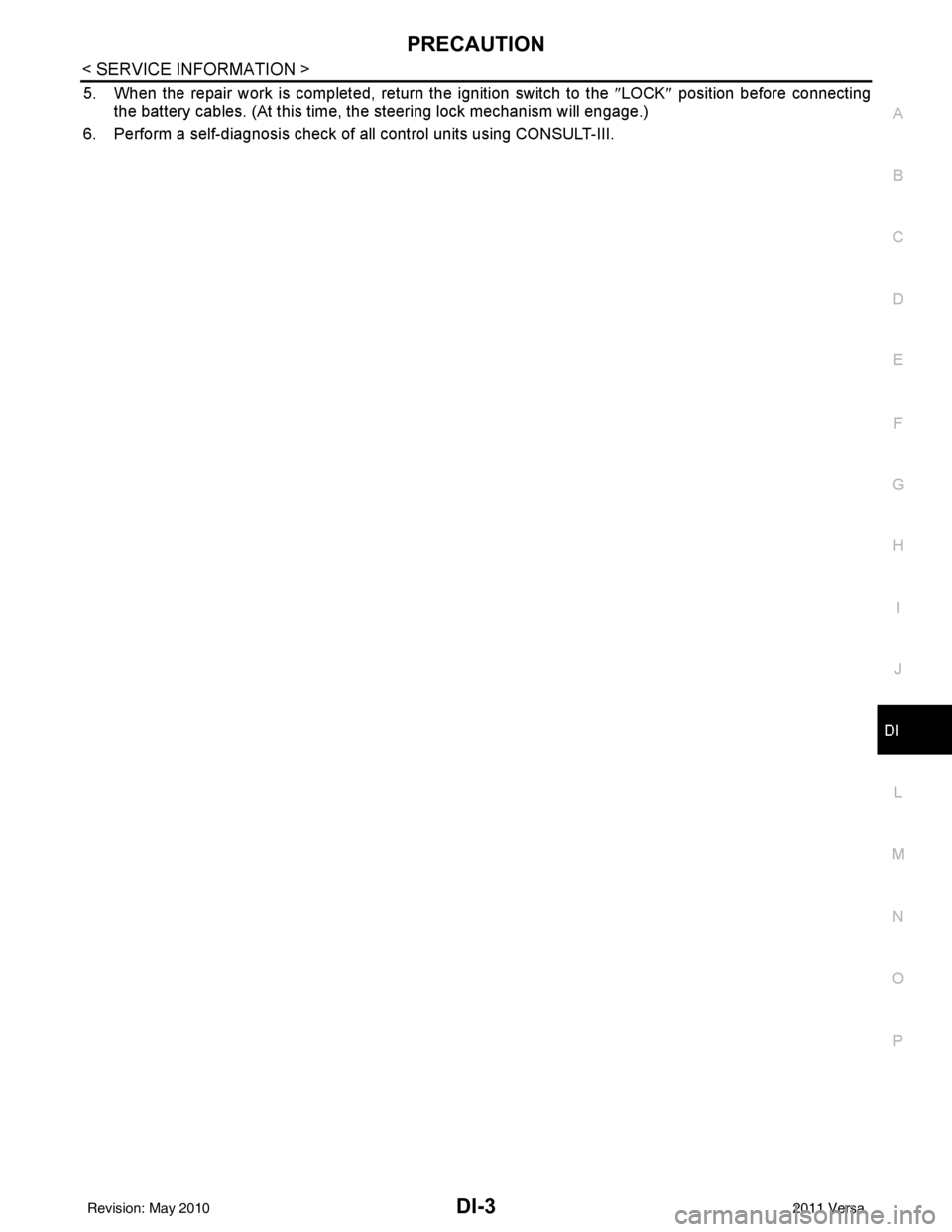

If the diagnosis function is activated with “trip A” displayed, the mileage on “trip A” will indicate “0000.0”,

but the actual trip mileage will be retained. (The same applies for “trip B”.)

2. Turn ignition switch OFF.

3. While pushing the odo/trip meter switch (1), turn the ignition switch ON.

4. Confirm that the trip meter displays “0000.0”.

5. Push the odo/trip meter switch at least 3 times. (Within 7 sec- onds after the ignition switch is turned ON.)

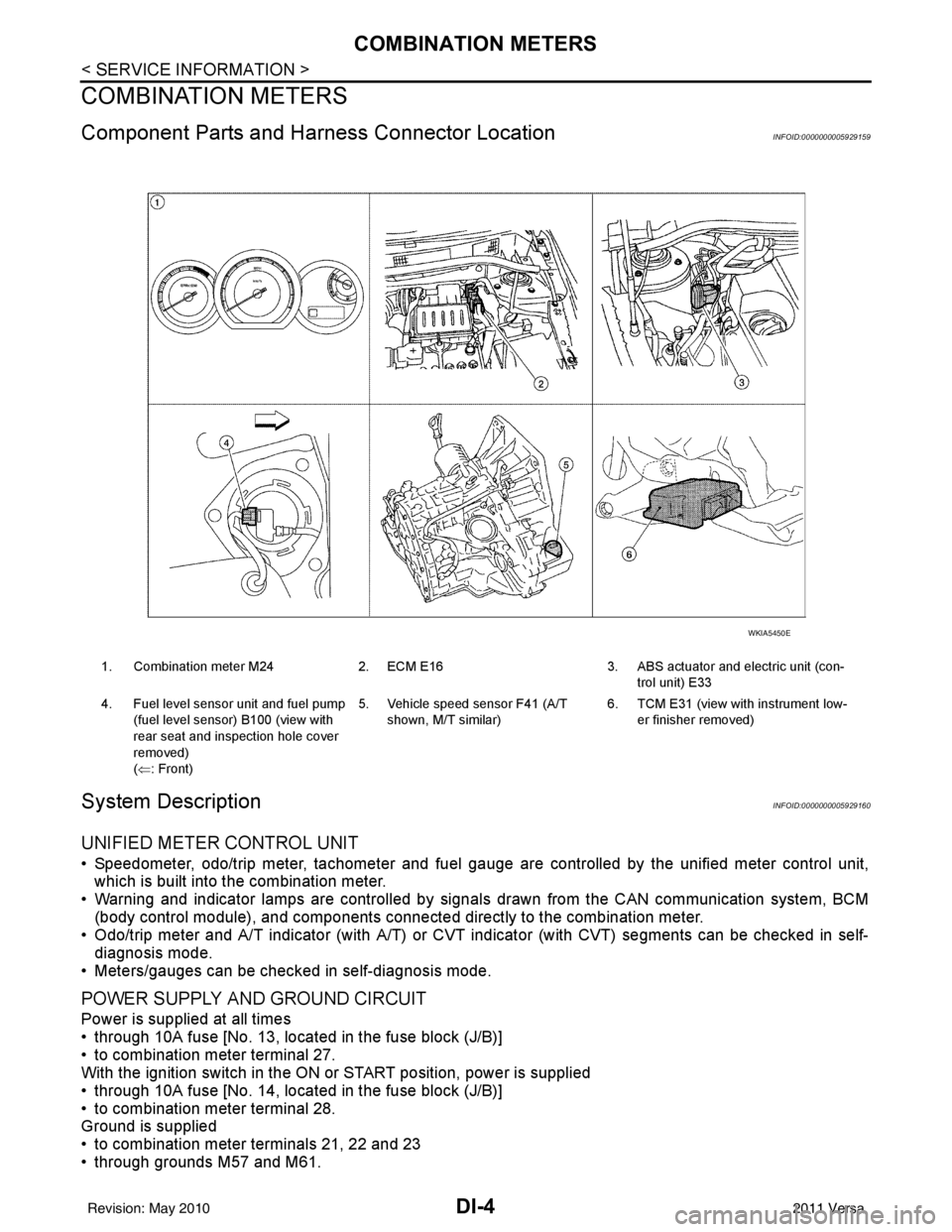

6. All the segments on the odo/trip meter, and simultaneously the low-fuel warning lamp indicator illumi- nates. At this time, the unified meter control unit is turned to self-diagnosis mode.

• M/T MODELS (1)

• A/T AND CVT MODELS (2)

NOTE:

• Check combination meter power supply and ground circuit when self-diagnosis mode of combination

meter does not start. Replace combination meter if normal. Refer to IP-12, "

Removal and Installation" .

• If any of the segments is not displayed, replace combination meter. Refer to IP-12, "

Removal and Instal-

lation" .

7. Each meter activates while pressing odo/trip meter switch. (At this time, the low-fuel warning lamp turns off, low water temperature indicator lamp and high water temperature warning lamp turn on.)

NOTE:

If any of the meter and gages are not activat ed, replace combination meter. Refer to IP-12, "

Removal and

Installation" .

PKIC1031E

PKIC0699E

WKIA5452E

Revision: May 2010 2011 Versa