Time NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1252 of 3787

COMBINATION METERSDI-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

CONSULT-III Function (METER/M&A)INFOID:0000000005929167

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

NOTE:

“TIME” indicates the following.

• 0: Indicates that a malfunction is detected at present.

• 1-63: Indicates that a malfunction was detected in the past. (Displays number of ignition switch OFF → ON

cycles after malfunction is detected. Self-di agnostic result is erased when “63” is exceeded.)

DATA MONITOR

Display Item List

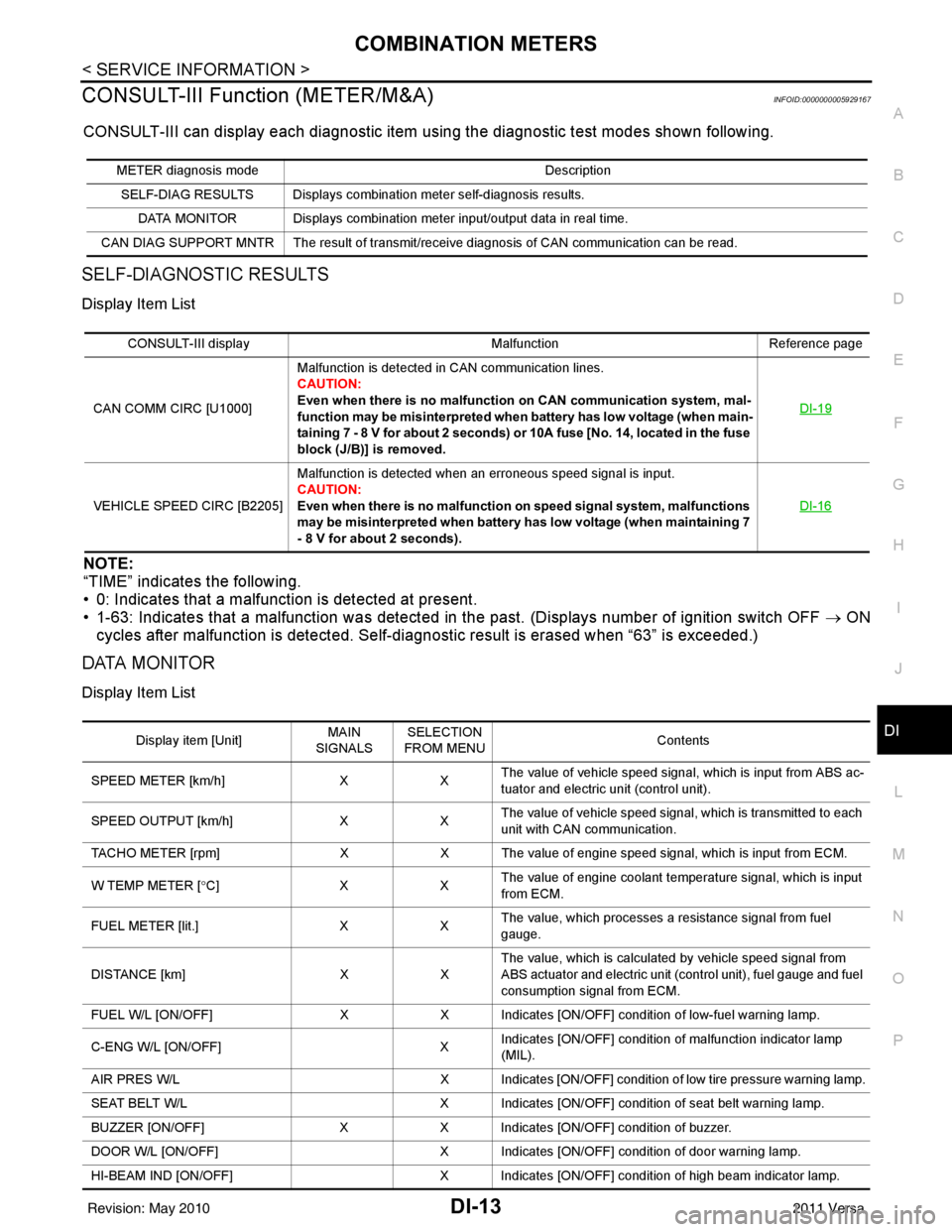

METER diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results. DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

CONSULT-III display MalfunctionReference page

CAN COMM CIRC [U1000] Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfuncti

on on CAN communication system, mal-

function may be misinterpreted when battery has low voltage (when main-

taining 7 - 8 V for about 2 seconds) or 10A fuse [No. 14, located in the fuse

block (J/B)] is removed. DI-19

VEHICLE SPEED CIRC [B2205]

Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction

on speed signal system, malfunctions

may be misinterpreted when battery has low voltage (when maintaining 7

- 8 V for about 2 seconds). DI-16

Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

SPEED METER [km/h] XXThe value of vehicle speed signa

l, which is input from ABS ac-

tuator and electric unit (control unit).

SPEED OUTPUT [km/h] XXThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] XX The value of engine speed signal, which is input from ECM.

W TEMP METER [ °C] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] XXThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] XXThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption signal from ECM.

FUEL W/L [ON/OFF] XX Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] XIndicates [ON/OFF] condition of malfunction indicator lamp

(MIL).

AIR PRES W/L X Indicates [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] XX Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

Revision: May 2010 2011 Versa

Page 1258 of 3787

COMBINATION METERSDI-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

5.CHECK FUEL LEVEL SENSOR UNIT

Check fuel level sensor unit. Refer to DI-20, "

Electrical Component Inspection" .

OK or NG

OK >> Check fuel level sensor unit installation, and c heck whether the float arm interferes or binds with

any of the internal components in the fuel tank. Repair or replace malfunctioning part, if neces-

sary.

NG >> Replace fuel level sensor unit.

Fuel Gauge Fluctuates, Indica tes Wrong Value, or VariesINFOID:0000000005929174

1.CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates onl y during driving or at the instant of stopping.

Does the indication value vary only during dr iving or at the at the instant of stopping?

YES >> The pointer fluctuation may be caused by fuel level change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble diagnosis.

Fuel Gauge Does Not Move to Full-positionINFOID:0000000005929175

1.OBSERVE FUEL GAUGE

Does it take a long time for the pointer to move to FULL position?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.IDENTIFY FUELING CONDITION

Was the vehicle fueled with the ignition switch ON?

YES or NO

YES >> Be sure to fuel the vehicle with the ignition swit ch OFF. Otherwise, it will take a long time to move

to FULL position because of the c haracteristic of the fuel gauge.

NO >> GO TO 3.

3.OBSERVE VEHICLE POSITION

Is the vehicle parked on an incline?

YES or NO

YES >> Check the fuel level indicati on with vehicle on a level surface.

NO >> GO TO 4.

4.OBSERVE FUEL GAUGE POINTER

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES or NO

YES >> Check the components. Refer to DI-20, "Electrical Component Inspection" .

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

DTC [U1000] CAN Communication CircuitINFOID:0000000005929176

Symptom: Display CAN COMM CIRC [U1000] at the re sult of self-diagnosis for combination meter.

1.CHECK CAN COMMUNICATION

1. Select "SELF-DIAG RESULTS" mode for "METER/M&A" with CONSULT-III.

2. Print out CONSULT-III screen.

>> Go to "CAN SYSTEM". Refer to LAN-17, "

Trouble Diagnosis Flow Chart".

Revision: May 2010 2011 Versa

Page 1282 of 3787

WARNING CHIMEDI-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

WARNING CHIME

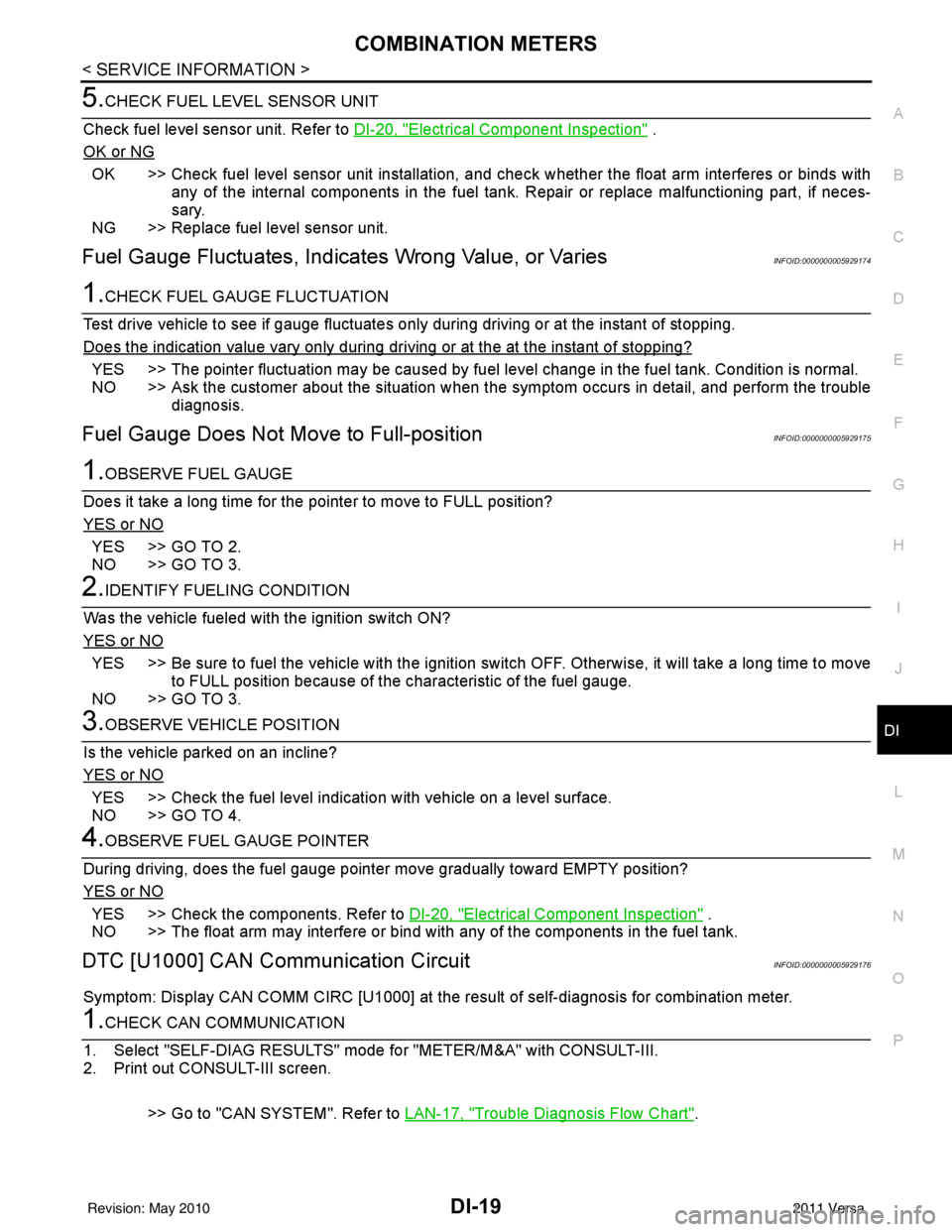

Component Parts and Har ness Connector LocationINFOID:0000000005929191

System DescriptionINFOID:0000000005929192

• Buzzer for warning chime system is installed in the combination meter.

• The buzzer sounds when combination meter receives buzzer output signal with CAN communication line.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70,

1. Combination meter M24 2. BCM M18, M19, M20 (view with

glove box removed) 3. Intelligent Key unit M52 (with Intelli-

gent Key)

4. Key switch and key lock solenoid M27 (without Intelligent Key) 5. Key switch and ignition knob switch

M73 (with Intelligent Key) 6. Combination switch (lighting switch)

M28

7. Front door switch LH B8 8. Parking brake switch M17

AWMIA0117ZZ

Revision: May 2010 2011 Versa

Page 1287 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, afte NISSAN TIIDA 2011 Service Repair Manual DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, afte](/img/5/57396/w960_57396-1286.png)

DI-48

< SERVICE INFORMATION >

WARNING CHIME

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after printing the monitor item, go to “LAN system”. Refer to

LAN-17, "

Trouble Diagnosis Flow Chart".

Trouble DiagnosisINFOID:0000000005929196

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom and customer complaint.

2. Understand the outline of system. Refer to DI-43, "

System Description".

3. Perform the preliminary inspection. Refer to "PRELIMINARY INSPECTION".

4. According to symptom chart, repair or replac e the cause of the malfunction. Refer to "SYMPTOM

CHART".

5. Does warning chime system operate normally? If it operates normally, GO TO 6. If not, GO TO 4.

6. Inspection End.

PRELIMINARY INSPECTION

BCM diagnostic test item Diagnostic mode

Description

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU PART NUMBER BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Monitored item ALL SIGNALS SELECTION

FROM MENU Contents

IGN ON SW XX Indicates [ON/OFF] condition of ignition switch.

KEY ON SW XX Indicates [ON/OFF] condition of key switch.

DOOR SW-DR XX Indicates [ON/OFF] condition of front door switch LH.

LIGHT SW 1ST XX Indicates [ON/OFF] condition of lighting switch.

BUCKLE SW XX Indicates [ON/OFF] condition of seat belt buckle switch LH.

Test item Malfunction is detected when···

IGN KEY WARN ALM This test is able to check key warning chime operation.

LIGHT WARN ALM This test is able to check light warning chime operation.

SEAT BELT WARN TEST This test is able to check seat belt warning chime operation.

Display item [Code] Malfunction is detected when...

CAN communication [U1000] Malfunction is detected in CAN communication.

Revision: May 2010 2011 Versa

Page 1315 of 3787

![NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou](/img/5/57396/w960_57396-1314.png)

INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to EC-24, "

IDLE SPEED : Special Repair

Requirement". For specification, refer to EC-503, "Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-25, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

>> GO TO 5.

5.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Perform EC-25, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-26, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. For procedure, refer to EC-24, "

IDLE SPEED : Special Repair Requirement".

For specification, refer to EC-503, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-272, "

DTC Logic".

• Check crankshaft position sensor (POS) and circuit. Refer to EC-267, "

DTC Logic".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace. Then GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is rare.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to BL-247, "

ECM Re-communicating Function".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

PBIA8513J

Revision: May 2010 2011 Versa

Page 1318 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-24

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

IDLE SPEED

IDLE SPEED : DescriptionINFOID:0000000005929749

This describes how to check the idle speed. For the

actual procedure, follow th NISSAN TIIDA 2011 Service Repair Manual EC-24

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

IDLE SPEED

IDLE SPEED : DescriptionINFOID:0000000005929749

This describes how to check the idle speed. For the

actual procedure, follow th](/img/5/57396/w960_57396-1317.png)

EC-24

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

IDLE SPEED

IDLE SPEED : DescriptionINFOID:0000000005929749

This describes how to check the idle speed. For the

actual procedure, follow the instructions in “BASIC

INSPECTION”.

IDLE SPEED : Special Repair RequirementINFOID:0000000005929750

1.CHECK IDLE SPEED

With CONSULT-III

Check idle speed in “DATA MONITOR” mode with CONSULT-III.

With GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

IGNITION TIMING

IGNITION TIMING : DescriptionINFOID:0000000005929751

This describes how to check the ignition timing. For the actual procedure, follow the instructions in “BASIC

INSPECTION”.

IGNITION TIMING : Special Repair RequirementINFOID:0000000005929752

1.CHECK IGNITION TIMING

1. Attach timing light to No. 1 ignition coil (1) wire as shown.

2. Check ignition timing.

>> INSPECTION END

VIN REGISTRATION

VIN REGISTRATION : DescriptionINFOID:0000000005929753

VIN Registration is an operation to registering VIN in ECM. It must be performed each time ECM is replaced.

NOTE:

Accurate VIN which is registered in ECM ma y be required for Inspection & Maintenance (I/M).

2 : Timing light

: Vehicle front

PBIB2955E

1 : Timing indicator

MBIB1331E

Revision: May 2010 2011 Versa

Page 1319 of 3787

![NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005929754

1.CHECK VIN

Check the VIN of the vehic NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005929754

1.CHECK VIN

Check the VIN of the vehic](/img/5/57396/w960_57396-1318.png)

INSPECTION AND ADJUSTMENTEC-25

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION : Special Repair RequirementINFOID:0000000005929754

1.CHECK VIN

Check the VIN of the vehicle and note it. Refer to GI-43, "

Model Variation".

>> GO TO 2.

2.PERFORM VIN REGISTRATION

With CONSULT-III

1. Turn ignition switch ON and engine stopped.

2. Select “VIN REGISTRATION” in “WORK SUPPORT” mode.

3. Follow the instruction of CONSULT-III display.

>> END

ACCELERATOR PEDAL RELEAS ED POSITION LEARNING

ACCELERATOR PEDAL RELEASED PO SITION LEARNING : DescriptionINFOID:0000000005929755

Accelerator Pedal Released Position Learning is a function of ECM to learn the fully released position of the

accelerator pedal by monitoring the accelerator pedal pos ition sensor output signal. It must be performed each

time harness connector of accelerator pedal position sensor or ECM is disconnected.

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Re-

quirement

INFOID:0000000005929756

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

>> END

THROTTLE VALVE CLOSED POSITION LEARNING

THROTTLE VALVE CLOSED POSITION LEARNING : DescriptionINFOID:0000000005929757

Throttle Valve Closed Position Learning is a function of ECM to learn the fully closed position of the throttle

valve by monitoring the throttle position sensor out put signal. It must be performed each time harness connec-

tor of electric throttle contro l actuator or ECM is disconnected.

THROTTLE VALVE CLOSED POSITION LEA RNING : Special Repair Requirement

INFOID:0000000005929758

1.START

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

>> END

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING : DescriptionINFOID:0000000005929759

Idle Air Volume Learning is a function of ECM to lear n the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

Revision: May 2010 2011 Versa

Page 1320 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO](/img/5/57396/w960_57396-1319.png)

EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING

: Special Repair RequirementINFOID:0000000005929760

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (A/T), Neutral (M/T)

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- A/T models

• With CONSULT-III: Drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “TRANSMISSION”

system indicates less than 0.9 V.

• Without CONSULT-III: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

Revision: May 2010 2011 Versa

Page 1321 of 3787

![NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-27

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

9. Start engine and let it idle.

10. Wait 20 seconds.

>> GO TO 4.

4.CHECK IDLE SPEED AND IGNITION TIMING

Re NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-27

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

9. Start engine and let it idle.

10. Wait 20 seconds.

>> GO TO 4.

4.CHECK IDLE SPEED AND IGNITION TIMING

Re](/img/5/57396/w960_57396-1320.png)

INSPECTION AND ADJUSTMENTEC-27

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

9. Start engine and let it idle.

10. Wait 20 seconds.

>> GO TO 4.

4.CHECK IDLE SPEED AND IGNITION TIMING

Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifi-

cations.

Is the inspection result normal?

YES >> INSPECTION END

5.DETECT MALFUNCTIONING PART

Check the following

• Check that throttle valve is fully closed.

• Check PCV valve operation.

• Check that downstream of throttle valve is free from air leakage.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace malfunctioning part.

6.DETECT MALFUNCTIONING PART

Engine component parts and their installation conditi on are questionable. Check and eliminate the cause of

the incident.

It is useful to perform “TROUBLE DIAG NOSIS - SPECIFICATION VALUE”. Refer to EC-114, "

Description".

If any of the following conditions occur after the engi ne has started, eliminate the cause of the incident and

perform Idle Air Volume Learning again:

• Engine stalls.

• Erroneous idle.

>> INSPECTION END

MIXTURE RATIO SELF-LEARNING VALUE CLEAR

MIXTURE RATIO SELF-LEARNING VALUE CLEAR : DescriptionINFOID:0000000005929761

This describes how to erase the mixture ratio self-learning value. For the actual procedure, follow the instruc-

tions in “Diagnosis Procedure”.

MIXTURE RATIO SELF-LEARNING VALUE CLEAR : Special Repair Requirement

INFOID:0000000005929762

1.START

SEC897C

ITEMSPECIFICATION

Idle speed A/T: 700

± 50 rpm (in P or N position)

M/T: 650 ± 50 rpm (in Neutral position)

Ignition timing A/T: 6

± 5 °BTDC (in P or N position)

M/T: 6 ± 5 °BTDC (in Neutral position)

Revision: May 2010 2011 Versa

Page 1323 of 3787

![NISSAN TIIDA 2011 Service Repair Manual HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in NISSAN TIIDA 2011 Service Repair Manual HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in](/img/5/57396/w960_57396-1322.png)

HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in

the “SRT ITEM” table must have been performed at least

once. Each diagnosis may require actual driving for a long period of time under various conditions.

SRT ITEM

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

• *1: Though displayed on the CONSULT-III screen, “HO2S HTR” is not SRT item.

• *2: If completion of several SRTs is required, per form driving patterns (DTC confirmation procedure), one by

one based on the priority for models with CONSULT-III.

SRT SERVICE PROCEDURE

If a vehicle has failed the state emissions inspection due to one or more SRT items indicating “INCMP”, review

the flowchart diagnostic sequence, referring to the following flowchart.

SRT item*1

(CONSULT-III indication) Performance

Priority*2Required self-diagnostic items to set the SRT to “CMPLT” Corresponding

DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 P0133

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

EGR/VVT SYSTEM 3 Intake value timing control function P0011

Revision: May 2010 2011 Versa