engine NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3366 of 3787

MTC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Testing must be performed as follows:

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: With blower control dial in the "1" position

*2: With blower control dial in the "4" position.

TROUBLE DIAGNOSIS FOR ABNORMAL PRESSURE

Whenever system’s high and/or low side pressure(s) is/are abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial (Ventilation) set

Intake door lever (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 70 20 (68)

9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2 , psi) Low-pressure (Suction side)

kPa (bar, kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150) 159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77) 1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194) 196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86) 1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231) 248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95) 1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245) 308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104) 1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288) 377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Revision: May 2010 2011 Versa

Page 3367 of 3787

TROUBLE DIAGNOSISMTC-51

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

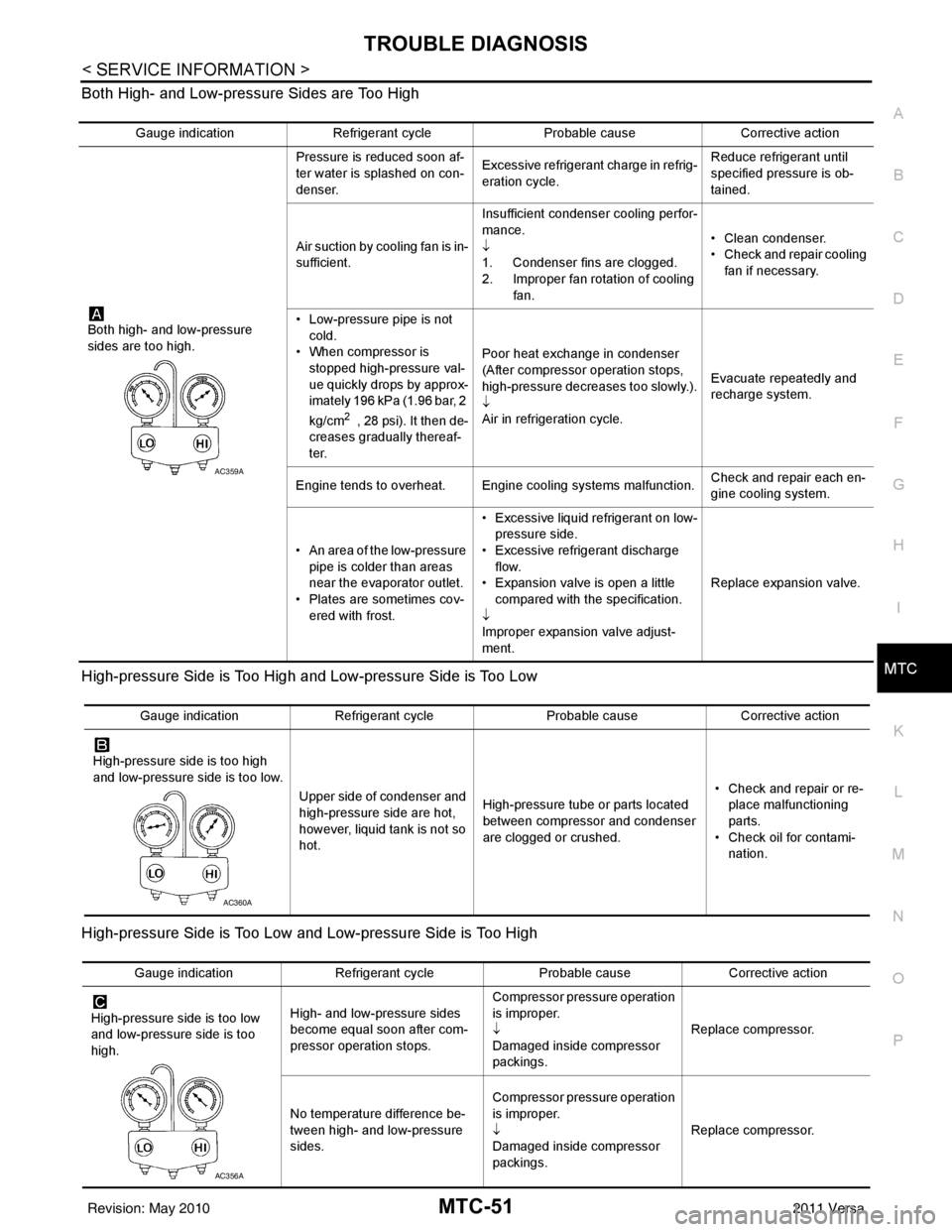

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication

Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in refrig-

eration cycle. Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. • Clean condenser.

• Check and repair cooling

fan if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2 , 28 psi). It then de-

creases gradually thereaf-

ter. Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.

Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction. Check and repair each en-

gine cooling system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant on low-

pressure side.

• Excessive refrigerant discharge flow.

• Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment. Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycle Probable causeCorrective action

High-pressure side is too high

and low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. • Check and repair or re-

place malfunctioning

parts.

• Check oil for contami- nation.

AC360A

Gauge indication Refrigerant cycle Probable causeCorrective action

High-pressure side is too low

and low-pressure side is too

high. High- and low-pressure sides

become equal soon after com-

pressor operation stops. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Revision: May 2010

2011 Versa

Page 3369 of 3787

TROUBLE DIAGNOSISMTC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Insufficient HeatingINFOID:0000000005930855

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check" .

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to CO-11, "

Inspection" (HR16DE) or CO-36, "Inspection" (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-14, "

Checking Radiator Cap" HR16DE or CO-39, "Checking Radiator

Cap" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

OK or NG

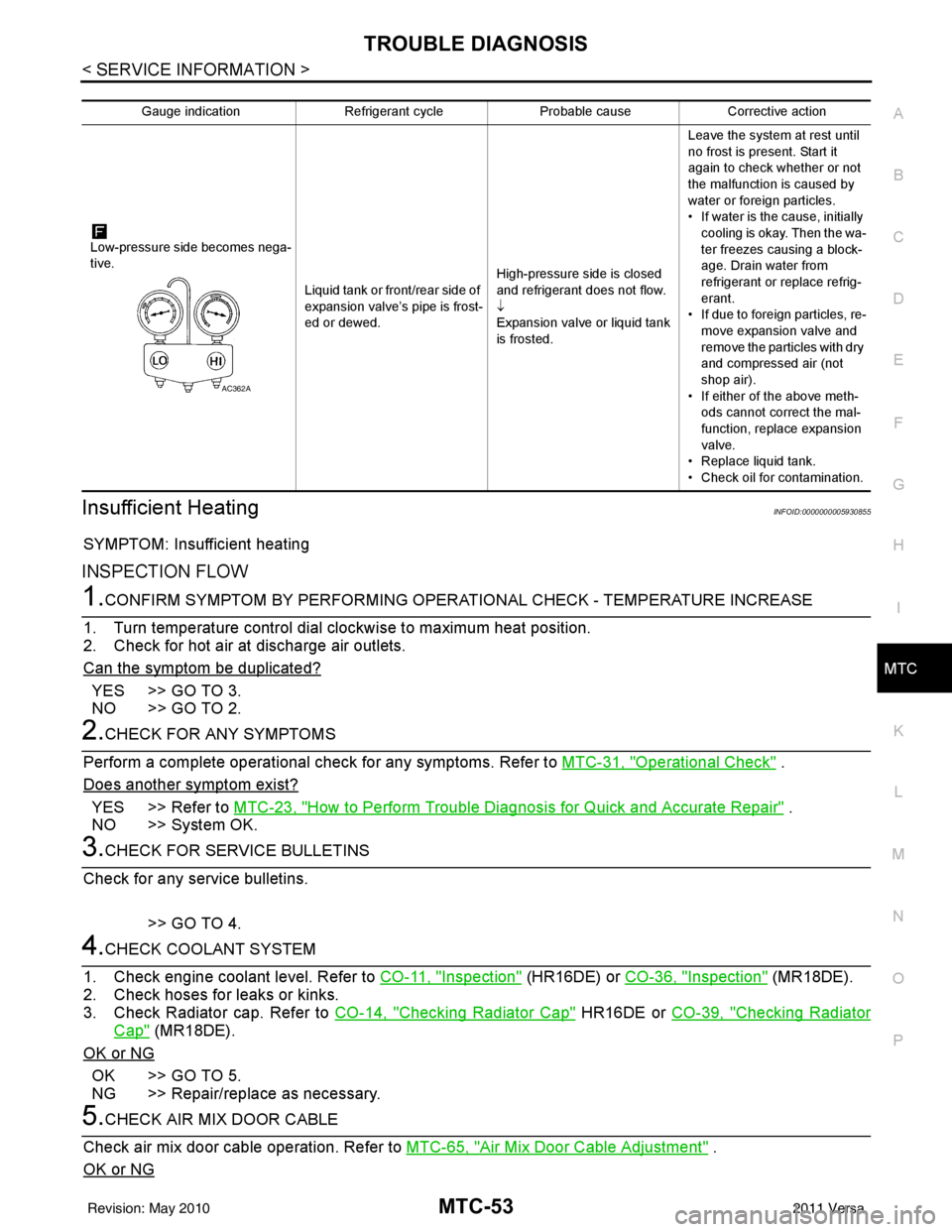

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: May 2010 2011 Versa

Page 3370 of 3787

MTC-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

YES >> GO TO 6.

NO >> Adjust or replace air mix door cable. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

6.CHECK AIR DUCTS

Check ducts for air leaks.

OK or NG

OK >> GO TO 7.

NG >> Repair air leaks.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> GO TO 8.

NO >> Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check engine control temperature sensor. Refer to EC-172, "

Component Inspection" (MR18DE) or EC-690,

"Component Inspection" (HR16DE).

OK or NG

OK >> System OK.

NG >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

OK or NG

OK >> GO TO 10.

NG >> Repair /replace as necessary. Retest GO TO 7.

10.BACK FLUSH HEATER CORE

1. Back flush heater core.

2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-11, "

Changing Engine Coolant" (HR16DE) or CO-36,

"Changing Engine Coolant" (MR18DE) .

4. Start engine and warm it up to normal operating temperature.

5. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inlet hose hot and the outlet hose warm?

YES >> System OK.

NO >> Replace heater core and refill engine coolant. Refer to MTC-68, "

Removal and Installation" .

NoiseINFOID:0000000005930856

SYMPTOM: Noise

INSPECTION FLOW

Revision: May 2010 2011 Versa

Page 3375 of 3787

A/C UNIT ASSEMBLYMTC-59

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

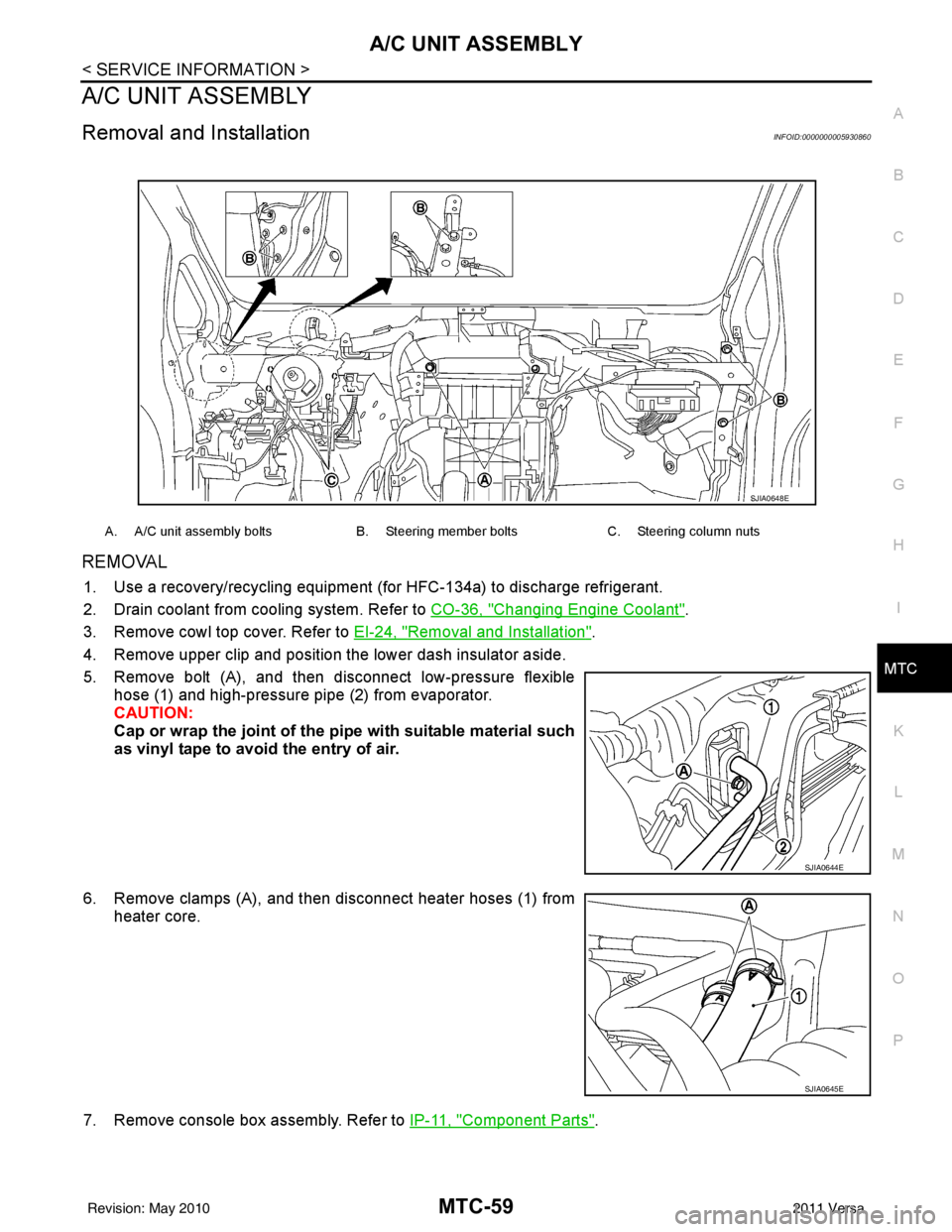

A/C UNIT ASSEMBLY

Removal and InstallationINFOID:0000000005930860

REMOVAL

1. Use a recovery/recycling equipment (f or HFC-134a) to discharge refrigerant.

2. Drain coolant from cooling system. Refer to CO-36, "

Changing Engine Coolant".

3. Remove cowl top cover. Refer to EI-24, "

Removal and Installation".

4. Remove upper clip and position the lower dash insulator aside.

5. Remove bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from heater core.

7. Remove console box assembly. Refer to IP-11, "

Component Parts".

A. A/C unit assembly boltsB. Steering member boltsC. Steering column nuts

SJIA0648E

SJIA0644E

SJIA0645E

Revision: May 2010 2011 Versa

Page 3376 of 3787

MTC-60

< SERVICE INFORMATION >

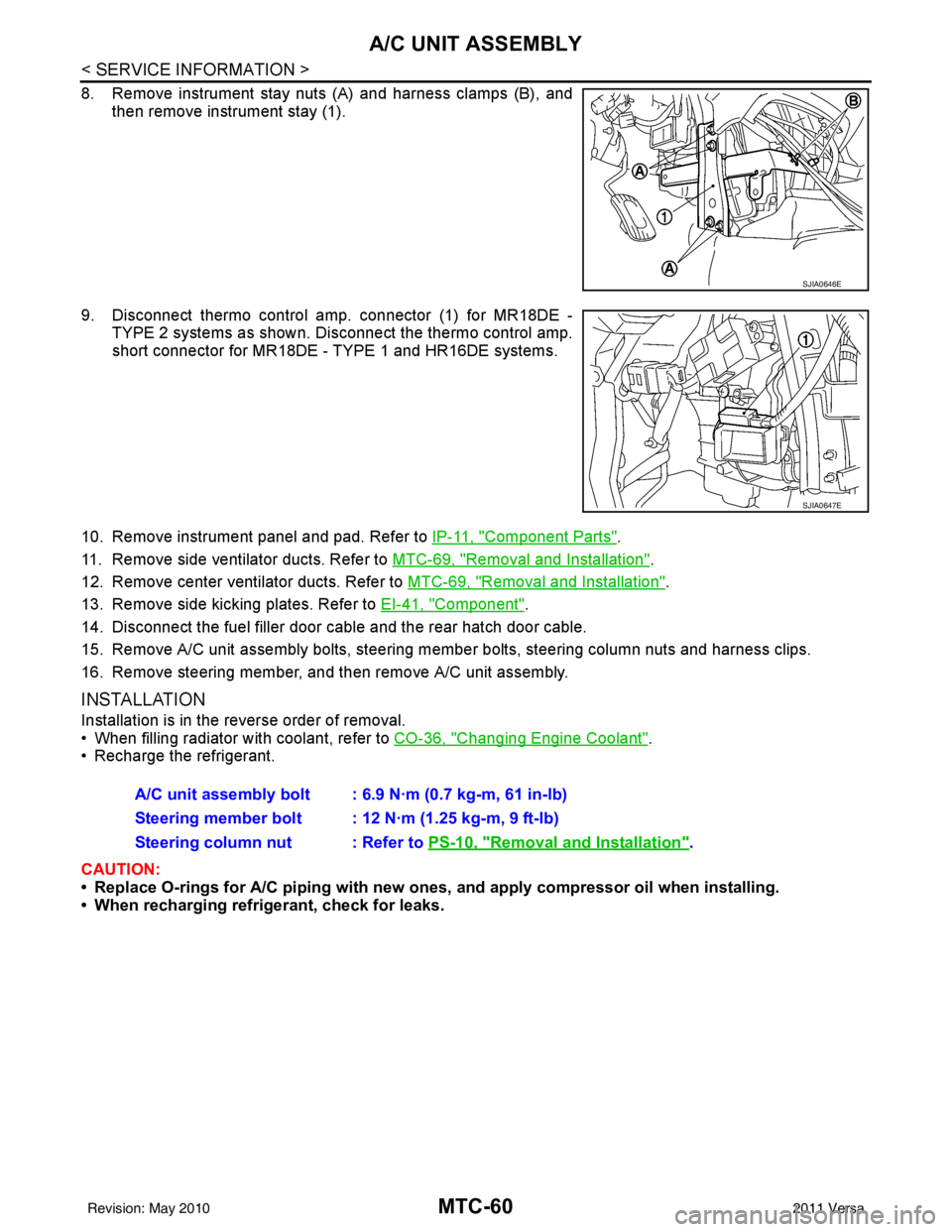

A/C UNIT ASSEMBLY

8. Remove instrument stay nuts (A) and harness clamps (B), andthen remove instrument stay (1).

9. Disconnect thermo control amp. connector (1) for MR18DE - TYPE 2 systems as shown. Di sconnect the thermo control amp.

short connector for MR18DE - TYPE 1 and HR16DE systems.

10. Remove instrument panel and pad. Refer to IP-11, "

Component Parts".

11. Remove side ventilator ducts. Refer to MTC-69, "

Removal and Installation".

12. Remove center ventilator ducts. Refer to MTC-69, "

Removal and Installation".

13. Remove side kicking plates. Refer to EI-41, "

Component".

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

• When filling radiator with coolant, refer to CO-36, "

Changing Engine Coolant".

• Recharge the refrigerant.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

SJIA0646E

SJIA0647E

A/C unit assembly bolt : 6.9 N·m (0.7 kg-m, 61 in-lb)

Steering member bolt : 12 N·m (1.25 kg-m, 9 ft-lb)

Steering column nut : Refer to PS-10, "

Removal and Installation".

Revision: May 2010 2011 Versa

Page 3395 of 3787

REFRIGERANT LINESMTC-79

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

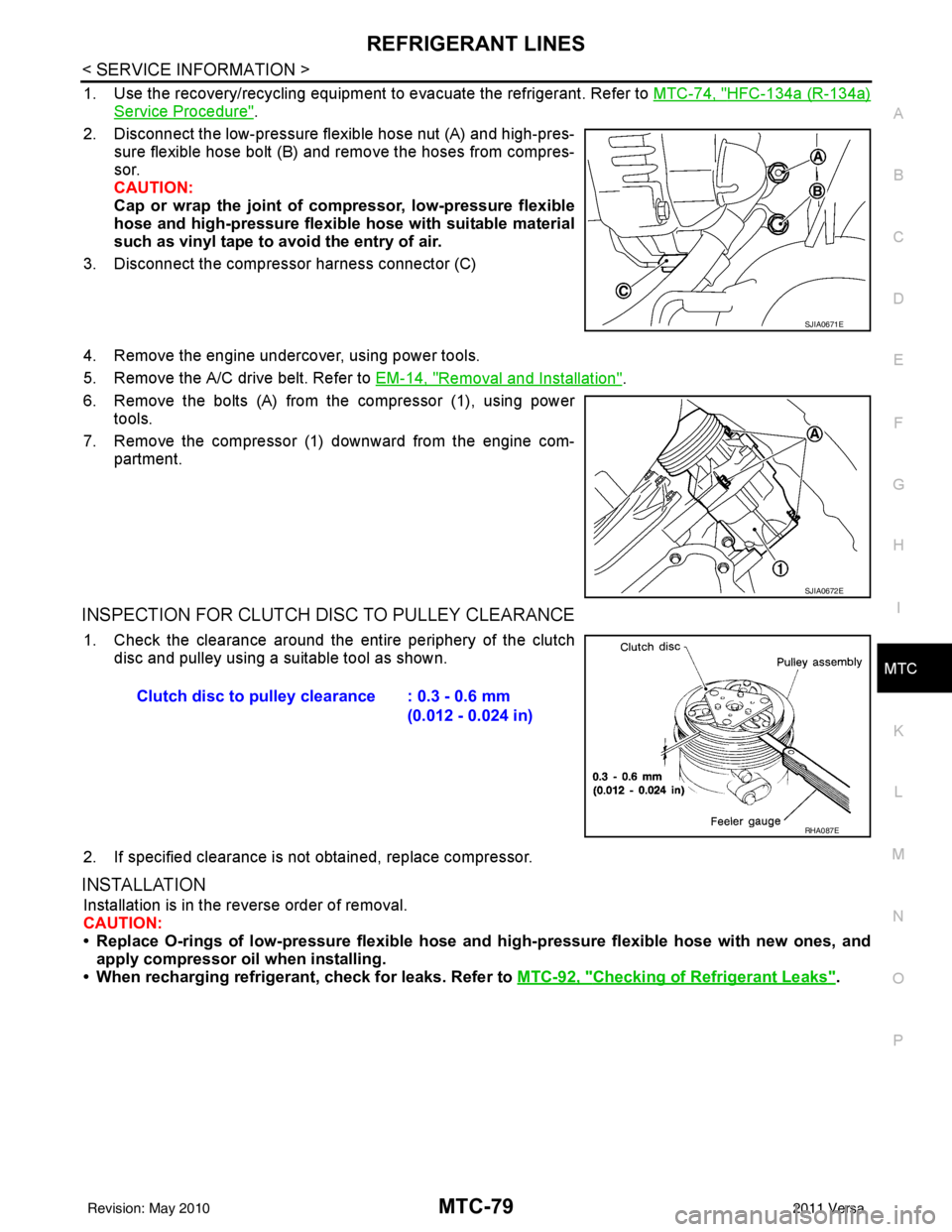

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to MTC-74, "HFC-134a (R-134a)

Service Procedure".

2. Disconnect the low-pressure flexible hose nut (A) and high-pres- sure flexible hose bolt (B) and remove the hoses from compres-

sor.

CAUTION:

Cap or wrap the joint of co mpressor, low-pressure flexible

hose and high-pressure flexible hose with suitable material

such as vinyl tape to avoid the entry of air.

3. Disconnect the compressor harness connector (C)

4. Remove the engine undercover, using power tools.

5. Remove the A/C drive belt. Refer to EM-14, "

Removal and Installation".

6. Remove the bolts (A) from the compressor (1), using power tools.

7. Remove the compressor (1) downward from the engine com- partment.

INSPECTION FOR CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch

disc and pulley using a suitable tool as shown.

2. If specified clearance is not obtained, replace compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with new ones, and

apply compressor oil when installing.

• When recharging refrigerant, check for leaks. Refer to MTC-92, "

Checking of Refrigerant Leaks".

SJIA0671E

SJIA0672E

Clutch disc to pulley clearance : 0.3 - 0.6 mm

(0.012 - 0.024 in)

RHA087E

Revision: May 2010 2011 Versa

Page 3396 of 3787

MTC-80

< SERVICE INFORMATION >

REFRIGERANT LINES

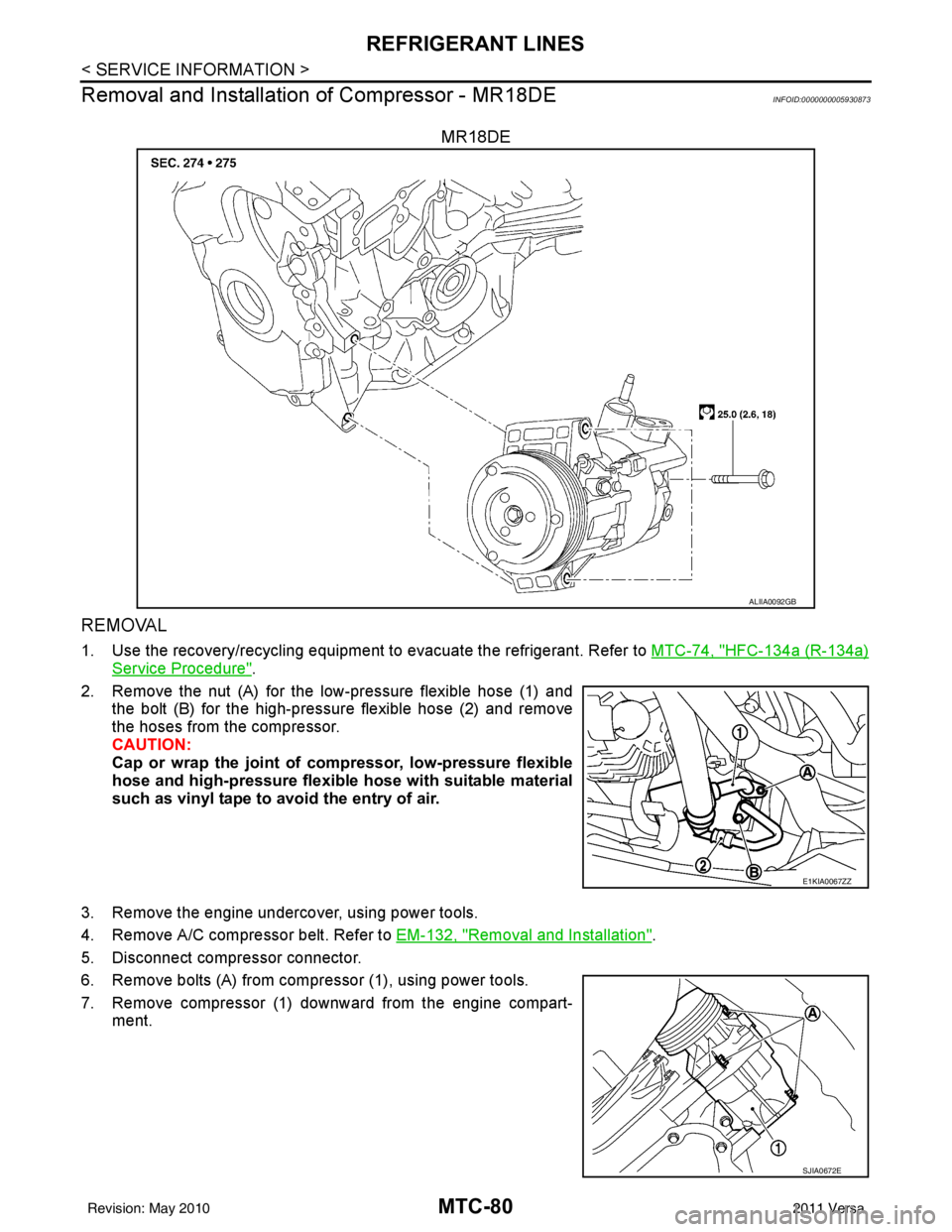

Removal and Installation of Compressor - MR18DE

INFOID:0000000005930873

MR18DE

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to MTC-74, "HFC-134a (R-134a)

Service Procedure".

2. Remove the nut (A) for the low-pressure flexible hose (1) and the bolt (B) for the high-pressure flexible hose (2) and remove

the hoses from the compressor.

CAUTION:

Cap or wrap the joint of co mpressor, low-pressure flexible

hose and high-pressure flexibl e hose with suitable material

such as vinyl tape to avoid the entry of air.

3. Remove the engine undercover, using power tools.

4. Remove A/C compressor belt. Refer to EM-132, "

Removal and Installation".

5. Disconnect compressor connector.

6. Remove bolts (A) from compressor (1), using power tools.

7. Remove compressor (1) downward from the engine compart- ment.

ALIIA0092GB

E1KIA0067ZZ

SJIA0672E

Revision: May 2010 2011 Versa

Page 3403 of 3787

REFRIGERANT LINESMTC-87

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

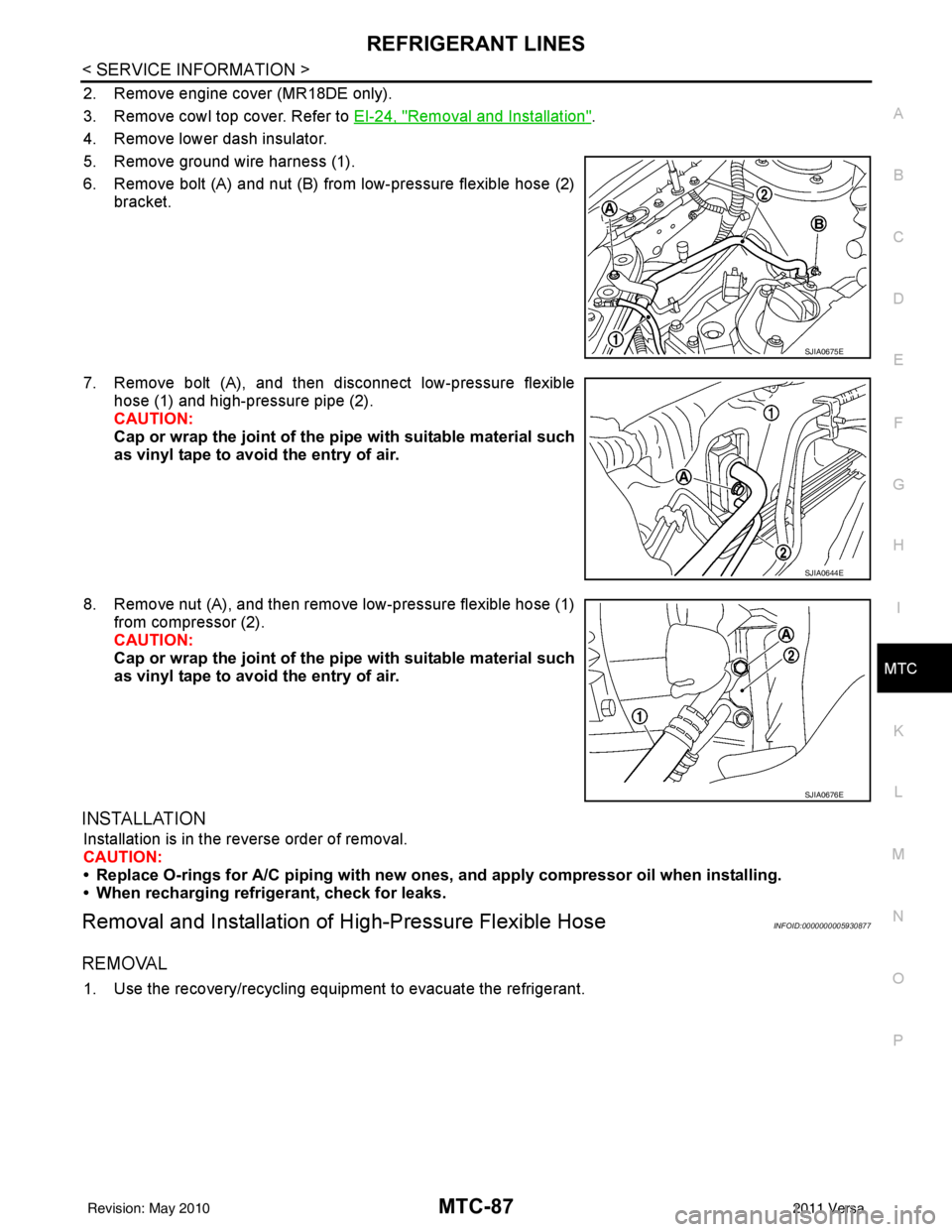

2. Remove engine cover (MR18DE only).

3. Remove cowl top cover. Refer to EI-24, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2) bracket.

7. Remove bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

8. Remove nut (A), and then remove low-pressure flexible hose (1) from compressor (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new on es, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of High-Pressure Flexible HoseINFOID:0000000005930877

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

SJIA0675E

SJIA0644E

SJIA0676E

Revision: May 2010 2011 Versa

Page 3409 of 3787

REFRIGERANT LINESMTC-93

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and oils, may falsely trigger the leak detector. Make sure the surfaces to be checked are

clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionINFOID:0000000005930886

(This procedure is only necessary when recharging t he system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pres sure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool J-41459.

3. Connect the injector tool to the A/C low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a componen t, pour the dye directly into the open system

connection and proceed wi th the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak , it may take from minutes to days for the dye to

penetrate a leak and become visible.

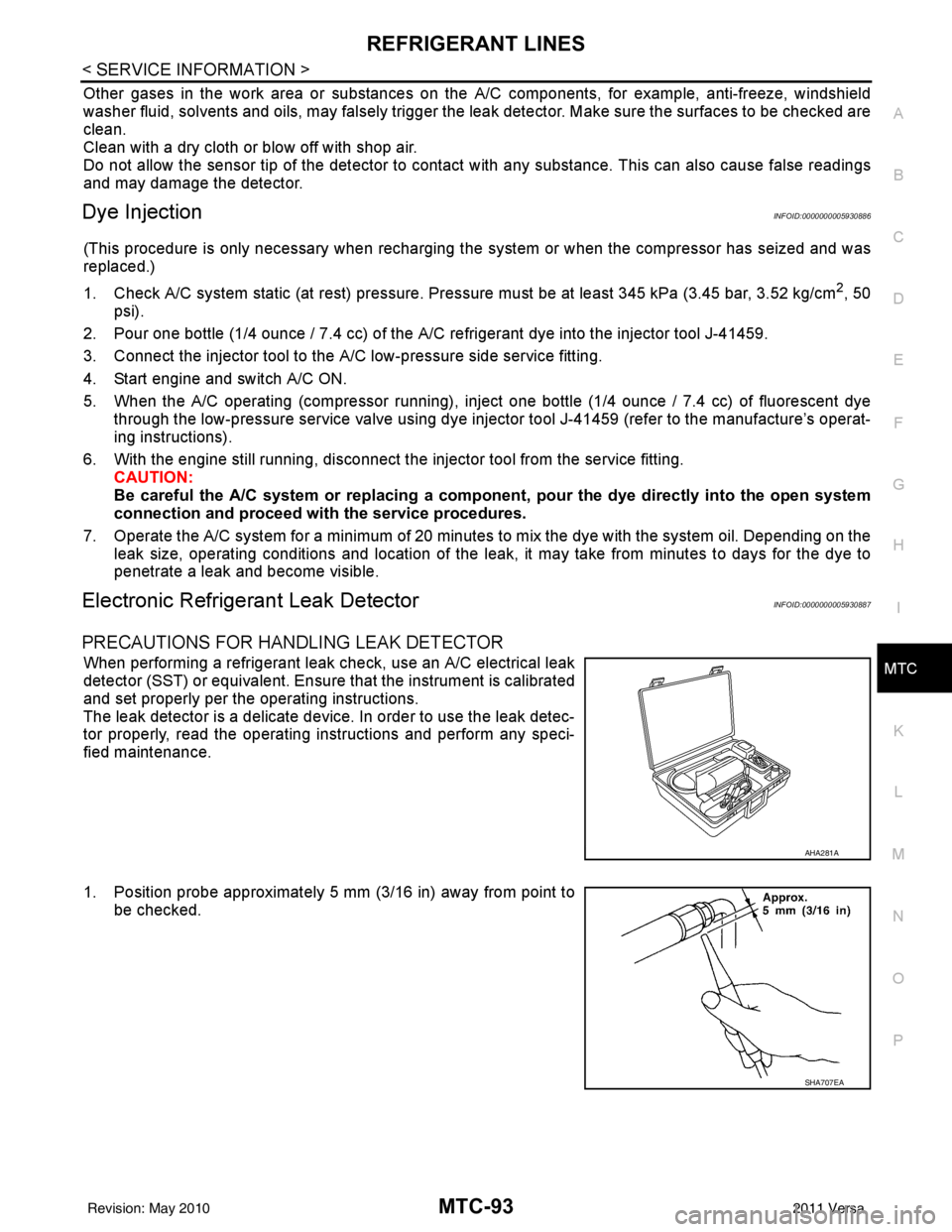

Electronic Refrigerant Leak DetectorINFOID:0000000005930887

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

AHA281A

SHA707EA

Revision: May 2010 2011 Versa