system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3141 of 3787

ILLUMINATIONLT-109

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

ILLUMINATION

System DescriptionINFOID:0000000005929150

The control of the illumination lamps operation is dependent upon the position of the lighting switch. When the

lighting switch is placed in the 1ST or 2ND position, the BCM (body control module) receives input signal

requesting the illumination lamps to illuminate. This input signal is communicated to IPDM E/R (intelligent

power distribution module engine room) across CAN communication lines. CPU (central processing unit)

located in the IPDM E/R controls the tail lamp relay coil . This relay, when energized, directs power to the illu-

mination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in IPDM E/R,

• to tail lamp relay, located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70, and

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in IPDM E/R, and

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61

• to IPDM E/R terminals 39 and 59, and

• through grounds E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND positi on, BCM receives input signal requesting the illumination

lamps to illuminate. This input signal is communicat ed to IPDM E/R across CAN communication lines. CPU

located in the IPDM E/R controls the tail lamp relay coil, which, when energized, directs power

• through 10A fuse (No. 37, located in IPDM E/R)

• through IPDM E/R terminal 29

• to illumination control switch terminal 1

• to VDC OFF switch terminal 3 (with VDC)

• to audio unit terminal 9

• to front air control terminal 5

• to A/T shift selector terminal 3 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

• to hazard switch terminal 3

• to combination meter terminal 12

• to door mirror remote control switch terminal 16

• to combination switch (spiral cable) terminal 26 (with steering wheel audio control switches)

• to steering wheel audio control switches through combinat ion switch (spiral cable) terminal 18 (with steering

wheel audio control switches).

Ground is supplied

• to VDC OFF switch terminal 4 (with VDC)

• to illumination control switch terminal 3, and

• through grounds M57 and M61.

The illumination control switch controls illuminat ion intensity by varying the ground to the following

• through illumination control switch terminal 2

• to audio unit terminal 8

• to front air control terminal 6

• to A/T shift selector terminal 4 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

Revision: May 2010 2011 Versa

Page 3142 of 3787

LT-110

< SERVICE INFORMATION >

ILLUMINATION

• to hazard switch terminal 4

• to combination meter terminal 13

• to door mirror remote control switch terminal 15

• to combination switch (spiral cable) terminal 27 (with steering wheel audio control switches)

• to steering wheel audio control switches through combination switch (spiral cable) terminal 21 (with steeringwheel audio control switches).

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-74, "System Description".

CAN Communication System DescriptionINFOID:0000000005929151

Refer to LAN-7, "System Description" .

Revision: May 2010 2011 Versa

Page 3149 of 3787

LU-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION LU

A

LU

N

O P

CONTENTS

ENGINE LUBRICATION SYSTEM

HR16DE

PRECAUTION ....... ........................................

2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Liquid Gasket .....................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

FUNCTION DIAGNOSIS ...............................6

DESCRIPTION ............................................... .....6

Engine Lubrication System ................................. ......6

Engine Lubrication System Schematic ......................6

ON-VEHICLE MAINTENANCE .....................7

ENGINE OIL ................................................... .....7

Inspection ............................................................ ......7

Draining .....................................................................8

Refilling .....................................................................8

OIL FILTER .........................................................9

Removal and Installation ...........................................9

ON-VEHICLE REPAIR .... .............................10

OIL PUMP ....................................................... ....10

Removal and Installation .........................................10

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ..................

11

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

11

Engine Oil Capacity ............................................. ....11

Engine Oil Pressure .................................................11

MR18DE

SERVICE INFORMATION .. .........................

12

PRECAUTIONS .................................................12

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

12

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

12

Precaution for Liquid Gasket ...................................13

PREPARATION .................................................14

Special Service Tool ................................................14

Commercial Service Tool ........................................14

LUBRICATION SYSTEM ..................................16

Lubrication Circuit ....................................................16

ENGINE OIL ......................................................17

Inspection ................................................................17

Changing Engine Oil ................................................18

OIL FILTER .......................................................20

Removal and Installation .........................................20

OIL PUMP .........................................................21

Component ..............................................................21

Removal and Installation .........................................21

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

23

Standard and Limit ..................................................23

Revision: May 2010 2011 Versa

Page 3150 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Res NISSAN TIIDA 2011 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Res](/img/5/57396/w960_57396-3149.png)

LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Liquid GasketINFOID:0000000005928682

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful no t to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

Tool number : KV10111100 (J-37228)

WBIA0566E

Revision: May 2010 2011 Versa

Page 3154 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LU-6

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Lubrication SystemINFOID:0000000005928685

Engine Lubricati

on System SchematicINFOID:0000000005928686

JPBIA0325GB

NISSAN TIIDA 2011 Service Repair Manual LU-6

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Lubrication SystemINFOID:0000000005928685

Engine Lubricati

on System SchematicINFOID:0000000005928686

JPBIA0325GB](/img/5/57396/w960_57396-3153.png)

LU-6

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Lubrication SystemINFOID:0000000005928685

Engine Lubricati

on System SchematicINFOID:0000000005928686

JPBIA0325GB

JPBIA0326GB

Revision: May 2010 2011 Versa

Page 3160 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928694

T NISSAN TIIDA 2011 Service Repair Manual LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928694

T](/img/5/57396/w960_57396-3159.png)

LU-12

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928694

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005928695

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3164 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LU-16

< SERVICE INFORMATION >[MR18DE]

LUBRICATION SYSTEM

LUBRICATION SYSTEM

Lubrication CircuitINFOID:0000000005928699

PBIC4575E

Revision: May 2010

2011 Versa NISSAN TIIDA 2011 Service Repair Manual LU-16

< SERVICE INFORMATION >[MR18DE]

LUBRICATION SYSTEM

LUBRICATION SYSTEM

Lubrication CircuitINFOID:0000000005928699

PBIC4575E

Revision: May 2010

2011 Versa](/img/5/57396/w960_57396-3163.png)

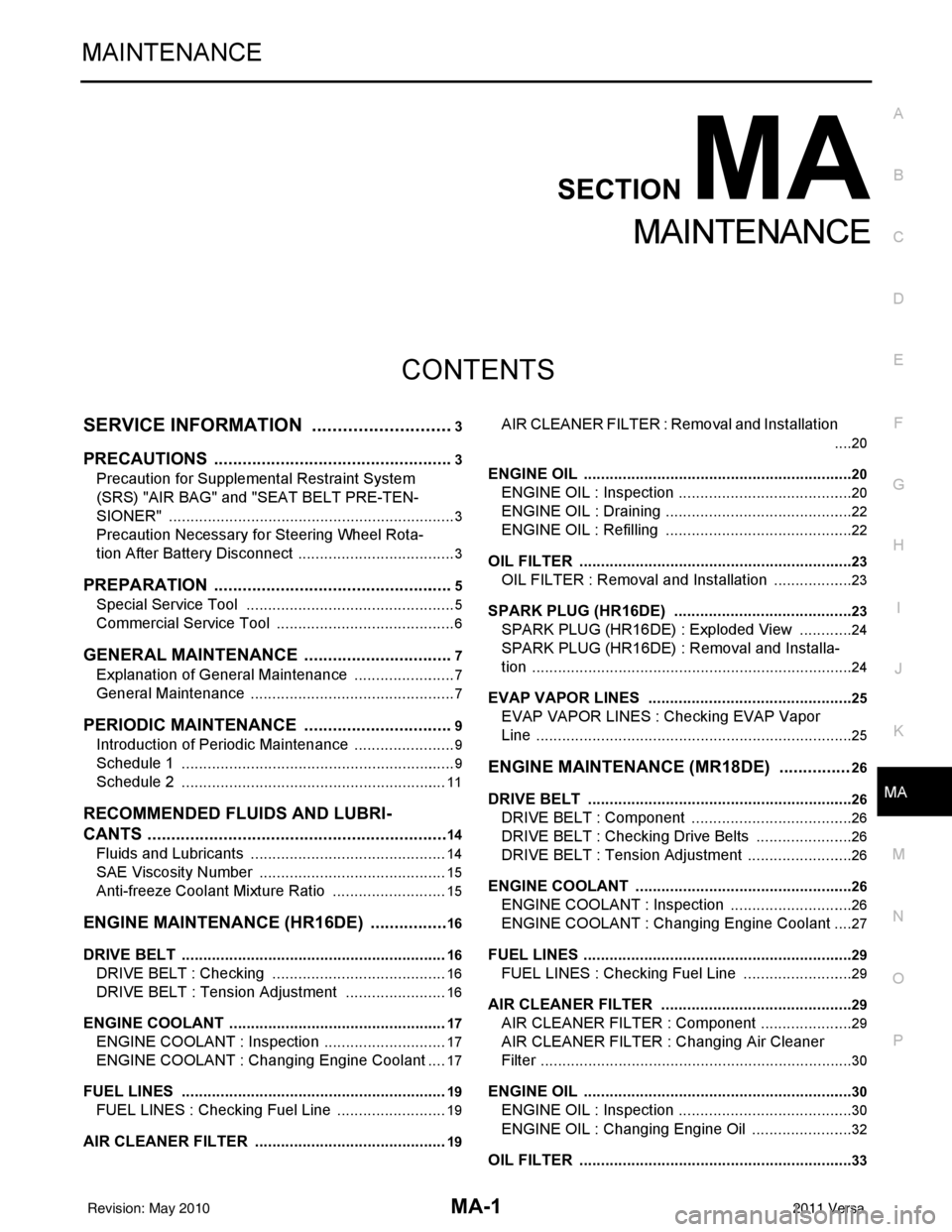

LU-16

< SERVICE INFORMATION >[MR18DE]

LUBRICATION SYSTEM

LUBRICATION SYSTEM

Lubrication CircuitINFOID:0000000005928699

PBIC4575E

Revision: May 2010

2011 Versa

Page 3172 of 3787

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K

M

SECTION MA

A

B

MA

N

O P

CONTENTS

MAINTENANCE

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

GENERAL MAINTENANCE ........................... .....7

Explanation of General Maintenance .................. ......7

General Maintenance ................................................7

PERIODIC MAINTENANCE ................................9

Introduction of Periodic Maintenance .................. ......9

Schedule 1 ................................................................9

Schedule 2 ..............................................................11

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

14

Fluids and Lubricants .......................................... ....14

SAE Viscosity Number ............................................15

Anti-freeze Coolant Mixture Ratio ...........................15

ENGINE MAINTENANCE (HR16DE) .................16

DRIVE BELT .......................................................... ....16

DRIVE BELT : Checking .........................................16

DRIVE BELT : Tension Adjustment ........................16

ENGINE COOLANT ............................................... ....17

ENGINE COOLANT : Inspection .............................17

ENGINE COOLANT : Changing Engine Coolant ....17

FUEL LINES .......................................................... ....19

FUEL LINES : Checking Fuel Line ..........................19

AIR CLEANER FILTER ......................................... ....19

AIR CLEANER FILTER : Removal and Installation

....

20

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................22

ENGINE OIL : Refilling ............................................22

OIL FILTER ............................................................ ....23

OIL FILTER : Removal and Installation ...................23

SPARK PLUG (HR16DE) ...................................... ....23

SPARK PLUG (HR16DE) : Exploded View .............24

SPARK PLUG (HR16DE) : Removal and Installa-

tion ....................................................................... ....

24

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Checking EVAP Vapor

Line ..........................................................................

25

ENGINE MAINTENANCE (MR18DE) ...............26

DRIVE BELT .......................................................... ....26

DRIVE BELT : Component ......................................26

DRIVE BELT : Checking Drive Belts .......................26

DRIVE BELT : Tension Adjustment .........................26

ENGINE COOLANT ............................................... ....26

ENGINE COOLANT : Inspection .............................26

ENGINE COOLANT : Changing Engine Coolant ....27

FUEL LINES ........................................................... ....29

FUEL LINES : Checking Fuel Line ..........................29

AIR CLEANER FILTER ......................................... ....29

AIR CLEANER FILTER : Component ......................29

AIR CLEANER FILTER : Changing Air Cleaner

Filter .........................................................................

30

ENGINE OIL ........................................................... ....30

ENGINE OIL : Inspection .........................................30

ENGINE OIL : Changing Engine Oil ........................32

OIL FILTER ............................................................ ....33

Revision: May 2010 2011 Versa

Page 3173 of 3787

MA-2

OIL FILTER : Removal and Installation ..................33

SPARK PLUG ........................................................ ...34

SPARK PLUG : Component ...................................34

SPARK PLUG : Removal and Installation ..............35

EVAP VAPOR LINES ............................................. ...36

EVAP VAPOR LINES : Checking EVAP Vapor

Line .........................................................................

36

CHASSIS AND BODY MAINTENANCE ............37

EXHAUST SYSTEM ............................................... ...37

EXHAUST SYSTEM : Checking Exhaust System

HR16DE .............................................................. ...

37

EXHAUST SYSTEM : Checking Exhaust System

MR18DE .............................................................. ...

37

CVT FLUID ............................................................. ...37

CVT FLUID : Checking CVT Fluid ..........................37

CVT FLUID : Changing CVT Fluid ..........................38

CLUTCH FLUID ..................................................... ...39

CLUTCH FLUID : Air Bleeding Procedure ..............39

M/T OIL ................................................................... ...40

M/T OIL : Draining (RS5F91R) ...............................40

M/T OIL : Refilling (RS5F91R) ................................41

M/T OIL : Inspection (RS5F91R) ............................41

M/T OIL : Changing M/T Oil (RS6F94R) .................41

M/T OIL : Checking M/T Oil (RS6FF94R) ...............42

A/T FLUID .............................................................. ...42

A/T FLUID : Checking A/T Fluid .............................42

A/T FLUID : Changing A/T Fluid .............................43

WHEELS ................................................................. ...43

WHEELS : Adjustment ............................................43

BRAKE FLUID LEVEL AND LEAKS ..................... ...45

BRAKE FLUID LEVEL AND LEAKS : On Board In-

spection ...................................................................

45

BRAKE FLUID LEVEL AND LEAKS : Drain and

Refill ........................................................................

45

BRAKE LINES AND CABLES ............................... ...46

BRAKE LINES AND CABLES : Checking Brake

Line and Cables ................................................... ...

46

DISC BRAKE .......................................................... ...46

DISC BRAKE : On Board Inspection ......................46

DRUM BRAKE ....................................................... ...46

DRUM BRAKE : Inspection .....................................46

AXLE AND SUSPENSION PARTS ........................ ...47

AXLE AND SUSPENSION PARTS : Axle and

Suspension Parts ................................................. ...

47

DRIVE SHAFT ........................................................ ...48

DRIVE SHAFT : Drive Shaft ...................................48

LOCKS, HINGES AND HOOD LATCH .................. ...48

LOCKS, HINGES AND HOOD LATCH : Lubricat-

ing Locks, Hinges and Hood Latch .........................

49

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ................................... ...

49

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Checking Seat

Belts, Buckles, Retractors, Anchors and Adjusters

...

49

Revision: May 2010 2011 Versa

Page 3174 of 3787

PRECAUTIONSMA-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005931125

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005931126

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa