fuse NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2994 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LAN-148

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur NISSAN TIIDA 2011 Service Repair Manual LAN-148

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur](/img/5/57396/w960_57396-2993.png)

LAN-148

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 10)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system. NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Revision: May 2010 2011 Versa

Page 3007 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CAN COMMUNICATION CIRCUITLAN-161

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Foll NISSAN TIIDA 2011 Service Repair Manual CAN COMMUNICATION CIRCUITLAN-161

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Foll](/img/5/57396/w960_57396-3006.png)

CAN COMMUNICATION CIRCUITLAN-161

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 11)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Revision: May 2010 2011 Versa

Page 3019 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CAN COMMUNICATION CIRCUITLAN-173

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Foll NISSAN TIIDA 2011 Service Repair Manual CAN COMMUNICATION CIRCUITLAN-173

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Foll](/img/5/57396/w960_57396-3018.png)

CAN COMMUNICATION CIRCUITLAN-173

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 12)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Revision: May 2010 2011 Versa

Page 3032 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur NISSAN TIIDA 2011 Service Repair Manual LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur](/img/5/57396/w960_57396-3031.png)

LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system. NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Revision: May 2010 2011 Versa

Page 3037 of 3787

HEADLAMP (FOR USA)LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP (FOR USA)

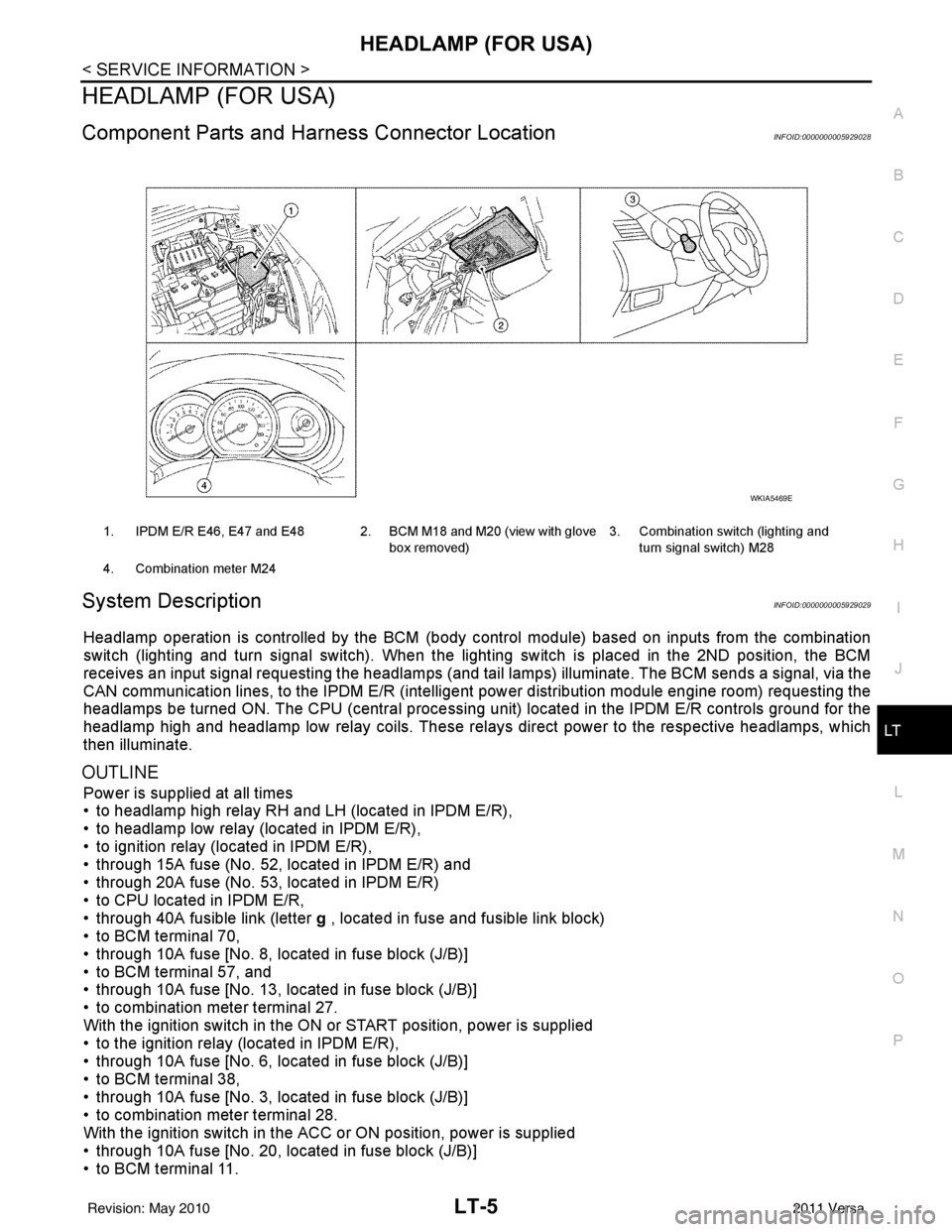

Component Parts and Har ness Connector LocationINFOID:0000000005929028

System DescriptionINFOID:0000000005929029

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting and turn signal switch). When the light ing switch is placed in the 2ND position, the BCM

receives an input signal requesting the headlamps (and tail lamps) illuminate. The BCM sends a signal, via the

CAN communication lines, to the IPDM E/R (intelligent power distribution module engine room) requesting the

headlamps be turned ON. The CPU (centra l processing unit) located in the IPDM E/R controls ground for the

headlamp high and headlamp low relay coils. These relays direct power to the respective headlamps, which

then illuminate.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R),

• to headlamp low relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57, and

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting and

turn signal switch) M28

4. Combination meter M24

WKIA5469E

Revision: May 2010 2011 Versa

Page 3038 of 3787

LT-6

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

Ground is supplied

• to BCM terminal 67

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61, and

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives an input signal requesting the headlamps to illumi-

nate. The BCM then sends a signal, via the CAN comm unication lines, to the IPDM E/R requesting the low

beam headlamps be turned ON. The CPU located in the IPDM E/R controls ground to the headlamp low relay

coil, which when energized, directs power

• through 15A fuse (No. 41, located in IPDM E/R)

• through IPDM E/R terminal 54

• to headlamp RH terminal 3, and

• through 15A fuse (No. 40, located in IPDM E/R)

• through IPDM E/R terminal 52

• to headlamp LH terminal 3.

Ground is supplied

• to headlamp RH and LH terminals 2

• through grounds E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in 2ND position and high beam swit ch in the HIGH position, the BCM receives an input

signal requesting the headlamp high beams to illuminate. T he flash to pass feature can be used any time and

also sends a signal to the BCM. This input signal is then communicated to the IPDM E/R and the combination

meter via the CAN communication. The CPU located in the IPDM E/R controls the headlamp high relays (LH

and RH), which when energized, directs power

• through 10A fuse (No. 34, located in IPDM E/R)

• through IPDM E/R terminal 56

• to headlamp RH terminal 1, and

• through 10A fuse (No. 35, located in IPDM E/R)

• through IPDM E/R terminal 55

• to headlamp LH terminal 1.

Ground is supplied

• to headlamp RH and LH terminal 2

• through grounds E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

The BCM sends a signal, via the CAN communication lines, to the combination meter requesting the high

beam indicator lamp be turned ON.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-74, "System Description" .

CAN COMMUNICATION SYSTEM DESCRIPTIONINFOID:0000000005929030

Refer to LAN-7 .

Revision: May 2010 2011 Versa

Page 3048 of 3787

LT-16

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

Without CONSULT-III

1. Start auto active test. Refer to PG-20, "

Auto Active Test" .

2. Make sure headlamp high beam operates.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-III. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Make sure “HL HI REQ” turns ON when lighting switch is in high position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM" .

4.HEADLAMP HIGH BEAM FUSE INSPECTION

Inspect 10A fuse No. 34 (RH) and fuse No. 35 (LH).

OK or NG

OK >> GO TO 5.

NG >> Repair harness.

5.BULB INSPECTION

Inspect inoperative headlamp bulbs.

OK or NG

OK >> GO TO 6.

NG >> Replace headlamp bulb. LT-24, "

Bulb Replacement" .

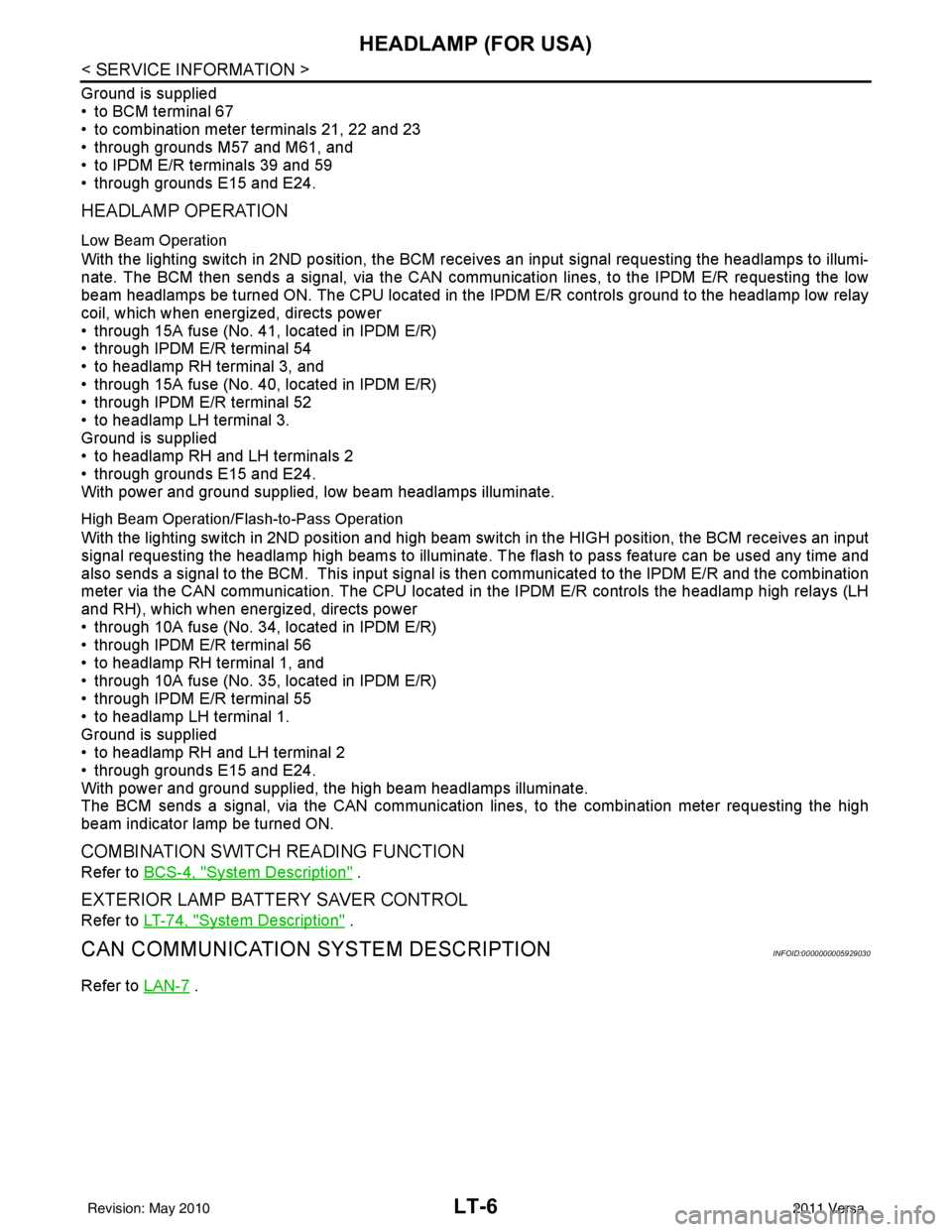

6.CHECK HEADLAMP INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect headlamp connector.

3. Select “IPDM E/R” on CONSULT-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “HI” screen.

6. When headlamp high beam is operating, check voltage between headlamp harness connector and ground (Headlamp high beam

repeats ON–OFF every 2 seconds).

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect headlamp connector.

3. Start auto active test. Refer to PG-20, "

Auto Active Test" .

Headlamp high beam should operate

(Headlamp high beam repeats ON–OFF every 2 sec-

onds).

Headlamp high beam should operate.

When lighting switch is high

position

: HL HI REQ ON

Te r m i n a l

Vo l ta g e

(+)

(−)

Headlamp connector Terminal

RH E26 1Ground Battery voltage

LH E25

PKIC0960E

Revision: May 2010 2011 Versa

Page 3049 of 3787

HEADLAMP (FOR USA)LT-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

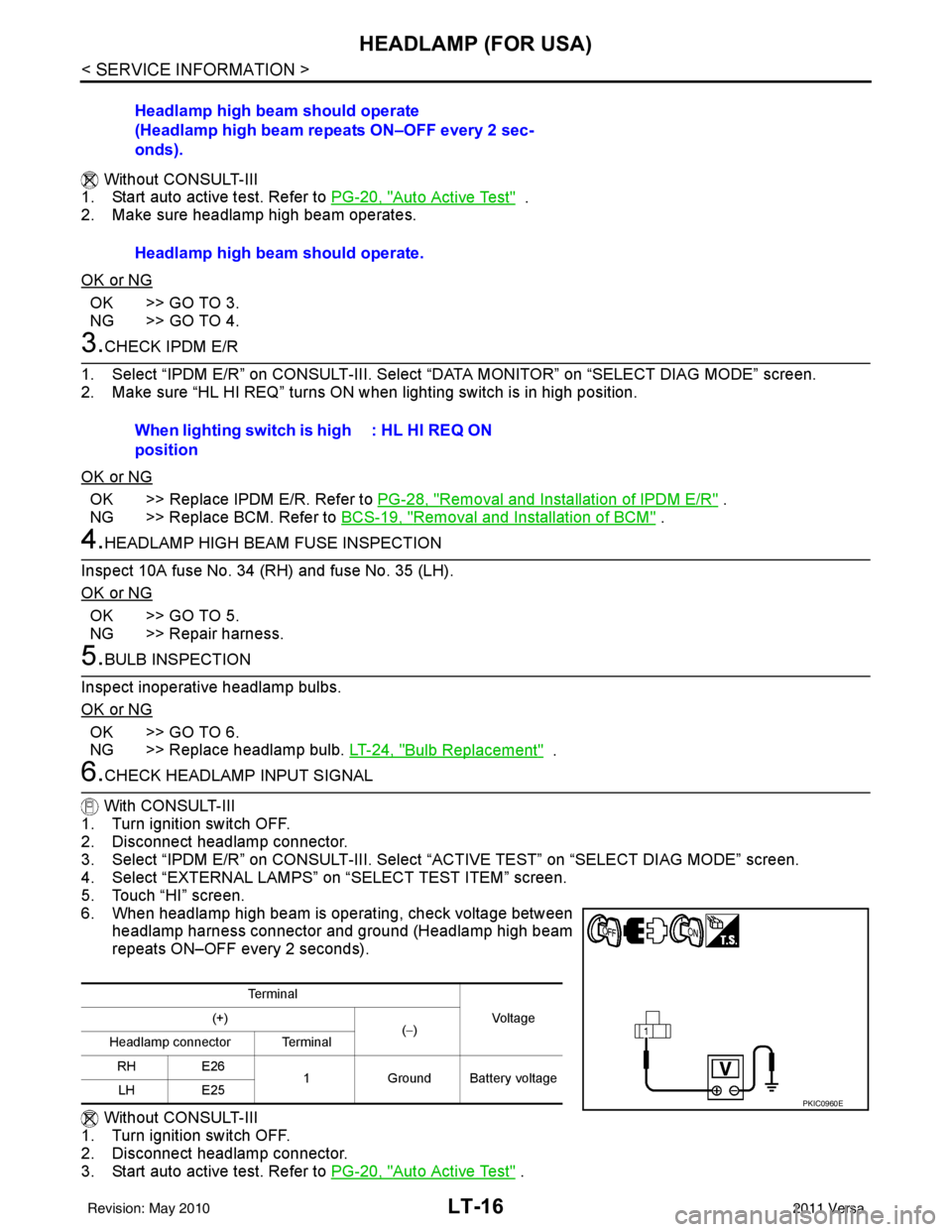

4. When headlamp high beam is operating, check voltage between headlamp harness connector and ground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 8.

7.CHECK HEADLAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between headlamp harness connector and ground.

OK or NG

OK >> Check front combination lamp connector for damage or poor connection. Repair as necessary.

NG >> Repair harness.

8.CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector (A) and headlamp harness connector (B).

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

Headlamp High Beam Does No t Illuminate (One Side)INFOID:0000000005929040

1.HEADLAMP HIGH BEAM FUSE INSPECTION

Inspect 10A fuse No. 34 (RH) or fuse No. 35 (LH).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK BULB

Check headlamp bulb which does not illuminate.

OK or NG

OK >> GO TO 3.

NG >> Replace bulb. Refer to LT-24, "

Bulb Replacement" .

Te r m i n a l

Vo l ta g e

(+)

(−)

Headlamp connector Terminal

RH E26 1Ground Battery voltage

LH E25

Headlamp connector Terminal

Ground Continuity

RH E26 2Y es

LH E25

PKIC0961E

Circuit AB

Continuity

Connector Terminal Connector Terminal

RH E47 56 E26

1 Yes

LH 55 E25

WKIA5470E

Revision: May 2010 2011 Versa

Page 3051 of 3787

HEADLAMP (FOR USA)LT-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

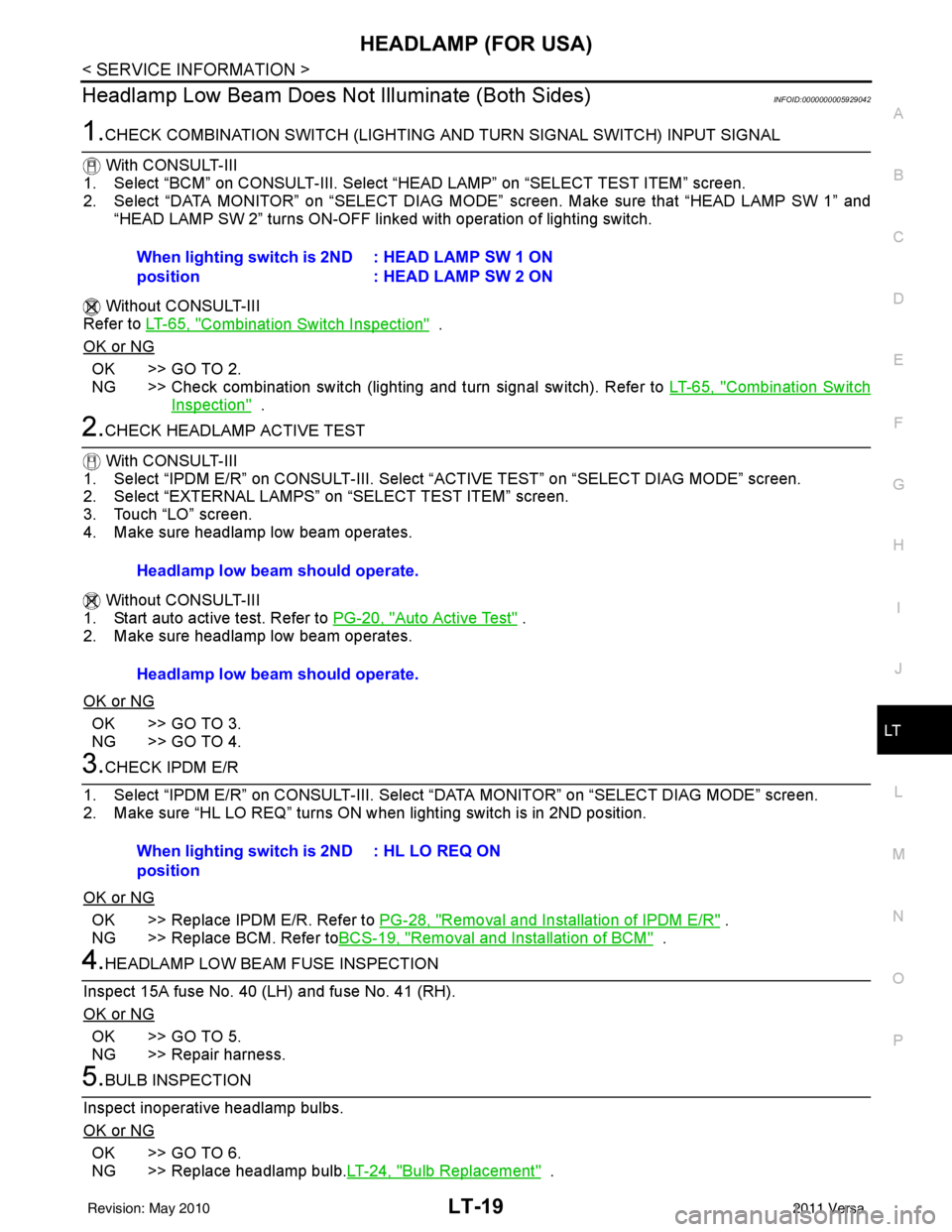

Headlamp Low Beam Does No t Illuminate (Both Sides)INFOID:0000000005929042

1.CHECK COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen. Make sure that “HEAD LAMP SW 1” and

“HEAD LAMP SW 2” turns ON-OFF li nked with operation of lighting switch.

Without CONSULT-III

Refer to LT-65, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting and turn signal switch). Refer to LT-65, "

Combination Switch

Inspection" .

2.CHECK HEADLAMP ACTIVE TEST

With CONSULT-III

1. Select “IPDM E/R” on CONSUL T-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “LO” screen.

4. Make sure headlamp low beam operates.

Without CONSULT-III

1. Start auto active test. Refer to PG-20, "

Auto Active Test" .

2. Make sure headlamp low beam operates.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSUL T-III. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Make sure “HL LO REQ” turns ON when lighting switch is in 2ND position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM" .

4.HEADLAMP LOW BEAM FUSE INSPECTION

Inspect 15A fuse No. 40 (LH) and fuse No. 41 (RH).

OK or NG

OK >> GO TO 5.

NG >> Repair harness.

5.BULB INSPECTION

Inspect inoperative headlamp bulbs.

OK or NG

OK >> GO TO 6.

NG >> Replace headlamp bulb. LT-24, "

Bulb Replacement" .

When lighting switch is 2ND

position

: HEAD LAMP SW 1 ON

: HEAD LAMP SW 2 ON

Headlamp low beam should operate.

Headlamp low beam should operate.

When lighting switch is 2ND

position: HL LO REQ ON

Revision: May 2010

2011 Versa

Page 3053 of 3787

HEADLAMP (FOR USA)LT-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

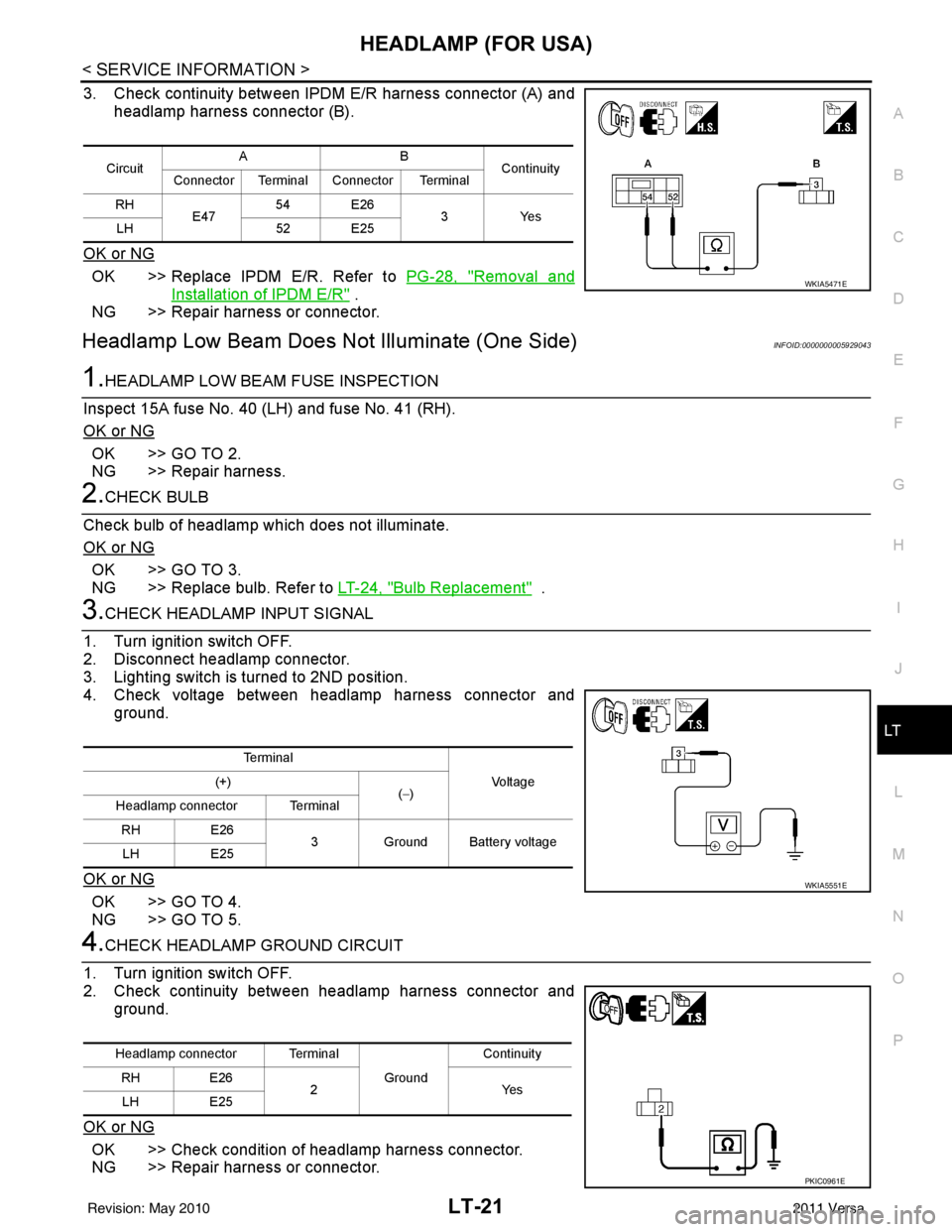

3. Check continuity between IPDM E/R harness connector (A) and headlamp harness connector (B).

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

Headlamp Low Beam Does Not Illuminate (One Side)INFOID:0000000005929043

1.HEADLAMP LOW BEAM FUSE INSPECTION

Inspect 15A fuse No. 40 (LH) and fuse No. 41 (RH).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK BULB

Check bulb of headlamp which does not illuminate.

OK or NG

OK >> GO TO 3.

NG >> Replace bulb. Refer to LT-24, "

Bulb Replacement" .

3.CHECK HEADLAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect headlamp connector.

3. Lighting switch is turned to 2ND position.

4. Check voltage between headlamp harness connector and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 5.

4.CHECK HEADLAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between headlamp harness connector and ground.

OK or NG

OK >> Check condition of headlamp harness connector.

NG >> Repair harness or connector.

Circuit AB

Continuity

Connector Terminal Connector Terminal

RH E47 54 E26

3Yes

LH 52 E25

WKIA5471E

Te r m i n a l

Vo l ta g e

(+)

(−)

Headlamp connector Terminal

RH E26

3 Ground Battery voltage

LH E25

WKIA5551E

Headlamp connector Terminal

Ground Continuity

RH E26

2Y es

LH E25

PKIC0961E

Revision: May 2010 2011 Versa