fuse NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2800 of 3787

GW-46

< SERVICE INFORMATION >

FRONT DOOR GLASS AND REGULATOR

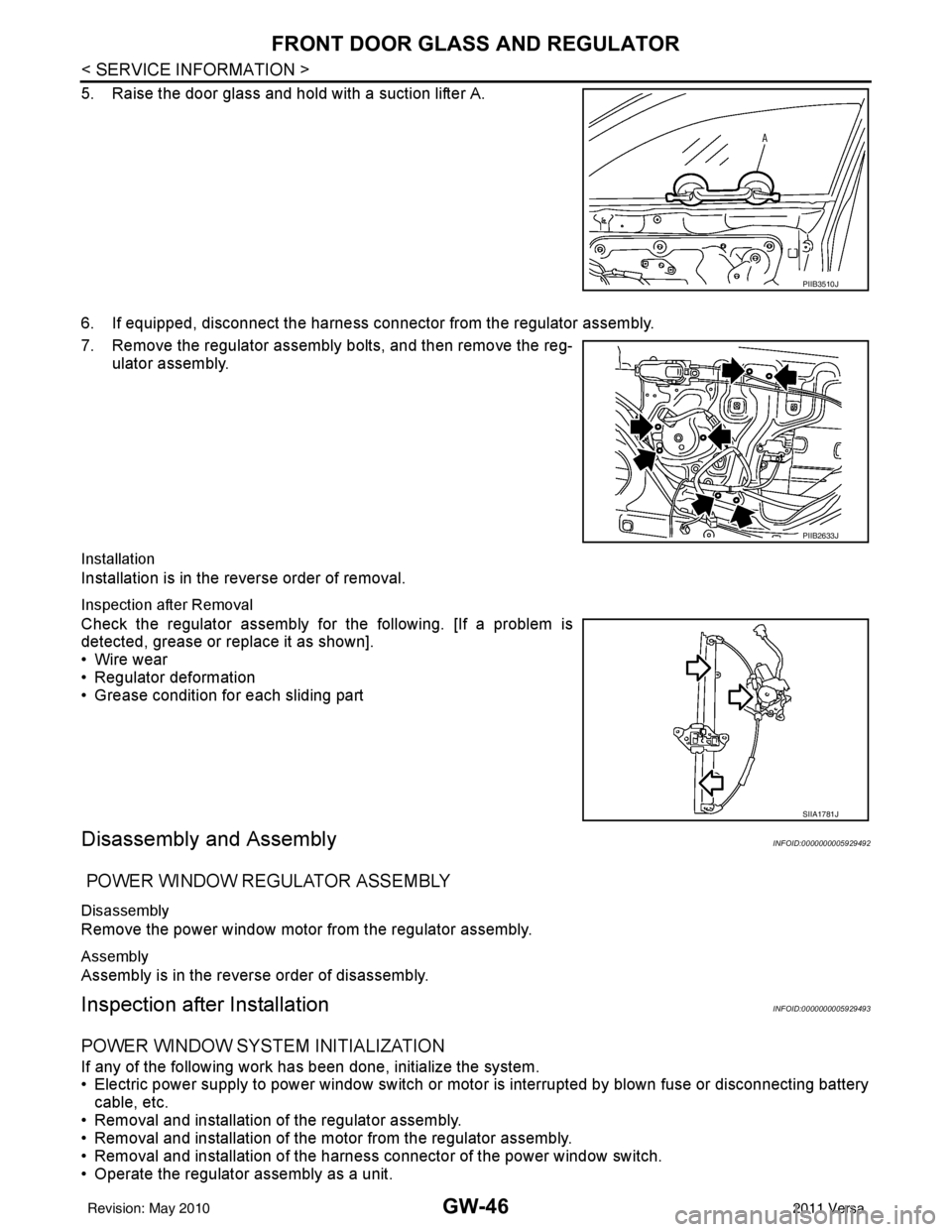

5. Raise the door glass and hold with a suction lifter A.

6. If equipped, disconnect the harness connector from the regulator assembly.

7. Remove the regulator assembly bolts, and then remove the reg-ulator assembly.

Installation

Installation is in the reverse order of removal.

Inspection after Removal

Check the regulator assembly fo r the following. [If a problem is

detected, grease or replace it as shown].

• Wire wear

• Regulator deformation

• Grease condition for each sliding part

Disassembly and AssemblyINFOID:0000000005929492

POWER WINDOW REGULATOR ASSEMBLY

Disassembly

Remove the power window motor from the regulator assembly.

Assembly

Assembly is in the reverse order of disassembly.

Inspection after InstallationINFOID:0000000005929493

POWER WINDOW SYSTEM INITIALIZATION

If any of the following work has been done, initialize the system.

• Electric power supply to power window switch or moto r is interrupted by blown fuse or disconnecting battery

cable, etc.

• Removal and installation of the regulator assembly.

• Removal and installation of the motor from the regulator assembly.

• Removal and installation of the harness connector of the power window switch.

• Operate the regulator assembly as a unit.

PIIB3510J

PIIB2633J

SIIA1781J

Revision: May 2010 2011 Versa

Page 2806 of 3787

GW-52

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Power is supplied at all times

• through 15A fuses (No. 46 and 47, located in the IPDM E/R)

• to rear window defogger relay

• through 10A fuse [No. 5 (with heated mirrors), located in the fuse block (J/B)]

• to heated mirror relay terminal 3

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition relay

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to front air control terminal 8

• through body grounds M57 and M61

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

When front air control (rear window defogger switch) is turned to ON, ground is supplied

• to BCM terminal 9

• through front air control terminal 3

• through front air control terminal 8

• through body grounds M57 and M61.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via CAN communication (CAN-H, CAN-L).

When IPDM E/R receives rear window defogger switch signals, ground is supplied

• to rear window defogger relay (located in the IPDM E/R)

• through IPDM E/R terminals 39 and 59

• through body grounds E15 and E24

Then rear window defogger relay is energized.

With power and ground supplied, rear window def ogger filaments heat and defog the rear window.

When rear window defogger relay is turned to ON (with heated mirrors), power is supplied

• through heated mirror relay terminal 5

• to door mirror (LH and RH) terminal 1.

Door mirror (LH and RH) is grounded through body grounds M57 and M61.

With power and ground supplied, rear window defogger filaments heat and defog the rear window and door

mirror filaments heat and defog the mirrors.

CAN Communication System DescriptionINFOID:0000000005929499

Refer to LAN-7, "System Description".

Revision: May 2010 2011 Versa

Page 2811 of 3787

REAR WINDOW DEFOGGERGW-57

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

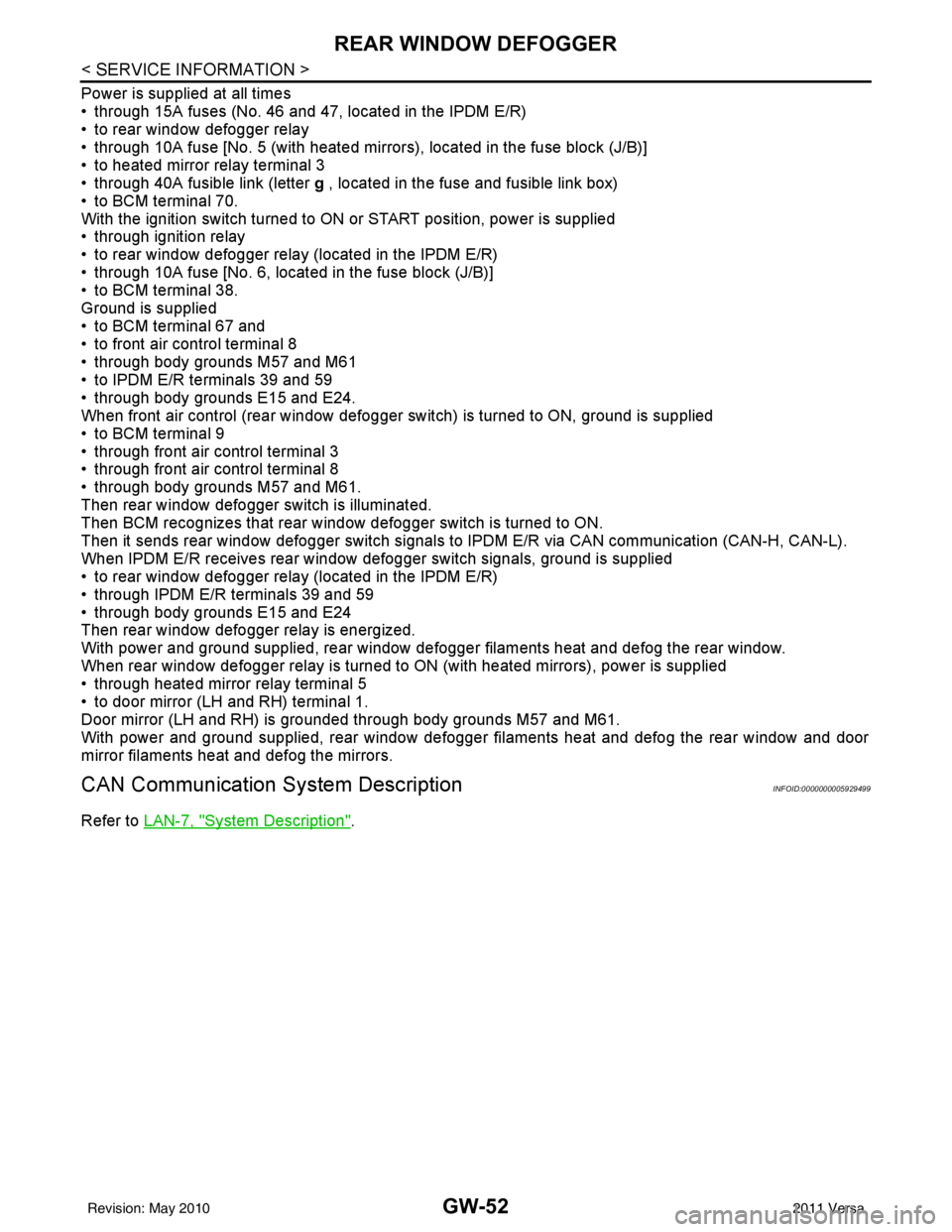

1. Turn ignition switch OFF.

2. Disconnect BCM and front air control.

3. Check continuity between BCM connector M18 (A) terminal 9 and front air control connector M33 (B) terminal 3.

4. Check continuity between BCM connector M18 (A) terminal 9 and ground

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK REAR WINDOW DEFOGGER SWITCH

Check continuity between fr ont air control terminals.

OK or NG

OK >> GO TO 4.

NG >> Replace front air control. Refer to MTC-56, "

Removal

and Installation" .

4.CHECK REAR WINDOW DEFOGGER SWITCH GROUND

Check continuity between front air control connector M33 terminal 8

and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness.

5.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M18 terminal 9 and ground.

OK or NG

OK >> Replace front air control. Refer to MTC-56 .

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installa-

tion of BCM" .

Rear Window Defogger Circuit InspectionINFOID:0000000005929508

1.CHECK FUSES

Check if any of the following fuses in IPDM E/R are blown. 9 - 3

: Continuity should exist.

9 - Ground : Continuity should not exist.

PIIB6479E

Terminals Condition Continuity

38 Rear window defogger switch is ON

(pressed)

Ye s

Rear window defogger switch is OFF

(released) No

PIIB6480E

Connector

Terminal

Ground Continuity

8Y es

M33

PIIB6481E

9 - Ground : Approx. 5V

WIIA0523E

Revision: May 2010 2011 Versa

Page 2812 of 3787

GW-58

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

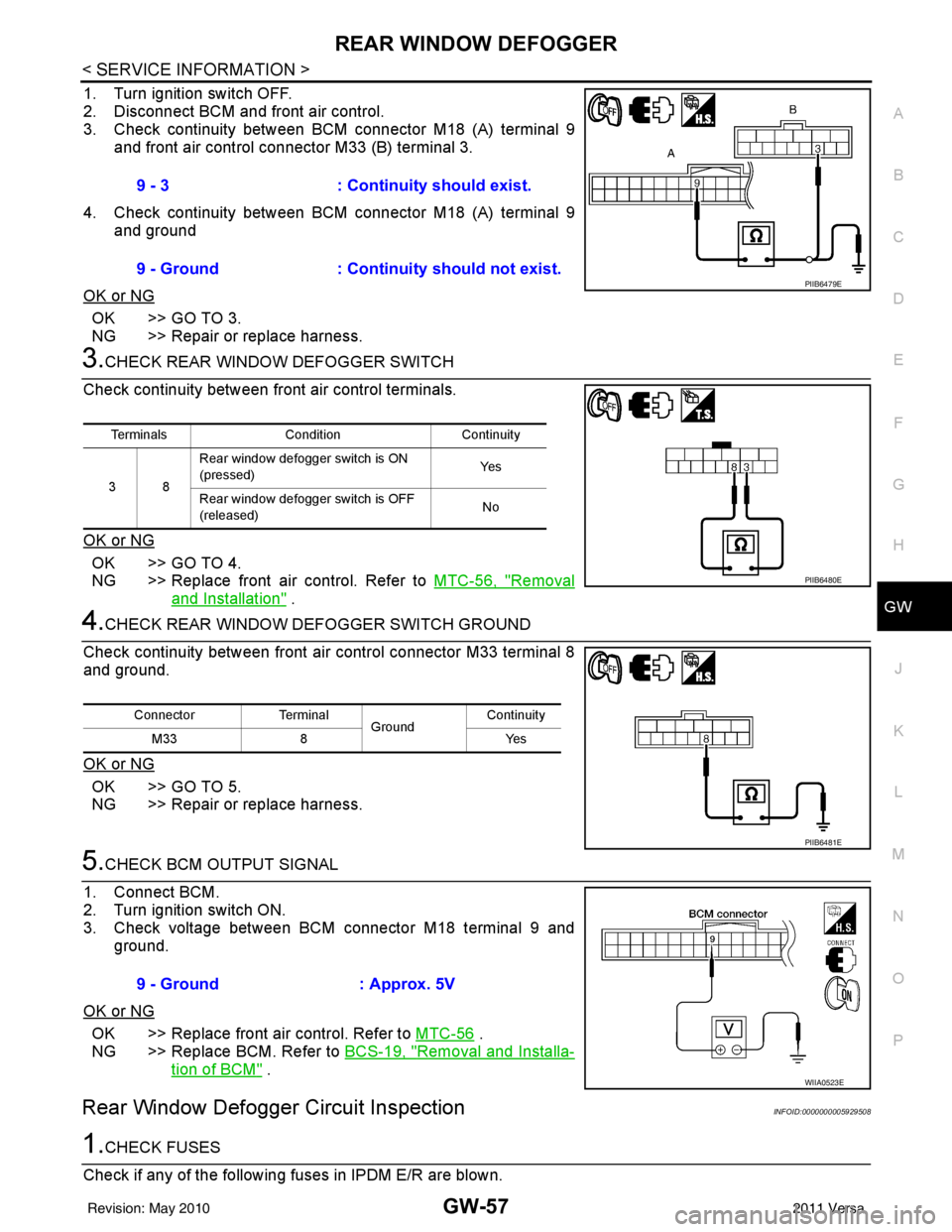

2.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK REAR WINDOW DEFOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger connector D413 (Hatchback) or B141 (Sedan) terminal 2 and ground.

OK or NG

OK >> Check filament. Refer to GW-61, "Filament Check" .

• If filament is OK.

Check the condition of the harness and the connector.

• If filament is NG. Repair filament. Refer to GW-62, "

Filament Repair" .

NG >> Repair or replace harness.

4.CHECK CONDENSER-1 CIRCUIT

1. Disconnect condenser-1.

2. Check continuity between rear window defogger connector and condenser-1 connector.

3. Check continuity between rear window defogger connector and ground.

Component Parts AmpereFuse No.

IPDM E/R 15A46

IPDM E/R 15A47

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D412

(Hatch- back)

B140 (Se-

dan) 1Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1847E

2 - Ground

: Continuity should exist.

LIIA1848E

AB

Continuity

Connector Terminal Connector Terminal

D412 (Hatchback) B140 (Sedan) 1 D411 (Hatch-

back)

B131 (Sedan) 2Y

es

PIIB6486E

Revision: May 2010 2011 Versa

Page 2814 of 3787

GW-60

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace IPDM E/R. Refer to PG-28, "

Removal and Installation of IPDM E/R" .

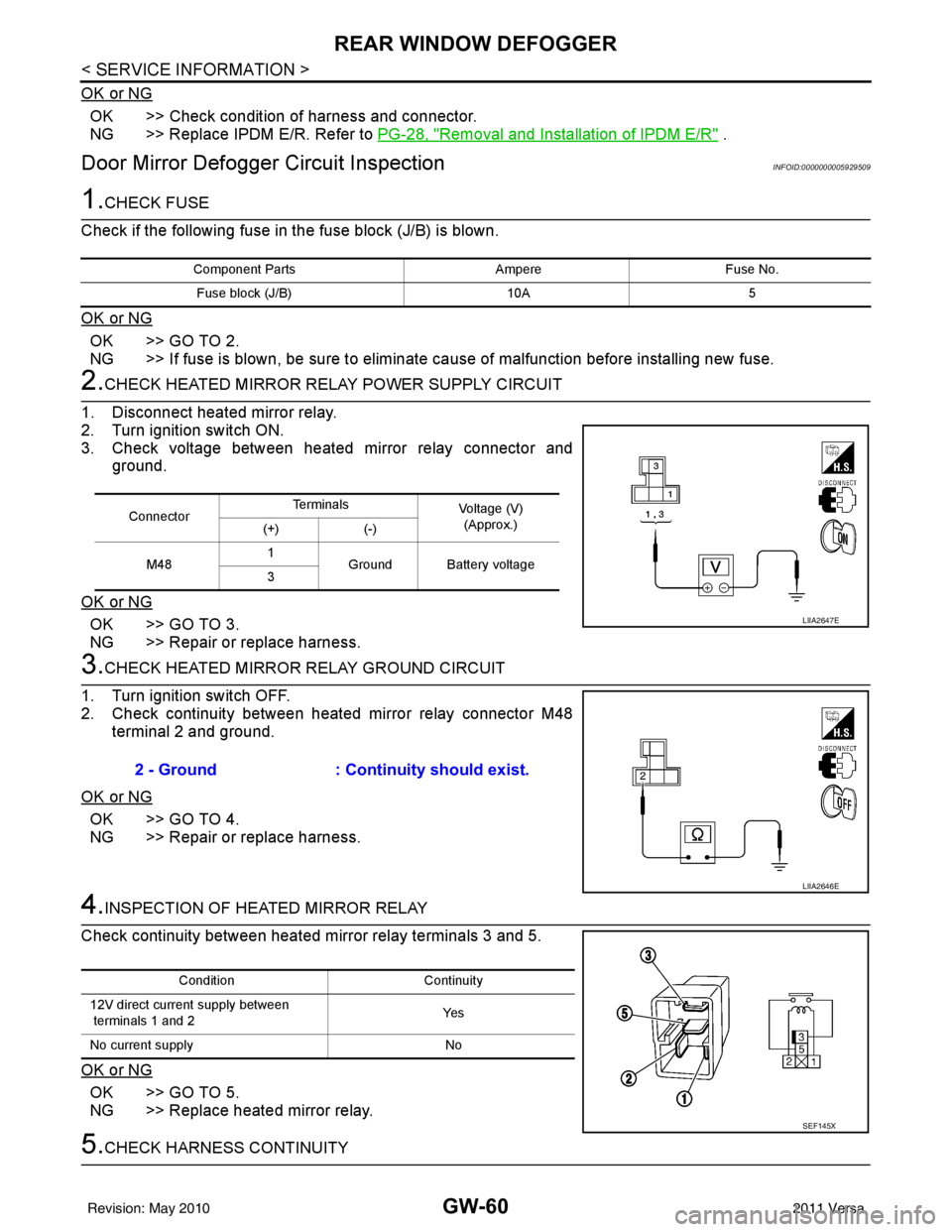

Door Mirror Defogger Circuit InspectionINFOID:0000000005929509

1.CHECK FUSE

Check if the following fuse in the fuse block (J/B) is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK HEATED MIRROR RELAY POWER SUPPLY CIRCUIT

1. Disconnect heated mirror relay.

2. Turn ignition switch ON.

3. Check voltage between heated mirror relay connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK HEATED MIRROR RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between heated mirror relay connector M48 terminal 2 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.INSPECTION OF HEATED MIRROR RELAY

Check continuity between heated mirror relay terminals 3 and 5.

OK or NG

OK >> GO TO 5.

NG >> Replace heated mirror relay.

5.CHECK HARNESS CONTINUITY

Component Parts AmpereFuse No.

Fuse block (J/B) 10A5

ConnectorTe r m i n a l s

Voltage (V)

(Approx.)

(+) (-)

M48 1

Ground Battery voltage

3

LIIA2647E

2 - Ground : Continuity should exist.

LIIA2646E

Condition Continuity

12V direct current supply between

terminals 1 and 2 Ye s

No current supply No

SEF145X

Revision: May 2010 2011 Versa

Page 2820 of 3787

GW-66

< SERVICE INFORMATION >

DOOR MIRROR

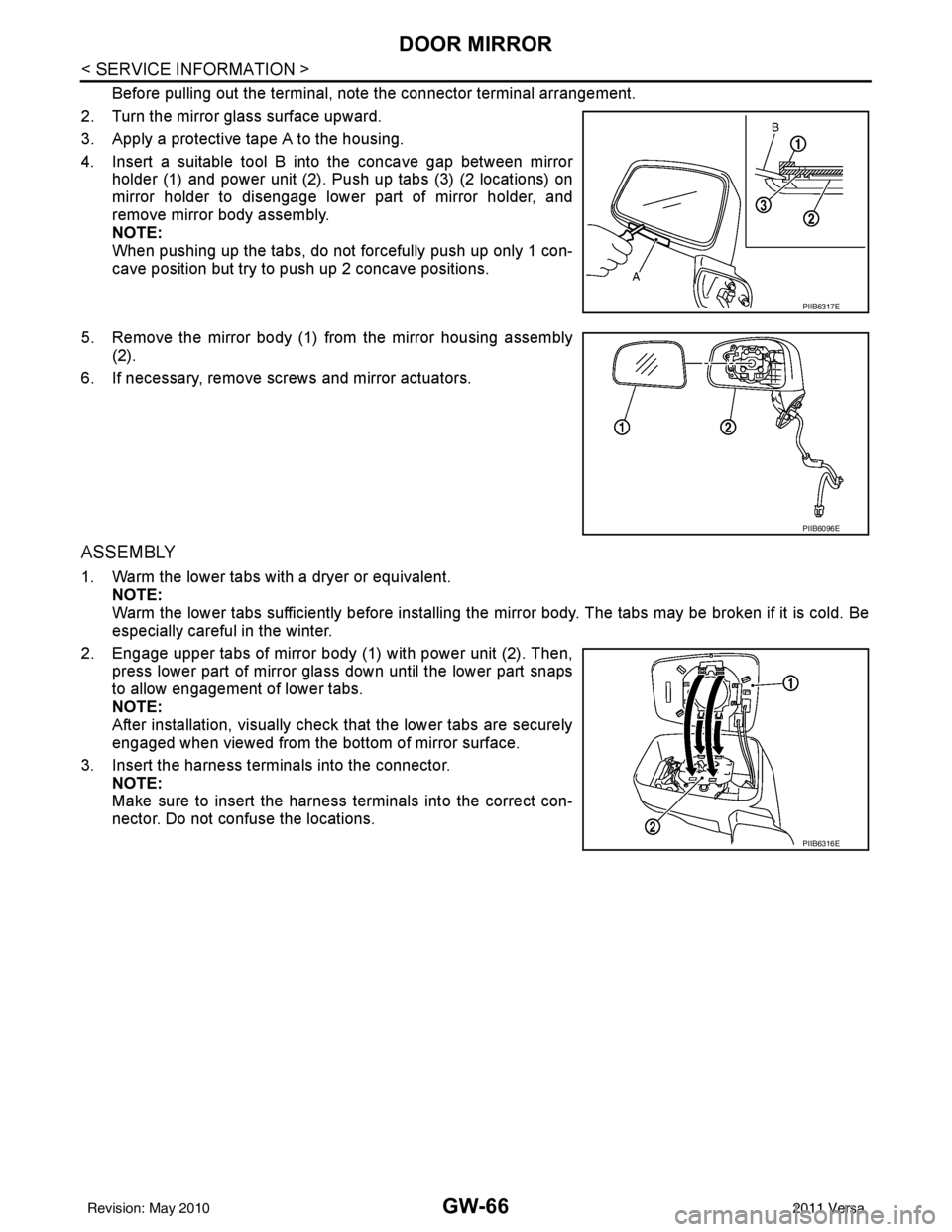

Before pulling out the terminal, note the connector terminal arrangement.

2. Turn the mirror glass surface upward.

3. Apply a protective tape A to the housing.

4. Insert a suitable tool B into the concave gap between mirror holder (1) and power unit (2). Push up tabs (3) (2 locations) on

mirror holder to disengage lower part of mirror holder, and

remove mirror body assembly.

NOTE:

When pushing up the tabs, do not forcefully push up only 1 con-

cave position but try to push up 2 concave positions.

5. Remove the mirror body (1) from the mirror housing assembly (2).

6. If necessary, remove screws and mirror actuators.

ASSEMBLY

1. Warm the lower tabs with a dryer or equivalent. NOTE:

Warm the lower tabs sufficiently before installing the mirror body. The tabs may be broken if it is cold. Be

especially careful in the winter.

2. Engage upper tabs of mirror body (1) with power unit (2). Then, press lower part of mirror glass down until the lower part snaps

to allow engagement of lower tabs.

NOTE:

After installation, visually check that the lower tabs are securely

engaged when viewed from the bottom of mirror surface.

3. Insert the harness terminals into the connector. NOTE:

Make sure to insert the harness terminals into the correct con-

nector. Do not confuse the locations.

PIIB6317E

PIIB6096E

PIIB6316E

Revision: May 2010 2011 Versa

Page 2833 of 3787

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

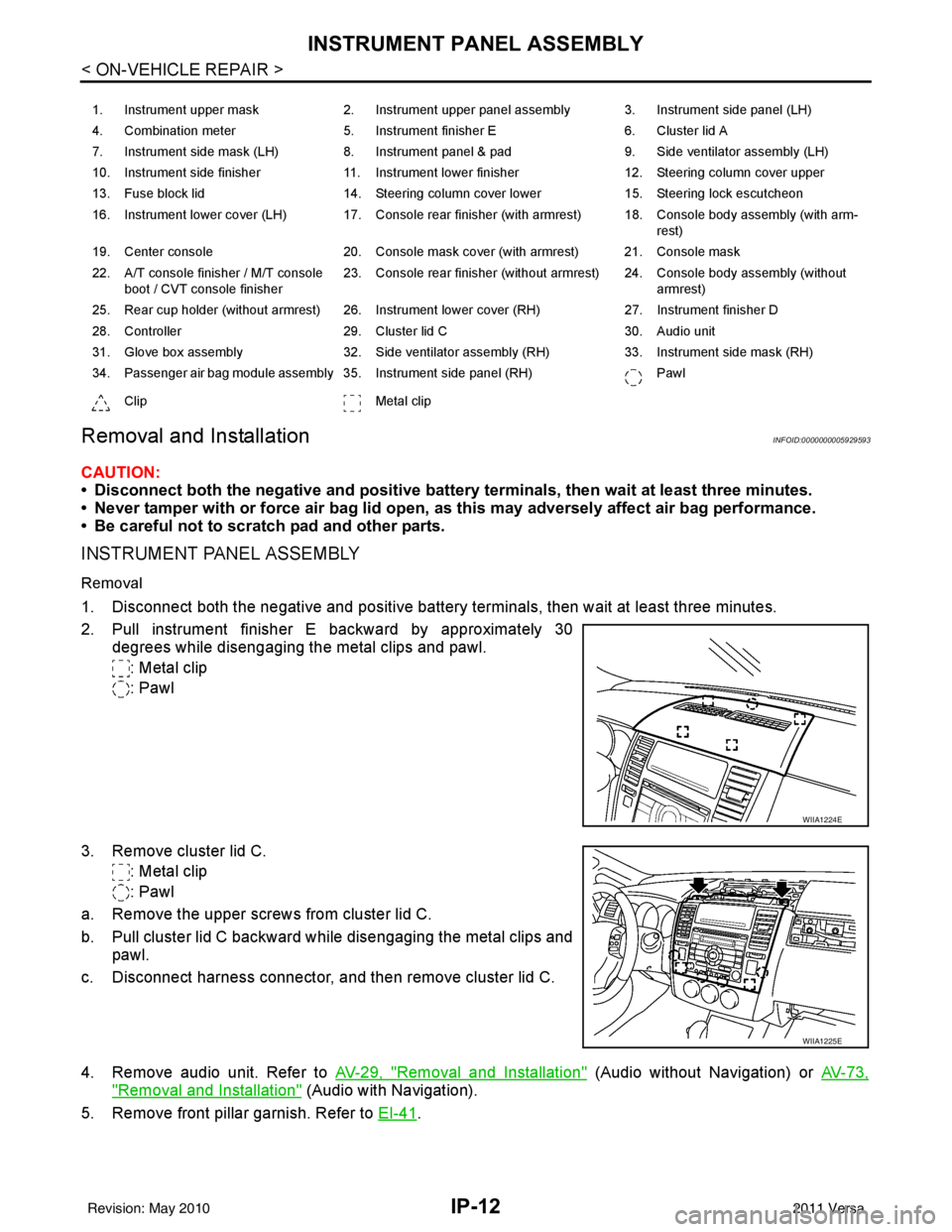

Removal and Installation

INFOID:0000000005929593

CAUTION:

• Disconnect both the negative and positive battery terminals, then wait at least three minutes.

• Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

• Be careful not to scratch pad and other parts.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Disconnect both the negative and positive battery terminals, then wait at least three minutes.

2. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

: Metal clip

: Pawl

3. Remove cluster lid C. : Metal clip

: Pawl

a. Remove the upper screws from cluster lid C.

b. Pull cluster lid C backward while disengaging the metal clips and pawl.

c. Disconnect harness connector, and then remove cluster lid C.

4. Remove audio unit. Refer to AV-29, "

Removal and Installation" (Audio without Navigation) or AV-73,

"Removal and Installation" (Audio with Navigation).

5. Remove front pillar garnish. Refer to EI-41

.

1. Instrument upper mask 2. Instrument upper panel assembly 3. Instrument side panel (LH)

4. Combination meter 5. Instrument finisher E 6. Cluster lid A

7. Instrument side mask (LH) 8. Instrument panel & pad 9. Side ventilator assembly (LH)

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm- rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console boot / CVT console finisher 23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument side mask (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip

WIIA1224E

WIIA1225E

Revision: May 2010 2011 Versa

Page 2835 of 3787

IP-14

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

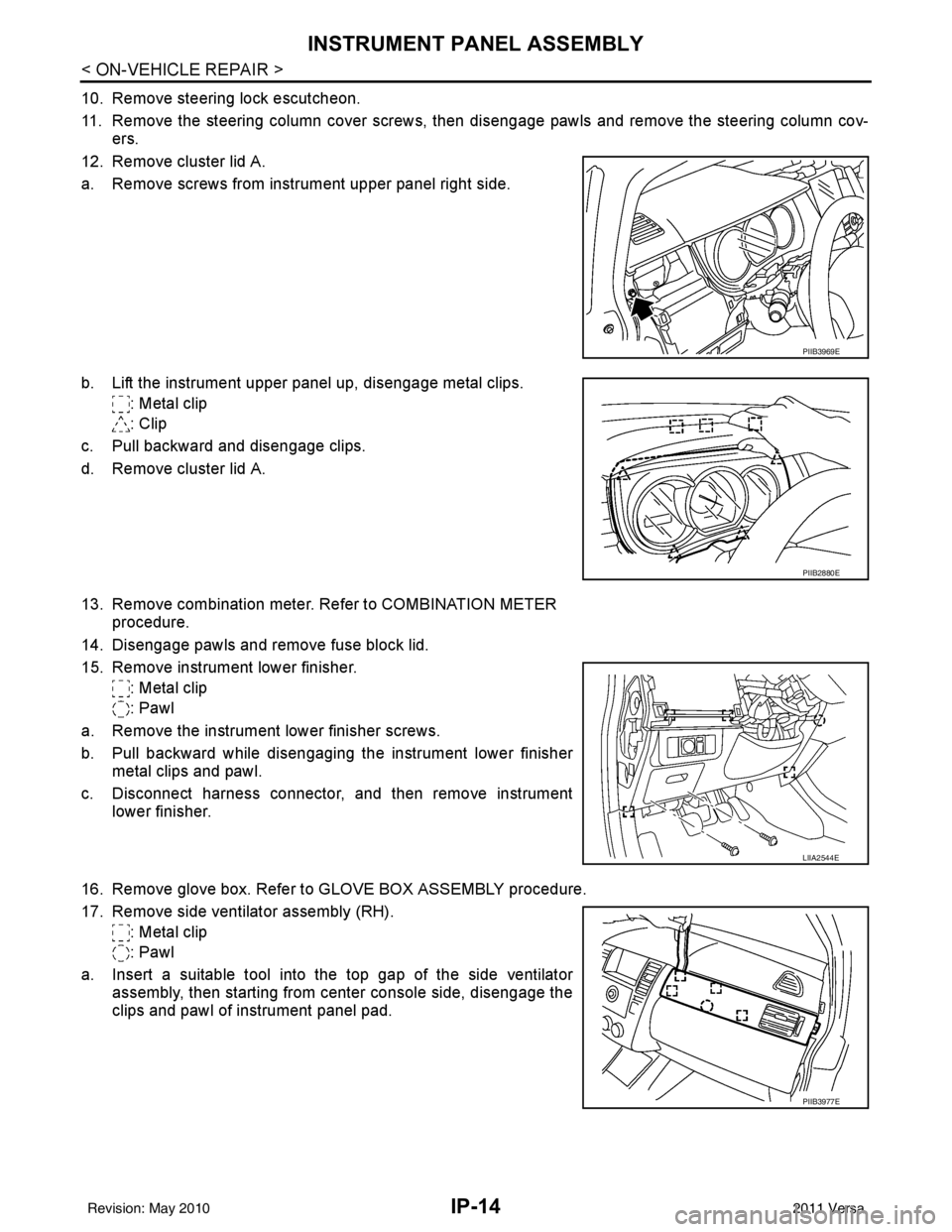

10. Remove steering lock escutcheon.

11. Remove the steering column cover screws, then disengage pawls and remove the steering column cov-

ers.

12. Remove cluster lid A.

a. Remove screws from instrument upper panel right side.

b. Lift the instrument upper panel up, disengage metal clips. : Metal clip

: Clip

c. Pull backward and disengage clips.

d. Remove cluster lid A.

13. Remove combination meter. Refer to COMBINATION METER procedure.

14. Disengage pawls and remove fuse block lid.

15. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

16. Remove glove box. Refer to GLOVE BOX ASSEMBLY procedure.

17. Remove side ventilator assembly (RH). : Metal clip

: Pawl

a. Insert a suitable tool into the top gap of the side ventilator assembly, then starting from center console side, disengage the

clips and pawl of instrument panel pad.

PIIB3969E

PIIB2880E

LIIA2544E

PIIB3977E

Revision: May 2010 2011 Versa

Page 2842 of 3787

INSTRUMENT PANEL ASSEMBLYIP-21

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

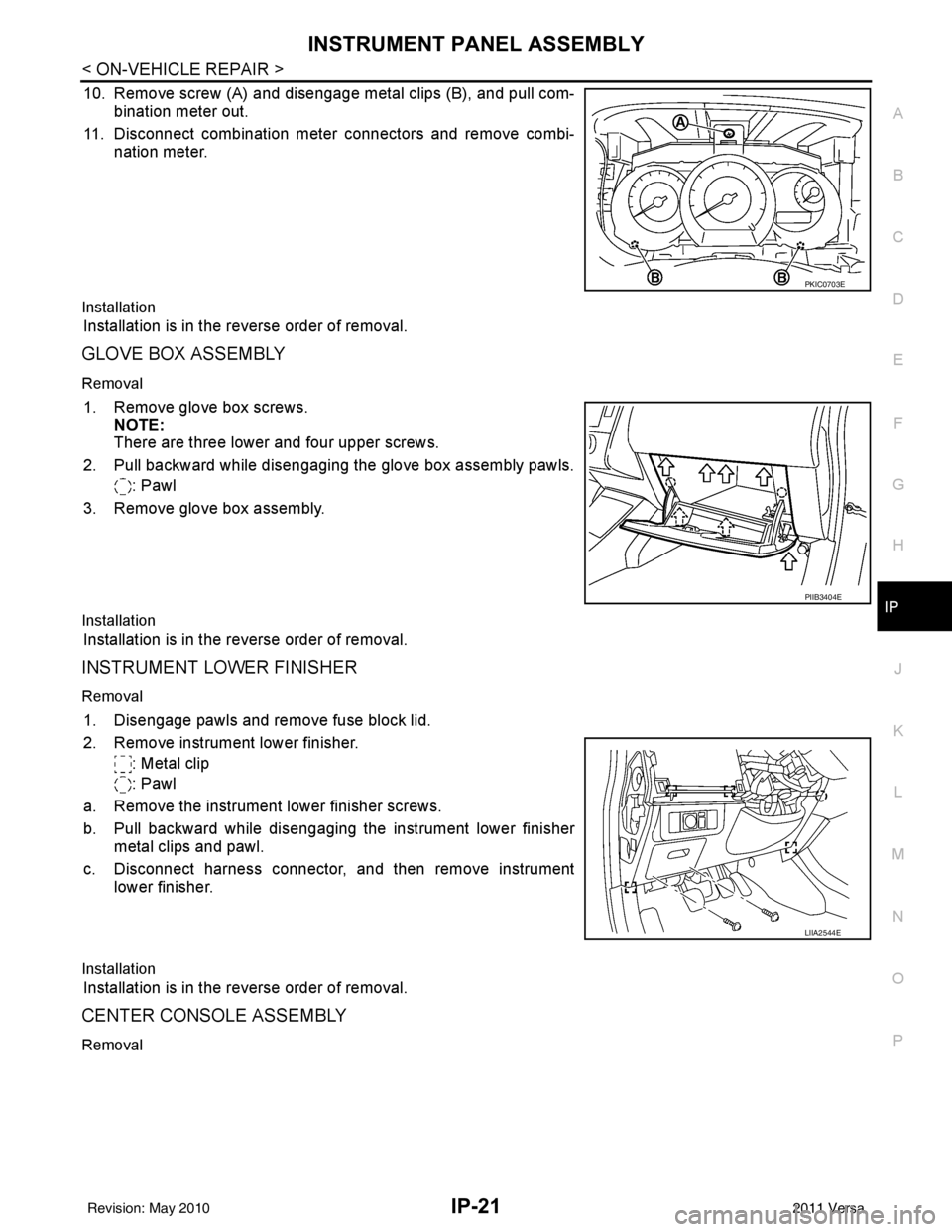

10. Remove screw (A) and disengage metal clips (B), and pull com- bination meter out.

11. Disconnect combination meter connectors and remove combi- nation meter.

Installation

Installation is in the reverse order of removal.

GLOVE BOX ASSEMBLY

Removal

1. Remove glove box screws.NOTE:

There are three lower and four upper screws.

2. Pull backward while disengaging the glove box assembly pawls. : Pawl

3. Remove glove box assembly.

Installation

Installation is in the reverse order of removal.

INSTRUMENT LOWER FINISHER

Removal

1. Disengage pawls and remove fuse block lid.

2. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER CONSOLE ASSEMBLY

Removal

PKIC0703E

PIIB3404E

LIIA2544E

Revision: May 2010 2011 Versa

Page 2856 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000005928519

DTC of CAN communication is indicated on SELF-DIAG

RESULTS on C NISSAN TIIDA 2011 Service Repair Manual LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000005928519

DTC of CAN communication is indicated on SELF-DIAG

RESULTS on C](/img/5/57396/w960_57396-2855.png)

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000005928519

DTC of CAN communication is indicated on SELF-DIAG

RESULTS on CONSULT-III if a CAN communication

signal is not transmitted or received between units for 2 seconds or more.

NOTE:

DTCs of CAN communication are as follows:

• U0101

• U0140

• U0164

• U1000

• U1001

CAN COMMUNICATION SYSTEM ERROR

• CAN communication line open (CAN-H, CAN-L, or both)

• CAN communication line short (ground, between CAN communication lines, other harnesses)

• Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN DTC OF CAN COMMUNICATION IS INDICATED EVEN THOUGH CAN COMMUNICATION

SYSTEM IS NORMAL

• Removal/installation of parts: Error may be detec ted when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

• Fuse blown out (removed): CAN co mmunication of the unit may cease.

• Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition switch ON (Depending on the control unit which carries out CAN communication).

• Error may be detected if the power supply circuit of the control unit, which carries out CAN communication, malfunctions (Depending on the control unit which carries out CAN communication).

• Error may be detected if reprogramming is not completed normally.

CAUTION:

CAN communication system is normal if DTC of CAN communication is indicated on SELF-DIAG

RESULTS of CONSULT-III under th e above conditions. Erase the memo ry of the self-diagnosis of each

unit.

Symptom When Error Occurs in CAN Communication SystemINFOID:0000000005928520

In CAN communication system, multiple units mutually transmit and receive signals. Each unit cannot transmit

and receive signals if any error occurs on CAN communicati on line. Under this condition, multiple control units

related to the root cause malfunction or go into fail-safe mode.

ERROR EXAMPLE

NOTE:

• Each vehicle differs in symptom of each unit under fail-safe mode and CAN communication line wiring.

• Refer to LAN-22, "

Abbreviation List" for the unit abbreviation.

Revision: May 2010 2011 Versa