Block NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2814 of 3787

GW-60

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace IPDM E/R. Refer to PG-28, "

Removal and Installation of IPDM E/R" .

Door Mirror Defogger Circuit InspectionINFOID:0000000005929509

1.CHECK FUSE

Check if the following fuse in the fuse block (J/B) is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

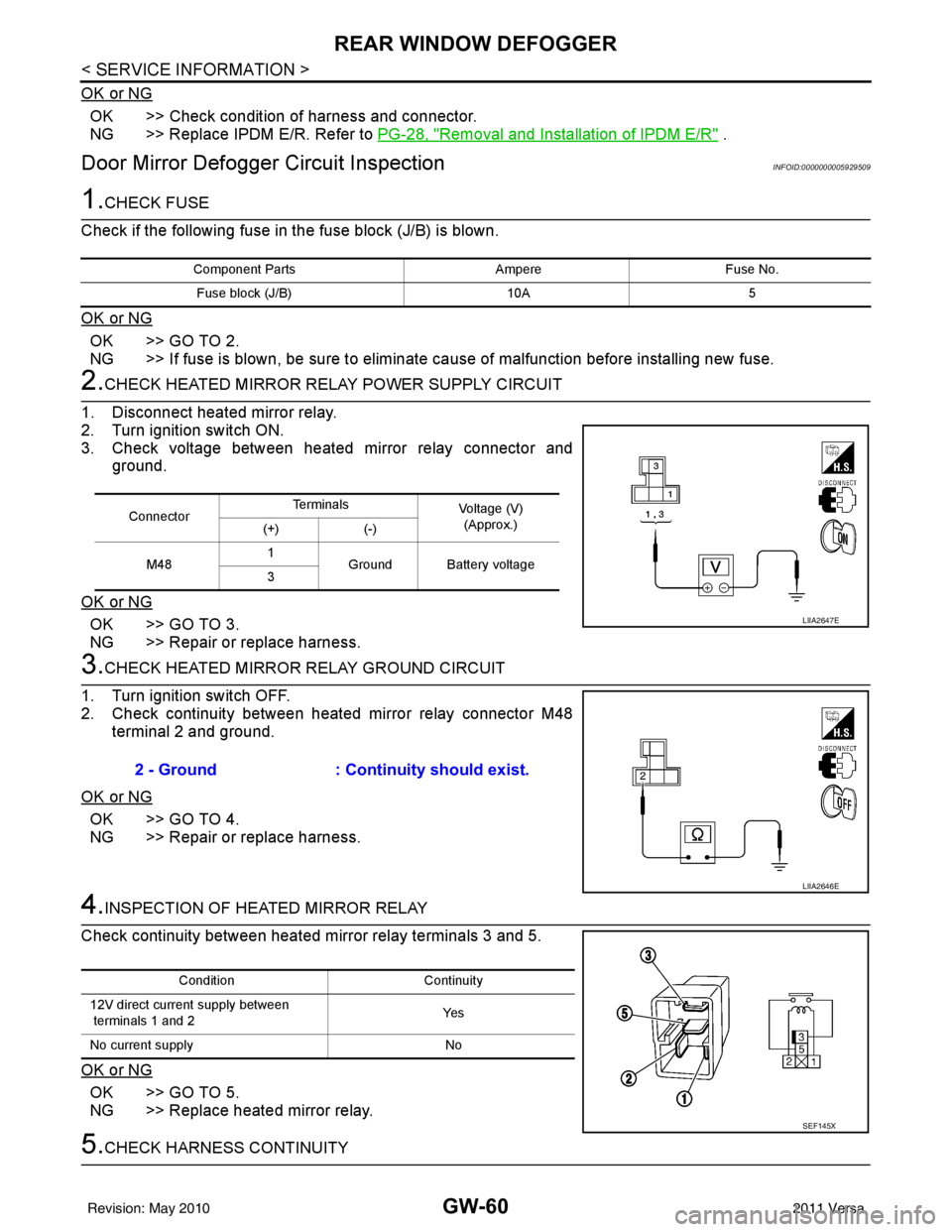

2.CHECK HEATED MIRROR RELAY POWER SUPPLY CIRCUIT

1. Disconnect heated mirror relay.

2. Turn ignition switch ON.

3. Check voltage between heated mirror relay connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

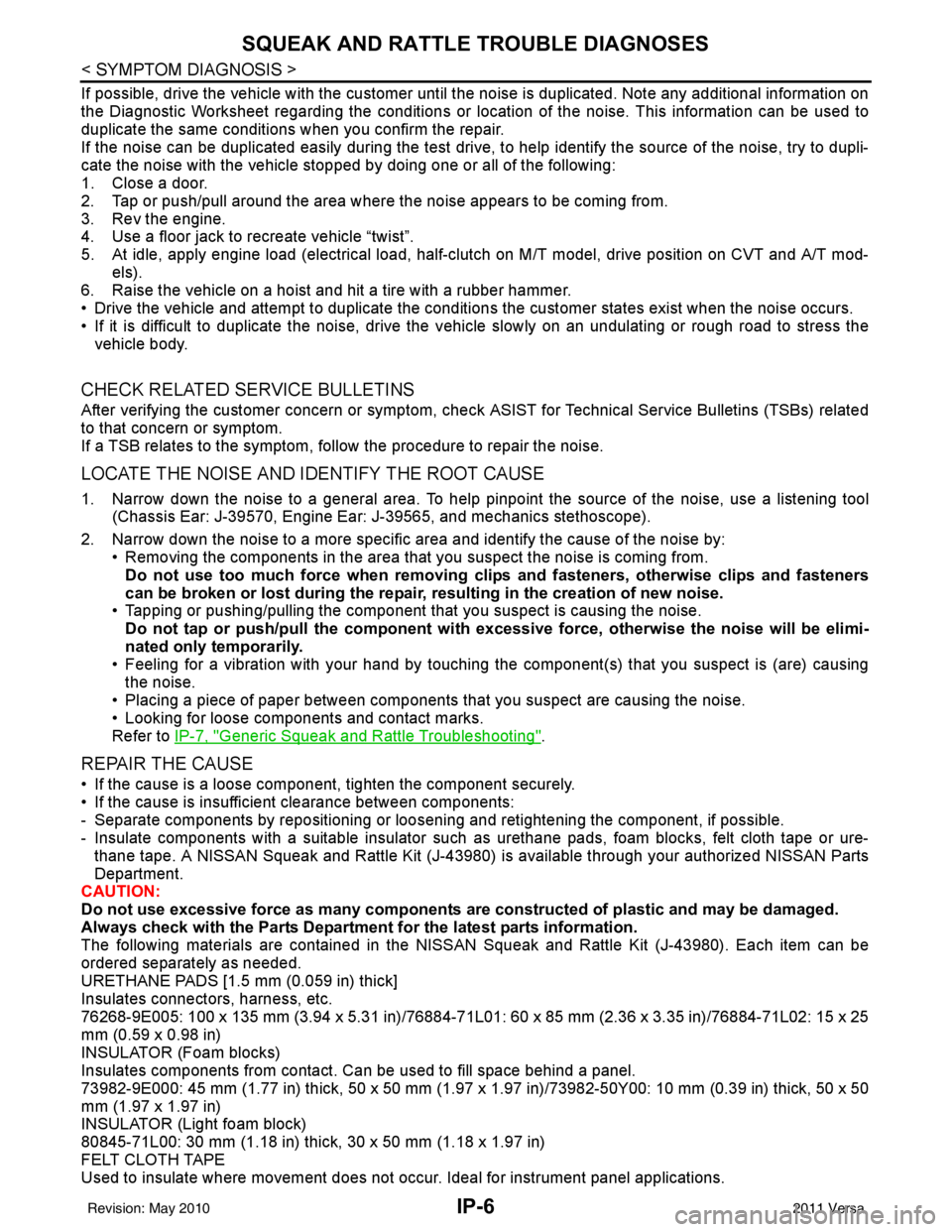

3.CHECK HEATED MIRROR RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between heated mirror relay connector M48 terminal 2 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

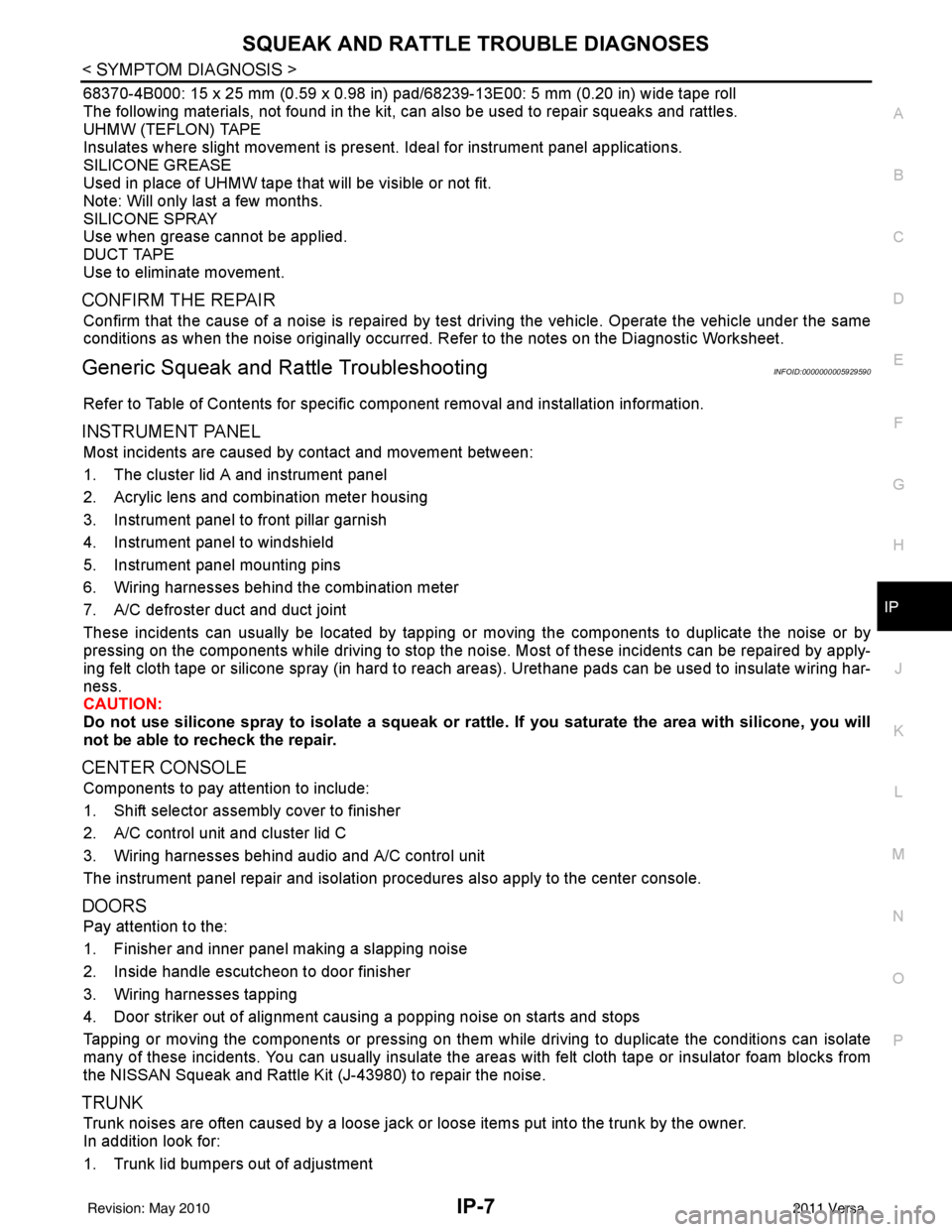

4.INSPECTION OF HEATED MIRROR RELAY

Check continuity between heated mirror relay terminals 3 and 5.

OK or NG

OK >> GO TO 5.

NG >> Replace heated mirror relay.

5.CHECK HARNESS CONTINUITY

Component Parts AmpereFuse No.

Fuse block (J/B) 10A5

ConnectorTe r m i n a l s

Voltage (V)

(Approx.)

(+) (-)

M48 1

Ground Battery voltage

3

LIIA2647E

2 - Ground : Continuity should exist.

LIIA2646E

Condition Continuity

12V direct current supply between

terminals 1 and 2 Ye s

No current supply No

SEF145X

Revision: May 2010 2011 Versa

Page 2827 of 3787

IP-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1. Close a door.

2. Tap or push/pull around the area where the noise appears to be coming from.

3. Rev the engine.

4. Use a floor jack to recreate vehicle “twist”.

5. At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T mod-

els).

6. Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clip s and fasteners, otherwise clips and fasteners

can be broken or lost during the repair , resulting in the creation of new noise.

• Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be elimi-

nated only temporarily.

• Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing

the noise.

• Placing a piece of paper between components that you suspect are causing the noise.

• Looking for loose components and contact marks.

Refer to IP-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

Revision: May 2010 2011 Versa

Page 2828 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/ 68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929590

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: May 2010 2011 Versa

Page 2833 of 3787

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

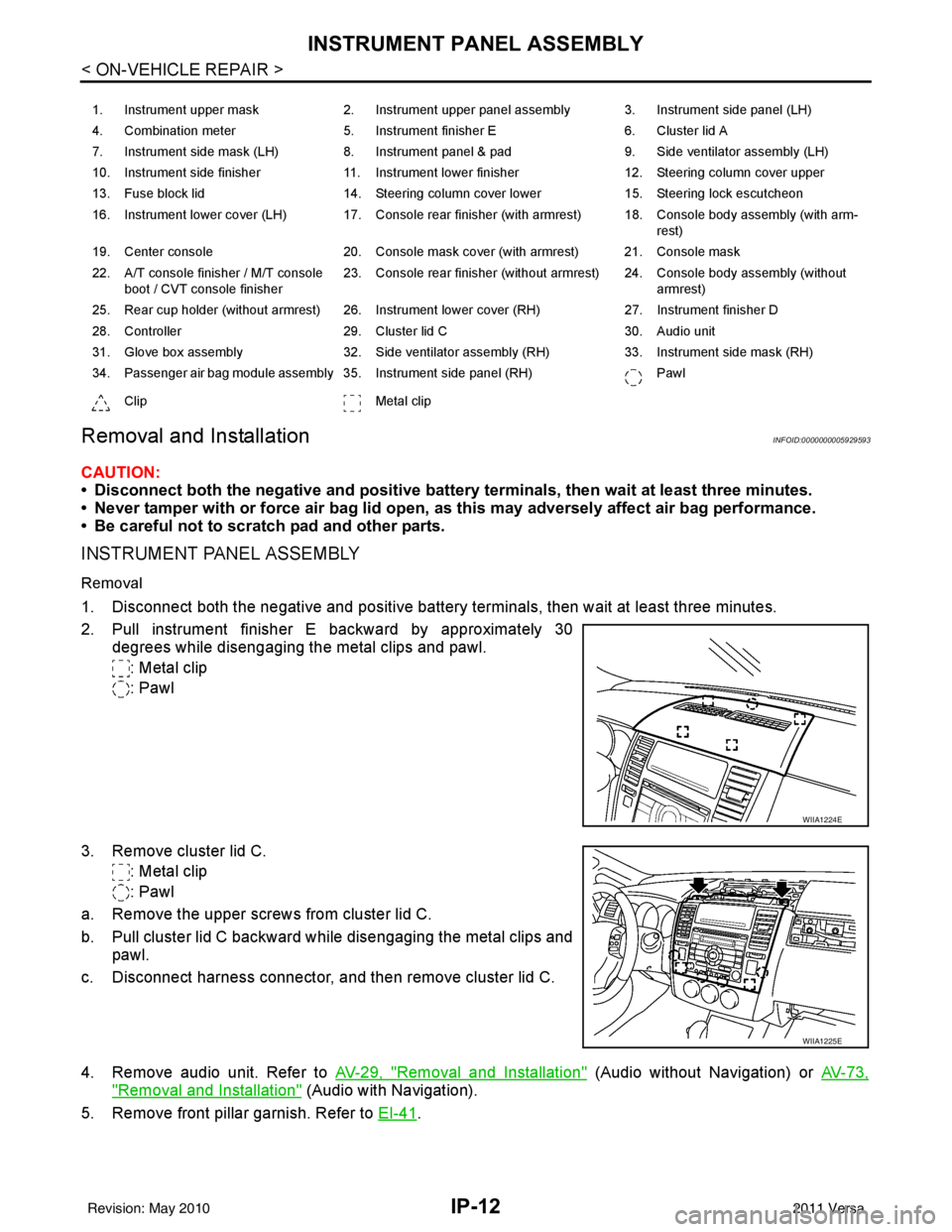

Removal and Installation

INFOID:0000000005929593

CAUTION:

• Disconnect both the negative and positive battery terminals, then wait at least three minutes.

• Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

• Be careful not to scratch pad and other parts.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Disconnect both the negative and positive battery terminals, then wait at least three minutes.

2. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

: Metal clip

: Pawl

3. Remove cluster lid C. : Metal clip

: Pawl

a. Remove the upper screws from cluster lid C.

b. Pull cluster lid C backward while disengaging the metal clips and pawl.

c. Disconnect harness connector, and then remove cluster lid C.

4. Remove audio unit. Refer to AV-29, "

Removal and Installation" (Audio without Navigation) or AV-73,

"Removal and Installation" (Audio with Navigation).

5. Remove front pillar garnish. Refer to EI-41

.

1. Instrument upper mask 2. Instrument upper panel assembly 3. Instrument side panel (LH)

4. Combination meter 5. Instrument finisher E 6. Cluster lid A

7. Instrument side mask (LH) 8. Instrument panel & pad 9. Side ventilator assembly (LH)

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm- rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console boot / CVT console finisher 23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument side mask (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip

WIIA1224E

WIIA1225E

Revision: May 2010 2011 Versa

Page 2835 of 3787

IP-14

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

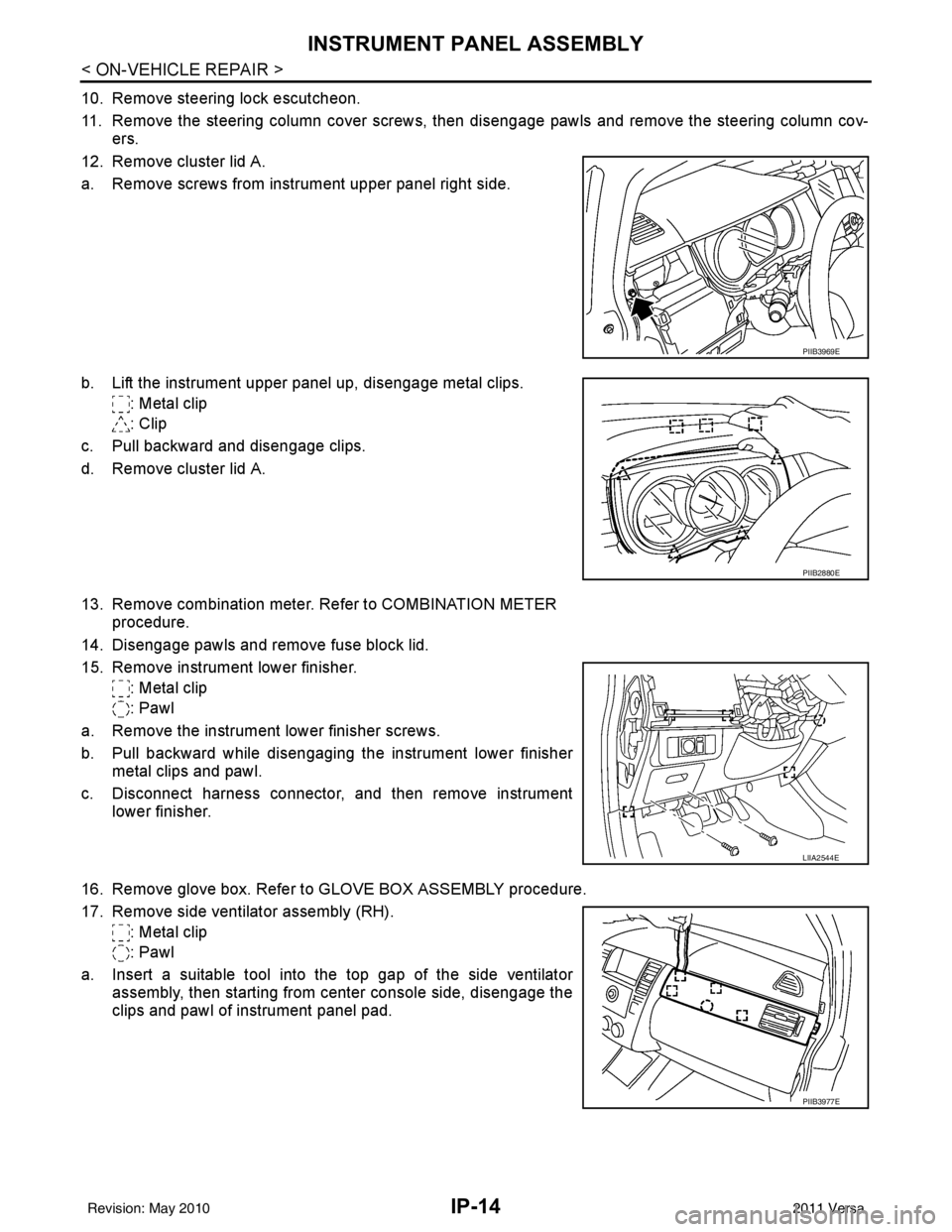

10. Remove steering lock escutcheon.

11. Remove the steering column cover screws, then disengage pawls and remove the steering column cov-

ers.

12. Remove cluster lid A.

a. Remove screws from instrument upper panel right side.

b. Lift the instrument upper panel up, disengage metal clips. : Metal clip

: Clip

c. Pull backward and disengage clips.

d. Remove cluster lid A.

13. Remove combination meter. Refer to COMBINATION METER procedure.

14. Disengage pawls and remove fuse block lid.

15. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

16. Remove glove box. Refer to GLOVE BOX ASSEMBLY procedure.

17. Remove side ventilator assembly (RH). : Metal clip

: Pawl

a. Insert a suitable tool into the top gap of the side ventilator assembly, then starting from center console side, disengage the

clips and pawl of instrument panel pad.

PIIB3969E

PIIB2880E

LIIA2544E

PIIB3977E

Revision: May 2010 2011 Versa

Page 2842 of 3787

INSTRUMENT PANEL ASSEMBLYIP-21

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

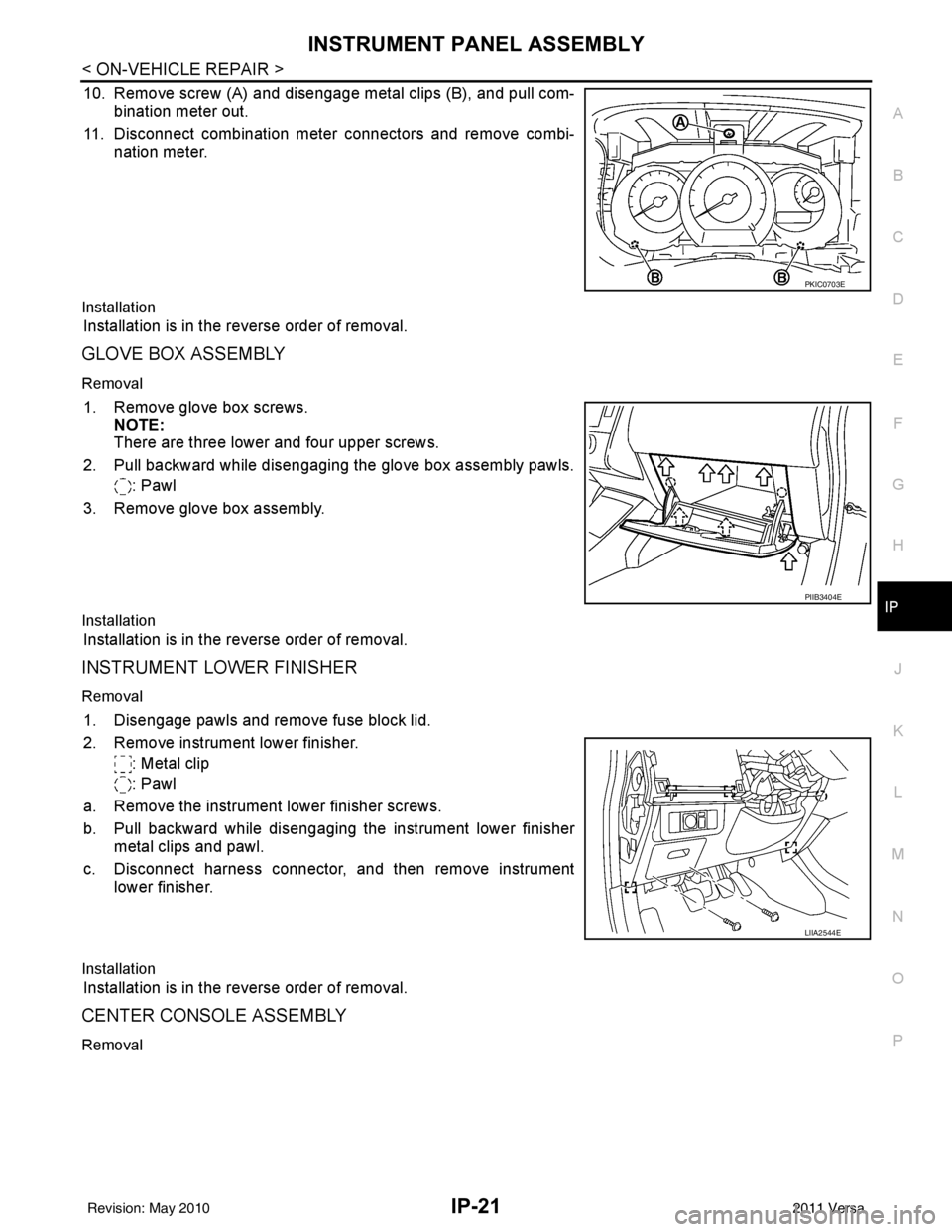

10. Remove screw (A) and disengage metal clips (B), and pull com- bination meter out.

11. Disconnect combination meter connectors and remove combi- nation meter.

Installation

Installation is in the reverse order of removal.

GLOVE BOX ASSEMBLY

Removal

1. Remove glove box screws.NOTE:

There are three lower and four upper screws.

2. Pull backward while disengaging the glove box assembly pawls. : Pawl

3. Remove glove box assembly.

Installation

Installation is in the reverse order of removal.

INSTRUMENT LOWER FINISHER

Removal

1. Disengage pawls and remove fuse block lid.

2. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER CONSOLE ASSEMBLY

Removal

PKIC0703E

PIIB3404E

LIIA2544E

Revision: May 2010 2011 Versa

Page 3037 of 3787

HEADLAMP (FOR USA)LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

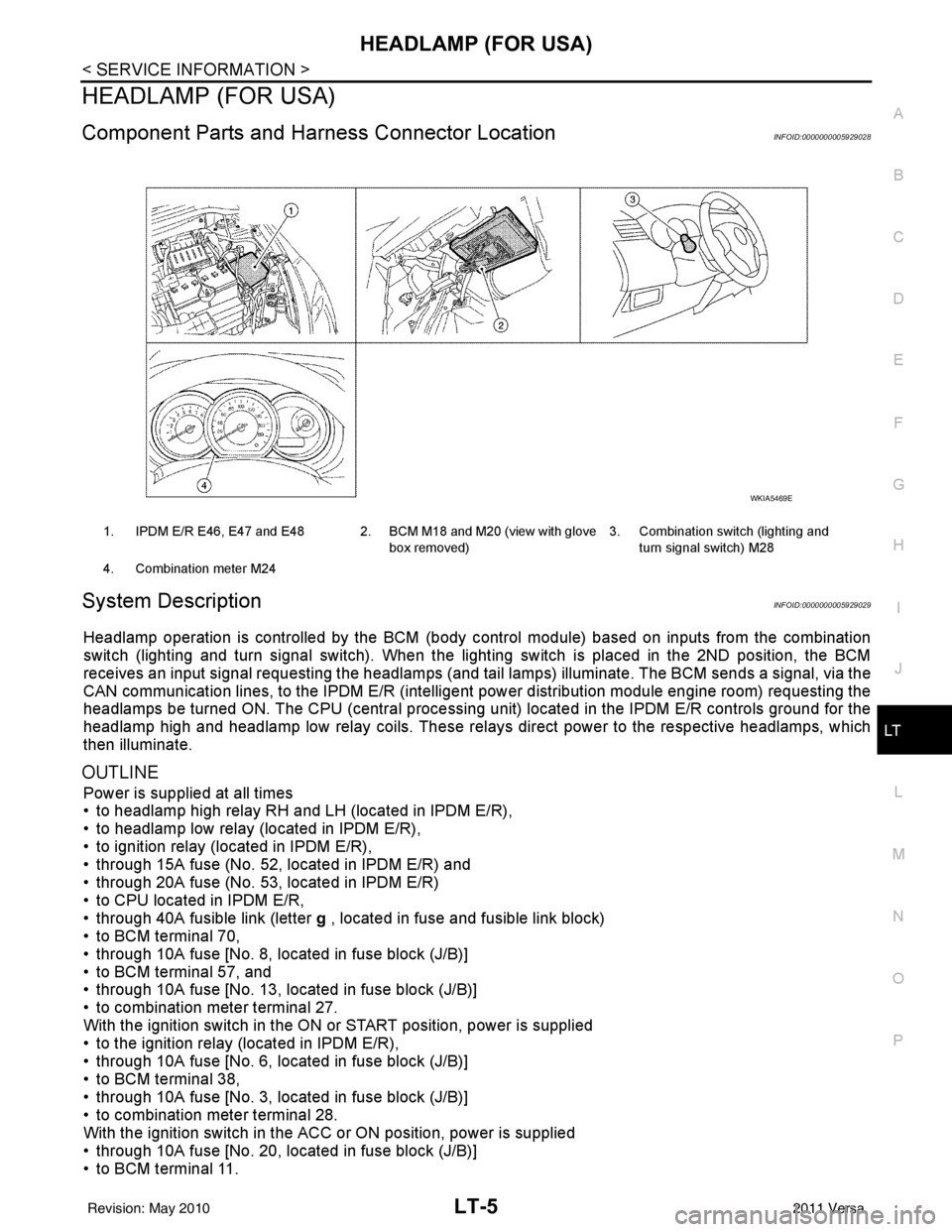

HEADLAMP (FOR USA)

Component Parts and Har ness Connector LocationINFOID:0000000005929028

System DescriptionINFOID:0000000005929029

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting and turn signal switch). When the light ing switch is placed in the 2ND position, the BCM

receives an input signal requesting the headlamps (and tail lamps) illuminate. The BCM sends a signal, via the

CAN communication lines, to the IPDM E/R (intelligent power distribution module engine room) requesting the

headlamps be turned ON. The CPU (centra l processing unit) located in the IPDM E/R controls ground for the

headlamp high and headlamp low relay coils. These relays direct power to the respective headlamps, which

then illuminate.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R),

• to headlamp low relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57, and

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting and

turn signal switch) M28

4. Combination meter M24

WKIA5469E

Revision: May 2010 2011 Versa

Page 3046 of 3787

LT-14

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

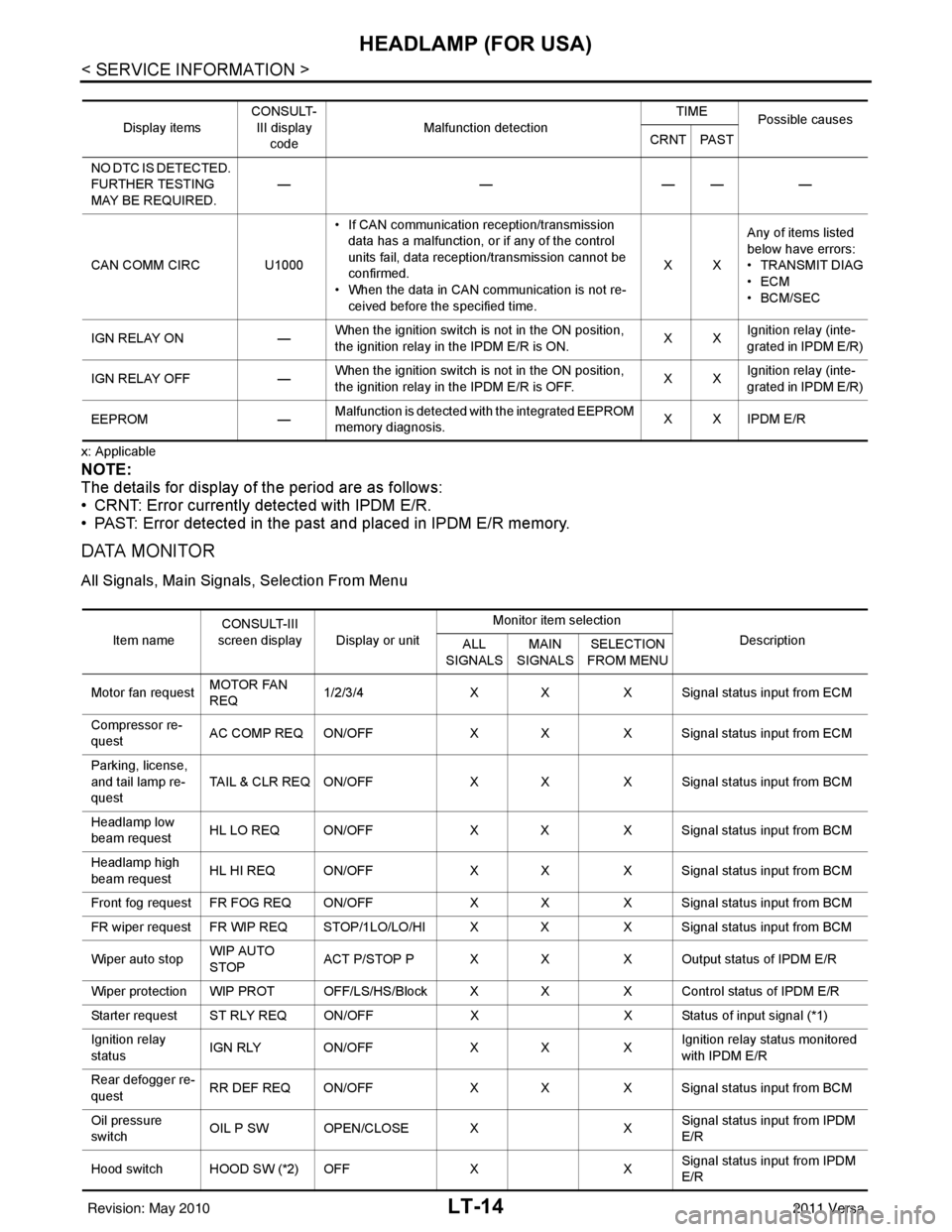

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display itemsCONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. —————

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is de

tected with the integrated EEPROM

memory diagnosis. X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: May 2010

2011 Versa

Page 3056 of 3787

LT-24

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

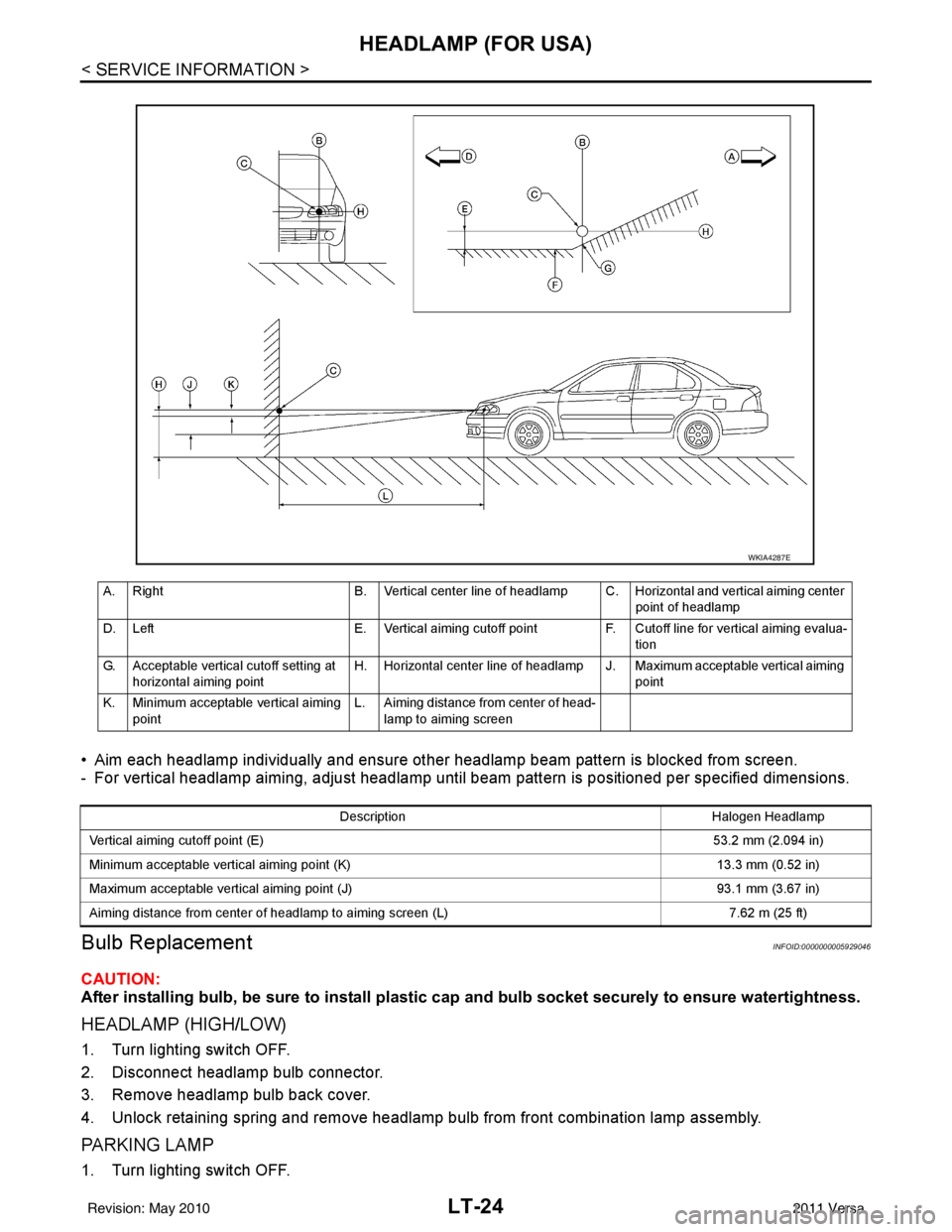

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For vertical headlamp aiming, adjust headlamp until beam pattern is positioned per specified dimensions.

Bulb ReplacementINFOID:0000000005929046

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to ensure watertightness.

HEADLAMP (HIGH/LOW)

1. Turn lighting switch OFF.

2. Disconnect headlamp bulb connector.

3. Remove headlamp bulb back cover.

4. Unlock retaining spring and remove headlamp bulb from front combination lamp assembly.

PA R K I N G L A M P

1. Turn lighting switch OFF.

A. Right B. Vertical center line of headlamp C. Horizontal and vertical aiming center

point of headlamp

D. Left E. Vertical aiming cutoff point F. Cutoff line for vertical aiming evalua-

tion

G. Acceptable vertical cutoff setting at horizontal aiming point H. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming point L. Aiming distance from center of head-

lamp to aiming screen

WKIA4287E

Description Halogen Headlamp

Vertical aiming cutoff point (E) 53.2 mm (2.094 in)

Minimum acceptable vertical aiming point (K) 13.3 mm (0.52 in)

Maximum acceptable vertical aiming point (J) 93.1 mm (3.67 in)

Aiming distance from center of headlamp to aiming screen (L) 7.62 m (25 ft)

Revision: May 2010 2011 Versa

Page 3059 of 3787

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-27

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

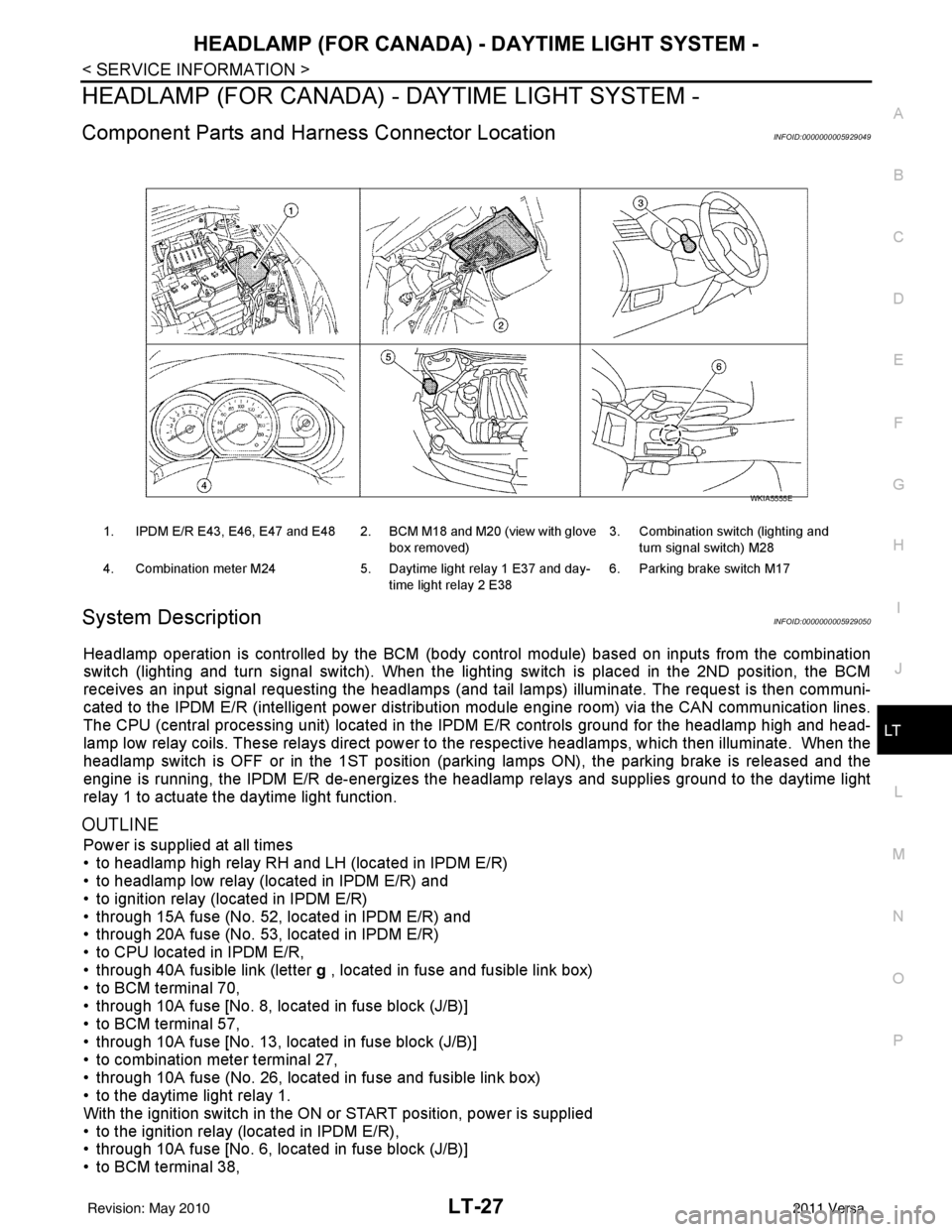

Component Parts and Harness Connector LocationINFOID:0000000005929049

System DescriptionINFOID:0000000005929050

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting and turn signal switch). When the light ing switch is placed in the 2ND position, the BCM

receives an input signal requesting the headlamps (and ta il lamps) illuminate. The request is then communi-

cated to the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines.

The CPU (central processing unit) located in t he IPDM E/R controls ground for the headlamp high and head-

lamp low relay coils. These relays direct power to the respective headlamps, which then illuminate. When the

headlamp switch is OFF or in the 1ST position (parking lamps ON), the parking brake is released and the

engine is running, the IPDM E/R de-energizes the headlamp relays and supplies ground to the daytime light

relay 1 to actuate the daytime light function.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R)

• to headlamp low relay (located in IPDM E/R) and

• to ignition relay (located in IPDM E/R)

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27,

• through 10A fuse (No. 26, located in fuse and fusible link box)

• to the daytime light relay 1.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

1. IPDM E/R E43, E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting and

turn signal switch) M28

4. Combination meter M24 5. Daytime light relay 1 E37 and day-

time light relay 2 E38 6. Parking brake switch M17

WKIA5555E

Revision: May 2010

2011 Versa