Error NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3029 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TCM BRANCH LINE CIRCUITLAN-183

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 13)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928677

1.CHECK CONNECTOR

1. NISSAN TIIDA 2011 Service Repair Manual TCM BRANCH LINE CIRCUITLAN-183

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 13)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928677

1.CHECK CONNECTOR

1.](/img/5/57396/w960_57396-3028.png)

TCM BRANCH LINE CIRCUITLAN-183

< SERVICE INFORMATION > [CAN SYSTEM (TYPE 13)]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928677

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connector of the TCM for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of TCM.

2. Check the resistance between the TCM harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the TCM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the TCM. Refer to the following.

• A/T models: AT-169, "

Diagnosis Procedure"

• CVT models: CVT-115, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the TCM. Refer to the following.

• A/T models: AT-212, "

Removal and Installation"

• CVT models: CVT-159, "Removal and Installation"

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit.

TCM harness connector

Resistance (Ω)

Connector No. Terminal No.

E31 5 6 Approx. 54 – 66

Revision: May 2010 2011 Versa

Page 3030 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LAN-184

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

IPDM-E BRANCH LINE CIRCUIT

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928678

1.CHECK CONNECTOR

1. Turn the ignition switch OFF NISSAN TIIDA 2011 Service Repair Manual LAN-184

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

IPDM-E BRANCH LINE CIRCUIT

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928678

1.CHECK CONNECTOR

1. Turn the ignition switch OFF](/img/5/57396/w960_57396-3029.png)

LAN-184

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

IPDM-E BRANCH LINE CIRCUIT

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000005928678

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors fo r damage, bend and loose connection (unit side and con-

nector side).

- IPDM E/R

- Harness connector E7 (M/T models without ABS)

- Harness connector M69 (M /T models without ABS)

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of IPDM E/R.

2. Check the resistance between the IPDM E/R harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the IPDM E/R branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circ uit of the IPDM E/R. Refer to PG-27, "

IPDM E/R Power/Ground

Circuit Inspection".

Is the inspection result normal?

YES (Present error)>>Replace the IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

YES (Past error)>>Error was detected in the IPDM E/R branch line.

NO >> Repair the power supply and the ground circuit.

IPDM E/R harness connector Resistance (Ω)

Connector No. Terminal No.

E46 4140Approx. 108 – 132

Revision: May 2010 2011 Versa

Page 3032 of 3787

![NISSAN TIIDA 2011 Service Repair Manual LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur NISSAN TIIDA 2011 Service Repair Manual LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedur](/img/5/57396/w960_57396-3031.png)

LAN-186

< SERVICE INFORMATION >[CAN SYSTEM (TYPE 13)]

CAN COMMUNICATION CIRCUIT

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow

the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system. NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Revision: May 2010 2011 Versa

Page 3046 of 3787

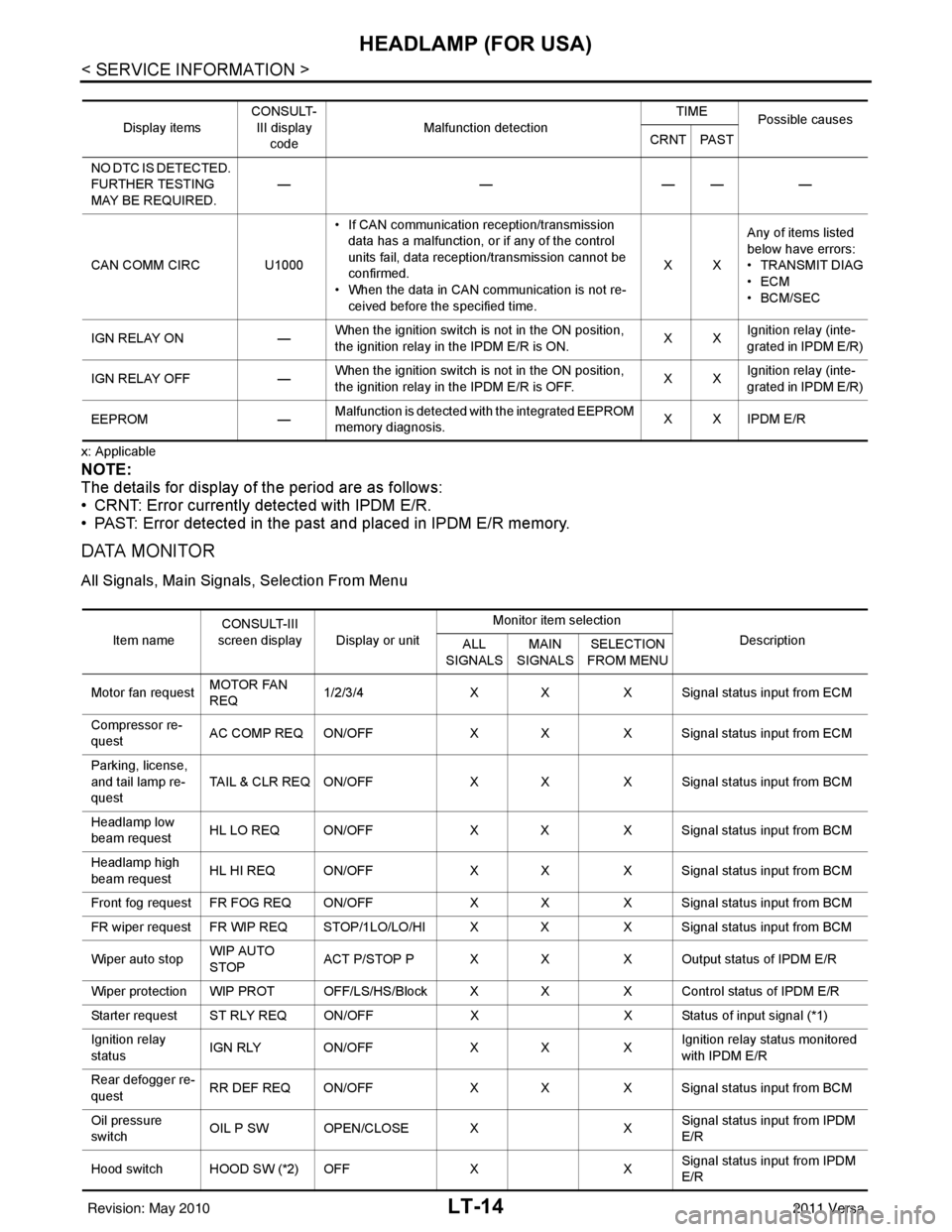

LT-14

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display itemsCONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. —————

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is de

tected with the integrated EEPROM

memory diagnosis. X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: May 2010

2011 Versa

Page 3439 of 3787

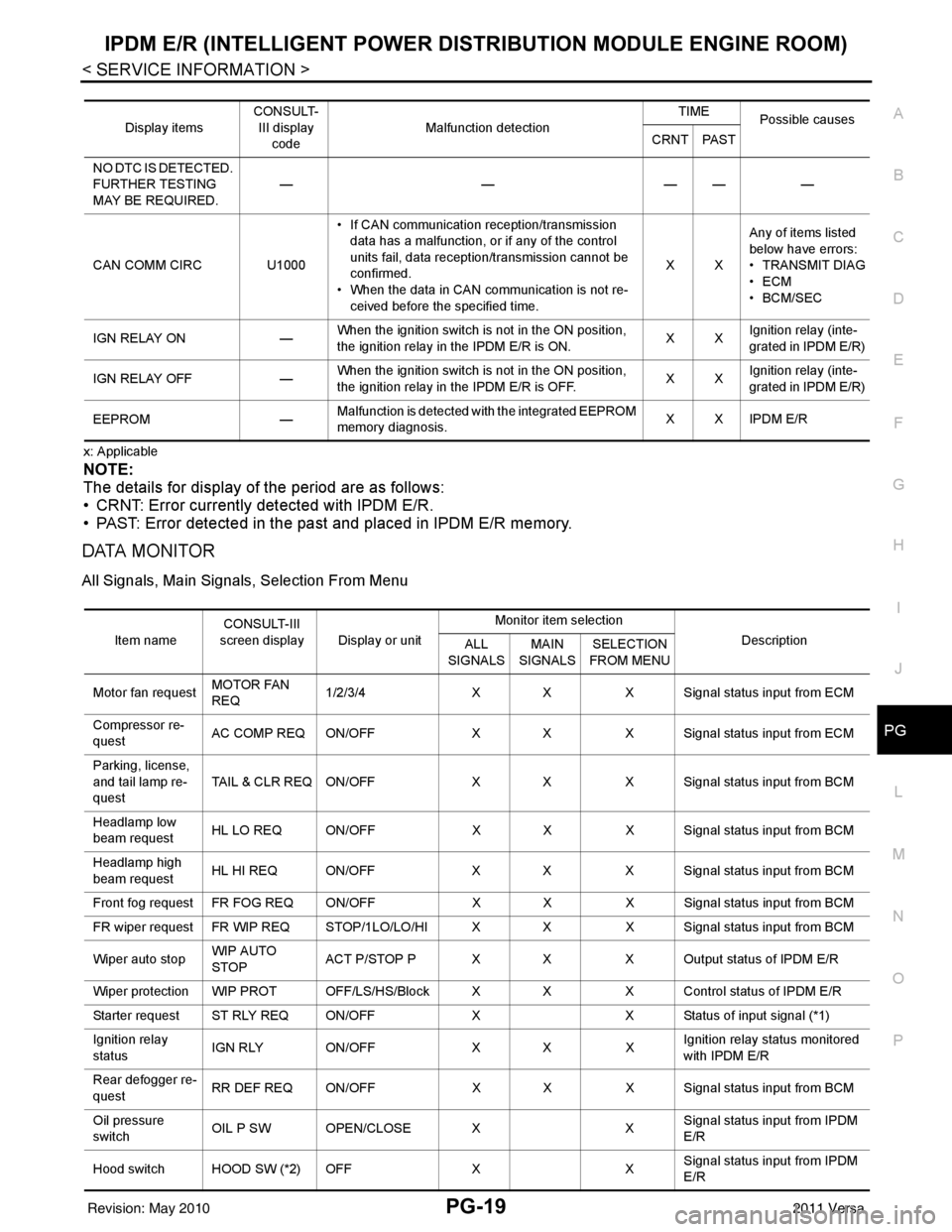

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display items CONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. ———

——

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have

errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is detected with the integrated EEPROM

memory diagnosis.

X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: May 2010

2011 Versa

Page 3448 of 3787

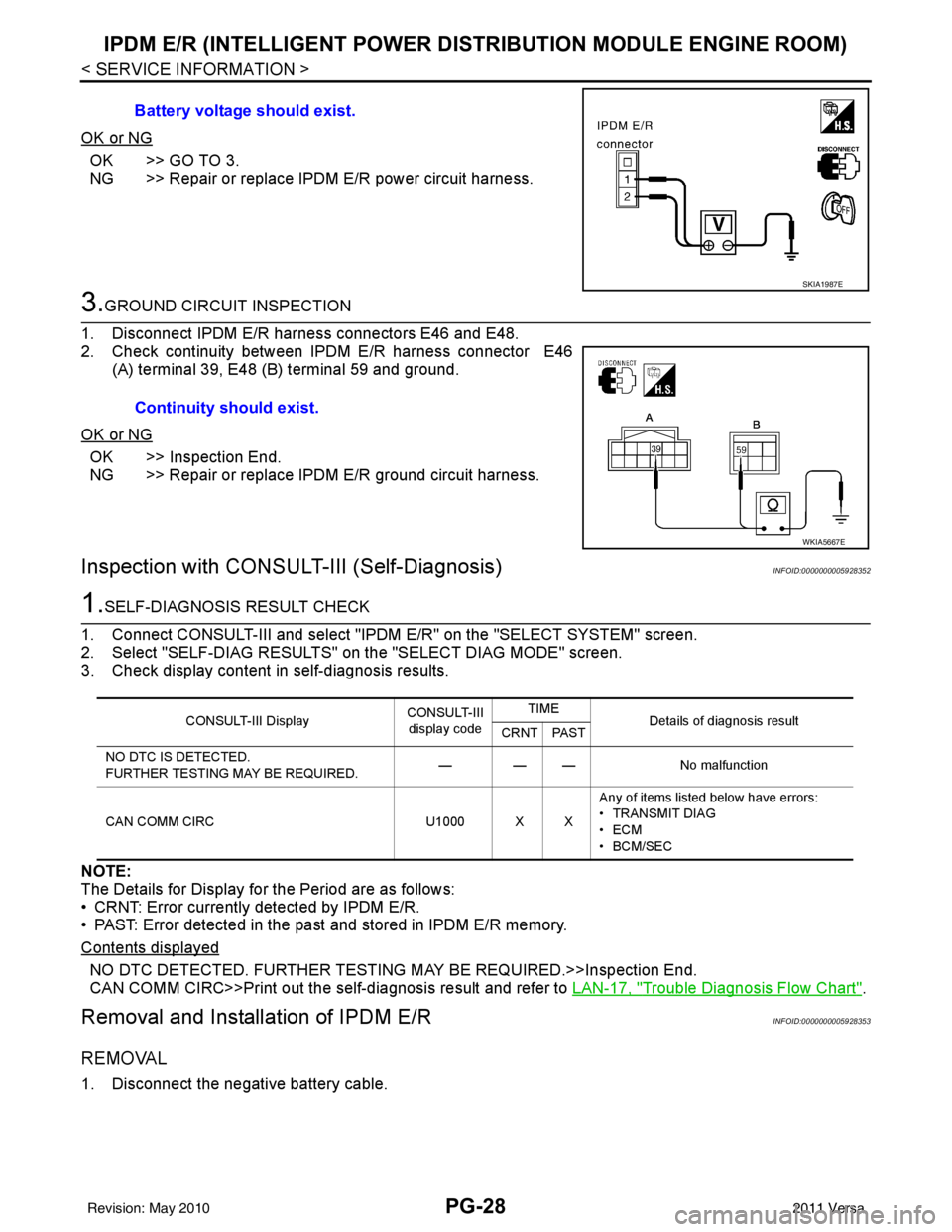

PG-28

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

OK or NG

OK >> GO TO 3.

NG >> Repair or replace IPDM E/R power circuit harness.

3.GROUND CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connectors E46 and E48.

2. Check continuity between IPDM E/R harness connector E46 (A) terminal 39, E48 (B) terminal 59 and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace IPDM E/R ground circuit harness.

Inspection with CONSULT-III (Self-Diagnosis)INFOID:0000000005928352

1.SELF-DIAGNOSIS RESULT CHECK

1. Connect CONSULT-III and select "IPDM E/R" on the "SELECT SYSTEM" screen.

2. Select "SELF-DIAG RESULTS" on the "SELECT DIAG MODE" screen.

3. Check display content in self-diagnosis results.

NOTE:

The Details for Display for the Period are as follows:

• CRNT: Error currently detected by IPDM E/R.

• PAST: Error detected in the past and stored in IPDM E/R memory.

Contents displayed

NO DTC DETECTED. FURTHER TESTING MAY BE REQUIRED.>>Inspection End.

CAN COMM CIRC>>Print out the self-diagnosis result and refer to LAN-17, "

Trouble Diagnosis Flow Chart".

Removal and Installation of IPDM E/RINFOID:0000000005928353

REMOVAL

1. Disconnect the negative battery cable. Battery voltage should exist.

SKIA1987E

Continuity should exist.

WKIA5667E

CONSULT-III Display

CONSULT-III

display code TIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED. — — —

No malfunction

CAN COMM CIRC U1000 X XAny of items listed below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

Revision: May 2010

2011 Versa

Page 3559 of 3787

RSU-6

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000005931084

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentInspectionINFOID:0000000005931085

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6

.

3. Wheel bearing axial end play. Refer to RAX-6, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-13, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Revision: May 2010 2011 Versa

Page 3692 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS con NISSAN TIIDA 2011 Service Repair Manual EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS con](/img/5/57396/w960_57396-3691.png)

EPS SYSTEMSTC-5

< SYSTEM DESCRIPTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

SYSTEM DESCRIPTION

EPS SYSTEM

System DiagramINFOID:0000000005931224

System DescriptionINFOID:0000000005931225

• EPS control unit performs an arithmetical operation on data, such as steering wheel turning force (sensor

signal) from the torque sensor, vehicle speed signal, etc. Then it generates an optimum assist torque signal

to the EPS motor according to the driving condition.

• EPS control unit decreases the output signal to EPS mo tor while extremely using the power steering func-

tion (e.g., full steering) consecutively for protec ting EPS motor and EPS control unit (Overload protection

control). While activating overload protection control, the assist torque gradually decreases, and the steering

wheel turning force becomes heavy. The normal assist torque reactivates by no steering.

• In case of an error in the electrical system, the fail- safe function stops output signals to the EPS motor. Then

the previous state is changed to the manual steering state.

• Self-diagnosis can be done with CONSULT-III.

• EPS control unit will decrease assistance under the following 2 conditions.

- Extensive steering at low speed will cause the ECU and MOTOR to heat up, once temperature reaches crit-

ical point ECU will reduce current to reduce heat up. System will recover as temperature lowers (reduced or

no assistance).

- Holding steering on rack-end (full lock) for 1 second will cause the system to engage rack-end protection. This reduces assistance down to 50% in order to prevent heat up. Assistance is immediately returned to

100% when steering released or turned away from rack-end.

- Communicates the signal from each control unit via CAN communication.

WGIA0187E

Control unit Signal status

ECM Transmits mainly the follow

ing signals to EPS control uni t via CAN communication.

Engine status signal

ABS actuator and electric unit

(control unit) Transmits mainly the follow

ing signals to EPS control uni t via CAN communication.

Vehicle speed signal

Revision: May 2010 2011 Versa

Page 3699 of 3787

![NISSAN TIIDA 2011 Service Repair Manual STC-12

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1604 TORQUE SENSOR

3.CHECK TORQUE SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between EPS control unit harness connector terminal and ground. CAUT NISSAN TIIDA 2011 Service Repair Manual STC-12

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1604 TORQUE SENSOR

3.CHECK TORQUE SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between EPS control unit harness connector terminal and ground. CAUT](/img/5/57396/w960_57396-3698.png)

STC-12

< DTC/CIRCUIT DIAGNOSIS >[EPS]

C1604 TORQUE SENSOR

3.CHECK TORQUE SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel is neutral position . (There is no steering force.)

Is the inspection result normal?

YES >> GO TO 4.

NO >> Torque sensor is malfunction. Replace steering column assembly. Refer to PS-10, "

Removal and

Installation".

4.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect torque sensor harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to PS-10, "Removal and Installation".

NO >> Repair or replace error-detected parts.

EPS control unit —Volt a ge

Connector Terminal

M53 4

Ground Approx. 2.5V

6

Revision: May 2010 2011 Versa

Page 3700 of 3787

![NISSAN TIIDA 2011 Service Repair Manual C1606 EPS MOTORSTC-13

< DTC/CIRCUIT DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

C1606 EPS MOTOR

DescriptionINFOID:0000000005931235

EPS motor provides the assist torque by the control signal f NISSAN TIIDA 2011 Service Repair Manual C1606 EPS MOTORSTC-13

< DTC/CIRCUIT DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

C1606 EPS MOTOR

DescriptionINFOID:0000000005931235

EPS motor provides the assist torque by the control signal f](/img/5/57396/w960_57396-3699.png)

C1606 EPS MOTORSTC-13

< DTC/CIRCUIT DIAGNOSIS > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

C1606 EPS MOTOR

DescriptionINFOID:0000000005931235

EPS motor provides the assist torque by the control signal from EPS control unit.

DTC LogicINFOID:0000000005931236

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC REPRODUCTION PROCEDURE

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform EPS control unit self-diagnosis.

Is DTC

“C1606” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-13, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005931237

1.CHECK EPS MOTOR

Check the EPS motor. Refer to STC-13, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> EPS motor is malfunction. Replace steering column assembly. Refer to PS-10, "

Removal and

Installation".

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect EPS motor harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to PS-10, "Removal and Installation".

NO >> Repair or replace error-detected parts.

Component Inspection INFOID:0000000005931238

1.CHECK EPS MOTOR

1. Turn the ignition switch OFF.

2. Disconnect EPS motor harness connector.

3. Check resistance between EPS motor connector terminals.

Is the inspection result normal?

YES >> Inspection End

DTC Display item Malfunction detected condition Possible cause

C1606 EPS MOTOR When the motor driver malfunction of EPS control

unit or EPS motor malfunction is detected. • Harness or connector

• EPS motor

• EPS control unit

EPS motor

Resistance (Approx.)

Te r m i n a l

19 20 0.1 Ω or less

Revision: May 2010 2011 Versa