engine control NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1295 of 3787

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

BASIC INSPECTION ....... ............................

15

DIAGNOSIS AND REPAIR WORK FLOW .... ....15

Work Flow ........................................................... ....15

Diagnostic Work Sheet ............................................18

INSPECTION AND ADJUSTMENT ....................20

BASIC INSPECTION .................................................20

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ....

20

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

23

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

23

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

23

IDLE SPEED .......................................................... ....24

IDLE SPEED : Description ........................ ..............24

IDLE SPEED : Special R epair Requirement ...........24

IGNITION TIMING .................................................. ....24

IGNITION TIMING : Description ..............................24

IGNITION TIMING : Special Repair Requirement ....24

VIN REGISTRATION ............................................. ....24

VIN REGISTRATION : Description .........................24

VIN REGISTRATION : Special Repair Require-

ment ........................................................................

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING ............................................................ ....

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Description .........................................

25

ACCELERATOR PEDAL RELEASED POSITION

LEARNING : Special Repair Requirement ..............

25

THROTTLE VALVE CLOSED POSITION LEARN-

ING ......................................................................... ....

25

THROTTLE VALVE CLOSED POSITION

LEARNING : Description .........................................

25

THROTTLE VALVE CLOSED POSITION

LEARNING : Special Repair Requirement ..............

25

IDLE AIR VOLUME LEARNING ............................ ....25

IDLE AIR VOLUME LEARNING : Description .........25

IDLE AIR VOLUME LEARNI NG : Special Repair

Requirement ........................................................ ....

26

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ................................................................... ....

27

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Description ................................................

27

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement .....................

27

HOW TO SET SRT CODE ................................29

Description ...............................................................29

SRT Set Driving Pattern ..........................................30

Work Procedure .......................................................32

HOW TO ERASE PERMANENT DTC ..............34

Description ...............................................................34

Work Procedure (Group A) ......................................35

Work Procedure (Group B) ......................................37

FUNCTION DIAGNOSIS ..............................40

ENGINE CONTRO L SYSTEM ..........................40

System Diagram ................................................. ....40

System Description ..................................................41

Component Parts Location ....................................41

Component Description ...........................................45

MULTIPORT FUEL INJECTION SYSTEM .......47

System Diagram .....................................................47

System Description ..................................................47

Component Parts Location ....................................50

Component Description ...........................................54

ELECTRIC IGNITION SYSTEM ........................56

Revision: May 2010 2011 Versa

Page 1299 of 3787

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Component Inspection (Fuel filler cap) ...............

..

344

Component Inspection (Drain filter) ......................345

P0460 FUEL LEVEL SENSOR ...................... ..346

Description .......................................................... ..346

DTC Logic .............................................................346

Diagnosis Procedure .............................................346

P0461 FUEL LEVEL SENSOR ........................347

Description .......................................................... ..347

DTC Logic .............................................................347

Component Function Check ..................................347

Diagnosis Procedure .............................................348

P0462, P0463 FUEL LEVEL SENSOR ............349

Description .......................................................... ..349

DTC Logic .............................................................349

Diagnosis Procedure .............................................349

P0500 VSS .......................................................351

Description .......................................................... ..351

DTC Logic .............................................................351

Component Function Check ..................................352

Diagnosis Procedure .............................................352

P0506 ISC SYSTEM .........................................353

Description .......................................................... ..353

DTC Logic .............................................................353

Diagnosis Procedure .............................................353

P0507 ISC SYSTEM .........................................355

Description .......................................................... ..355

DTC Logic .............................................................355

Diagnosis Procedure .............................................355

P0603 ECM POWER SUPPLY .........................357

Description .......................................................... ..357

DTC Logic .............................................................357

Diagnosis Procedure .............................................357

P0605 ECM .......................................................359

Description ............................................................359

DTC Logic .............................................................359

Diagnosis Procedure .............................................360

P0607 ECM .......................................................361

Description ............................................................361

DTC Logic .............................................................361

Diagnosis Procedure .............................................361

P0643 SENSOR POWER SUPPLY .................362

DTC Logic ........................................................... ..362

Wiring Diagram .....................................................363

Diagnosis Procedure .............................................363

P0850 PNP SWITCH ........................................366

Description ............................................................366

DTC Logic .............................................................366

Component Function Check ..................................367

Wiring Diagram .....................................................368

Diagnosis Procedure .............................................368

P1148 CLOSED LOOP CONTROL ................371

DTC Logic ............................................................ ..371

P1217 ENGINE OVER TEMPERATURE ........372

DTC Logic ..............................................................372

Component Function Check ..................................372

Diagnosis Procedure .............................................373

P1225 TP SENSOR .........................................376

Description .............................................................376

DTC Logic ..............................................................376

Diagnosis Procedure .............................................376

Special Repair Requirement ..................................377

P1226 TP SENSOR .........................................378

Description .............................................................378

DTC Logic ..............................................................378

Diagnosis Procedure .............................................378

Special Repair Requirement ..................................379

P1421 COLD START CONTROL ...................380

Description .............................................................380

DTC Logic ..............................................................380

Diagnosis Procedure .............................................380

P1715 INPUT SPEED SENSOR (PRIMARY

SPEED SENSOR) ...........................................

382

Description ........................................................... ..382

DTC Logic ..............................................................382

Diagnosis Procedure .............................................382

P1805 BRAKE SWITCH .................................383

Description .............................................................383

DTC Logic ..............................................................383

Wiring Diagram ......................................................384

Diagnosis Procedure .............................................384

Component Inspection (Stop Lamp Switch) ..........386

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

387

Description .............................................................387

DTC Logic ..............................................................387

Wiring Diagram ......................................................388

Diagnosis Procedure .............................................388

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ......................................................

391

Description ........................................................... ..391

DTC Logic ..............................................................391

Wiring Diagram ......................................................392

Diagnosis Procedure .............................................392

Component Inspection ...........................................395

Special Repair Requirement ..................................395

P2118 THROTTLE CONTROL MOTOR .........396

Description .............................................................396

DTC Logic ..............................................................396

Wiring Diagram ......................................................397

Diagnosis Procedure .............................................397

Component Inspection ...........................................398

Special Repair Requirement ..................................399

Revision: May 2010 2011 Versa

Page 1300 of 3787

EC-6

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .....................................................

400

Description ........................................................... ..400

DTC Logic ..............................................................400

Diagnosis Procedure .............................................400

Special Repair Requirement ..................................401

P2122, P2123 APP SENSOR ......................... .402

Description ........................................................... ..402

DTC Logic ..............................................................402

Wiring Diagram ......................................................403

Diagnosis Procedure .............................................403

Component Inspection ...........................................405

Special Repair Requirement ..................................405

P2127, P2128 APP SENSOR ......................... .406

Description ........................................................... ..406

DTC Logic ..............................................................406

Wiring Diagram ......................................................407

Diagnosis Procedure .............................................407

Component Inspection ...........................................409

Special Repair Requirement ..................................410

P2135 TP SENSOR ........................................ .411

Description ........................................................... ..411

DTC Logic ..............................................................411

Wiring Diagram ......................................................412

Diagnosis Procedure .............................................412

Component Inspection ...........................................414

Special Repair Requirement ..................................414

P2138 APP SENSOR ..................................... .415

Description ........................................................... ..415

DTC Logic ..............................................................415

Wiring Diagram ......................................................416

Diagnosis Procedure .............................................416

Component Inspection ...........................................419

Special Repair Requirement ..................................419

P2A00 A/F SENSOR 1 ................................... .420

Description ........................................................... ..420

DTC Logic ..............................................................420

Wiring Diagram ......................................................421

Diagnosis Procedure .............................................422

COOLING FAN ................................................425

Description ........................................................... ..425

Component Function Check ..................................425

Wiring Diagram ......................................................426

Diagnosis Procedure .............................................427

Component Inspection ...........................................429

ELECTRICAL LOAD SIGNAL .........................431

Description ........................................................... ..431

Component Function Check ..................................431

Diagnosis Procedure .............................................431

FUEL INJECTOR .............................................433

Description ........................................................... ..433

Component Function Check ..................................433

Wiring Diagram ......................................................434

Diagnosis Procedure ............................................ .434

Component Inspection ..........................................435

FUEL PUMP .....................................................437

Description ........................................................... .437

Component Function Check .................................437

Wiring Diagram .....................................................438

Diagnosis Procedure .............................................438

Component Inspection ..........................................440

IGNITION SIGNAL ............................................442

Description ........................................................... .442

Component Function Check .................................442

Wiring Diagram .....................................................443

Diagnosis Procedure .............................................444

Component Inspection (Ignition Coil with Power

Transistor) ............................................................ .

447

Component Inspection (Condenser-2) ..................448

MALFUNCTION INDICATOR LAMP ................449

Description ........................................................... .449

Component Function Check .................................449

Wiring Diagram .....................................................450

Diagnosis Procedure .............................................451

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

453

Description ........................................................... .453

Component Function Check .................................453

Diagnosis Procedure .............................................453

Component Inspection (Refueling EVAP vapor cut

valve) ................................................................... .

456

Component Inspection (Drain filter) ......................458

POSITIVE CRANKCASE VENTILATION .........459

Description ........................................................... .459

Component Inspection ..........................................459

REFRIGERANT PRESSURE SENSOR ...........460

Description ........................................................... .460

Component Function Check .................................460

Wiring Diagram .....................................................461

Diagnosis Procedure .............................................461

ECU DIAGNOSIS ......................................464

ECM ................................................................ ..464

Reference Value .................................................. .464

Wiring Diagram — ENGINE CONTROL SYSTEM

— ..........................................................................

474

Fail Safe ...............................................................475

DTC Inspection Priority Chart .............................477

DTC Index ............................................................478

Test Value and Test Limit .....................................481

SYMPTOM DIAGNOSIS ...........................488

ENGINE CONTROL SYSTEM SYMPTOMS .. ..488

Symptom Table .................................................... .488

NORMAL OPERATING CONDITION ...............492

Revision: May 2010 2011 Versa

Page 1301 of 3787

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Description ..........................................................

..

492

PRECAUTION ............................................493

PRECAUTIONS .............................................. ..493

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

493

Precaution for Procedure without Cowl Top Cover ..493

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

493

General Precautions .............................................494

PREPARATION .........................................497

PREPARATION .............................................. ..497

Special Service Tools .......................................... ..497

Commercial Service Tools ....................................497

ON-VEHICLE MAINTENANCE ..................499

FUEL PRESSURE .......................................... ..499

Inspection ............................................................ ..499

EVAP LEAK CHECK ........................................501

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

503

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

503

Idle Speed ........................................................... ..503

Ignition Timing .......................................................503

Calculated Load Value ..........................................503

Mass Air Flow Sensor ...........................................503

MR18DE

SERVICE INFORMATION .. .......................

504

INDEX FOR DTC ............................................ ..504

U0101-U1001 ...................................................... ..504

P0011-P0075 ........................................................504

P0101-P0128 ........................................................504

P0130-P0183 ........................................................505

P0222-P0420 ........................................................505

P0441-P0463 ........................................................506

P0500-P0643 ........................................................506

P0705-P0734 ........................................................507

P0740-P0840 ........................................................507

P0850-P1574 ........................................................508

P1610-P1615 ........................................................508

P1715-P1805 ........................................................508

P2100-P2A00 ........................................................509

PRECAUTIONS ................................................510

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

510

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

510

Precaution for Procedure without Cowl Top Cover ..511

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ................................................................

511

Precaution .............................................................511

PREPARATION ...............................................515

Special Service Tool ..............................................515

Commercial Service Tool ......................................515

ENGINE CONTROL SYSTEM ........................517

Schematic ............................................................ ..517

Multiport Fuel Injection (MFI) System ....................517

Electronic Ignition (EI) System ..............................520

Fuel Cut Control (at No Load and High Engine

Speed) ...................................................................

520

AIR CONDITIONING CUT CONTROL ............522

Input/Output Signal Chart ......................................522

System Description ................................................522

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

523

System Description ................................................523

Component Description .........................................524

CAN COMMUNICATION .................................525

System Description ................................................525

EVAPORATIVE EMISSION SYSTEM .............526

Description .............................................................526

Component Inspection ...........................................528

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Revision: May 2010 2011 Versa

Page 1302 of 3787

EC-8

Idle Air Volume Learning .......................................580

Fuel Pressure Check .............................................582

TROUBLE DIAGNOSIS ...................................585

Trouble Diagnosis Introduction ............................ ..585

DTC Inspection Priority Chart ................................590

Fail-Safe Chart ......................................................590

Symptom Matrix Chart ...........................................592

Engine Control Component Parts Location ...........596

Vacuum Hose Drawing ..........................................602

Circuit Diagram .................................................... ..603

ECM Harness Connector Terminal Layout ............605

ECM Terminal and Reference Value ................... ..605

CONSULT-III Function (ENGINE) .........................612

Generic Scan Tool (GST) Function .......................618

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

620

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

624

Description ........................................................... ..624

Testing Condition ...................................................624

Inspection Procedure .............................................624

Diagnosis Procedure .............................................624

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT ........................................................

632

Description ........................................................... ..632

Diagnosis Procedure .............................................632

POWER SUPPLY AND GROUND CIRCUIT ...633

Wiring Diagram .................................................... ..633

Diagnosis Procedure .............................................634

Ground Inspection .................................................638

DTC U0101 CAN COMMUNICATION LINE ....639

Description ........................................................... ..639

On Board Diagnosis Logic .....................................639

DTC Confirmation Procedure ................................639

Wiring Diagram ......................................................640

Diagnosis Procedure .............................................640

DTC U0140 CAN COMMUNICATION LINE ....641

Description ........................................................... ..641

On Board Diagnosis Logic .....................................641

DTC Confirmation Procedure ................................641

Wiring Diagram ......................................................642

Diagnosis Procedure .............................................642

DTC U1001 CAN COMMUNICATION LINE ....643

Description ........................................................... ..643

On Board Diagnosis Logic .....................................643

DTC Confirmation Procedure ................................643

Wiring Diagram ......................................................644

Diagnosis Procedure .............................................644

DTC P0011 IVT CONTROL .............................645

Description ........................................................... ..645

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

645

On Board Diagnosis Logic .....................................646

DTC Confirmation Procedure ............................... .646

Diagnosis Procedure .............................................647

Component Inspection ..........................................648

Removal and Installation .......................................648

DTC P0031, P0032 A/F SENSOR 1 HEATER ..649

Description ........................................................... .649

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

649

On Board Diagnosis Logic ....................................649

DTC Confirmation Procedure ................................649

Wiring Diagram .....................................................650

Diagnosis Procedure .............................................651

Component Inspection ..........................................652

Removal and Installation .......................................653

DTC P0037, P0038 HO2S2 HEATER ............ ..654

Description ........................................................... .654

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

654

On Board Diagnosis Logic ....................................654

DTC Confirmation Procedure ................................654

Wiring Diagram .....................................................655

Diagnosis Procedure .............................................656

Component Inspection ..........................................658

Removal and Installation .......................................658

DTC P0075 IVT CONTROL SOLENOID

VALVE ............................................................ ..

659

Component Description ....................................... .659

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

659

On Board Diagnosis Logic ....................................659

DTC Confirmation Procedure ................................659

Wiring Diagram .....................................................660

Diagnosis Procedure .............................................661

Component Inspection ..........................................662

Removal and Installation .......................................663

DTC P0101 MAF SENSOR ............................ ..664

Component Description ....................................... .664

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

664

On Board Diagnosis Logic ....................................664

DTC Confirmation Procedure ................................664

Overall Function Check .........................................665

Wiring Diagram .....................................................667

Diagnosis Procedure .............................................668

Component Inspection ..........................................670

Removal and Installation .......................................671

DTC P0102, P0103 MAF SENSOR ................ ..672

Component Description ....................................... .672

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

672

On Board Diagnosis Logic ....................................672

DTC Confirmation Procedure ................................672

Wiring Diagram .....................................................674

Diagnosis Procedure .............................................675

Component Inspection ..........................................677

Revision: May 2010 2011 Versa

Page 1306 of 3787

EC-12

Description .............................................................889

On Board Diagnosis Logic .....................................889

DTC Confirmation Procedure ................................889

Diagnosis Procedure .............................................889

DTC P0507 ISC SYSTEM ................................891

Description ........................................................... ..891

On Board Diagnosis Logic .....................................891

DTC Confirmation Procedure ................................891

Diagnosis Procedure .............................................891

DTC P050A, P050B, P050E COLD START

CONTROL ........................................................

893

Description ........................................................... ..893

On Board Diagnosis Logic .....................................893

DTC Confirmation Procedure ................................893

Diagnosis Procedure .............................................894

DTC P0605 ECM ..............................................895

Component Description ....................................... ..895

On Board Diagnosis Logic .....................................895

DTC Confirmation Procedure ................................895

Diagnosis Procedure .............................................896

DTC P0607 ECM ..............................................897

Description ........................................................... ..897

On Board Diagnosis Logic .....................................897

DTC Confirmation Procedure ................................897

Diagnosis Procedure .............................................897

DTC P0643 SENSOR POWER SUPPLY ........898

On Board Diagnosis Logic ................................... ..898

DTC Confirmation Procedure ................................898

Wiring Diagram ......................................................899

Diagnosis Procedure .............................................900

DTC P0850 PNP SWITCH ...............................903

Component Description ....................................... ..903

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

903

On Board Diagnosis Logic .....................................903

DTC Confirmation Procedure ................................903

Overall Function Check .........................................904

Wiring Diagram ......................................................905

Diagnosis Procedure .............................................906

DTC P1148 CLOSED LOOP CONTROL .........909

On Board Diagnosis Logic ................................... ..909

DTC P1211 TCS CONTROL UNIT ..................910

Description ........................................................... ..910

On Board Diagnosis Logic .....................................910

DTC Confirmation Procedure ................................910

Diagnosis Procedure .............................................910

DTC P1212 TCS COMMUNICATION LINE .....911

Description ........................................................... ..911

On Board Diagnosis Logic .....................................911

DTC Confirmation Procedure ................................911

Diagnosis Procedure .............................................911

DTC P1217 ENGINE OVER TEMPERATURE ..912

System Description .............................................. .912

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

913

On Board Diagnosis Logic ....................................913

Overall Function Check .........................................913

Wiring Diagram .....................................................915

Diagnosis Procedure .............................................916

Main 13 Causes of Overheating ...........................919

Component Inspection ..........................................920

DTC P1225 TP SENSOR ..................................921

Component Description ....................................... .921

On Board Diagnosis Logic ....................................921

DTC Confirmation Procedure ................................921

Diagnosis Procedure .............................................921

Removal and Installation .......................................922

DTC P1226 TP SENSOR ................................ ..923

Component Description ....................................... .923

On Board Diagnosis Logic ....................................923

DTC Confirmation Procedure ................................923

Diagnosis Procedure .............................................923

Removal and Installation .......................................924

DTC P1564 ASCD STEERING SWITCH ........ ..925

Component Description ....................................... .925

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

925

On Board Diagnosis Logic ....................................925

DTC Confirmation Procedure ................................926

Wiring Diagram .....................................................927

Diagnosis Procedure .............................................928

Component Inspection ..........................................930

DTC P1572 ASCD BRAKE SWITCH ...............931

Component Description ....................................... .931

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

931

On Board Diagnosis Logic ....................................931

DTC Confirmation Procedure ................................932

Wiring Diagram .....................................................933

Diagnosis Procedure .............................................934

Component Inspection ..........................................938

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

940

Component Description ....................................... .940

On Board Diagnosis Logic ....................................940

DTC Confirmation Procedure ................................940

Diagnosis Procedure .............................................940

DTC P1715 INPUT SPEED SENSOR ..............942

A/T .......................................................................... .942

A/T : Description ...................................................942

A/T : CONSULT-III Reference Value in Data Mon-

itor Mode ...............................................................

942

A/T : On Board Diagnosis Logic ............................942

A/T : Diagnosis Procedure ....................................942

Revision: May 2010 2011 Versa

Page 1308 of 3787

EC-14

Wiring Diagram ....................................................1005

Diagnosis Procedure ...........................................1005

ELECTRICAL LOAD SIGNAL ........................1007

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1007

Diagnosis Procedure ...........................................1007

FUEL INJECTOR ............................................1009

Component Description .......................................1009

CONSULT-III Reference Va lue in Data Monitor

Mode ....................................................................

1009

Wiring Diagram ....................................................1010

Diagnosis Procedure ...........................................1011

Component Inspection .........................................1013

Removal and Installation .....................................1013

FUEL PUMP ....................................................1014

Description ...........................................................1014

CONSULT-III Reference Va lue in Data Monitor

Mode ....................................................................

1014

Wiring Diagram ....................................................1015

Diagnosis Procedure ...........................................1016

Component Inspection .........................................1018

Removal and Installation .....................................1018

IGNITION SIGNAL ..........................................1019

Component Description .......................................1019

Wiring Diagram ....................................................1020

Diagnosis Procedure ............................................1023

Component Inspection .........................................1026

Removal and Installation ......................................1027

REFRIGERANT PRESSURE SENSOR .........1028

Component Description .......................................1028

Wiring Diagram ....................................................1029

Diagnosis Procedure ............................................1030

Removal and Installation ......................................1032

MIL AND DATA LINK CONNECTOR .............1033

Wiring Diagram ....................................................1033

SERVICE DATA AND SPECIFICATIONS

(SDS) ..............................................................

1035

Fuel Pressure .......................................................1035

Idle Speed and Ignition Timing ............................1035

Calculated Load Value .........................................1035

Mass Air Flow Sensor ..........................................1035

Intake Air Temperature Se nsor ............................1035

Engine Coolant Temperature Sensor ..................1035

Air Fuel Ratio (A/F) Sensor 1 Heater ...................1036

Heated Oxygen sensor 2 Heater .........................1036

Crankshaft Position Sensor (POS) ......................1036

Camshaft Position Sensor (PHASE) ....................1036

Throttle Control Motor ...... ....................................1036

Fuel Injector .........................................................1036

Fuel Pump ............................................................1036

Revision: May 2010 2011 Versa

Page 1312 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-18

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORK FLOW

NO-1 >> No request for I/M examination from the custom

er: Before returning the vehicle to the customer,

always erase unnecessary DTC NISSAN TIIDA 2011 Service Repair Manual EC-18

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORK FLOW

NO-1 >> No request for I/M examination from the custom

er: Before returning the vehicle to the customer,

always erase unnecessary DTC](/img/5/57396/w960_57396-1311.png)

EC-18

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORK FLOW

NO-1 >> No request for I/M examination from the custom

er: Before returning the vehicle to the customer,

always erase unnecessary DTC in ECM and TCM (Transmission Control Module). Refer to EC-

29, "Description".

NO-2 >> I/M examination, request ed from the customer: GO TO 13.

13.PREPARE FOR I/M EXAMINATION

1. Set SRT codes. Refer to EC-29, "

Description".

2. Erase permanent DTCs. Refer to EC-34, "

Description".

>> INSPECTION END

Diagnostic Work SheetINFOID:0000000005929745

DESCRIPTION

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about an incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one on the WORKSHEET

SAMPLE in order to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and

DTC to be detected. Examples:

• Vehicle ran out of fuel, which caused the engine to misfire.

• Fuel filler cap was left off or incorrectly screwed on, allowing fuel to evaporate into the atmosphere.

SEF907L

Revision: May 2010 2011 Versa

Page 1320 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO](/img/5/57396/w960_57396-1319.png)

EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING

: Special Repair RequirementINFOID:0000000005929760

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (A/T), Neutral (M/T)

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- A/T models

• With CONSULT-III: Drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “TRANSMISSION”

system indicates less than 0.9 V.

• Without CONSULT-III: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

Revision: May 2010 2011 Versa

Page 1334 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa NISSAN TIIDA 2011 Service Repair Manual EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa](/img/5/57396/w960_57396-1333.png)

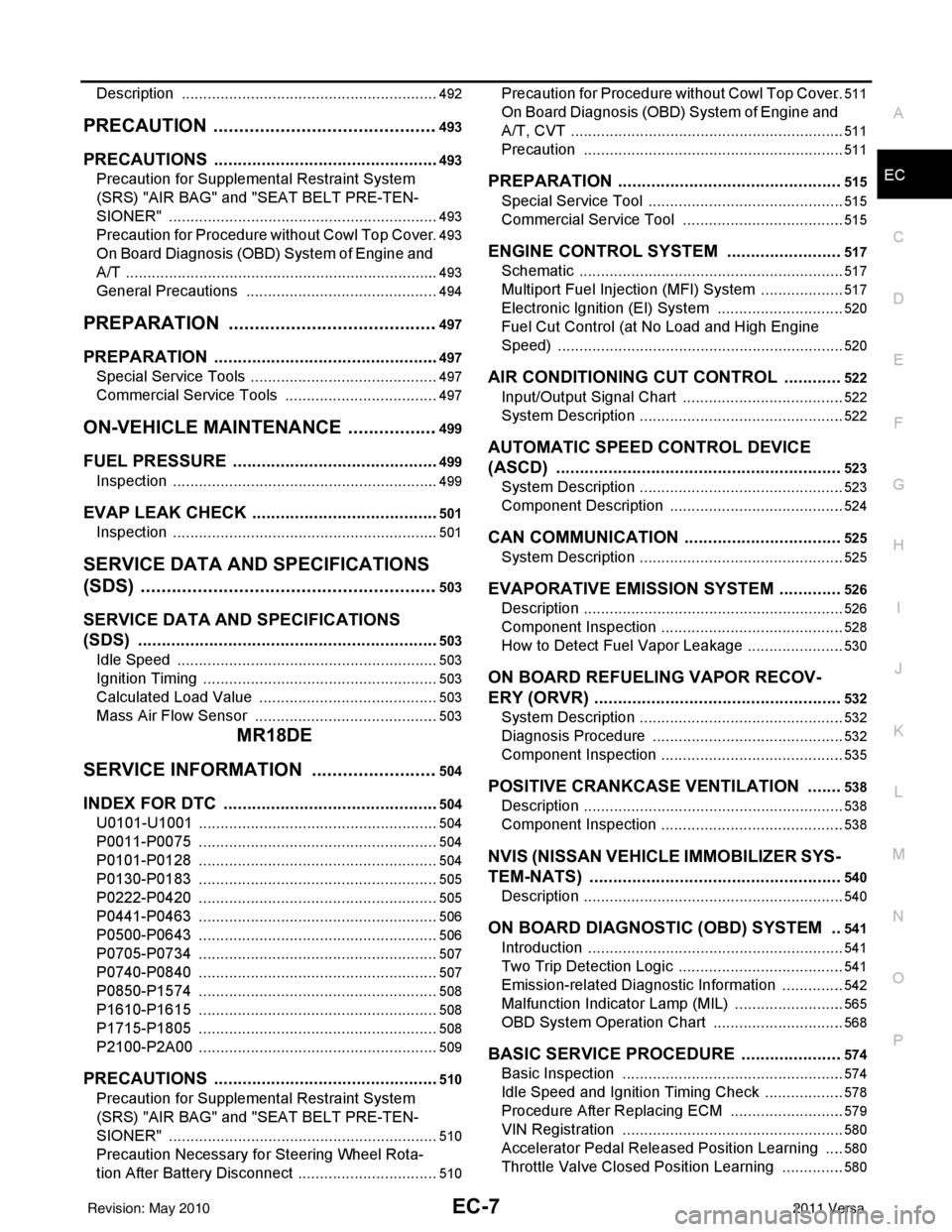

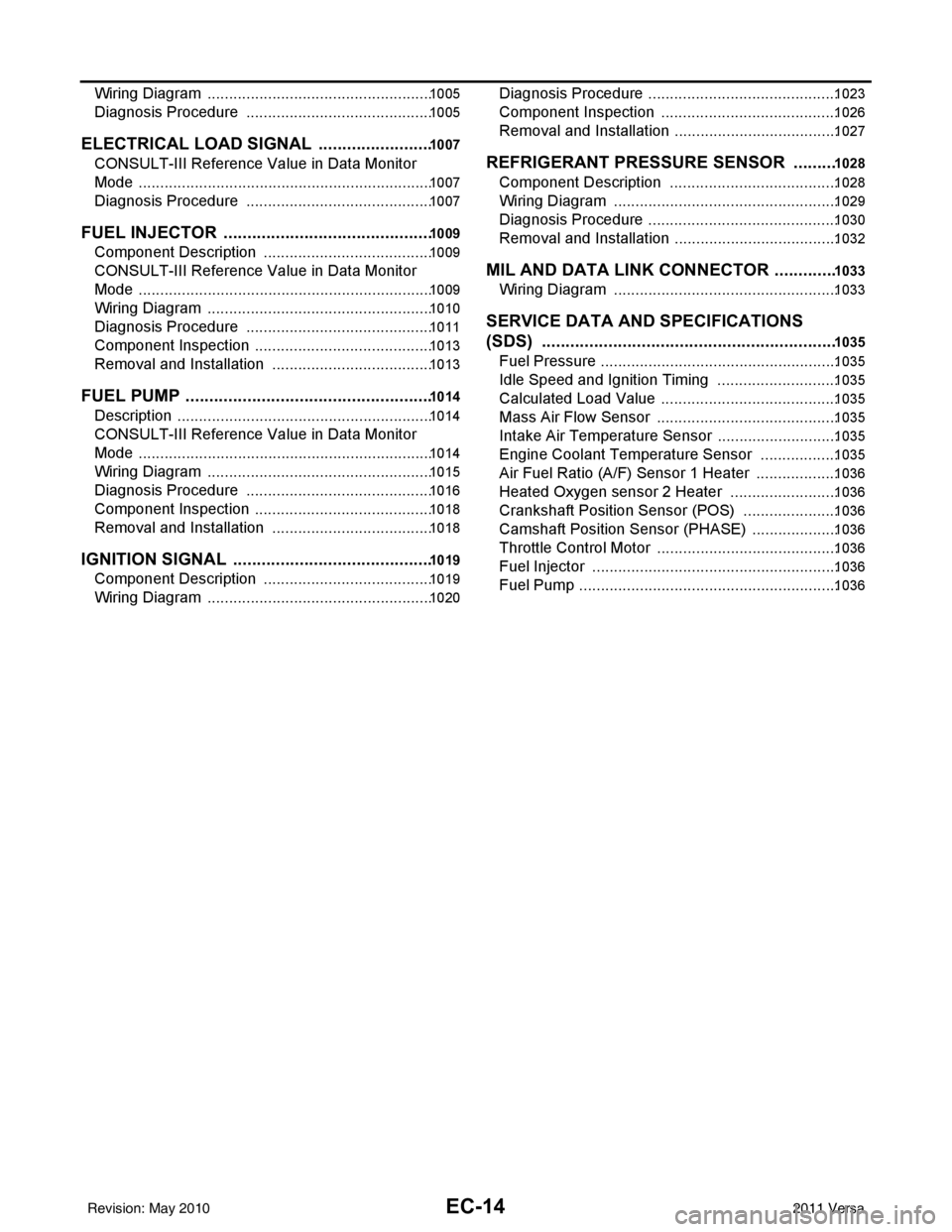

EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa