boot NISSAN TIIDA 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2646 of 3787

FAX-4

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000005931065

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005931066

Tool number

(Kent-Moore No.)

Tool name Description

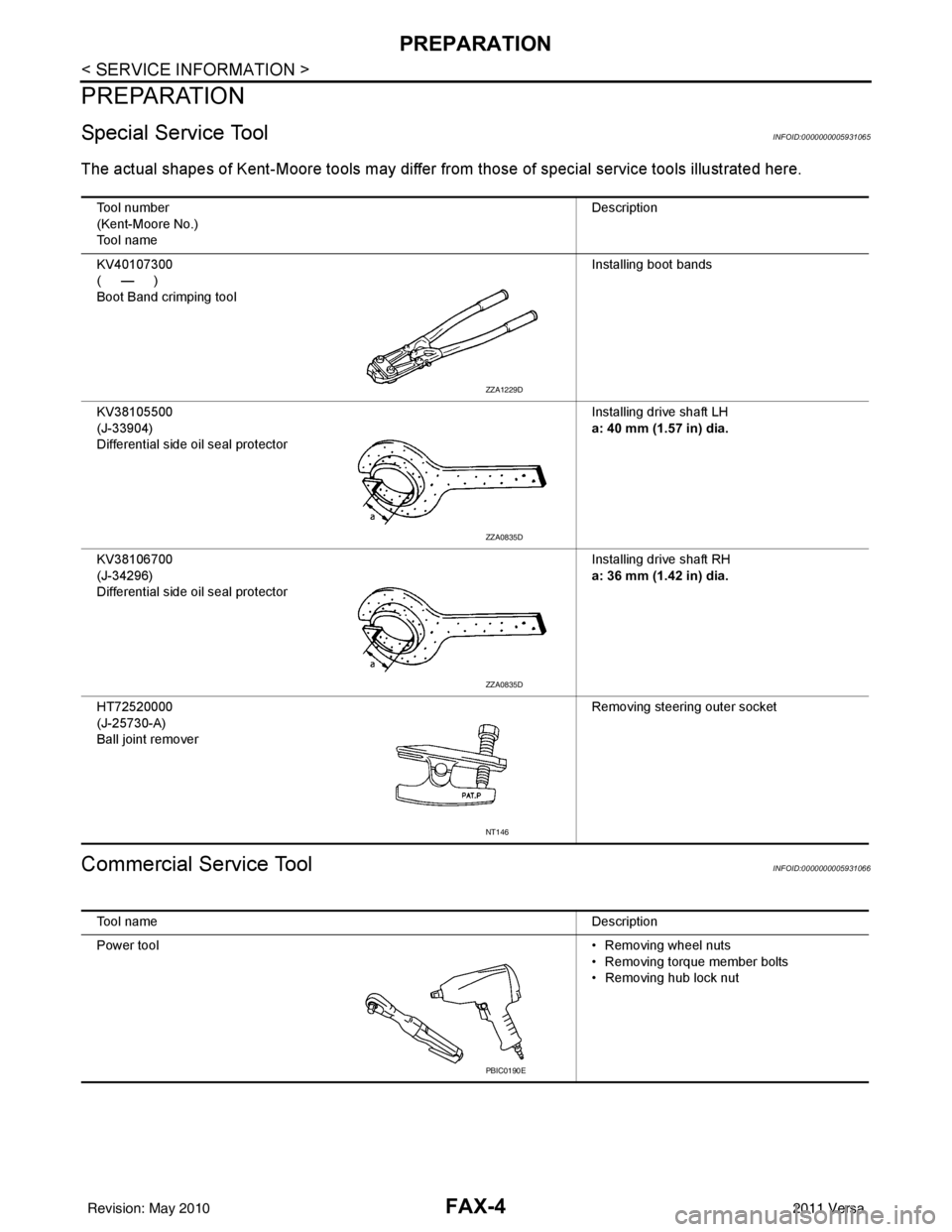

KV40107300

(—)

Boot Band crimping tool Installing boot bands

KV38105500

(J-33904)

Differential side oil seal protector Installing drive shaft LH

a: 40 mm (1.57 in) dia.

KV38106700

(J-34296)

Differential side oil seal protector Installing drive shaft RH

a: 36 mm (1.42 in) dia.

HT72520000

(J-25730-A)

Ball joint remover Removing steering outer socket

ZZA1229D

ZZA0835D

ZZA0835D

NT146

Tool name

Description

Power tool • Removing wheel nuts

• Removing torque member bolts

• Removing hub lock nut

PBIC0190E

Revision: May 2010 2011 Versa

Page 2649 of 3787

FRONT WHEEL HUB AND KNUCKLEFAX-7

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

2. Without disassembling the hydraulic lines, remove the torque member bolts using power tool. Then repo- sition the torque member and brake caliper assembly aside with wire. Refer to BR-25

.

CAUTION:

Do not depress brake pedal while brake caliper is removed.

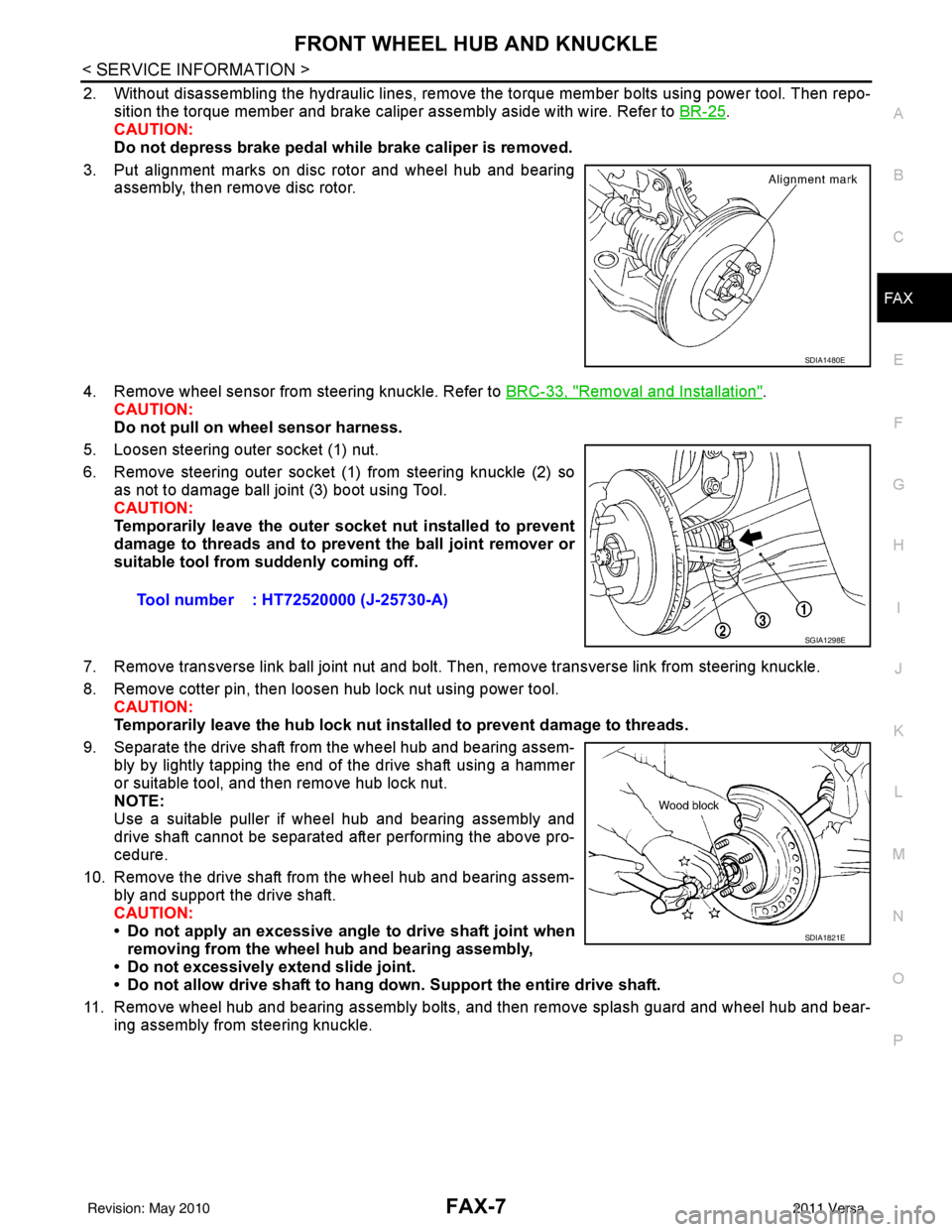

3. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

4. Remove wheel sensor from steering knuckle. Refer to BRC-33, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so as not to damage ball joint (3) boot using Tool.

CAUTION:

Temporarily leave the outer socket nut installed to prevent

damage to threads and to prevent the ball joint remover or

suitable tool from suddenly coming off.

7. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

8. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

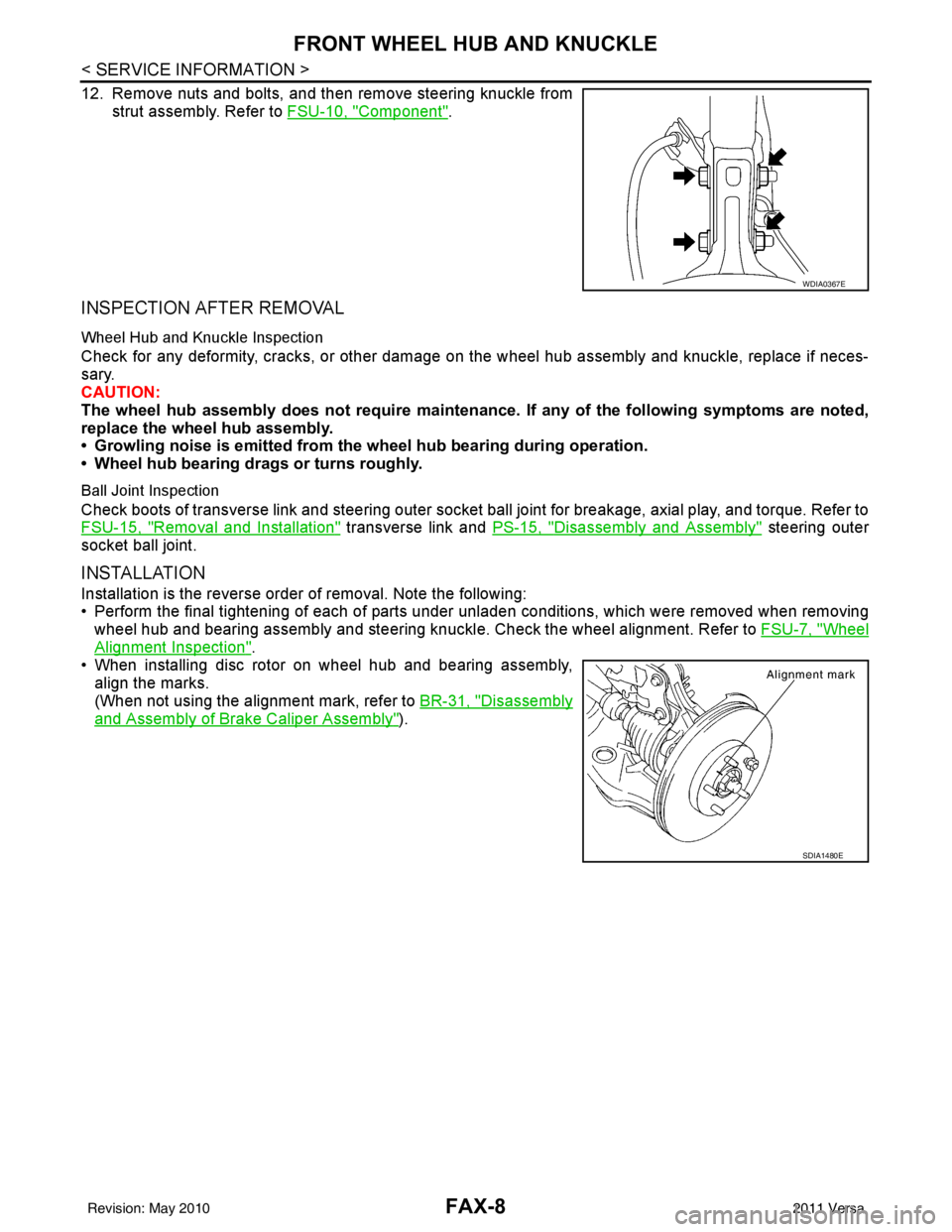

9. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

10. Remove the drive shaft from the wheel hub and bearing assem- bly and support the drive shaft.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

11. Remove wheel hub and bearing assembly bolts, and then remove splash guard and wheel hub and bear- ing assembly from steering knuckle.

SDIA1480E

Tool number : HT72520000 (J-25730-A)

SGIA1298E

SDIA1821E

Revision: May 2010 2011 Versa

Page 2650 of 3787

FAX-8

< SERVICE INFORMATION >

FRONT WHEEL HUB AND KNUCKLE

12. Remove nuts and bolts, and then remove steering knuckle fromstrut assembly. Refer to FSU-10, "

Component".

INSPECTION AFTER REMOVAL

Wheel Hub and Knuckle Inspection

Check for any deformity, cracks, or other damage on the wheel hub assembly and knuckle, replace if neces-

sary.

CAUTION:

The wheel hub assembly does not require maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-15, "

Removal and Installation" transverse link and PS-15, "Disassembly and Assembly" steering outer

socket ball joint.

INSTALLATION

Installation is the reverse order of removal. Note the following:

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing wheel hub and bearing assembly and steering knuckl e. Check the wheel alignment. Refer to FSU-7, "

Wheel

Alignment Inspection".

• When installing disc rotor on wheel hub and bearing assembly,

align the marks.

(When not using the alignment mark, refer to BR-31, "

Disassembly

and Assembly of Brake Caliper Assembly").

WDIA0367E

SDIA1480E

Revision: May 2010 2011 Versa

Page 2651 of 3787

FRONT DRIVE SHAFTFAX-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

FRONT DRIVE SHAFT

On-Vehicle Inspection and ServiceINFOID:0000000005931070

• Check drive shaft mounting point and joint for looseness and other damage.

• Check boot for cracks and other damage.

Replace or repair components as necessary. Refer to FAX-9, "

Removal and Installation (Left Side)", FAX-10,

"Removal and Installation (Right Side)", FAX-13, "Disassembly and Assembly (Left Side)", or FAX-18, "Disas-

sembly and Assembly (Right Side)".

CAUTION:

Replace entire drive shaft assembly when noi se or vibration occur from drive shaft.

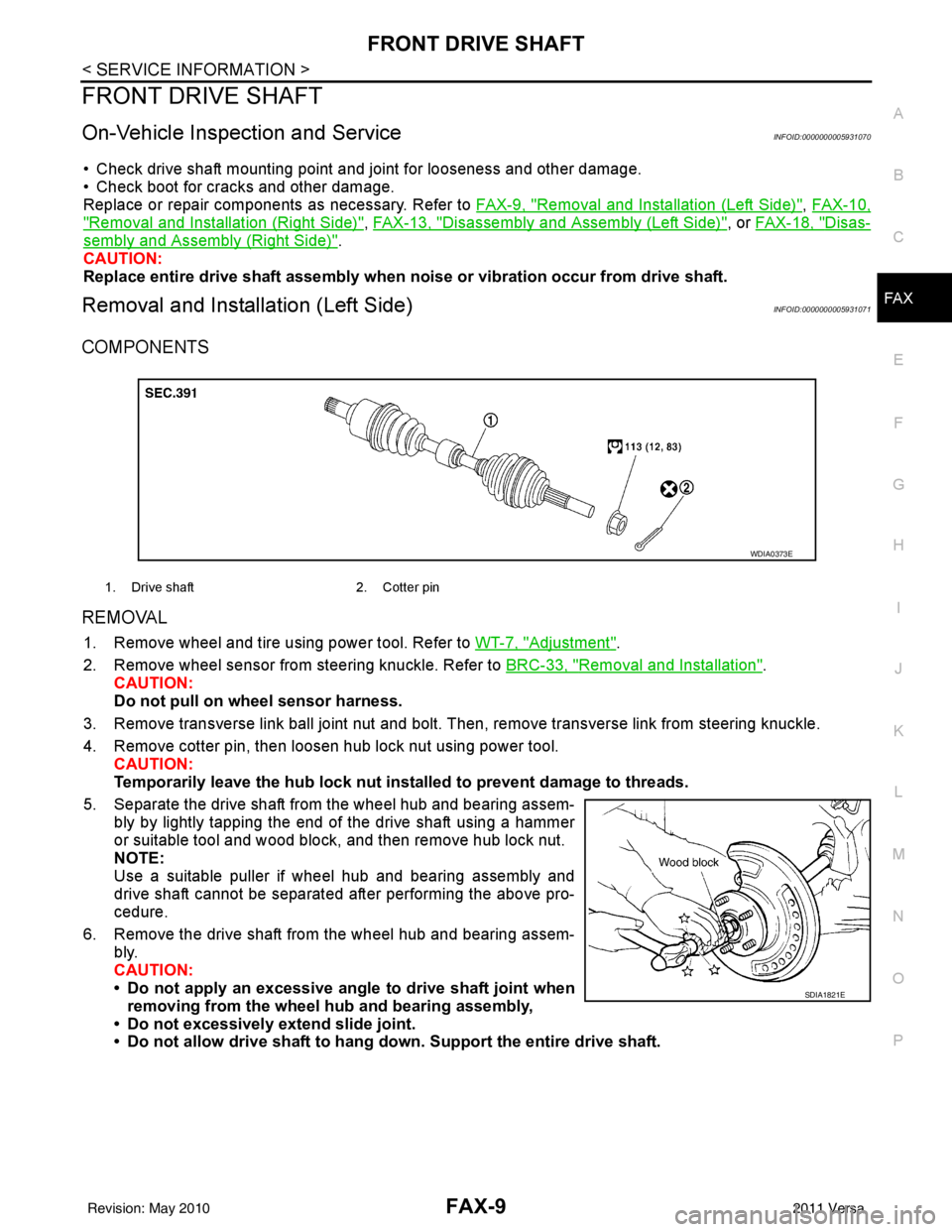

Removal and Installation (Left Side)INFOID:0000000005931071

COMPONENTS

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Adjustment".

2. Remove wheel sensor from steering knuckle. Refer to BRC-33, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

3. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

4. Remove cotter pin, then loosen hub lock nut using power tool. CAUTION:

Temporarily leave the hub lock nut inst alled to prevent damage to threads.

5. Separate the drive shaft from the wheel hub and bearing assem- bly by lightly tapping the end of the drive shaft using a hammer

or suitable tool and wood block, and then remove hub lock nut.

NOTE:

Use a suitable puller if wheel hub and bearing assembly and

drive shaft cannot be separated after performing the above pro-

cedure.

6. Remove the drive shaft from the wheel hub and bearing assem- bly.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the wheel hub and bearing assembly,

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang do wn. Support the entire drive shaft.

1. Drive shaft 2. Cotter pin

WDIA0373E

SDIA1821E

Revision: May 2010 2011 Versa

Page 2652 of 3787

FAX-10

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

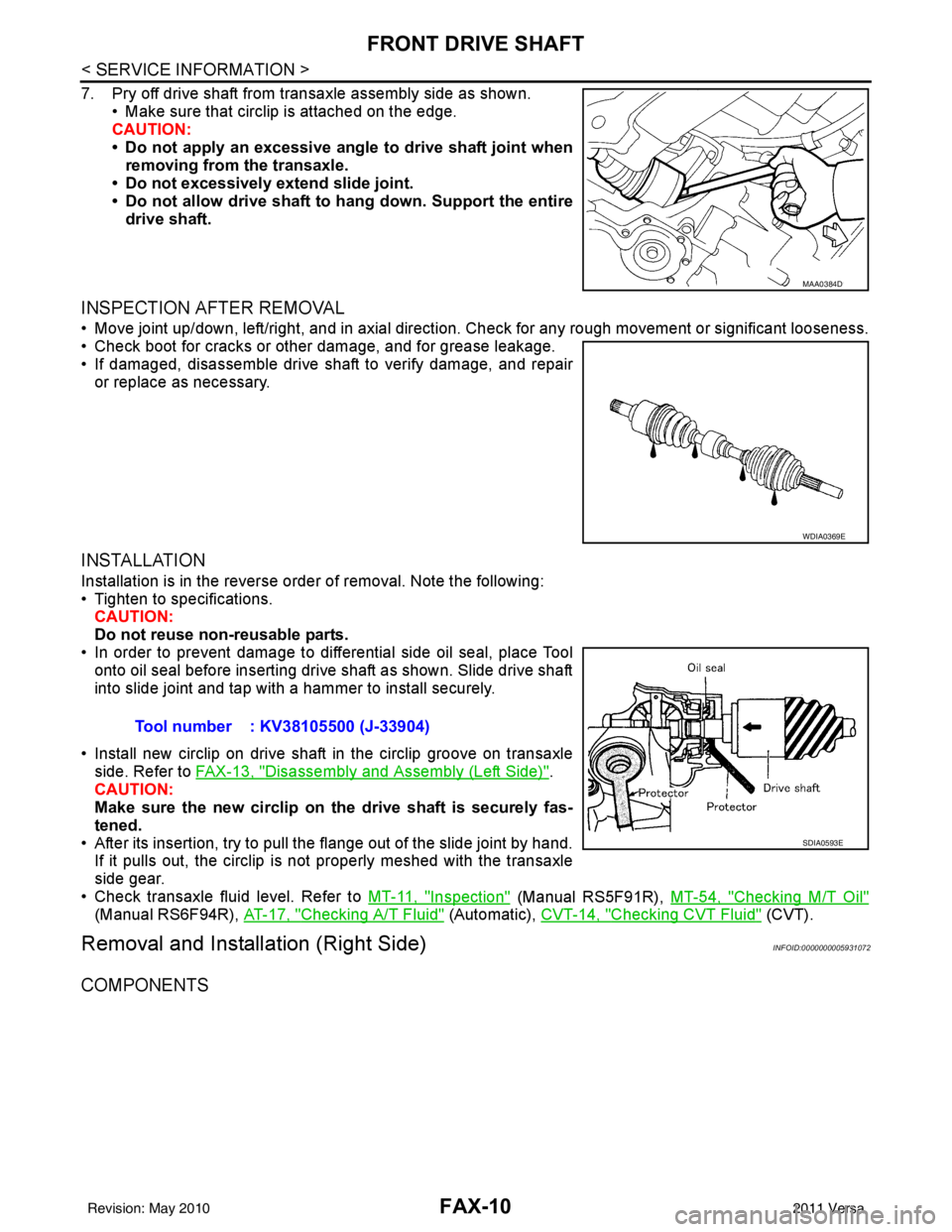

7. Pry off drive shaft from transaxle assembly side as shown.• Make sure that circlip is attached on the edge.

CAUTION:

• Do not apply an excessive angle to drive shaft joint when

removing from the transaxle.

• Do not excessively extend slide joint.

• Do not allow drive shaft to hang down. Support the entire

drive shaft.

INSPECTION AFTER REMOVAL

• Move joint up/down, left/right, and in axial direction. Check for any rough movement or significant looseness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary.

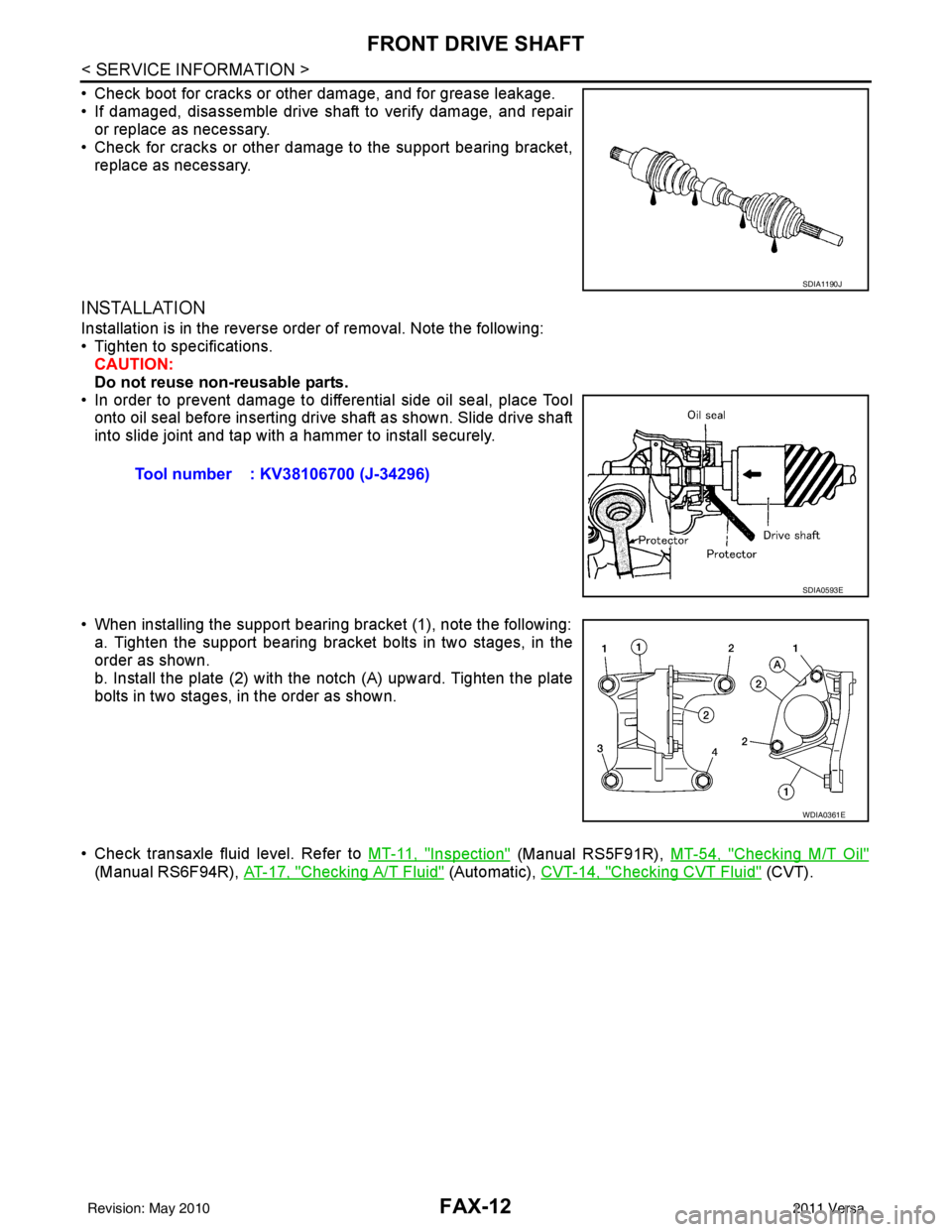

INSTALLATION

Installation is in the reverse order of removal. Note the following:

• Tighten to specifications.CAUTION:

Do not reuse non-reusable parts.

• In order to prevent damage to differential side oil seal, place Tool

onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

• Install new circlip on drive shaft in the circlip groove on transaxle side. Refer to FAX-13, "

Disassembly and Assembly (Left Side)".

CAUTION:

Make sure the new circlip on the drive shaft is securely fas-

tened.

• After its insertion, try to pull the flange out of the slide joint by hand. If it pulls out, the circlip is not properly meshed with the transaxle

side gear.

• Check transaxle fluid level. Refer to MT-11, "

Inspection" (Manual RS5F91R), MT-54, "Checking M/T Oil"

(Manual RS6F94R), AT-17, "Checking A/T Fluid" (Automatic), CVT-14, "Checking CVT Fluid" (CVT).

Removal and Installation (Right Side)INFOID:0000000005931072

COMPONENTS

MAA0384D

WDIA0369E

Tool number : KV38105500 (J-33904)

SDIA0593E

Revision: May 2010 2011 Versa

Page 2654 of 3787

FAX-12

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repairor replace as necessary.

• Check for cracks or other damage to the support bearing bracket, replace as necessary.

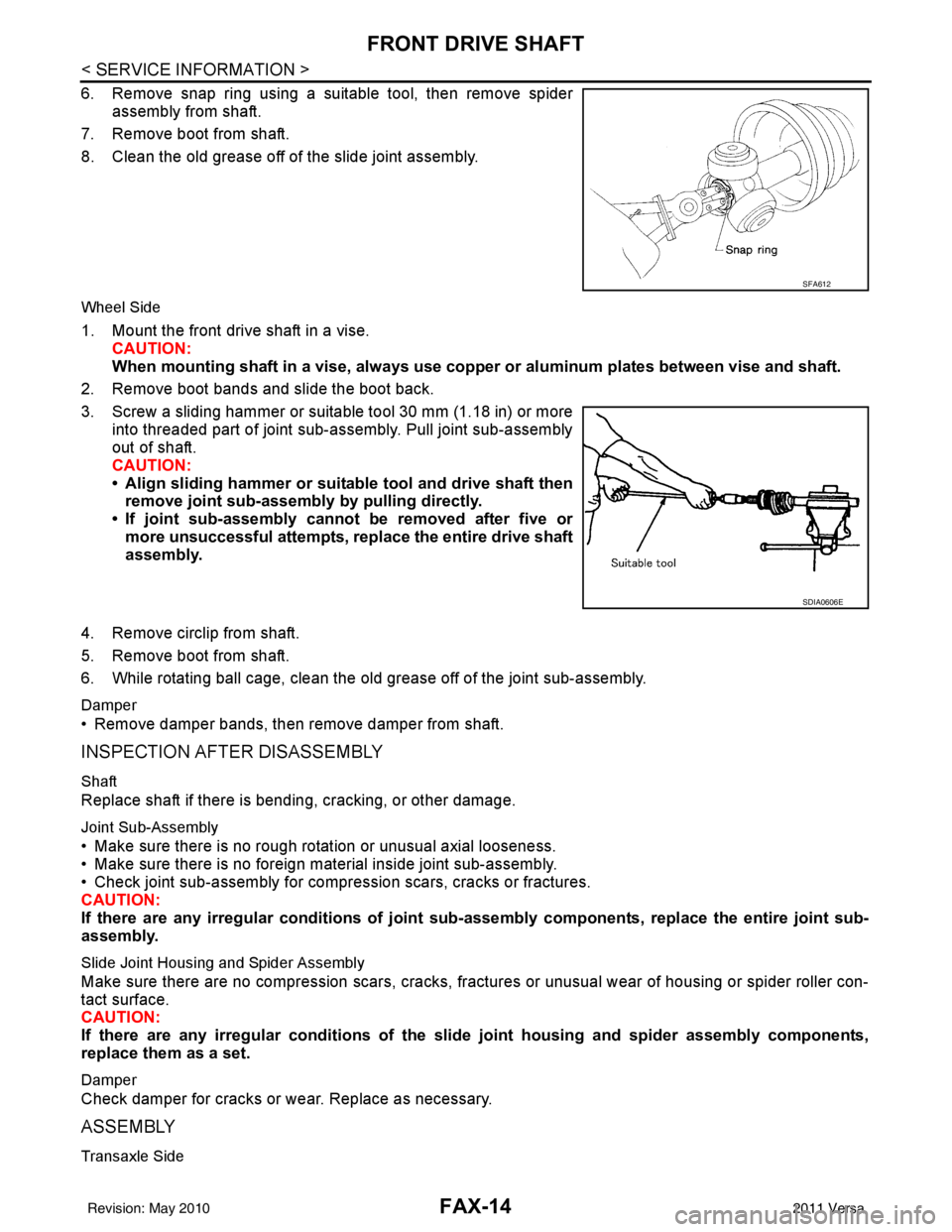

INSTALLATION

Installation is in the reverse order of removal. Note the following:

• Tighten to specifications.CAUTION:

Do not reuse non-reusable parts.

• In order to prevent damage to differential side oil seal, place Tool onto oil seal before inserting drive shaft as shown. Slide drive shaft

into slide joint and tap with a hammer to install securely.

• When installing the support bearing bracket (1), note the following: a. Tighten the support bearing bracket bolts in two stages, in the

order as shown.

b. Install the plate (2) with the notch (A) upward. Tighten the plate

bolts in two stages, in the order as shown.

• Check transaxle fluid level. Refer to MT-11, "

Inspection" (Manual RS5F91R), MT-54, "Checking M/T Oil"

(Manual RS6F94R), AT-17, "Checking A/T Fluid" (Automatic), CVT-14, "Checking CVT Fluid" (CVT).

SDIA1190J

Tool number : KV38106700 (J-34296)

SDIA0593E

WDIA0361E

Revision: May 2010 2011 Versa

Page 2655 of 3787

FRONT DRIVE SHAFTFAX-13

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

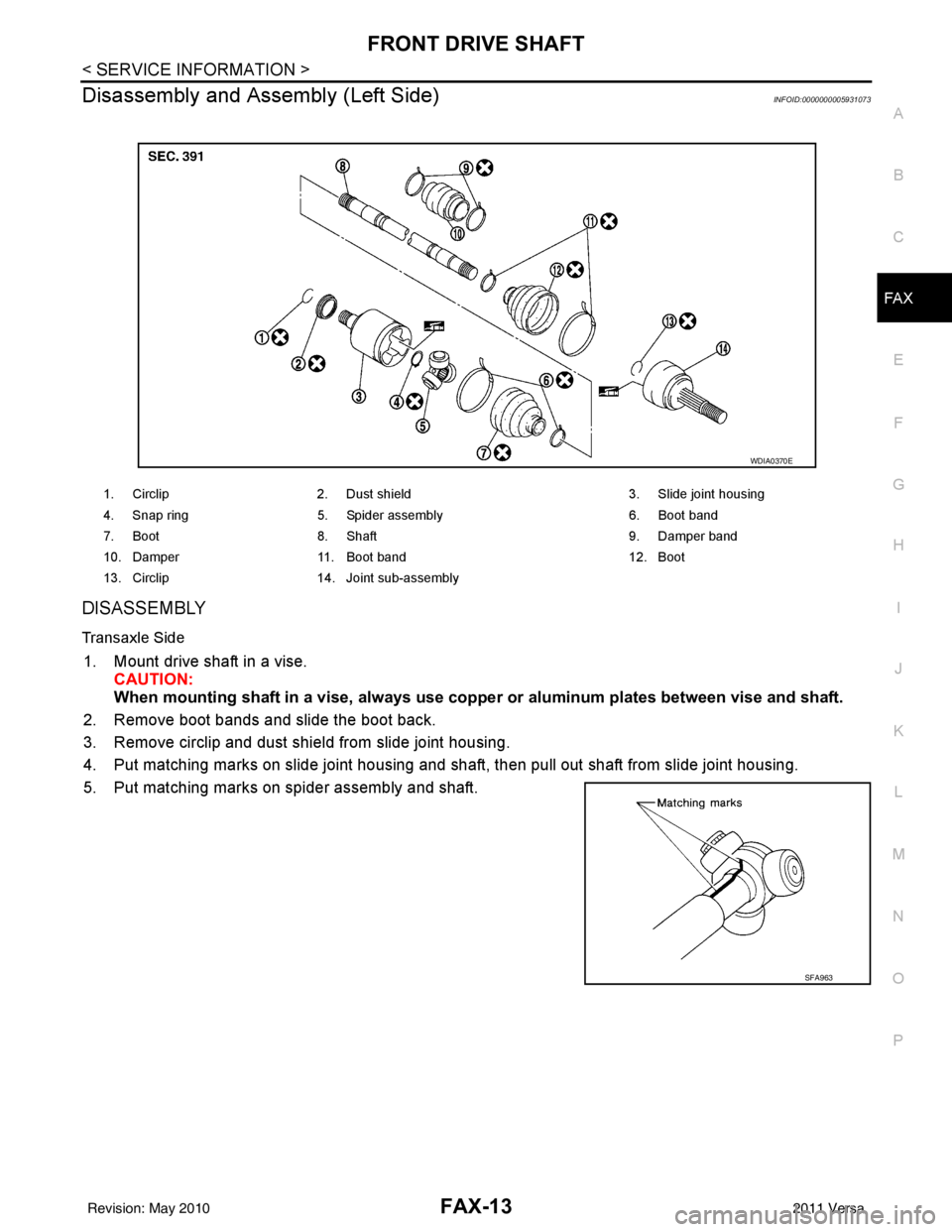

Disassembly and Assembly (Left Side)INFOID:0000000005931073

DISASSEMBLY

Transaxle Side

1. Mount drive shaft in a vise. CAUTION:

When mounting shaft in a vise, always use copper or alum inum plates between vise and shaft.

2. Remove boot bands and slide the boot back.

3. Remove circlip and dust shield from slide joint housing.

4. Put matching marks on slide joint housing and shaf t, then pull out shaft from slide joint housing.

5. Put matching marks on spider assembly and shaft.

1. Circlip 2. Dust shield 3. Slide joint housing

4. Snap ring 5. Spider assembly 6. Boot band

7. Boot 8. Shaft 9. Damper band

10. Damper 11. Boot band 12. Boot

13. Circlip 14. Joint sub-assembly

WDIA0370E

SFA963

Revision: May 2010 2011 Versa

Page 2656 of 3787

FAX-14

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

6. Remove snap ring using a suitable tool, then remove spiderassembly from shaft.

7. Remove boot from shaft.

8. Clean the old grease off of the slide joint assembly.

Wheel Side

1. Mount the front drive shaft in a vise. CAUTION:

When mounting shaf t in a vise, always use copper or al uminum plates between vise and shaft.

2. Remove boot bands and slide the boot back.

3. Screw a sliding hammer or suitable tool 30 mm (1.18 in) or more into threaded part of joint sub-assembly. Pull joint sub-assembly

out of shaft.

CAUTION:

• Align sliding hammer or suitab le tool and drive shaft then

remove joint sub-assembly by pulling directly.

• If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace the entire drive shaft

assembly.

4. Remove circlip from shaft.

5. Remove boot from shaft.

6. While rotating ball cage, clean the old grease off of the joint sub-assembly.

Damper

• Remove damper bands, then remove damper from shaft.

INSPECTION AFTER DISASSEMBLY

Shaft

Replace shaft if there is bending, cracking, or other damage.

Joint Sub-Assembly

• Make sure there is no rough rotation or unusual axial looseness.

• Make sure there is no foreign material inside joint sub-assembly.

• Check joint sub-assembly for compression scars, cracks or fractures.

CAUTION:

If there are any irregular condit ions of joint sub-assembly componen ts, replace the entire joint sub-

assembly.

Slide Joint Housing and Spider Assembly

Make sure there are no compression scars, cracks, fractures or unusual wear of housing or spider roller con-

tact surface.

CAUTION:

If there are any irregular conditions of the slide joint housing and spider assembly components,

replace them as a set.

Damper

Check damper for cracks or wear. Replace as necessary.

ASSEMBLY

Transaxle Side

SFA612

SDIA0606E

Revision: May 2010 2011 Versa

Page 2657 of 3787

FRONT DRIVE SHAFTFAX-15

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

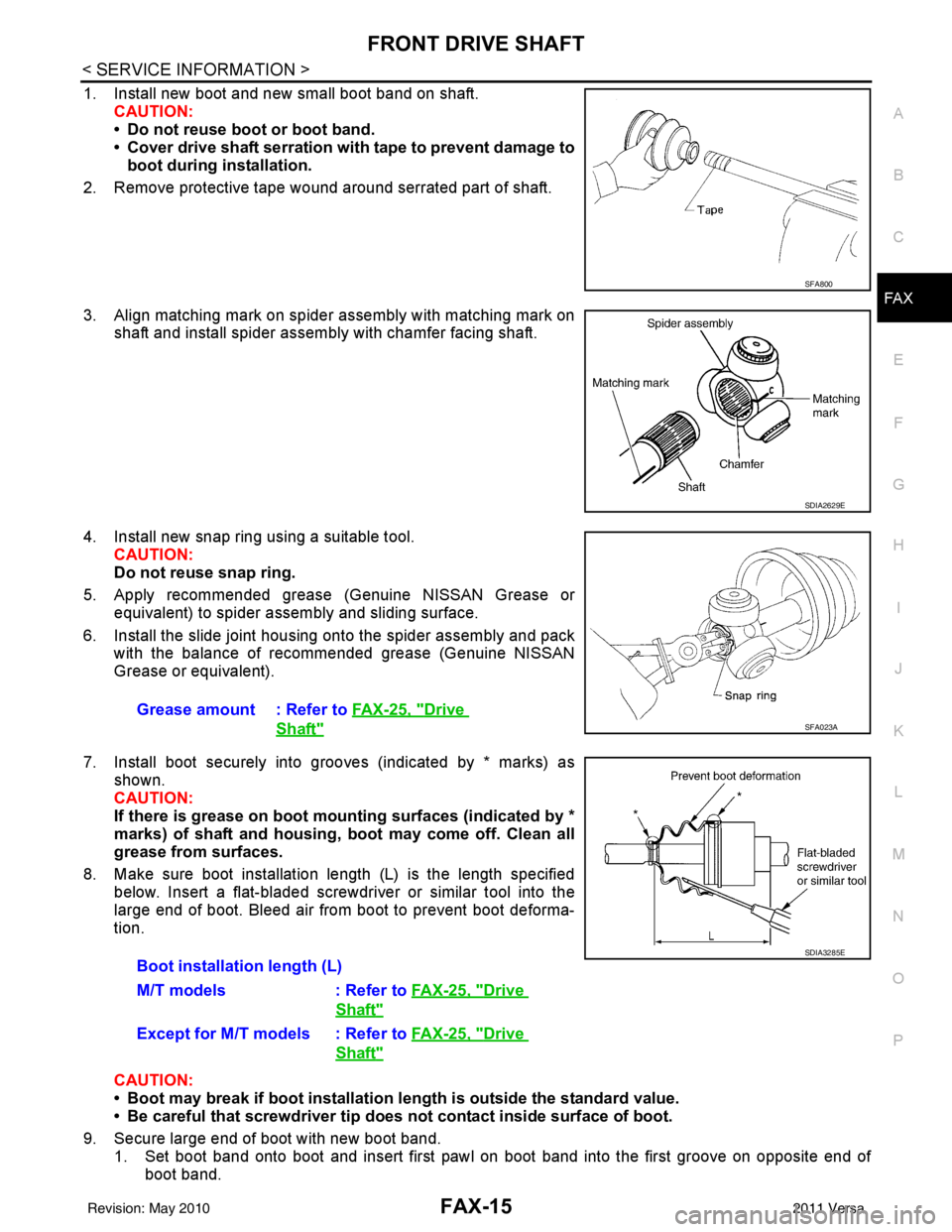

1. Install new boot and new small boot band on shaft. CAUTION:

• Do not reuse boot or boot band.

• Cover drive shaft serration with tape to prevent damage toboot during installation.

2. Remove protective tape wound around serrated part of shaft.

3. Align matching mark on spider assembly with matching mark on shaft and install spider assembly with chamfer facing shaft.

4. Install new snap ring using a suitable tool. CAUTION:

Do not reuse snap ring.

5. Apply recommended grease (Genuine NISSAN Grease or equivalent) to spider assembly and sliding surface.

6. Install the slide joint housing onto the spider assembly and pack with the balance of recommended grease (Genuine NISSAN

Grease or equivalent).

7. Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Clean all

grease from surfaces.

8. Make sure boot installation length (L) is the length specified below. Insert a flat-bladed screwdriver or similar tool into the

large end of boot. Bleed air from boot to prevent boot deforma-

tion.

CAUTION:

• Boot may break if boot installation le ngth is outside the standard value.

• Be careful that screwdriver tip does not contact inside surface of boot.

9. Secure large end of boot with new boot band. 1. Set boot band onto boot and insert first pawl on boot band into the first groove on opposite end of boot band.

SFA800

SDIA2629E

Grease amount : Refer to FAX-25, "Drive

Shaft" SFA023A

Boot installation length (L)

M/T models : Refer to FAX-25, "

Drive

Shaft"

Except for M/T models : Refer to FAX-25, "Drive

Shaft"

SDIA3285E

Revision: May 2010 2011 Versa

Page 2658 of 3787

FAX-16

< SERVICE INFORMATION >

FRONT DRIVE SHAFT

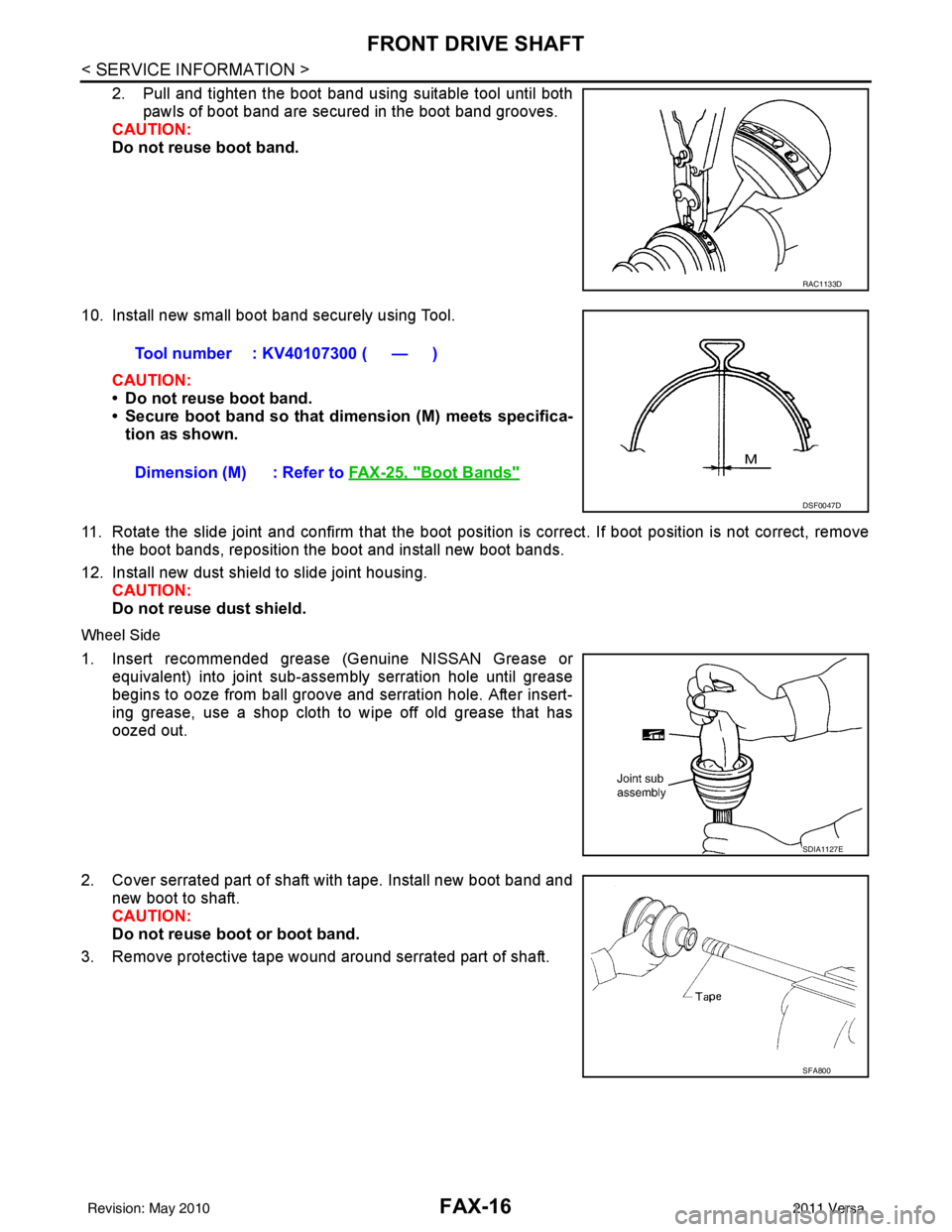

2. Pull and tighten the boot band using suitable tool until bothpawls of boot band are secured in the boot band grooves.

CAUTION:

Do not reuse boot band.

10. Install new small boot band securely using Tool. CAUTION:

• Do not reuse boot band.

• Secure boot band so that dimension (M) meets specifica-

tion as shown.

11. Rotate the slide joint and confirm that the boot posit ion is correct. If boot position is not correct, remove

the boot bands, reposition the boot and install new boot bands.

12. Install new dust shield to slide joint housing. CAUTION:

Do not reuse dust shield.

Wheel Side

1. Insert recommended grease (Genuine NISSAN Grease orequivalent) into joint sub-assembly serration hole until grease

begins to ooze from ball groove and serration hole. After insert-

ing grease, use a shop cloth to wipe off old grease that has

oozed out.

2. Cover serrated part of shaft with tape. Install new boot band and new boot to shaft.

CAUTION:

Do not reuse boot or boot band.

3. Remove protective tape wound around serrated part of shaft.

RAC1133D

Tool number : KV40107300 ( — )

Dimension (M) : Refer to FAX-25, "

Boot Bands"

DSF0047D

SDIA1127E

SFA800

Revision: May 2010 2011 Versa