heating NISSAN TIIDA 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1052 of 3787

![NISSAN TIIDA 2011 Service User Guide CO-52

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c

aught in the valves of water control

valve (1). Immerse fully in a container (B) fille NISSAN TIIDA 2011 Service User Guide CO-52

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c

aught in the valves of water control

valve (1). Immerse fully in a container (B) fille](/img/5/57396/w960_57396-1051.png)

CO-52

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Place a thread (A) so that it is c

aught in the valves of water control

valve (1). Immerse fully in a container (B) filled with water. Heat

while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open valve lift amount.

NOTE:

The full-open valve lift amount standard temperature for water con-

trol valve is the reference value.

• After checking the full-open valve lift amount, lower the water tem- perature and check the valve closing temperature.

• If out of the specification, replace water control valve.

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the water control valve.

- Install water control valve making sure rubber ring (1) groove fits

securely to water control valve flange (A).

CAUTION:

Replace the rubber ring with a new one.

- While the mark (A) points to up, install water control valve (2) with frame center (B) facing straight upward into water outlet (1).

• Use the following procedure to install the water outlet.

- Install the water outlet to the cylinder head without disp lacing the water control valve from the valve position.

• Use the following procedure to install the water hoses. Standard : Refer to

CO-55, "

Standard and Limit"

PBIC3314J

PBIC3317J

PBIC4700E

Revision: May 2010 2011 Versa

Page 1306 of 3787

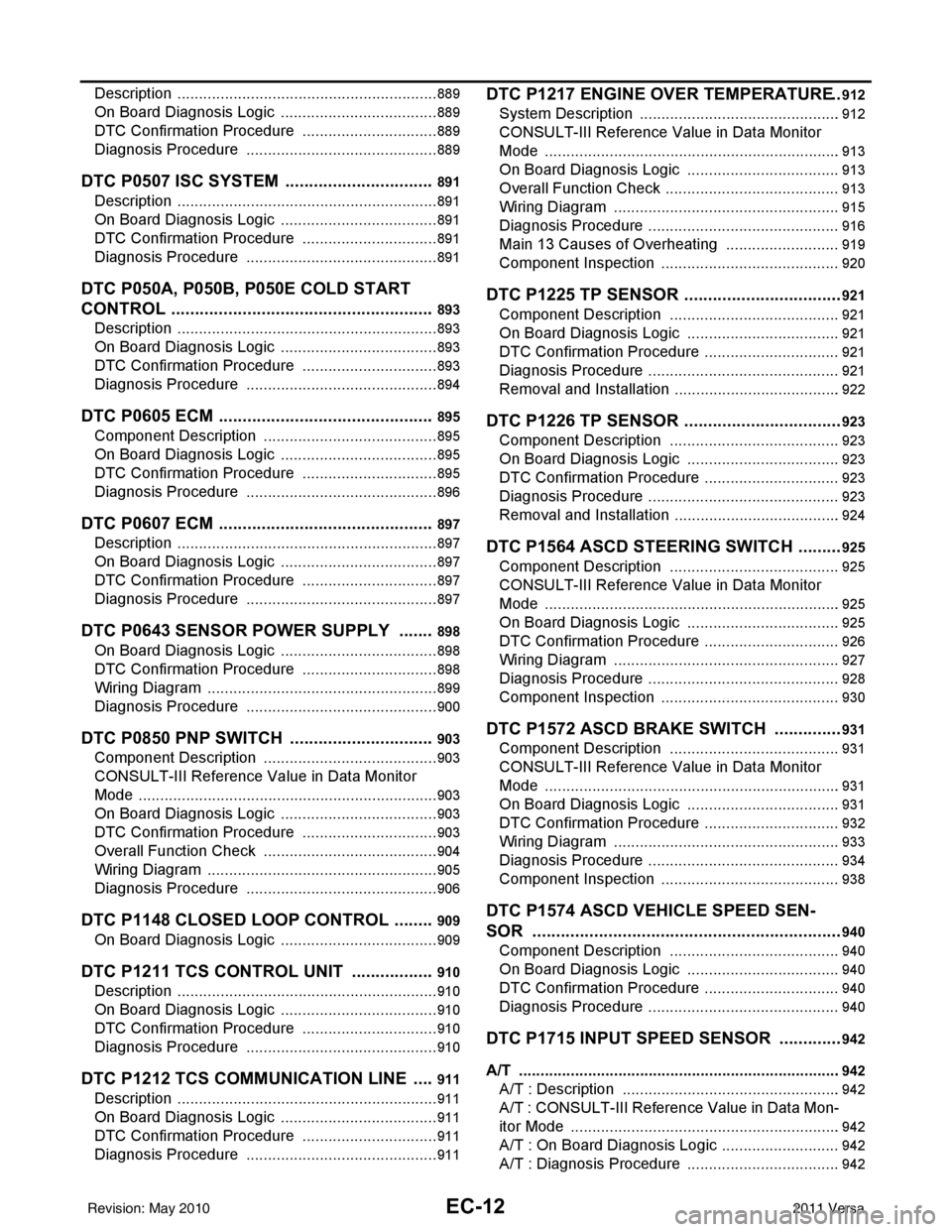

EC-12

Description .............................................................889

On Board Diagnosis Logic .....................................889

DTC Confirmation Procedure ................................889

Diagnosis Procedure .............................................889

DTC P0507 ISC SYSTEM ................................891

Description ........................................................... ..891

On Board Diagnosis Logic .....................................891

DTC Confirmation Procedure ................................891

Diagnosis Procedure .............................................891

DTC P050A, P050B, P050E COLD START

CONTROL ........................................................

893

Description ........................................................... ..893

On Board Diagnosis Logic .....................................893

DTC Confirmation Procedure ................................893

Diagnosis Procedure .............................................894

DTC P0605 ECM ..............................................895

Component Description ....................................... ..895

On Board Diagnosis Logic .....................................895

DTC Confirmation Procedure ................................895

Diagnosis Procedure .............................................896

DTC P0607 ECM ..............................................897

Description ........................................................... ..897

On Board Diagnosis Logic .....................................897

DTC Confirmation Procedure ................................897

Diagnosis Procedure .............................................897

DTC P0643 SENSOR POWER SUPPLY ........898

On Board Diagnosis Logic ................................... ..898

DTC Confirmation Procedure ................................898

Wiring Diagram ......................................................899

Diagnosis Procedure .............................................900

DTC P0850 PNP SWITCH ...............................903

Component Description ....................................... ..903

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

903

On Board Diagnosis Logic .....................................903

DTC Confirmation Procedure ................................903

Overall Function Check .........................................904

Wiring Diagram ......................................................905

Diagnosis Procedure .............................................906

DTC P1148 CLOSED LOOP CONTROL .........909

On Board Diagnosis Logic ................................... ..909

DTC P1211 TCS CONTROL UNIT ..................910

Description ........................................................... ..910

On Board Diagnosis Logic .....................................910

DTC Confirmation Procedure ................................910

Diagnosis Procedure .............................................910

DTC P1212 TCS COMMUNICATION LINE .....911

Description ........................................................... ..911

On Board Diagnosis Logic .....................................911

DTC Confirmation Procedure ................................911

Diagnosis Procedure .............................................911

DTC P1217 ENGINE OVER TEMPERATURE ..912

System Description .............................................. .912

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

913

On Board Diagnosis Logic ....................................913

Overall Function Check .........................................913

Wiring Diagram .....................................................915

Diagnosis Procedure .............................................916

Main 13 Causes of Overheating ...........................919

Component Inspection ..........................................920

DTC P1225 TP SENSOR ..................................921

Component Description ....................................... .921

On Board Diagnosis Logic ....................................921

DTC Confirmation Procedure ................................921

Diagnosis Procedure .............................................921

Removal and Installation .......................................922

DTC P1226 TP SENSOR ................................ ..923

Component Description ....................................... .923

On Board Diagnosis Logic ....................................923

DTC Confirmation Procedure ................................923

Diagnosis Procedure .............................................923

Removal and Installation .......................................924

DTC P1564 ASCD STEERING SWITCH ........ ..925

Component Description ....................................... .925

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

925

On Board Diagnosis Logic ....................................925

DTC Confirmation Procedure ................................926

Wiring Diagram .....................................................927

Diagnosis Procedure .............................................928

Component Inspection ..........................................930

DTC P1572 ASCD BRAKE SWITCH ...............931

Component Description ....................................... .931

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

931

On Board Diagnosis Logic ....................................931

DTC Confirmation Procedure ................................932

Wiring Diagram .....................................................933

Diagnosis Procedure .............................................934

Component Inspection ..........................................938

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

940

Component Description ....................................... .940

On Board Diagnosis Logic ....................................940

DTC Confirmation Procedure ................................940

Diagnosis Procedure .............................................940

DTC P1715 INPUT SPEED SENSOR ..............942

A/T .......................................................................... .942

A/T : Description ...................................................942

A/T : CONSULT-III Reference Value in Data Mon-

itor Mode ...............................................................

942

A/T : On Board Diagnosis Logic ............................942

A/T : Diagnosis Procedure ....................................942

Revision: May 2010 2011 Versa

Page 1463 of 3787

![NISSAN TIIDA 2011 Service User Guide P0116 ECT SENSOREC-169

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Soak the vehicle until the resistance between “fuel

level sensor unit and fuel pump” terminals 4 and 5

b NISSAN TIIDA 2011 Service User Guide P0116 ECT SENSOREC-169

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Soak the vehicle until the resistance between “fuel

level sensor unit and fuel pump” terminals 4 and 5

b](/img/5/57396/w960_57396-1462.png)

P0116 ECT SENSOREC-169

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Soak the vehicle until the resistance between “fuel

level sensor unit and fuel pump” terminals 4 and 5

becomes 0.5 k Ω higher than the value measured before soaking.

CAUTION:

Never turn ignition switch ON during the soaking time.

NOTE:

Soak time changes depending on ambient air temperature. It may take several hours.

6. Start engine and let it idle for 20 minutes.

7. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> EC-169, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000005929851

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connections E15, 24. Refer to EC-127, "

Ground Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-169, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "

Exploded View".

3.CHECK INTERMITTENT INCIDENT

Refer to EC-122, "

Diagnosis Procedure".

>> INSPECTION END

Component InspectionINFOID:0000000005929852

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine coolant temperature sensor harness connector.

3. Remove engine coolant temperature sensor.

4. Check resistance between engine coolant temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "

Exploded View".

Terminals ConditionResistance

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63 kΩ

50 (122) 0.68 - 1.00 k Ω

90 (194) 0.236 - 0.260 k Ω

PBIB2005E

Revision: May 2010 2011 Versa

Page 1467 of 3787

![NISSAN TIIDA 2011 Service User Guide P0117, P0118 ECT SENSOREC-173

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as show NISSAN TIIDA 2011 Service User Guide P0117, P0118 ECT SENSOREC-173

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as show](/img/5/57396/w960_57396-1466.png)

P0117, P0118 ECT SENSOREC-173

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "

Exploded View".

Terminals ConditionResistance

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63 kΩ

50 (122) 0.68 - 1.00 k Ω

90 (194) 0.236 - 0.260 k Ω

PBIB2005E

Revision: May 2010 2011 Versa

Page 1474 of 3787

![NISSAN TIIDA 2011 Service User Guide EC-180

< COMPONENT DIAGNOSIS >[HR16DE]

P0125 ECT SENSOR

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as shown in the figure.

Is the inspection resu NISSAN TIIDA 2011 Service User Guide EC-180

< COMPONENT DIAGNOSIS >[HR16DE]

P0125 ECT SENSOR

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as shown in the figure.

Is the inspection resu](/img/5/57396/w960_57396-1473.png)

EC-180

< COMPONENT DIAGNOSIS >[HR16DE]

P0125 ECT SENSOR

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "

Exploded View".

Terminals ConditionResistance

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63 k

Ω

50 (122) 0.68 - 1.00 kΩ

90 (194) 0.236 - 0.260 k Ω

PBIB2005E

Revision: May 2010 2011 Versa

Page 1478 of 3787

![NISSAN TIIDA 2011 Service User Guide EC-184

< COMPONENT DIAGNOSIS >[HR16DE]

P0128 THERMOSTAT FUNCTION

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine coolant temperature sensor. Refer to

CO-24, "

Exploded View".

2. NISSAN TIIDA 2011 Service User Guide EC-184

< COMPONENT DIAGNOSIS >[HR16DE]

P0128 THERMOSTAT FUNCTION

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine coolant temperature sensor. Refer to

CO-24, "

Exploded View".

2.](/img/5/57396/w960_57396-1477.png)

EC-184

< COMPONENT DIAGNOSIS >[HR16DE]

P0128 THERMOSTAT FUNCTION

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine coolant temperature sensor. Refer to

CO-24, "

Exploded View".

2.CHECK THERMOSTAT

Refer to CO-23, "

Inspection".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace thermostat. Refer to CO-22, "

Removal and Installation".

Component InspectionINFOID:0000000006141197

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine coolant temperature sensor harness connector.

3. Remove engine coolant temperature sensor.

4. Check resistance between engine coolant temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "

Exploded View".

Terminals ConditionResistance

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63 k

Ω

50 (122) 0.68 - 1.00 kΩ

90 (194) 0.236 - 0.260 k Ω

PBIB2005E

Revision: May 2010 2011 Versa

Page 1542 of 3787

![NISSAN TIIDA 2011 Service User Guide EC-248

< COMPONENT DIAGNOSIS >[HR16DE]

P0181 FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000005929920

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect � NISSAN TIIDA 2011 Service User Guide EC-248

< COMPONENT DIAGNOSIS >[HR16DE]

P0181 FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000005929920

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect �](/img/5/57396/w960_57396-1541.png)

EC-248

< COMPONENT DIAGNOSIS >[HR16DE]

P0181 FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000005929920

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor uni t and fuel pump” harness connector.

3. Remove fuel level sensor unit.

4. Check resistance between “fuel level sensor unit and fuel pump”

terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace “fuel level sensor unit, fuel filter and fuel pump assembly”. Refer to FL-6, "

Component".

Terminals Condition Resistance

4 and 5 Temperature [ °C ( °F)] 20 (68) 2.3 - 2.7 k

Ω

50 (122) 0.79 - 0.90 kΩ

PBIB0931E

Revision: May 2010 2011 Versa

Page 1546 of 3787

![NISSAN TIIDA 2011 Service User Guide EC-252

< COMPONENT DIAGNOSIS >[HR16DE]

P0182, P0183

FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000006141114

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disco NISSAN TIIDA 2011 Service User Guide EC-252

< COMPONENT DIAGNOSIS >[HR16DE]

P0182, P0183

FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000006141114

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disco](/img/5/57396/w960_57396-1545.png)

EC-252

< COMPONENT DIAGNOSIS >[HR16DE]

P0182, P0183

FTT SENSOR

>> INSPECTION END

Component InspectionINFOID:0000000006141114

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor uni t and fuel pump” harness connector.

3. Remove fuel level sensor unit.

4. Check resistance between “fuel level sensor unit and fuel pump”

terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace “fuel level sensor unit, fuel filter and fuel pump assembly”. Refer to FL-6, "

Component".

Terminals Condition Resistance

4 and 5 Temperature [ °C ( °F)] 20 (68) 2.3 - 2.7 k

Ω

50 (122) 0.79 - 0.90 kΩ

PBIB0931E

Revision: May 2010 2011 Versa

Page 1551 of 3787

![NISSAN TIIDA 2011 Service User Guide P0300, P0301, P0302, P0303, P0304 MISFIRE

EC-257

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304 MISFIRE

DTC LogicINFOID:0000000005929932

DTC DETECTI NISSAN TIIDA 2011 Service User Guide P0300, P0301, P0302, P0303, P0304 MISFIRE

EC-257

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304 MISFIRE

DTC LogicINFOID:0000000005929932

DTC DETECTI](/img/5/57396/w960_57396-1550.png)

P0300, P0301, P0302, P0303, P0304 MISFIRE

EC-257

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304 MISFIRE

DTC LogicINFOID:0000000005929932

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates

enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and let it idle for about 15 minutes.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-258, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Turn ignition switch OFF and wait at least 10 seconds.

Sensor Input signal to ECM ECM function

Crankshaft position sensor (POS) Engine speedOn board diagnosis of misfire

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300 Multiple cylinder misfire detected Multiple cylinders misfire. • Improper spark plug • Insufficient compression

• Incorrect fuel pressure

• The fuel injector circuit is open or shorted

• Fuel injector

• Intake air leak

• The ignition signal circuit is open or shorted

• Lack of fuel

• Signal plate

• A/F sensor 1

• Incorrect PCV hose connection

P0301 No.1 cylinder misfire detected No. 1 cylinder misfires.

P0302 No. 2 cylinder misfire detected No. 2 cylinder misfires.

P0303 No. 3 cylinder misfire detected No. 3 cylinder misfires.

P0304 No. 4 cylinder misfire detected No. 4 cylinder misfires.

Revision: May 2010

2011 Versa

Page 1674 of 3787

![NISSAN TIIDA 2011 Service User Guide EC-380

< COMPONENT DIAGNOSIS >[HR16DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000005930052

ECM controls ignition timing and engine idle speed when engine is started wi NISSAN TIIDA 2011 Service User Guide EC-380

< COMPONENT DIAGNOSIS >[HR16DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000005930052

ECM controls ignition timing and engine idle speed when engine is started wi](/img/5/57396/w960_57396-1673.png)

EC-380

< COMPONENT DIAGNOSIS >[HR16DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000005930052

ECM controls ignition timing and engine idle speed when engine is started with pre-warming up condition.

This control promotes the activation of three way catalyst by heating the catalyst and reduces emissions.

DTC LogicINFOID:0000000005930053

DTC DETECTION LOGIC

NOTE:

If DTC P1421 is displayed with ot

her DTC, first perform the trouble diagnosis for other DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Check that the “COOLAN TEMP/S” indication is between 5 °C (41 °F) and 36 °C (97° F) (A/T) or 15 °C

(59 °F) and 36 °C (97° F) (M/T).

If “COOLAN TEMP/S” indication is within the specified value, go to the following step.

If “COOLAN TEMP/S” indication is out of the specified value, cool engine down or warm engine up and go

to step 1.

5. Start engine and let it idle for 5 minutes.

6. Check 1st trip DTC.

With GST

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected?

YES >> Go to EC-380, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000005930054

1.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-26, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 2.

NO >> Follow the instruction of Idle Air Volume Learning.

2.CHECK INTAKE SYSTEM

Check for the cause of intake air volume lacking. Refer to the following.

• Crushed intake air passage

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P1421 Cold start emission reduction

strategy monitoring ECM does not control ignition timing and engine

idle speed properly when engine is started with

pre-warming up condition. • Lack of intake air volume

• Fuel injection system

•ECM

Revision: May 2010

2011 Versa