system NISSAN TIIDA 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 25 of 3787

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000005928065

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure th e harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000005928066

•Before connecting or disconn ecting the TCM harness connec-

tor, turn ignition switch OF F and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

• When connecting or disconnect ing pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

• Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-75, "

TCM Terminal and Reference Value".)

• After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displ ayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could in terfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or reassembly.

SEF289H

AAT470A

MEF040DA

Revision: May 2010 2011 Versa

Page 26 of 3787

PRECAUTIONSAT-9

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• Gaskets, seals and O-rings should be replaced any time the A/T is disassembled.

• It is very important to perform func tional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and seals, or hold bearings and washers in pl ace during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-

18, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-17, "

Changing A/T Fluid", AT-17, "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000005928067

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to CO-16, "

Removal and Installation" (HR16DE engine models), CO-

40, "Removal and Installation" (MR18DE engine models).

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engi ne coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in flui d filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The e xception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-82, "

Diagnosis Procedure without CONSULT-III" for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo- ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-39, "

OBD-II Diagnostic Trouble Code

(DTC)" to complete the repair and avoid unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected us ing ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

- Transmission range switch

- A/T 1GR, 2GR, 3GR, or 4GR function

Revision: May 2010 2011 Versa

Page 27 of 3787

AT-10

< SERVICE INFORMATION >

PRECAUTIONS

*: For details of OBD-II, refer to AT- 3 9.

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector.

For description and how to disconnect, refer to PG-65

.

Revision: May 2010 2011 Versa

Page 38 of 3787

A/T CONTROL SYSTEMAT-21

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

A/T CONTROL SYSTEM

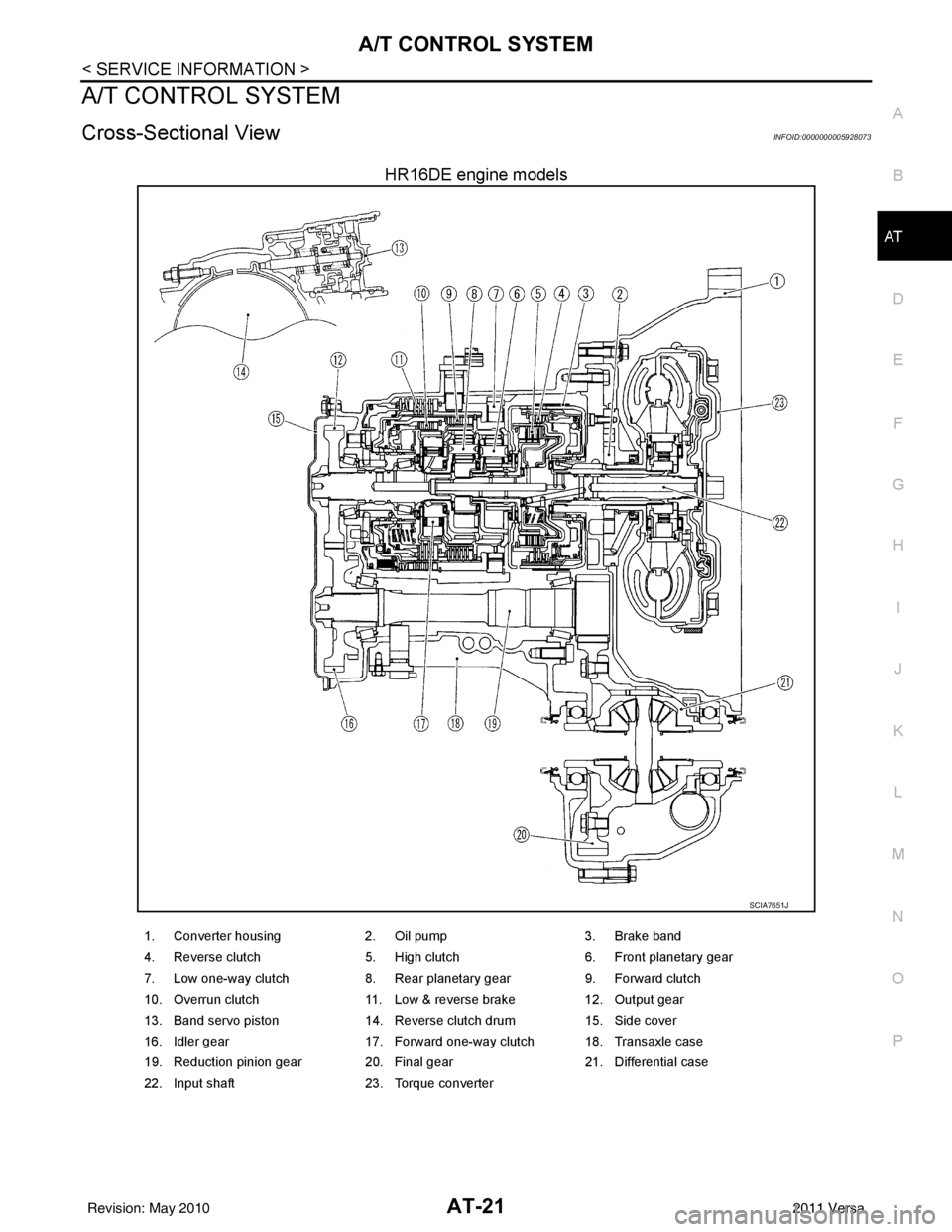

Cross-Sectional ViewINFOID:0000000005928073

HR16DE engine models

SCIA7651J

1. Converter housing 2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear 21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 39 of 3787

AT-22

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

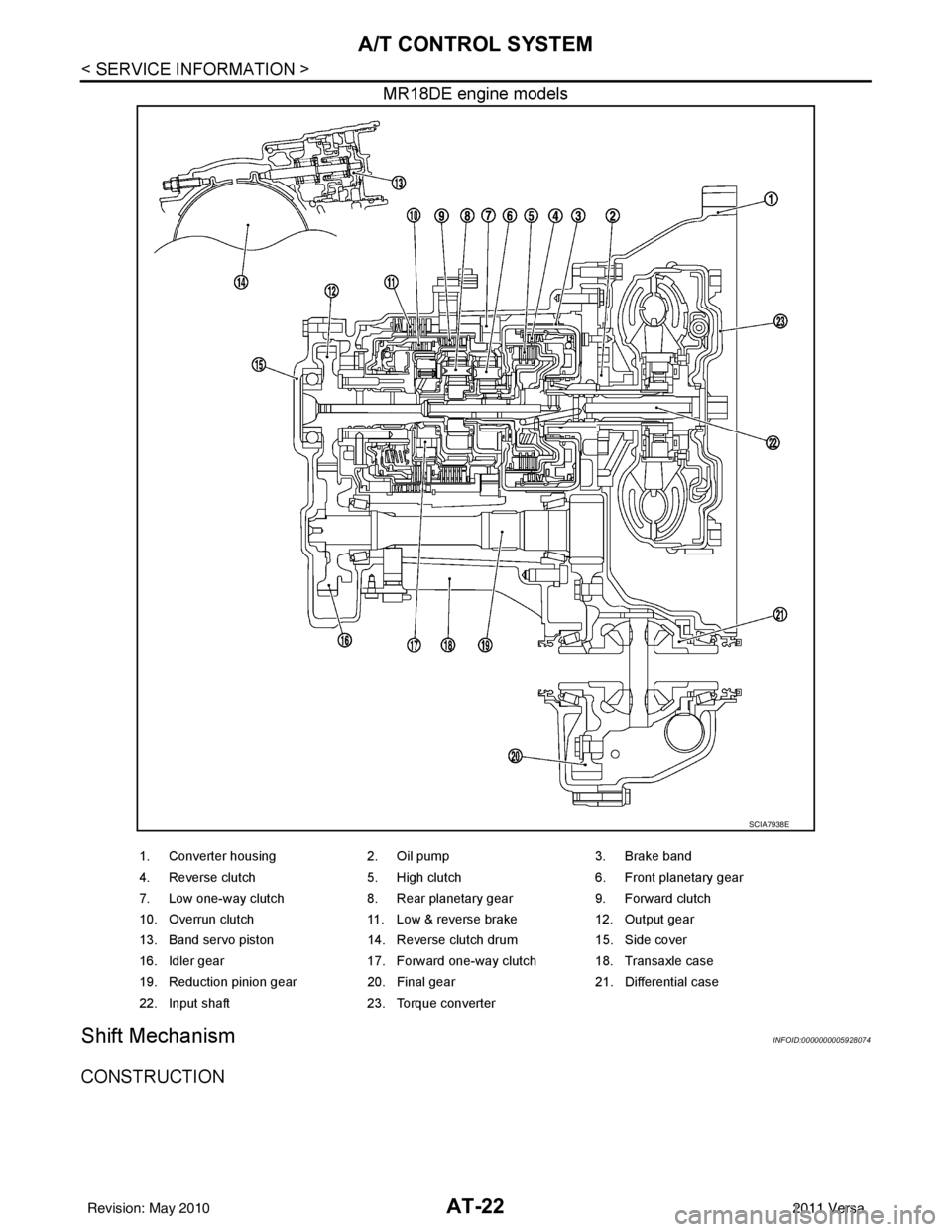

MR18DE engine models

Shift MechanismINFOID:0000000005928074

CONSTRUCTION

SCIA7938E

1. Converter housing2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 40 of 3787

A/T CONTROL SYSTEMAT-23

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

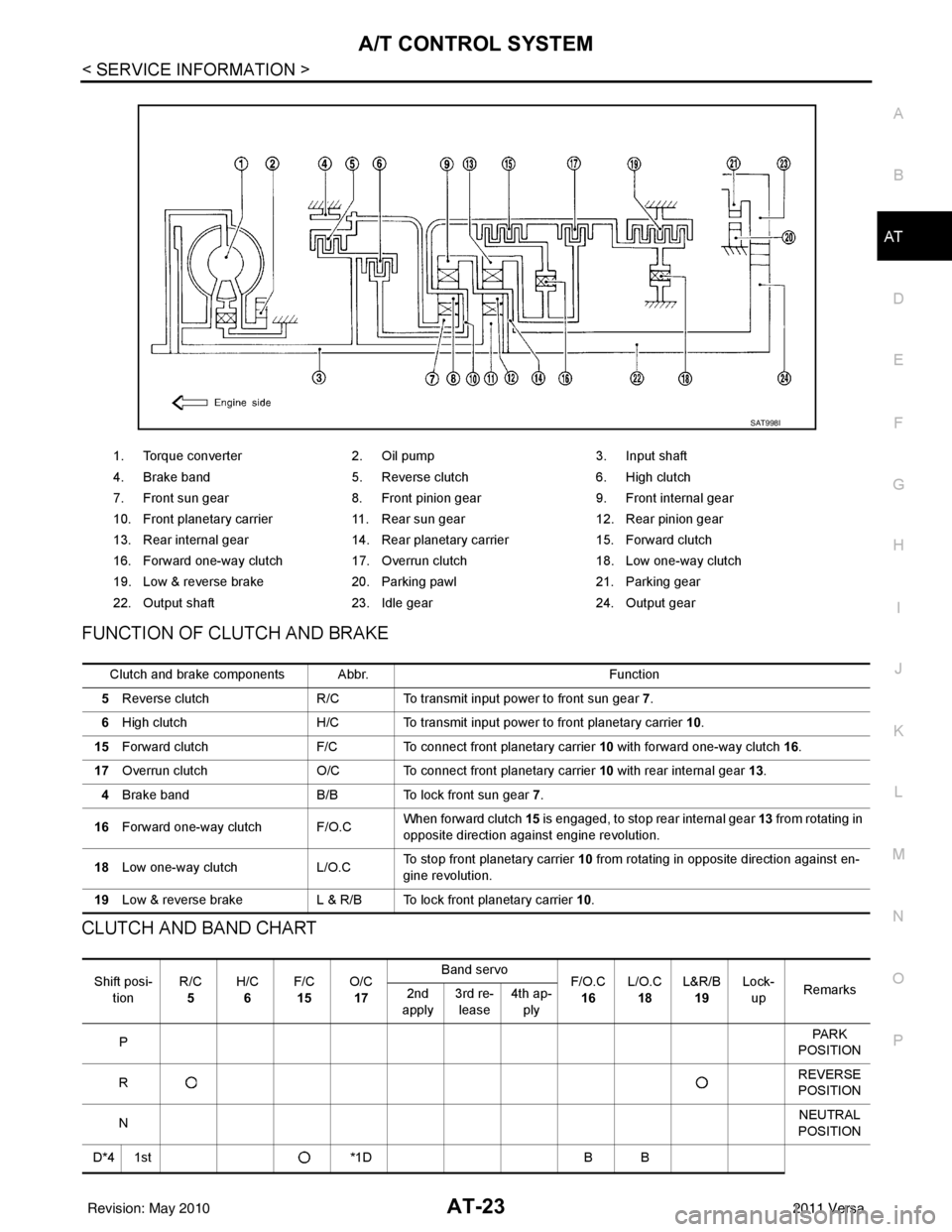

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5 Reverse clutch R/C To transmit input power to front sun gear 7 .

6 High clutch H/C To transmit input power to front planetary carrier 10.

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13 .

4 Brake band B/B To lock front sun gear 7.

16 Forward one-way clutch F/O.C When forward clutch 15

is engaged, to stop rear internal gear 13 from rotating in

opposite direction against engine revolution.

18 Low one-way clutch L/O.CTo stop front planetary carrier

10 from rotating in opposite direction against en-

gine revolution.

19 Low & reverse brake L & R/B To lock front planetary carrier 10.

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

P PA R K

POSITION

R REVERSE

POSITION

N NEUTRAL

POSITION

D*4 1st *1DB B

Revision: May 2010 2011 Versa

Page 41 of 3787

AT-24

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

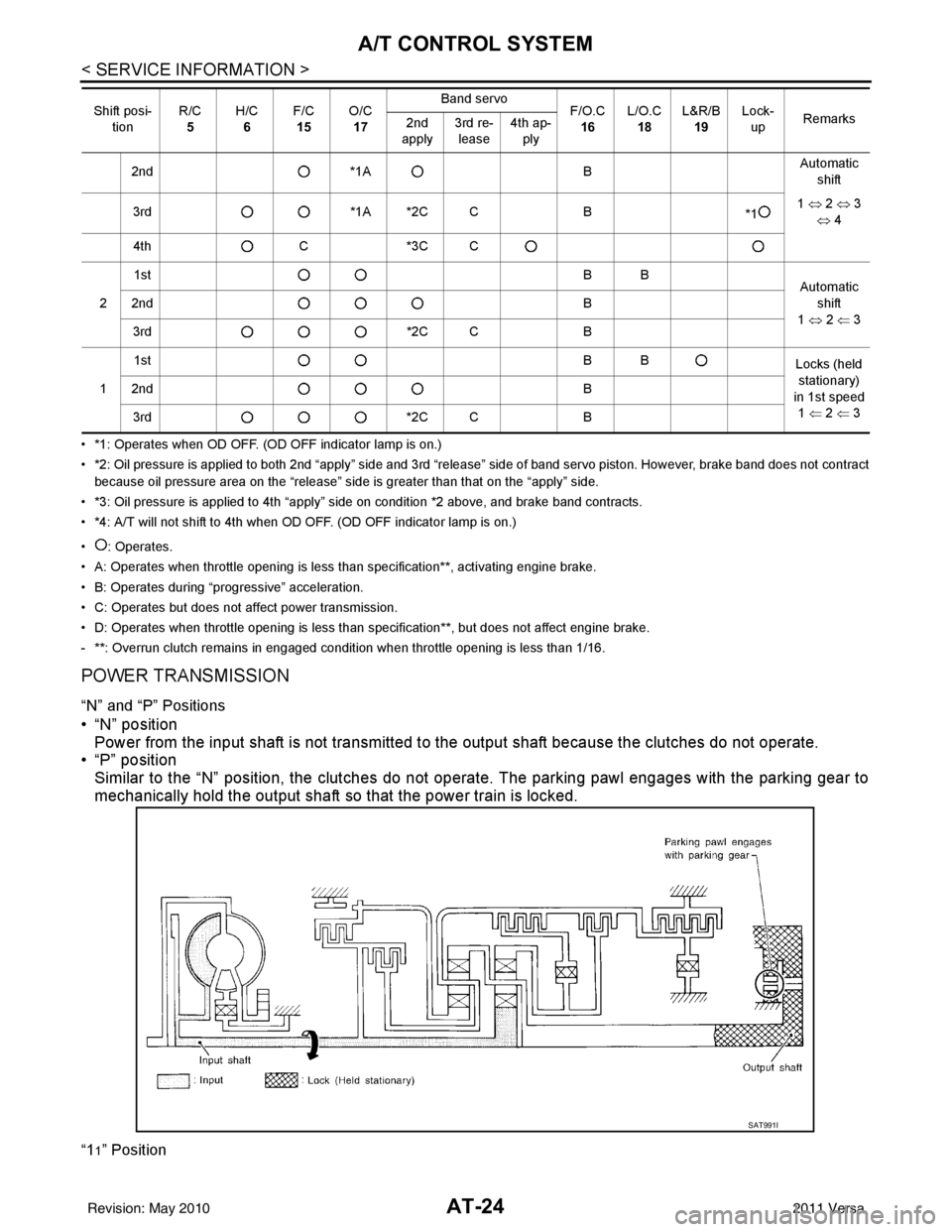

• *1: Operates when OD OFF. (OD OFF indicator lamp is on.)

• *2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

• *3: Oil pressure is applied to 4th “apply” side on condition *2 above, and brake band contracts.

• *4: A/T will not shift to 4th when OD OFF. (OD OFF indicator lamp is on.)

• : Operates.

• A: Operates when throttle opening is less than specification**, activating engine brake.

• B: Operates during “pro gressive” acceleration.

• C: Operates but does not affect power transmission.

• D: Operates when throttle opening is less than specification**, but does not affect engine brake.

- **: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

POWER TRANSMISSION

“N” and “P” Positions

• “N” position Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

• “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power train is locked.

“11” Position

2nd *1A BAutomatic

shift

3rd *1A *2C C B

*11

⇔ 2 ⇔ 3

⇔ 4

4th C*3C C

2 1st

BB

Automatic

shift

1 ⇔ 2 ⇐ 3

2nd

B

3rd *2C CB

1 1st

BB

Locks (held

stationary)

in 1st speed 1 ⇐ 2 ⇐ 3

2nd

B

3rd *2C CB

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

SAT991I

Revision: May 2010 2011 Versa

Page 42 of 3787

A/T CONTROL SYSTEMAT-25

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

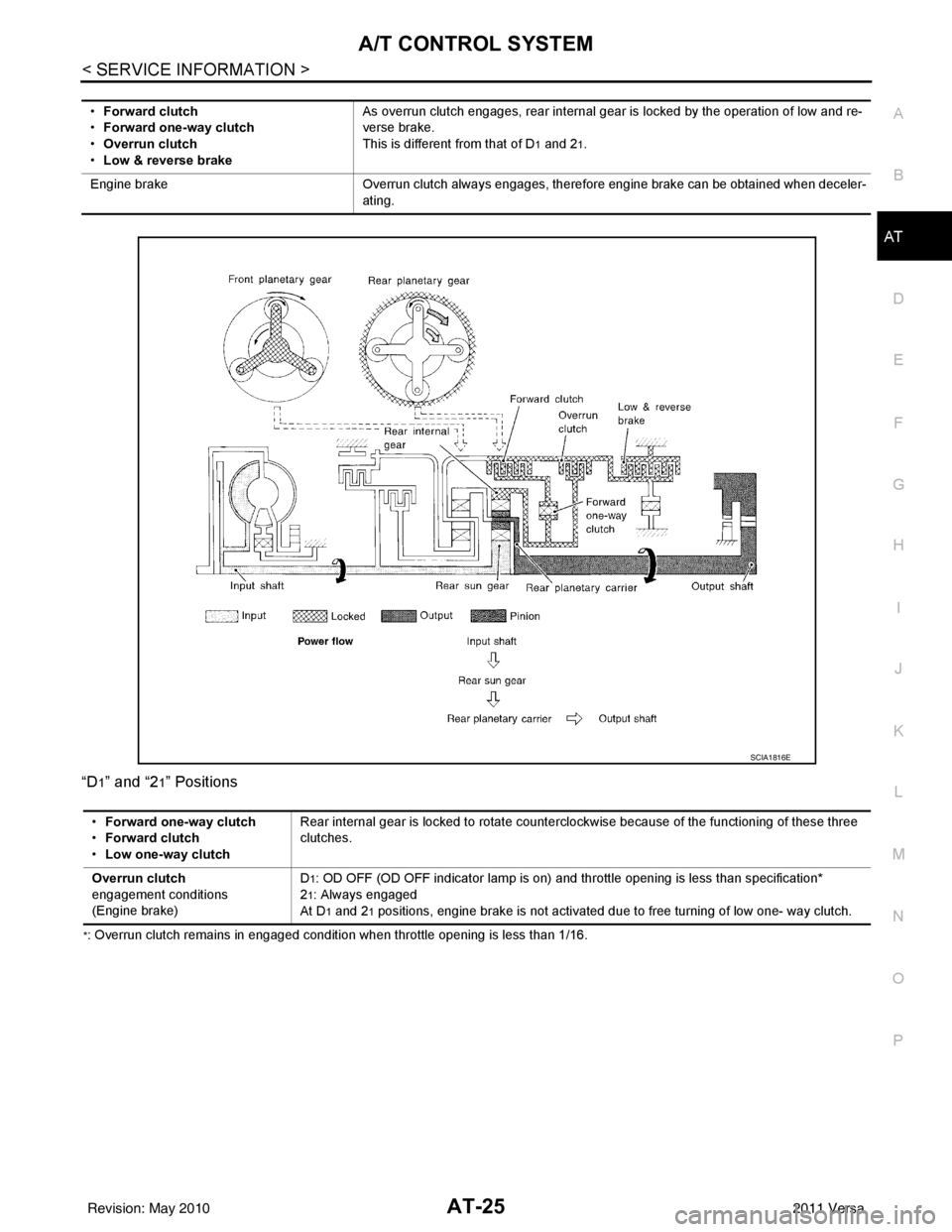

“D

1” and “21” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16. •

Forward clutch

• Forward one-way clutch

• Overrun clutch

• Low & reverse brake As overrun clutch engages, rear internal gear is locked by the operation of low and re-

verse brake.

This is different from that of D

1 and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SCIA1816E

• Forward one-way clutch

• Forward clutch

• Low one-way clutch Rear internal gear is locked to rotate counterclockwise because of the functioning of these three

clutches.

Overrun clutch

engagement conditions

(Engine brake) D

1: OD OFF (OD OFF indicator lamp is on) and th

rottle opening is less than specification*

2

1: Always engaged

At D

1 and 21 positions, engine brake is not activated due to free turning of low one- way clutch.

Revision: May 2010 2011 Versa

Page 43 of 3787

AT-26

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

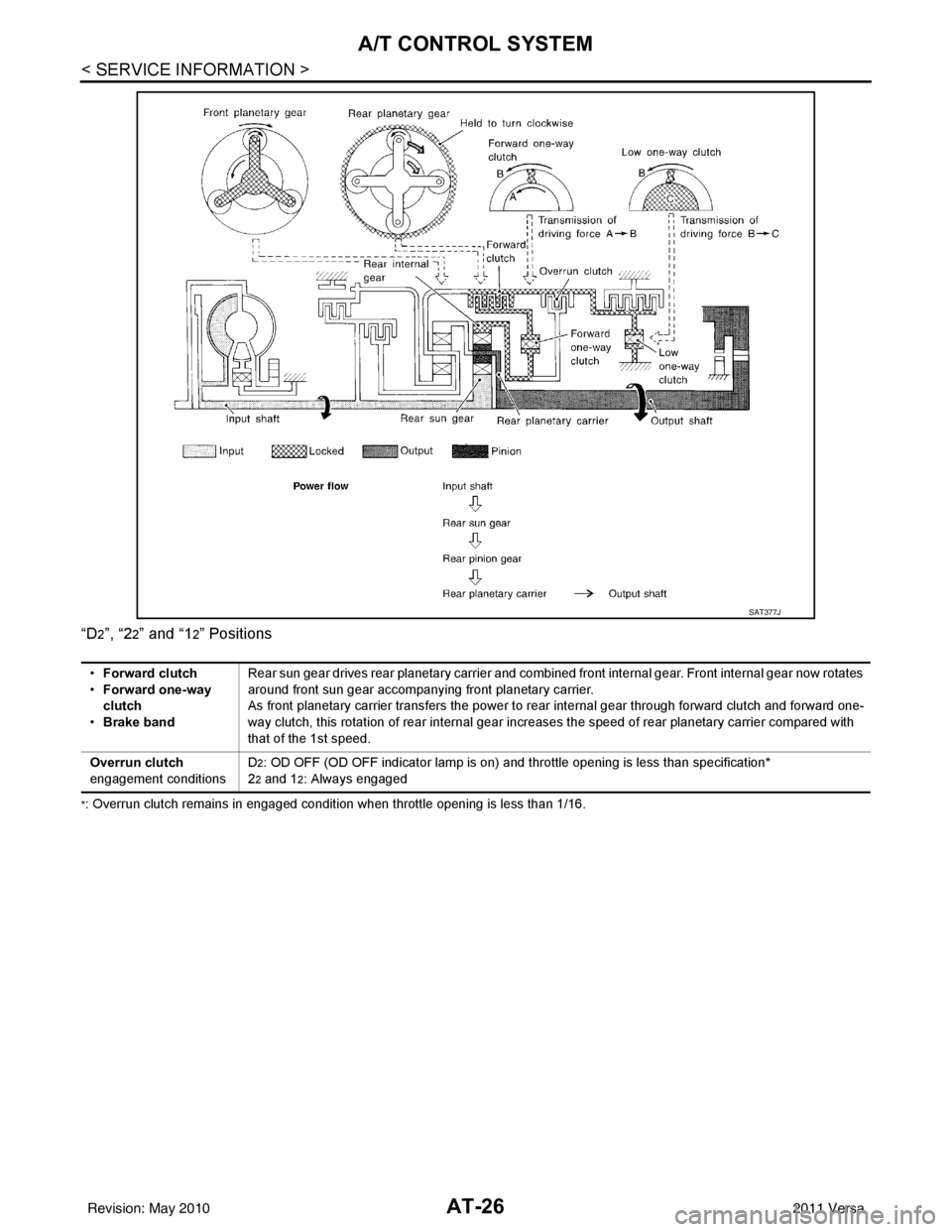

“D2”, “22” and “12” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

SAT377J

•Forward clutch

• Forward one-way

clutch

• Brake band Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates

around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward one-

way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with

that of the 1st speed.

Overrun clutch

engagement conditions D

2: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

2 and 12: Always engaged

Revision: May 2010 2011 Versa

Page 44 of 3787

A/T CONTROL SYSTEMAT-27

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

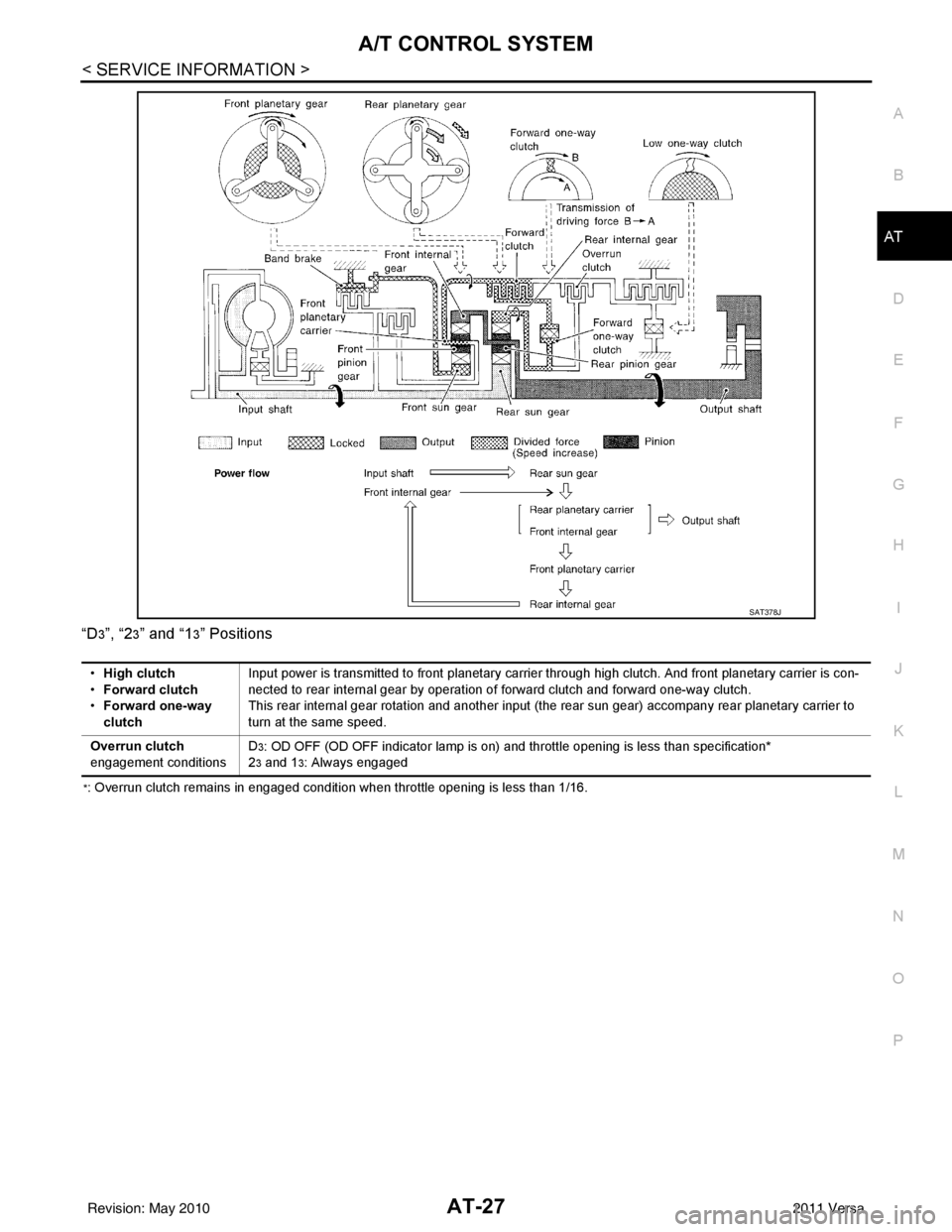

“D

3”, “23” and “13” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

SAT378J

•

High clutch

• Forward clutch

• Forward one-way

clutch Input power is transmitted to front planetary carrier through high clutch. And front planetary carrier is con-

nected to rear internal gear by operation of forward clutch and forward one-way clutch.

This rear internal gear rotation and another input (the rear sun gear) accompany rear planetary carrier to

turn at the same speed.

Overrun clutch

engagement conditions D

3: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

3 and 13: Always engaged

Revision: May 2010 2011 Versa