system NISSAN TIIDA 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 200 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-183

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> 1. Check transmission range switch (Refer to test group 1.) again after adjusting transmission

range switch (Refer to AT-225

).

- If OK, INSPECTION END

- If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch" .

3.CHECK STARTING SYSTEM

Check starting system. Refer to SC-9

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "P" Position, Vehicle Moves Forward or Backward When PushedINFOID:0000000005928249

SYMPTOM:

Vehicle moves when it is pushed forward or backward with selector lever in “P” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

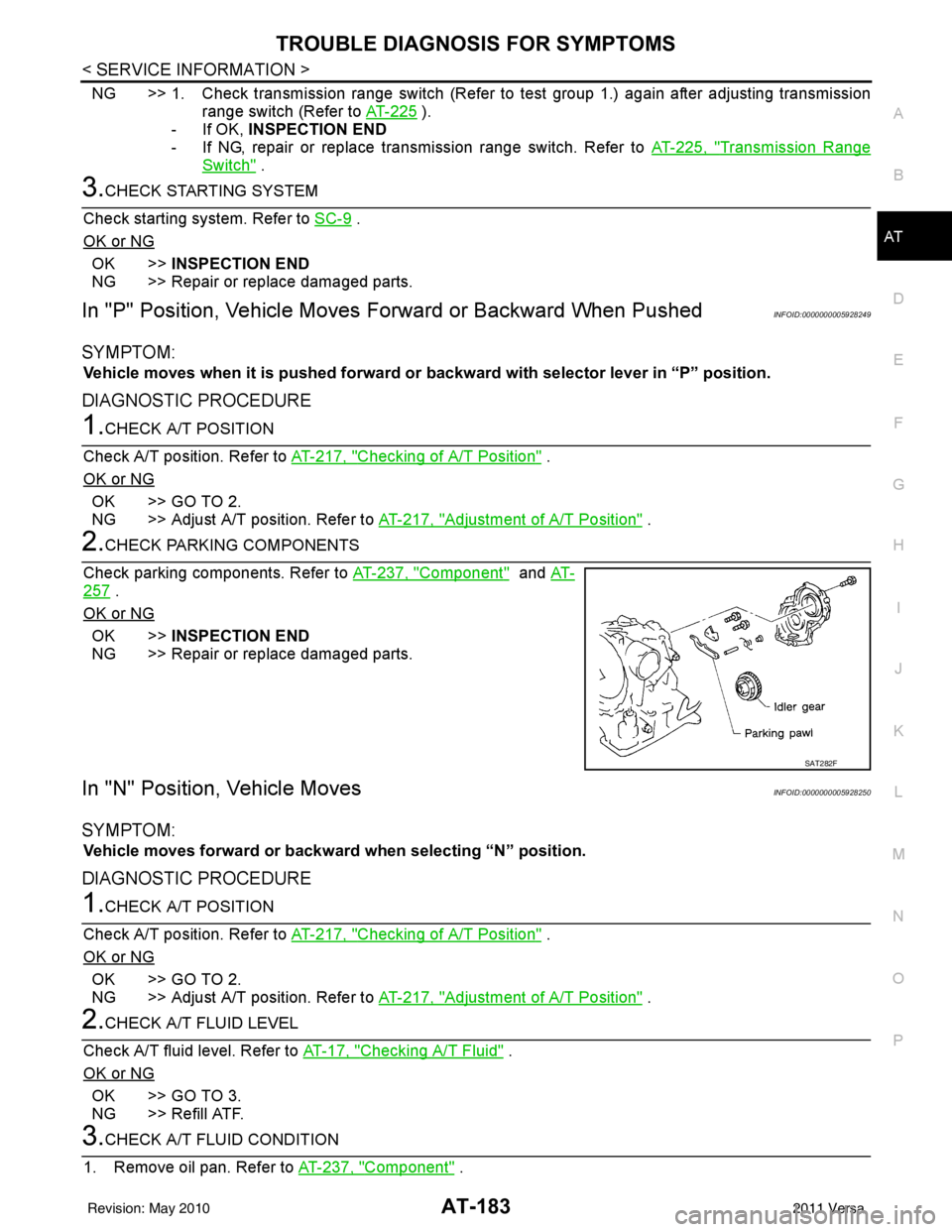

2.CHECK PARKING COMPONENTS

Check parking components. Refer to AT-237, "

Component" and AT-

257 .

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "N" Position, Vehicle MovesINFOID:0000000005928250

SYMPTOM:

Vehicle moves forward or backwar d when selecting “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-17, "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

SAT282F

Revision: May 2010 2011 Versa

Page 201 of 3787

AT-184

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2. Check A/T fluid condition. Refer to AT-51, "Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-257, "

Disassembly" .

2. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Reverse clutch assembly. Refer to AT-297, "

Reverse Clutch" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check at Idle" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Large Shock "N" → "R" PositionINFOID:0000000005928251

SYMPTOM:

There is a large shock when cha nging from “N” to “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trouble

Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- ter)

- Line pressure solenoid valve

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

Revision: May 2010 2011 Versa

Page 205 of 3787

AT-188

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-56, "

Check at Idle" .

Is

“Vehicle Dose Not Creep Backward in “R” Position” OK?

OK >> GO TO 2.

NG >> Go to AT-185, "

Vehicle Does Not Creep Backward in "R" Position" .

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor.

4.CHECK LINE PRESSURE

Check line pressure at stall point with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trou-

ble Diagnosis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift valve B

- Shift solenoid valve A

- Shift solenoid valve B

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Low one-way clutch. Refer to AT-257, "

Disassembly" .

- Forward one-way clutch. Refer to AT-318, "

Rear Internal Gear and Forward Clutch Hub" .

- High clutch assembly. Refer to AT-302, "

High Clutch" .

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

Revision: May 2010 2011 Versa

Page 209 of 3787

AT-192

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

- Shift solenoid valve B

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" and AT-61, "Cruise Test - Part 2" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 9.

9.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D3→ D4INFOID:0000000005928257

SYMPTOM:

•A/T does not shift from D3 to D4 at the specified speed on “Cruise Test — Part 1” and “Cruise Test

— Part 2”.

• A/T must be warm before D

3 to D4 shift will occur.

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-56, "

Check at Idle" and AT-58, "Cruise Test - Part 1" .

Are

“Vehicle Does Not Creep Forward in “D”, “2” or “1” Position” and “Vehicle Cannot Be Started from D1” OK?

YES >> GO TO 2.

NO >> Go to AT-186, "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" and AT-187, "Vehicle

Cannot Be Started from D1" .

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor.

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

Revision: May 2010 2011 Versa

Page 210 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-193

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Overrun clutch control valve

- Shift solenoid valve A

- Overrun clutch solenoid valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Servo piston assembly

- Brake band

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Overrun clutch control valve

- Shift solenoid valve A

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" and AT-61, "Cruise Test - Part 2" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Perform Lock-upINFOID:0000000005928258

SYMPTOM:

A/T does not perform lock-up at the specifi ed speed on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfuncti oning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

Revision: May 2010 2011 Versa

Page 211 of 3787

AT-194

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Torque converter relief valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Torque converter. Refer to AT-257, "

Disassembly" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

5.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Hold Lock-up ConditionINFOID:0000000005928259

SYMPTOM:

A/T does not hold lock-up condi tion for more than 30 seconds on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Revision: May 2010 2011 Versa

Page 212 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-195

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Lock-up Is Not ReleasedINFOID:0000000005928260

SYMPTOM:

Lock-up is not released when accelerator peda l is released on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfuncti oning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

Revision: May 2010 2011 Versa

Page 213 of 3787

AT-196

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000005928261

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

Revision: May 2010 2011 Versa

Page 223 of 3787

AT-206

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

DescriptionINFOID:0000000005928267

WITH INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock:With the ignition knob switch turned to ON, selector lever cannot be shifted from “P” position to any other

position unless brake pedal is depressed.

With the ignition knob switch turned to OFF, selector lever cannot be shifted from “P” position to any other

position.

• The shift lock and key interlock mechanisms are contro lled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the i gnition knob switch, respectively.

WITHOUT INTELLIGENT KEY

• The mechanical key interlock mechanism also operates as a shift lock:

With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are contro lled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside key cylinder, respectively.

Revision: May 2010 2011 Versa

Page 224 of 3787

A/T SHIFT LOCK SYSTEMAT-207

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

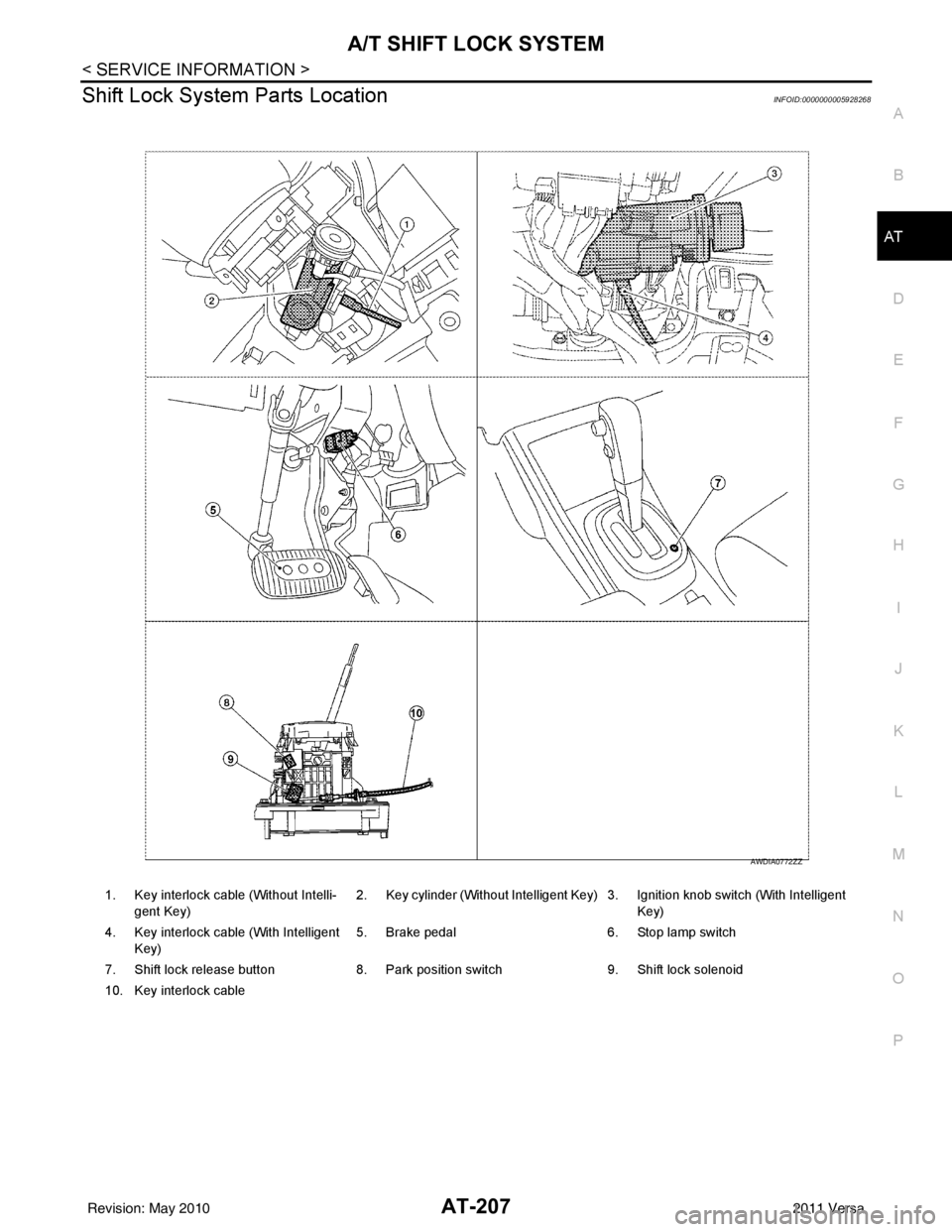

Shift Lock System Parts LocationINFOID:0000000005928268

1. Key interlock cable (Without Intelli- gent Key) 2. Key cylinder (Without Intelligent Key) 3. Ignition knob switch (With Intelligent

Key)

4. Key interlock cable (With Intelligent Key) 5. Brake pedal 6. Stop lamp switch

7. Shift lock release button 8. Park position switch9. Shift lock solenoid

10. Key interlock cable

AWDIA0772ZZ

Revision: May 2010 2011 Versa