system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 988 of 3787

CLUTCH PEDALCL-7

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

CL

N

O P

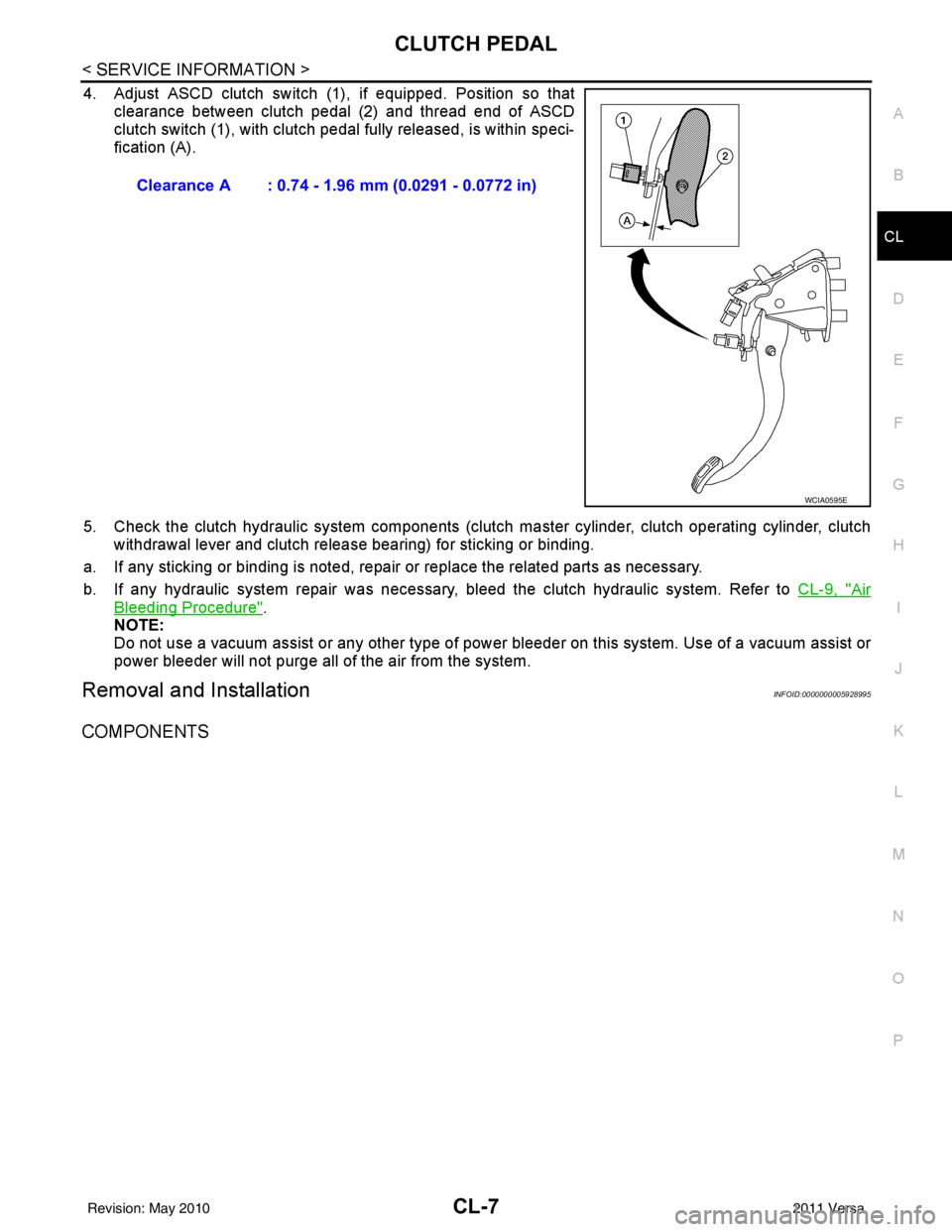

4. Adjust ASCD clutch switch (1 ), if equipped. Position so that

clearance between clutch pedal (2) and thread end of ASCD

clutch switch (1), with clutch pedal fully released, is within speci-

fication (A).

5. Check the clutch hydraulic system components (clutc h master cylinder, clutch operating cylinder, clutch

withdrawal lever and clutch release bearing) for sticking or binding.

a. If any sticking or binding is noted, repair or replace the related parts as necessary.

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system. Refer to CL-9, "

Air

Bleeding Procedure".

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Us e of a vacuum assist or

power bleeder will not purge all of the air from the system.

Removal and InstallationINFOID:0000000005928995

COMPONENTS

Clearance A : 0.74 - 1.96 mm (0.0291 - 0.0772 in)

WCIA0595E

Revision: May 2010 2011 Versa

Page 990 of 3787

CLUTCH FLUIDCL-9

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH FLUID

Air Bleeding ProcedureINFOID:0000000005928996

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

NOTE:

• Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or power bleeder will not purge all the air from the system.

• Carefully monitor fluid level in reservoir tank during bleeding operation.

1. Fill master cylinder reservoir tank with new clutch fluid.

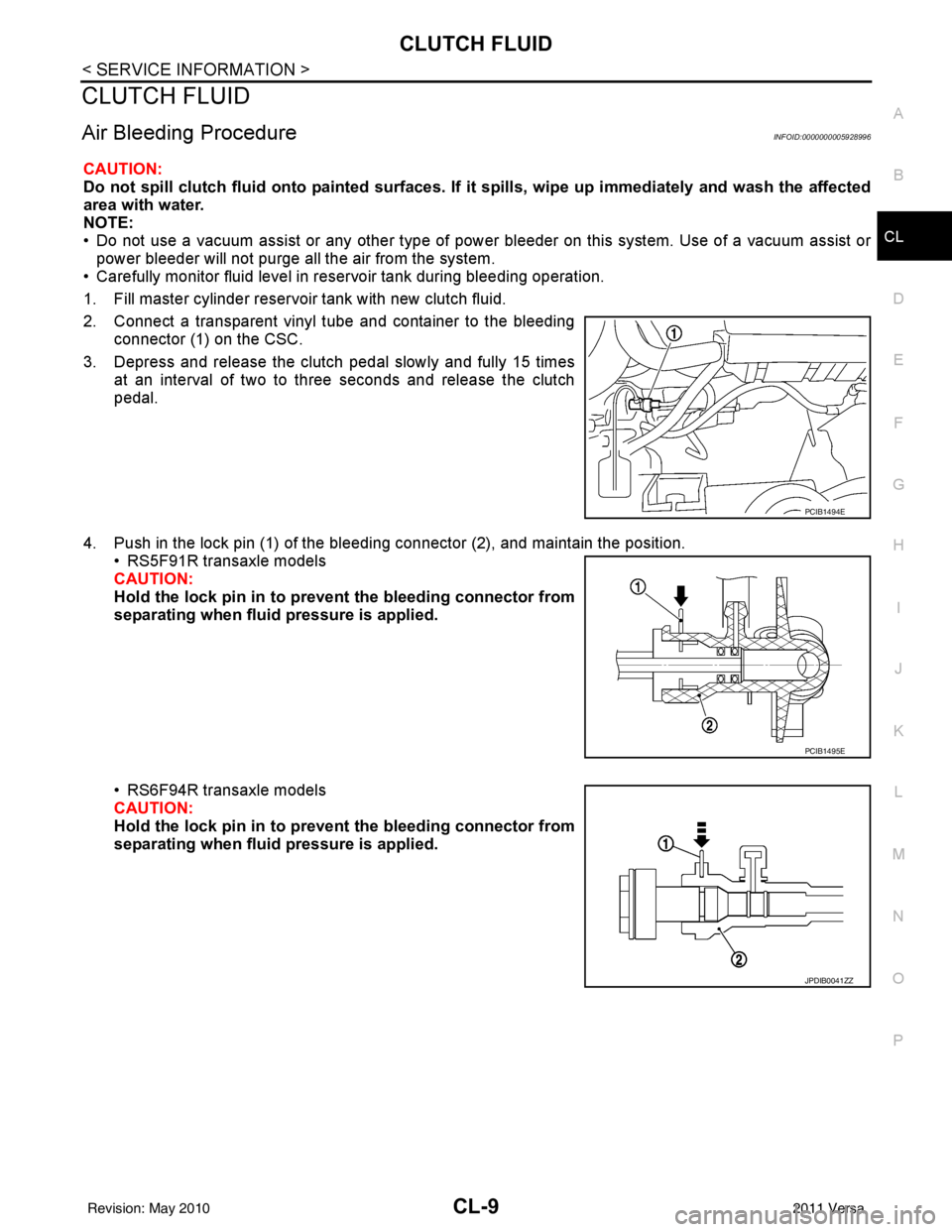

2. Connect a transparent vinyl tube and container to the bleeding connector (1) on the CSC.

3. Depress and release the clutch pedal slowly and fully 15 times at an interval of two to three seconds and release the clutch

pedal.

4. Push in the lock pin (1) of the bleeding connector (2), and maintain the position. • RS5F91R transaxle models

CAUTION:

Hold the lock pin in to preven t the bleeding connector from

separating when fluid pressure is applied.

• RS6F94R transaxle models

CAUTION:

Hold the lock pin in to preven t the bleeding connector from

separating when fluid pressure is applied.

PCIB1494E

PCIB1495E

JPDIB0041ZZ

Revision: May 2010 2011 Versa

Page 991 of 3787

CL-10

< SERVICE INFORMATION >

CLUTCH FLUID

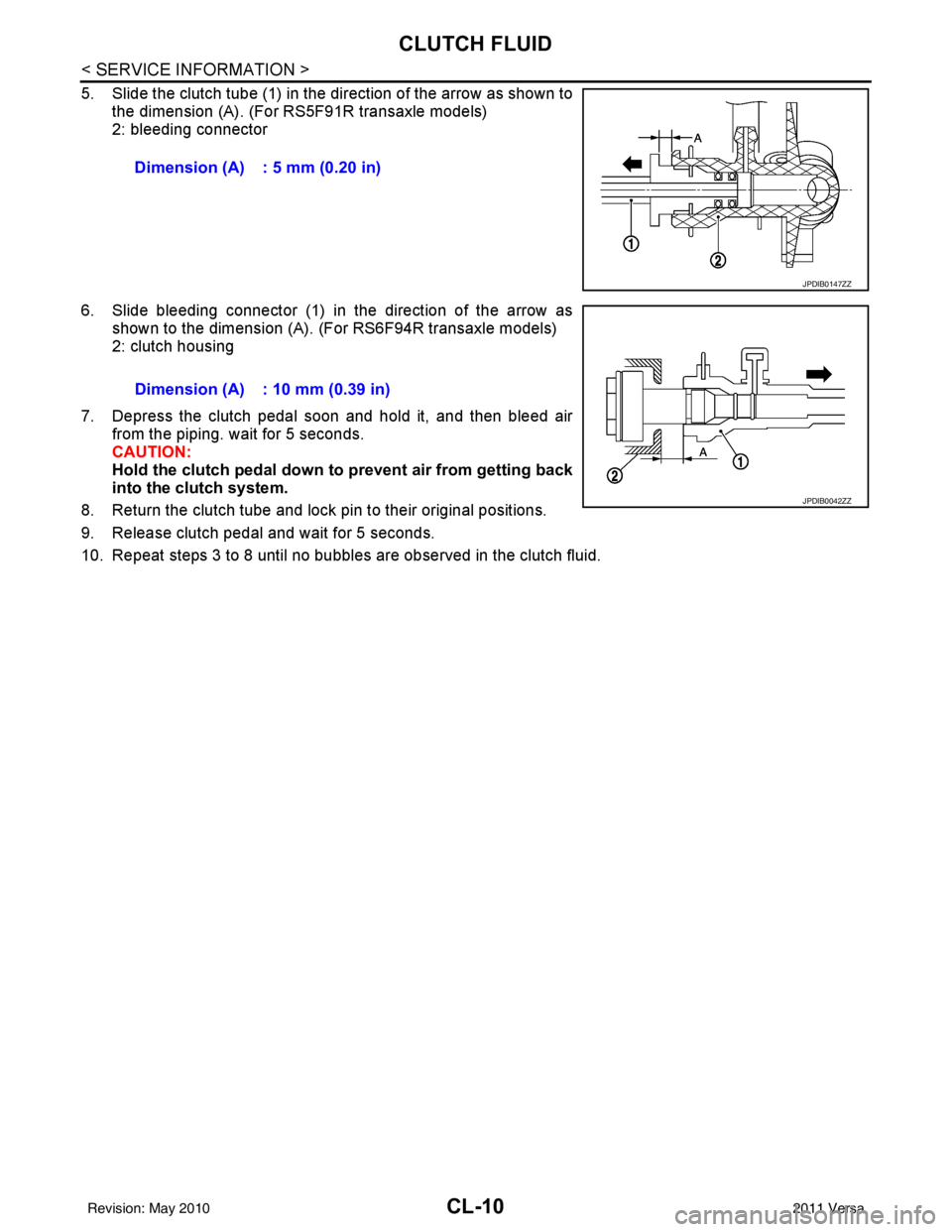

5. Slide the clutch tube (1) in the direction of the arrow as shown tothe dimension (A). (For RS5F91R transaxle models)

2: bleeding connector

6. Slide bleeding connector (1) in the direction of the arrow as shown to the dimension (A). (For RS6F94R transaxle models)

2: clutch housing

7. Depress the clutch pedal soon and hold it, and then bleed air from the piping. wait for 5 seconds.

CAUTION:

Hold the clutch pedal down to prevent air from getting back

into the clutch system.

8. Return the clutch tube and lock pin to their original positions.

9. Release clutch pedal and wait for 5 seconds.

10. Repeat steps 3 to 8 until no bubbles are observed in the clutch fluid. Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

Dimension (A) : 10 mm (0.39 in)

JPDIB0042ZZ

Revision: May 2010

2011 Versa

Page 993 of 3787

CL-12

< SERVICE INFORMATION >

CLUTCH MASTER CYLINDER

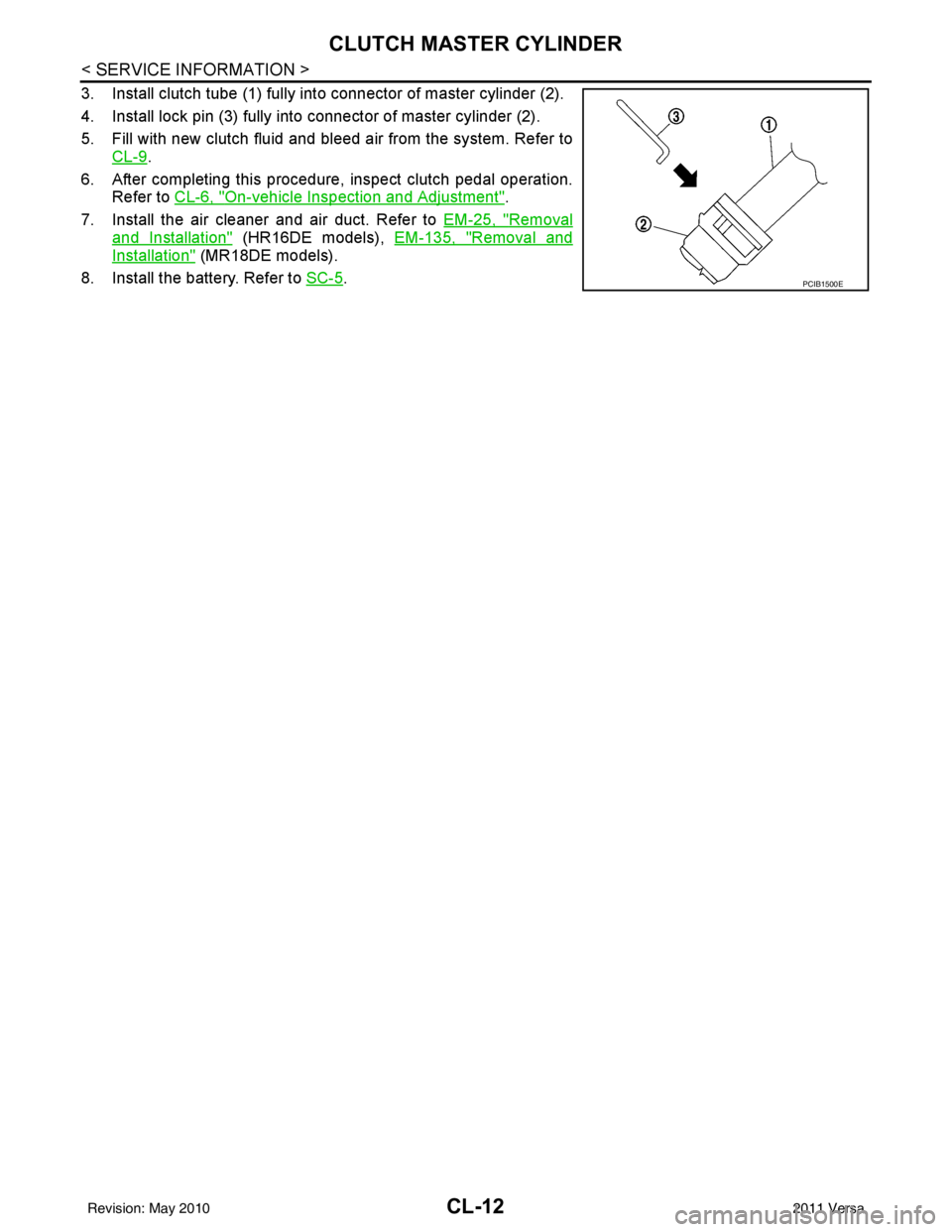

3. Install clutch tube (1) fully into connector of master cylinder (2).

4. Install lock pin (3) fully into connector of master cylinder (2).

5. Fill with new clutch fluid and bleed air from the system. Refer toCL-9

.

6. After completing this procedure, inspect clutch pedal operation. Refer to CL-6, "

On-vehicle Inspection and Adjustment".

7. Install the air cleaner and air duct. Refer to EM-25, "

Removal

and Installation" (HR16DE models), EM-135, "Removal and

Installation" (MR18DE models).

8. Install the battery. Refer to SC-5

.PCIB1500E

Revision: May 2010 2011 Versa

Page 995 of 3787

CL-14

< SERVICE INFORMATION >

CSC (CONCENTRIC SLAVE CYLINDER)

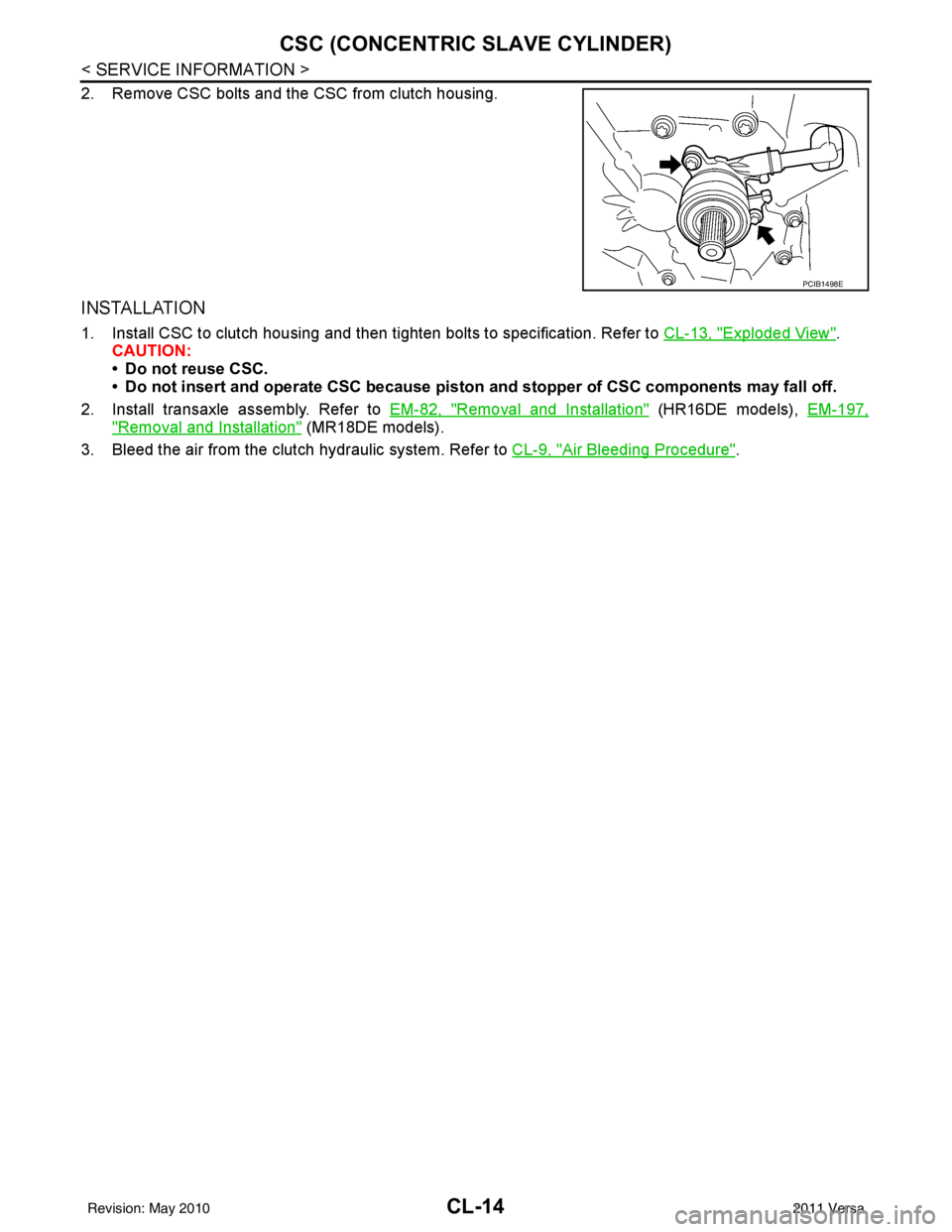

2. Remove CSC bolts and the CSC from clutch housing.

INSTALLATION

1. Install CSC to clutch housing and then tighten bolts to specification. Refer to CL-13, "Exploded View".

CAUTION:

• Do not reuse CSC.

• Do not insert and operate CSC because piston and stopper of CSC components may fall off.

2. Install transaxle assembly. Refer to EM-82, "

Removal and Installation" (HR16DE models), EM-197,

"Removal and Installation" (MR18DE models).

3. Bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding Procedure".

PCIB1498E

Revision: May 2010 2011 Versa

Page 996 of 3787

CLUTCH PIPINGCL-15

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH PIPING

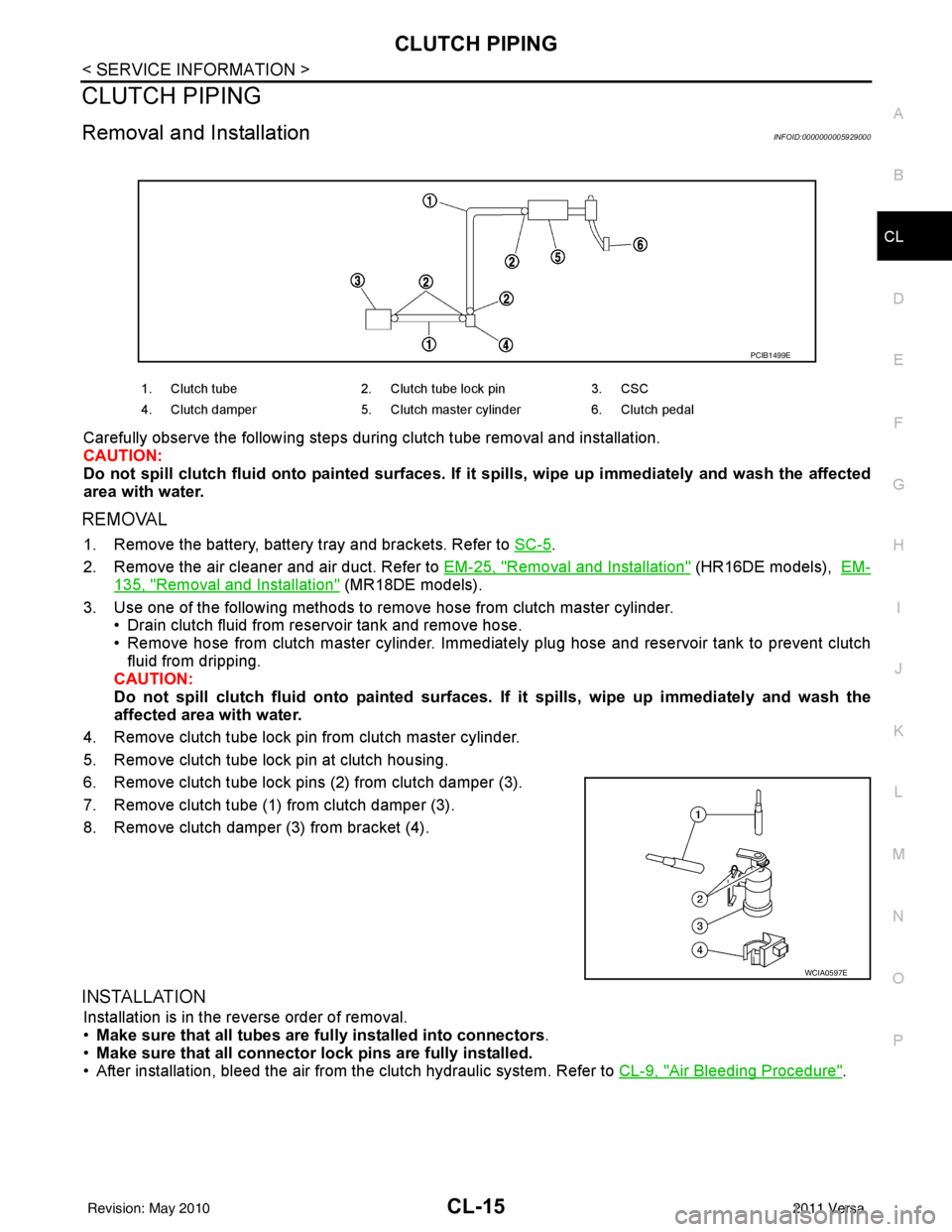

Removal and InstallationINFOID:0000000005929000

Carefully observe the following steps during clutch tube removal and installation.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

REMOVAL

1. Remove the battery, battery tray and brackets. Refer to SC-5.

2. Remove the air cleaner and air duct. Refer to EM-25, "

Removal and Installation" (HR16DE models), EM-

135, "Removal and Installation" (MR18DE models).

3. Use one of the following methods to remove hose from clutch master cylinder. • Drain clutch fluid from reservoir tank and remove hose.

• Remove hose from clutch master cylinder. Immediat ely plug hose and reservoir tank to prevent clutch

fluid from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

4. Remove clutch tube lock pin from clutch master cylinder.

5. Remove clutch tube lock pin at clutch housing.

6. Remove clutch tube lock pins (2) from clutch damper (3).

7. Remove clutch tube (1) from clutch damper (3).

8. Remove clutch damper (3) from bracket (4).

INSTALLATION

Installation is in the reverse order of removal.

• Make sure that all tubes are fu lly installed into connectors.

• Make sure that all connector lock pins are fully installed.

• After installation, bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding Procedure".

1. Clutch tube2. Clutch tube lock pin 3. CSC

4. Clutch damper 5. Clutch master cylinder 6. Clutch pedal

PCIB1499E

WCIA0597E

Revision: May 2010 2011 Versa

Page 1000 of 3787

SERVICE DATA AND SPECIFICATIONS (SDS)CL-19

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

CL

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

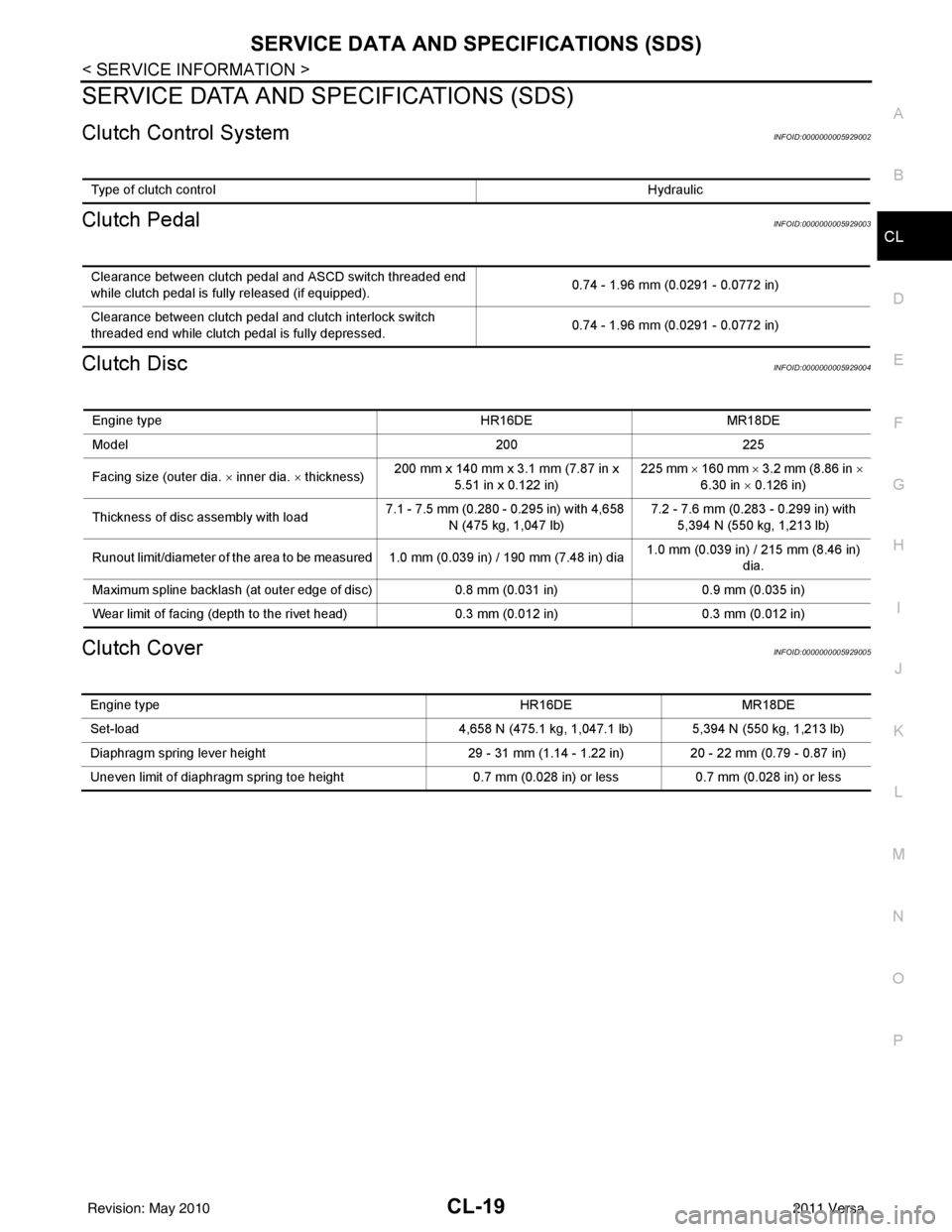

Clutch Control SystemINFOID:0000000005929002

Clutch PedalINFOID:0000000005929003

Clutch DiscINFOID:0000000005929004

Clutch CoverINFOID:0000000005929005

Type of clutch control Hydraulic

Clearance between clutch pedal and ASCD switch threaded end

while clutch pedal is fully released (if equipped). 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Clearance between clutch pedal and clutch interlock switch

threaded end while clutch pedal is fully depressed. 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Engine type

HR16DEMR18DE

Model 200225

Facing size (outer dia. × inner dia. × thickness) 200 mm x 140 mm x 3.1 mm (7.87 in x

5.51 in x 0.122 in) 225 mm ×

160 mm × 3.2 mm (8.86 in ×

6.30 in × 0.126 in)

Thickness of disc assembly with load 7.1 - 7.5 mm (0.280 - 0.295 in) with 4,658

N (475 kg, 1,047 lb) 7.2 - 7.6 mm (0.283 - 0.299 in) with

5,394 N (550 kg, 1,213 lb)

Runout limit/diameter of the area to be measured 1.0 mm (0.039 in) / 190 mm (7.48 in) dia 1.0 mm (0.039 in) / 215 mm (8.46 in)

dia.

Maximum spline backlash (at outer edge of disc) 0.8 mm (0.031 in)0.9 mm (0.035 in)

Wear limit of facing (depth to the rivet head) 0.3 mm (0.012 in)0.3 mm (0.012 in)

Engine type HR16DEMR18DE

Set-load 4,658 N (475.1 kg, 1,047.1 lb) 5,394 N (550 kg, 1,213 lb)

Diaphragm spring lever height 29 - 31 mm (1.14 - 1.22 in)20 - 22 mm (0.79 - 0.87 in)

Uneven limit of diaphragm spring toe height 0.7 mm (0.028 in) or less0.7 mm (0.028 in) or less

Revision: May 2010 2011 Versa

Page 1001 of 3787

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYMPTOM DIAGNOSIS ...............................7

OVERHEATING CAUSE ANALYSIS ............. .....7

Troubleshooting Chart ...............................................7

FUNCTION DIAGNOSIS .. .............................9

DESCRIPTION ............................................... .....9

Engine Cooling System ....................................... ......9

Engine Cooling System Schematic .........................10

ON-VEHICLE MAINTENANCE ....................11

ENGINE COOLANT ....................................... ....11

Inspection ............................................................ ....11

Changing Engine Coolant .......................................11

RADIATOR .........................................................14

Checking Radiator Cap ....................................... ....14

Checking Radiator ...................................................14

ON-VEHICLE REPAIR .................................16

RADIATOR ..................................................... ....16

Component .......................................................... ....16

Removal and Installation .........................................16

COOLING FAN ..................................................18

Component (Models with A/C) ............................. ....18

Component (Models without A/C) ............................18

Removal and Installation .........................................19

Disassembly and Assembly .....................................19

WATER PUMP ..................................................20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................21

THERMOSTAT ..................................................22

Exploded View .........................................................22

Removal and Installation .........................................22

Inspection ................................................................23

WATER OUTLET ..............................................24

Exploded View .........................................................24

Removal and Installation .........................................24

Inspection ................................................................25

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

26

Periodical Maintenance Specification .................. ....26

Radiator ...................................................................26

Thermostat ..............................................................26

MR18DE

SERVICE INFORMATION .. .........................

27

PRECAUTIONS .................................................27

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

27

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

27

Precaution for Liquid Gasket ...................................28

PREPARATION .................................................30

Revision: May 2010 2011 Versa

Page 1002 of 3787

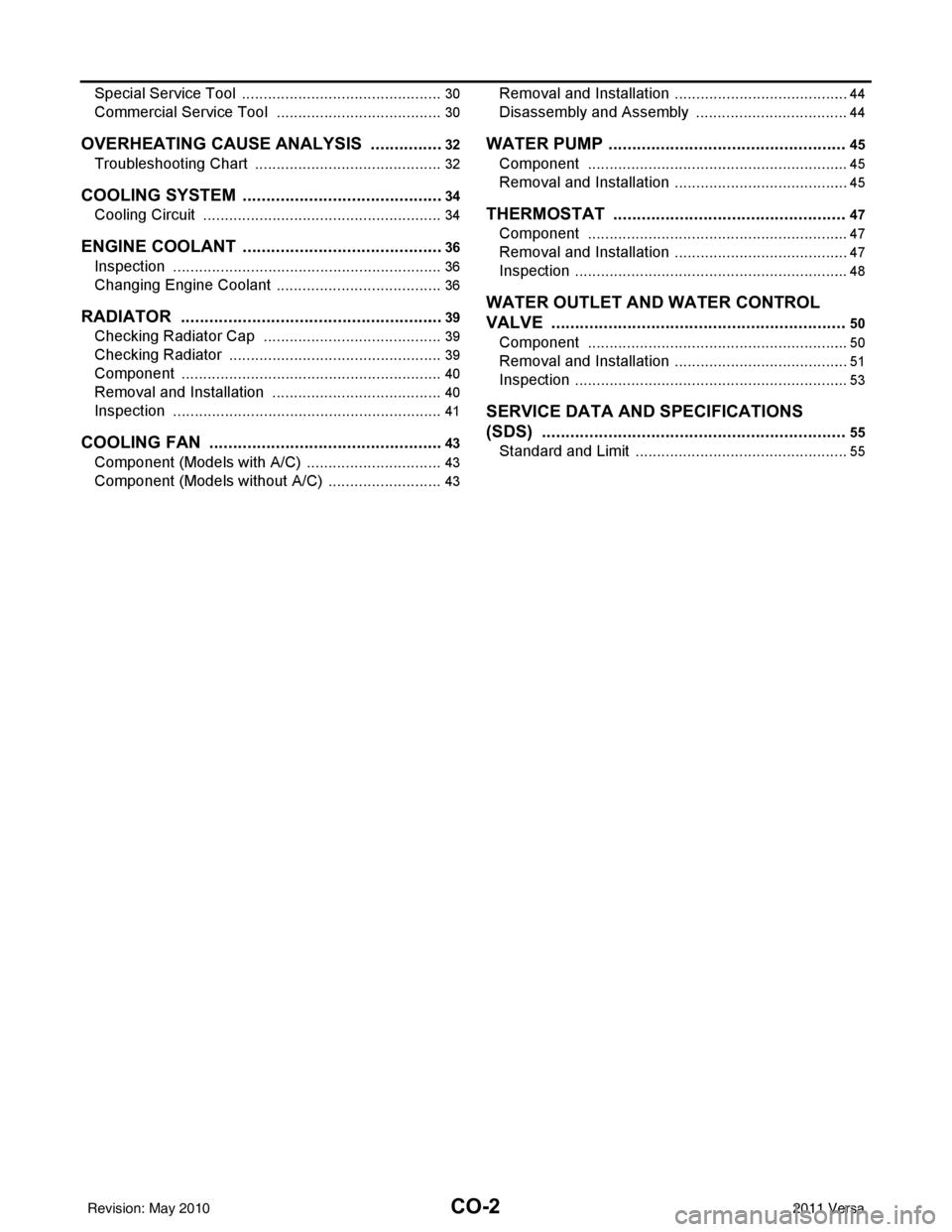

CO-2

Special Service Tool ...............................................30

Commercial Service Tool .......................................30

OVERHEATING CAUSE ANALYSIS ................32

Troubleshooting Chart ......................................... ...32

COOLING SYSTEM ...........................................34

Cooling Circuit ..................................................... ...34

ENGINE COOLANT ...........................................36

Inspection ............................................................ ...36

Changing Engine Coolant .......................................36

RADIATOR ........................................................39

Checking Radiator Cap ....................................... ...39

Checking Radiator ..................................................39

Component .............................................................40

Removal and Installation ........................................40

Inspection ...............................................................41

COOLING FAN ..................................................43

Component (Models with A/C) ................................43

Component (Models without A/C) ...........................43

Removal and Installation .........................................44

Disassembly and Assembly ................................. ...44

WATER PUMP ...................................................45

Component .......................................................... ...45

Removal and Installation .........................................45

THERMOSTAT ............................................... ...47

Component .......................................................... ...47

Removal and Installation .........................................47

Inspection ............................................................. ...48

WATER OUTLET AND WATER CONTROL

VALVE ...............................................................

50

Component .......................................................... ...50

Removal and Installation .........................................51

Inspection ............................................................. ...53

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

55

Standard and Limit ............................................... ...55

Revision: May 2010 2011 Versa

Page 1003 of 3787

![NISSAN TIIDA 2011 Service Repair Manual PRECAUTIONSCO-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000 NISSAN TIIDA 2011 Service Repair Manual PRECAUTIONSCO-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000](/img/5/57396/w960_57396-1002.png)

PRECAUTIONSCO-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005930769

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Liquid GasketINFOID:0000000005930771

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

Tool number : KV10111100 (J-37228)

WBIA0566E

Revision: May 2010 2011 Versa