Lighting NISSAN TIIDA 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1836 of 3787

![NISSAN TIIDA 2011 Service Service Manual EC-542

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on eng NISSAN TIIDA 2011 Service Service Manual EC-542

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on eng](/img/5/57396/w960_57396-1835.png)

EC-542

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part

of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected, and demands the

driver to repair the malfunction.

Emission-related Diagnostic InformationINFOID:0000000006341719

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

× : Applicable —: Not applicable

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Items

(CONSULT-III screen terms) DTC*

1

SRT

code Trip MIL Permanent

DTC

group

*4Reference

CONSULT-III

GST*

2ECM*3

LOST COMM (TCM) U0101

0101*5—1 ×BEC-639

LOST COMM (BCM) U0140

0140*5—1 ×BEC-641

CAN COMM CIRCUIT U1001

1001*5—2 — — EC-643

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0000

——

Flashing*6— EC-565

INT/V TIM CONT-B1 P0011 0011×2 × BEC-645

A/F SEN1 HTR (B1) P0031 0031 — 2 ×BEC-649

A/F SEN1 HTR (B1) P0032 0032 — 2 ×BEC-649

HO2S2 HTR (B1) P0037 0037 — 2 ×BEC-654

HO2S2 HTR (B1) P0038 0038 — 2 ×BEC-654

INT/V TIM V/CIR-B1 P0075 0075 — 2 ×BEC-659

MAF SEN/CIRCUIT-B1 P0101 0101 — 2 ×BEC-664

MAF SEN/CIRCUIT-B1 P0102 0102 — 1 ×BEC-672

MAF SEN/CIRCUIT-B1 P0103 0103 — 1 ×BEC-672

IAT SEN/CIRCUIT-B1 P0112 0112 — 2 ×BEC-679

IAT SEN/CIRCUIT-B1 P0113 0113 — 2 ×BEC-679

ECT SEN/CIRC P0116 0116 — 2 ×BEC-683

ECT SEN/CIRC P0117 0117 — 1 ×BEC-686

ECT SEN/CIRC P0118 0118 — 1 ×BEC-686

TP SEN 2/CIRC-B1 P0122 0122 — 1 ×BEC-691

TP SEN 2/CIRC-B1 P0123 0123 — 1 ×BEC-691

ECT SENSOR P0125 0125 — 2 ×BEC-696

IAT SENSOR-B1 P0127 0127 — 2 ×BEC-699

THERMSTAT FNCTN P0128 0128 — 2 ×BEC-702

A/F SENSOR1 (B1) P0130 0130 — 2 ×AEC-704

A/F SENSOR1 (B1) P0131 0131 — 2 ×BEC-710

A/F SENSOR1 (B1) P0132 0132 — 2 ×BEC-716

HO2S2 (B1) P0137 0137×2 × AEC-722

HO2S2 (B1) P0138 0138×2 × AEC-731

HO2S2 (B1) P0139 0139×2 × AEC-741

A/F SENSOR1 (B1) P014C 014C — 2 ×AEC-750

Revision: May 2010 2011 Versa

Page 1847 of 3787

![NISSAN TIIDA 2011 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoo NISSAN TIIDA 2011 Service Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoo](/img/5/57396/w960_57396-1846.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-553

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Suggested Maximum Speed in Each Gear

Downshift to a lower gear if the engine is not running smoothly, or if you need to accelerate.

Do not exceed the maximum suggested speed (shown below) in any gear. For level road driving, use the high-

est gear suggested for that speed. Always observe post

ed speed limits and drive according to the road condi-

tions to ensure safe operation. Do not over-rev t he engine when shifting to a lower gear as it may cause

engine damage or loss of vehicle control.

PERMANENT DIAGNOSTIC TROU BLE CODE (PERMANENT DTC)

Permanent DTC is defined in SAE J1979/ISO 15031-5 Service $0A.

ECM stores a DTC issuing a command of turning on MIL as a permanent DTC and keeps storing the DTC as

a permanent DTC until ECM judges that there is no presence of malfunction.

Permanent DTCs cannot be erased by using the Erase function of CONSULT-III or Generic Scan Tool (GST)

and by disconnecting the battery to shut off power to EC M. This prevents a vehicle from passing the state

emission inspection without repairing a malfunctioning part.

When not passing the state emission inspection due to more than one permanent DTC, permanent DTCs

should be erased, referring to this manual.

NOTE:

• The important items in state emission inspection are t hat MIL is not ON, SRT test items are set, and perma-

nent DTCs are not included.

• Permanent DTCs do not apply for regions that permanent DTCs are not regulated by law.

Permanent DTC Item

For permanent DTC items, MIL turns ON. Refer to EC-542, "Emission-related Diagnostic Information", “EMIS-

SION-RELATED DIAGNOSTIC INFORMATION ITEMS”.

Permanent DTC Set Timing

The setting timing of permanent DTC is stored in ECM with the lighting of MIL when a DTC is confirmed.

Permanent DTC Service Procedure

For normal acceleration in low alti-

tude areas

[less than 1,219 m (4,000 ft)]: For quick acceleration in low alti-

tude areas For high attitude areas

[over 1,219m (4,000 ft)]:

Gear change ACCEL shift point km/h (MPH) km/h (MPH)km/h (MPH)

1st to 2nd 13 (8)24 (15) 24 (15)

2nd to 3rd 27 (17)40 (25)40 (25)

3rd to 4th 40 (25)53 (33)65 (40)

4th to 5th 58 (36)71 (44)72 (45)

5th to 6th 82 (51)82 (51)82 (51)

Gear km/h (MPH)

1st 50 (30)

2nd 90 (55)

3rd —

4th —

5th —

6th —

Revision: May 2010 2011 Versa

Page 1860 of 3787

![NISSAN TIIDA 2011 Service Service Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine NISSAN TIIDA 2011 Service Service Manual EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine](/img/5/57396/w960_57396-1859.png)

EC-566

< SERVICE INFORMATION >[MR18DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-21

or see EC-1033.

2. When the engine is started, the MIL should go off. If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by MIL lighting up when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected, and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

When any SRT codes are not set, MIL may fl ash without DTC. For the details, refer to EC-542, "Emission-

related Diagnostic Information".

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

•It is better to count the ti me accurately with a clock.

SEF217U

Diagnostic Test

Mode KEY and ENG.

Statu s Function

Explanation of Function

Mode I Ignition switch in

ON position

Engine stopped BULB CHECK

This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION WARNING This is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stopped SELF-DIAGNOSTIC

RESULTS

This function allows DTCs an

d 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: May 2010 2011 Versa

Page 1885 of 3787

![NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-591

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-591

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there](/img/5/57396/w960_57396-1884.png)

TROUBLE DIAGNOSISEC-591

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore, when electrical controlled throttle and pa rt of ECM related diagnoses are continuously detected

as NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

DTC No. Detected items Engine operating condition in fail-safe mode

P0102

P0103 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118 Engine coolant temperature

sensor circuit Engine coolant temperature will be determined by ECM based on the following condi-

tion.

CONSULT-III displays the engine coolant temperature decided by ECM.

Condition Engine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON

or START 40

°C (104 °F)

Approx. 4 minutes or more after

engine starting. 80

°C (176 °F)

Except as shown above 40 - 80°

C (104 - 176 °F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cool-

ing fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135 Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening

in order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

P2100

P2103 Throttle control relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control func- tion ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control actu- ator (When electric throttle control actuator does not function properly due to the return

spring malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control ac

tuator by regulating the throttle opening to

20 degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops,

the engine stalls.

The engine can restart in N or P (A/T, CVT), Neutral (M/T) position, and engine speed

will not exceed 1,000 rpm or more.

P2122

P2123

P2127

P2128

P2138 Accelerator pedal position

sensor

The ECM controls the electric throttle control actuator in regulating the throttle opening

in order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

Engine operating condition in fail-safe mode

Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: May 2010 2011 Versa

Page 1909 of 3787

![NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-615

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR COND SIG

[ON/OFF]

• Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-615

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR COND SIG

[ON/OFF]

• Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air](/img/5/57396/w960_57396-1908.png)

TROUBLE DIAGNOSISEC-615

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR COND SIG

[ON/OFF]

• Indicates [ON/OFF] condition of the air conditioner switch as

determined by the air conditioner signal.

P/N POSI SW

[ON/OFF] • Indicates [ON/OFF] condition from the park/neutral position

(PNP) signal.

PW/ST SIGNAL

[ON/OFF] • [ON/OFF] condition of the power steering system (deter-

mined by the signal sent from EPS control unit) is indicated.

LOAD SIGNAL

[ON/OFF] • Indicates [ON/OFF] condition from the electrical load signal.

ON: Rear window defogger switch is ON and/or lighting

switch is in 2nd position.

OFF: Both rear window defogger switch and lighting switch

are OFF.

IGNITION SW

[ON/OFF] • Indicates [ON/OFF] condition from ignition switch.

HEATER FAN SW

[ON/OFF] • Indicates [ON/OFF] condition from the heater fan switch sig-

nal.

BRAKE SW

[ON/OFF] • Indicates [ON/OFF] condition from the stop lamp switch sig-

nal.

INJ PULSE-B1

[msec] • Indicates the actual fuel injection pulse width compensated

by ECM according to the input signals. • When the engine is stopped, a certain com-

puted value is indicated.

IGN TIMING

[BTDC] • Indicates the ignition timing computed by ECM according to

the input signals. • When the engine is stopped, a certain value

is indicated.

CAL/LD VALUE

[%] • “Calculated load value” indicates the value of the current air-

flow divided by peak airflow.

MASS AIRFLOW

[g·m/s] • Indicates the mass airflow computed by ECM according to

the signal voltage of the mass air flow sensor.

PURG VOL C/V

[%] • Indicates the EVAP canister purge volume control solenoid

valve control value computed by the ECM according to the in-

put signals.

• The opening becomes larger as the value increases.

INT/V TIM(B1)

[ ° CA] • Indicates [

°CA] of intake camshaft advanced angle.

INT/V SOL(B1)

[%] • The control value of the intake valve timing control solenoid

valve (determined by ECM according to the input signal) is in-

dicated.

• The advance angle becomes larger as the value increases

AIR COND RLY

[ON/OFF] • The air conditioner relay control condition (determined by

ECM according to the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF] • Indicates the fuel pump relay control condition determined by

ECM according to the input signals.

VENT CONT/V

[ON/OFF] • The control condition of the EVAP canister vent control valve

(determined by ECM according to the input signals) is indi-

cated.

ON: Closed

OFF: Open

THRTL RELAY

[ON/OFF] • Indicates the throttle control

motor relay control condition de-

termined by the ECM according to the input signals.

COOLING FAN

[HI/LOW/OFF] • Indicates the condition of the cooling fan (determined by

ECM according to the input signals).

HI: High speed operation

LOW: Low speed operation

OFF: Stop

HO2S2 HTR (B1)

[ON/OFF] • Indicates [ON/OFF] condition of heated oxygen sensor 2

heater determined by ECM according to the input signals.

I/P PULLY SPD

[rpm] • Indicates the engine speed computed from the input speed

se ns

or si

gnal.

Monitored item [Unit]

Description Remarks

Revision: May 2010 2011 Versa

Page 1915 of 3787

![NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-621

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 (B1)

• Revving engine from idle to 3,000 rpm quickly after the following conditions

are met

- Engine: NISSAN TIIDA 2011 Service Service Manual TROUBLE DIAGNOSISEC-621

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 (B1)

• Revving engine from idle to 3,000 rpm quickly after the following conditions

are met

- Engine:](/img/5/57396/w960_57396-1914.png)

TROUBLE DIAGNOSISEC-621

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 (B1)

• Revving engine from idle to 3,000 rpm quickly after the following conditions

are met

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3 V

←→ Approx. 0.6 -

1.0 V

HO2S2 MNTR (B1) LEAN ←→ RICH

VHCL SPEED SE • Turn drive wheels and compare CONSULT-III value with the speedometer

indication. Almost the same speed as the

speedometer indication.

BATTERY VOLT • Ignition switch: ON (Engine stopped) 11 - 14 V

ACCEL SEN 1 • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released

0.6 - 0.9 V

Accelerator pedal: Fully depressed 4.0 - 4.8 V

ACCEL SEN 2* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released

0.6 - 0.9 V

Accelerator pedal: Fully depressed 3.9 - 4.8 V

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8 V

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released

More than 0.36 V

• Shift lever: D (A/T, CVT), 1st (M/T) Accelerator pedal: Fully depressed

Less than 4.75 V

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS • Ignition switch: ON Accelerator pedal: Fully released

ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG • Engine: After warming up, idle the

engine Air conditioner switch: OFF

OFF

Air conditioner switch: ON

(Compressor operates.) ON

P/N POSI SW • Ignition switch: ON Shift lever: P or N (A/T, CVT),

Neutral (M/T)

ON

Shift lever: Except above OFF

PW/ST SIGNAL • Engine: After warming up, idle the

engine Steering wheel: Not being turned

OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ON Rear window defogger switch: ON

and/or Lighting switch: 2nd

ON

Rear window defogger switch and light-

ing switch: OFF OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW • Ignition switch: ON Heater fan: Operating

ON

Heater fan: Not operating OFF

BRAKE SW • Ignition switch: ON Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No load Idle

2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No load Idl

e

8° - 18 ° BT

DC

2,000 rpm 25° - 45 ° BTDC

CAL/LD VALUE • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No load Idle

10% - 35%

2,500 rpm 10% - 35%

Monitor item

Condition Specification

Revision: May 2010 2011 Versa

Page 1918 of 3787

![NISSAN TIIDA 2011 Service Service Manual EC-624

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000006341742

The specification (SP) value indicates the tol NISSAN TIIDA 2011 Service Service Manual EC-624

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000006341742

The specification (SP) value indicates the tol](/img/5/57396/w960_57396-1917.png)

EC-624

< SERVICE INFORMATION >[MR18DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000006341742

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode of CONSULT-III during normal operation of the Engine Control System. When the value in

“SPEC” of “DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When

the value in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may

have one or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width progr ammed into ECM prior to any learned on board correc-

tion)

• A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionINFOID:0000000006341743

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30 °C (68 - 86° F)

• Engine coolant temperature: 75 - 95 °C (167 - 203° F)

• Transmission: Warmed-up

- A/T and CVT models: After the engine is warmed up to normal operating temperature, drive vehicle until

“FLUID TEMP SE” (A/T or CVT) fluid temperature sensor signal) indicates more than 60 °C (140° F).

- M/T models: After the engine is warmed up to normal operating temperature, drive vehicle for 5 minutes.

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight ahead.

• Engine speed: Idle

Inspection ProcedureINFOID:0000000006341744

NOTE:

Perform “SPEC” of “DATA MONITOR” mode in maximum scale display.

1. Perform EC-574, "

Basic Inspection".

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1” and “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode

with CONSULT-III.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-624, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006341745

OVERALL SEQUENCE

Revision: May 2010 2011 Versa

Page 2301 of 3787

![NISSAN TIIDA 2011 Service Service Manual ELECTRICAL LOAD SIGNALEC-1007

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

CONSULT-III Reference Val

ue in Data Monitor ModeINFOID:0000000006342228

Specifica NISSAN TIIDA 2011 Service Service Manual ELECTRICAL LOAD SIGNALEC-1007

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

CONSULT-III Reference Val

ue in Data Monitor ModeINFOID:0000000006342228

Specifica](/img/5/57396/w960_57396-2300.png)

ELECTRICAL LOAD SIGNALEC-1007

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

CONSULT-III Reference Val

ue in Data Monitor ModeINFOID:0000000006342228

Specification data are reference values.

Diagnosis ProcedureINFOID:0000000006342229

1.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

1. Turn ignition switch ON.

2. Check “LOAD SIGNAL” in “DATA MONITOR” mode with CONSULT-III under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check “LOAD SIGNAL” in “DATA MONITOR” mode with CONSULT-III under the following conditions.

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK HEATER FAN SIGNAL CIRCUIT OVERALL FUNCTION

Check “HEATER FAN SW” in “DATA MONITOR” mode with CONSULT-III under the following conditions.

OK or NG

OK >> INSPECTION END .

NG >> GO TO 6.

4.CHECK HEADLAMP SYSTEM

Refer to LT- 5

or LT- 2 7.

>> INSPECTION END

5.CHECK REAR WINDOW DEFOGGER SYSTEM

Monitor item ConditionSpecification

LOAD SIGNAL • Ignition switch: ON Rear window defogger switch is ON and/or lighting

switch is in 2nd position.

ON

Rear window defogger switch is OFF and lighting switch

is OFF. OFF

HEATER FAN SW • Ignition switch: ON Heater fan: Operating.

ON

Heater fan: Not operating. OFF

ConditionLOAD SIGNAL

Lighting switch: ON at 2nd position ON

Lighting switch: OFF OFF

ConditionLOAD SIGNAL

Rear window defogger switch: ON ON

Rear window defogger switch: OFF OFF

ConditionHEATER FAN SW

Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

Revision: May 2010 2011 Versa

Page 2837 of 3787

IP-16

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

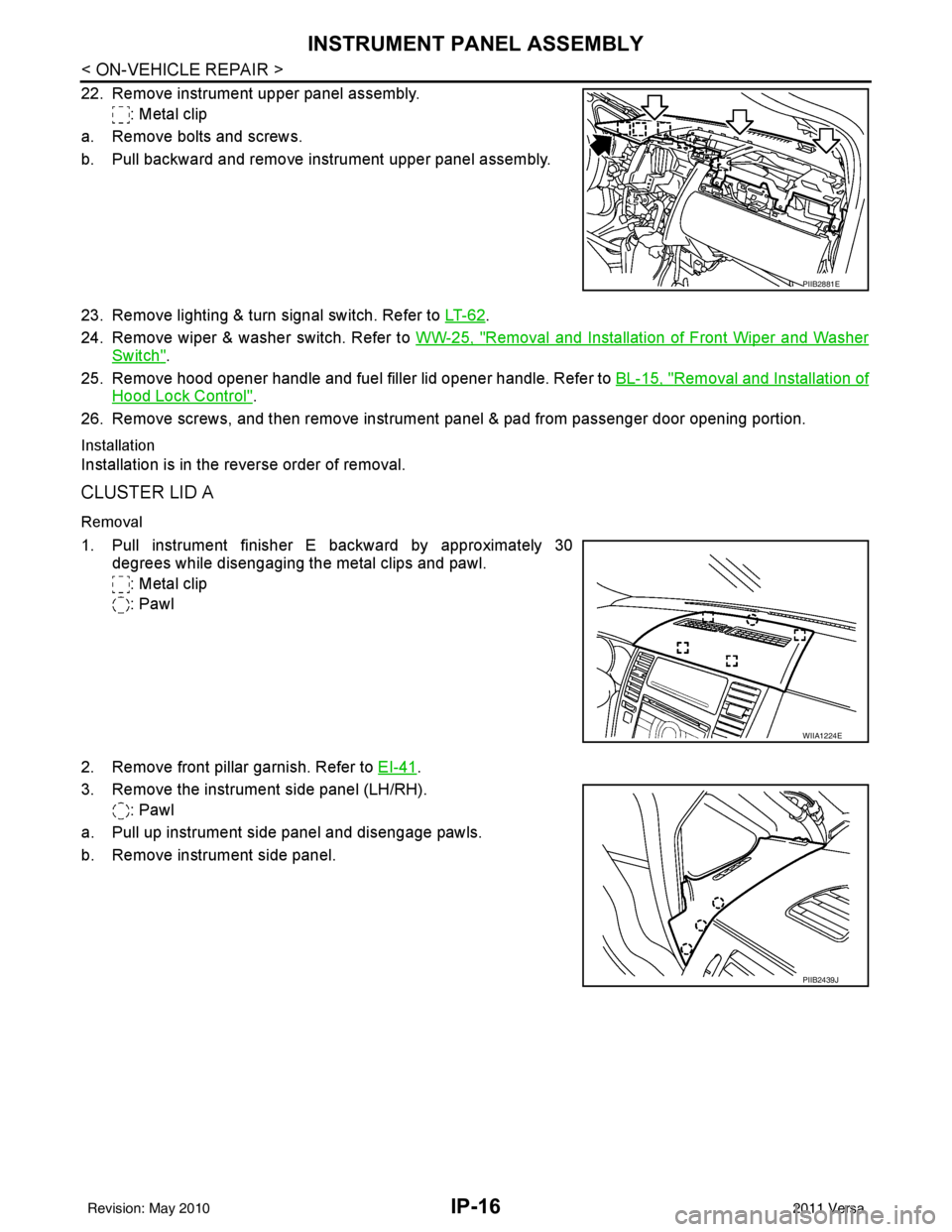

22. Remove instrument upper panel assembly.: Metal clip

a. Remove bolts and screws.

b. Pull backward and remove instrument upper panel assembly.

23. Remove lighting & turn signal switch. Refer to LT- 6 2

.

24. Remove wiper & washer switch. Refer to WW-25, "

Removal and Installation of Front Wiper and Washer

Switch".

25. Remove hood opener handle and fuel filler lid opener handle. Refer to BL-15, "

Removal and Installation of

Hood Lock Control".

26. Remove screws, and then remove instrument panel & pad from passenger door opening portion.

Installation

Installation is in the reverse order of removal.

CLUSTER LID A

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

: Metal clip

: Pawl

2. Remove front pillar garnish. Refer to EI-41

.

3. Remove the instrument side panel (LH/RH). : Pawl

a. Pull up instrument side panel and disengage pawls.

b. Remove instrument side panel.

PIIB2881E

WIIA1224E

PIIB2439J

Revision: May 2010 2011 Versa

Page 3033 of 3787

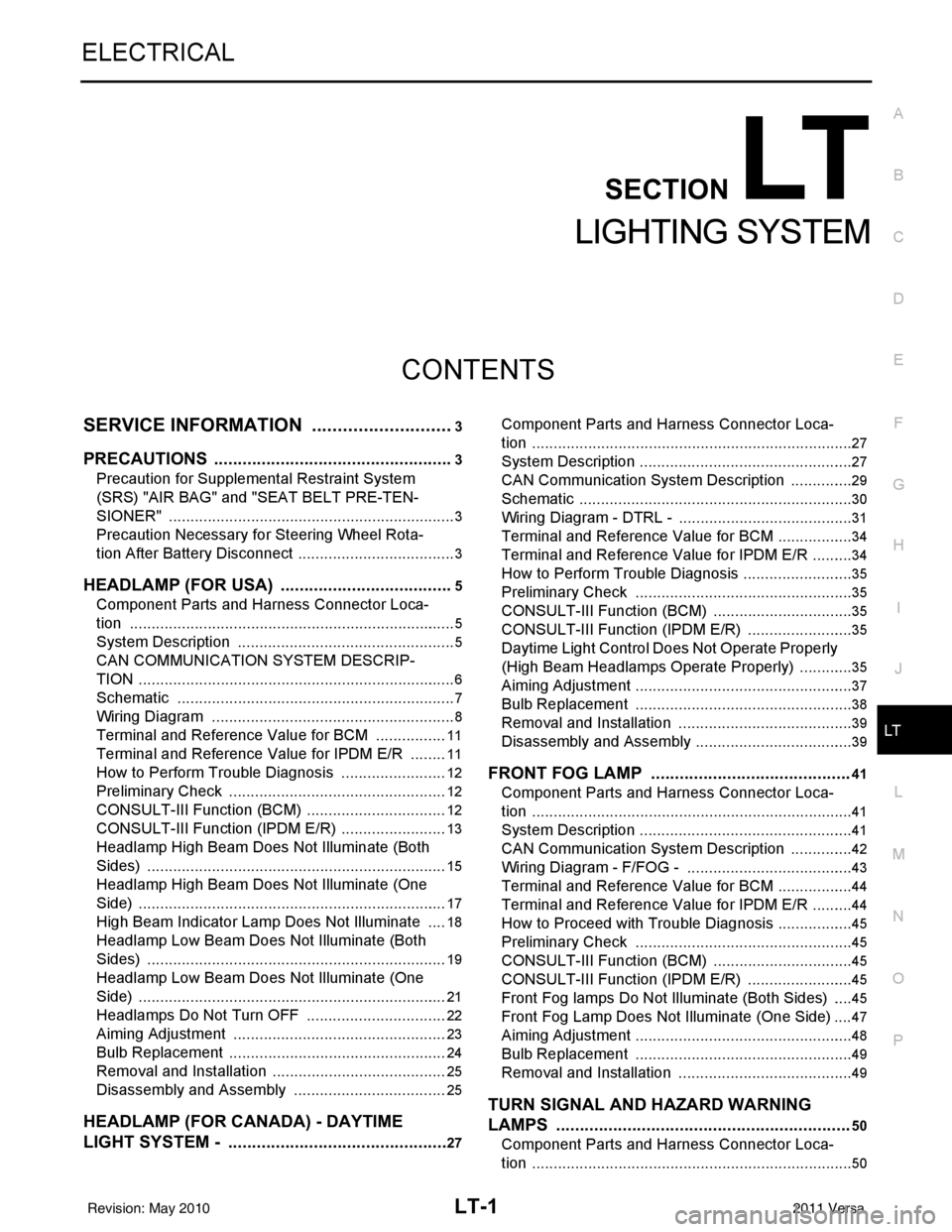

LT-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION LT

A

B

LT

N

O P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

HEADLAMP (FOR USA) .....................................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

CAN COMMUNICATION SYSTEM DESCRIP-

TION .................................................................... ......

6

Schematic .................................................................7

Wiring Diagram .........................................................8

Terminal and Reference Value for BCM .................11

Terminal and Reference Value for IPDM E/R .........11

How to Perform Trouble Diagnosis .........................12

Preliminary Check ...................................................12

CONSULT-III Function (BCM) .................................12

CONSULT-III Function (IPDM E/R) .........................13

Headlamp High Beam Does Not Illuminate (Both

Sides) .................................................................. ....

15

Headlamp High Beam Does Not Illuminate (One

Side) .................................................................... ....

17

High Beam Indicator Lamp Does Not Illuminate .....18

Headlamp Low Beam Does Not Illuminate (Both

Sides) .................................................................. ....

19

Headlamp Low Beam Does Not Illuminate (One

Side) .................................................................... ....

21

Headlamps Do Not Turn OFF .................................22

Aiming Adjustment ..................................................23

Bulb Replacement ...................................................24

Removal and Installation .........................................25

Disassembly and Assembly ................................ ....25

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ........................................... ....

27

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

27

System Description ..................................................27

CAN Communication System Description ...............29

Schematic ................................................................30

Wiring Diagram - DTRL - .........................................31

Terminal and Reference Value for BCM ..................34

Terminal and Reference Value for IPDM E/R ...... ....34

How to Perform Trouble Diagnosis ..........................35

Preliminary Check ...................................................35

CONSULT-III Function (BCM) .................................35

CONSULT-III Function (IPDM E/R) ..................... ....35

Daytime Light Control Does Not Operate Properly

(High Beam Headlamps Operate Properly) .............

35

Aiming Adjustment ...................................................37

Bulb Replacement ...................................................38

Removal and Installation .........................................39

Disassembly and Assembly .....................................39

FRONT FOG LAMP ..........................................41

Component Parts and Harness Connector Loca-

tion ...........................................................................

41

System Description ..................................................41

CAN Communication System Description ...............42

Wiring Diagram - F/FOG - .......................................43

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ...... ....44

How to Proceed with Trouble Diagnosis ..................45

Preliminary Check ............................................... ....45

CONSULT-III Function (BCM) .................................45

CONSULT-III Function (IPDM E/R) ..................... ....45

Front Fog lamps Do Not Illuminate (Both Sides) .....45

Front Fog Lamp Does Not Illuminate (One Side) ....47

Aiming Adjustment ...................................................48

Bulb Replacement ...................................................49

Removal and Installation .........................................49

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

50

Component Parts and Harness Connector Loca-

tion ...........................................................................

50

Revision: May 2010 2011 Versa