Lighting NISSAN TIIDA 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3094 of 3787

LT-62

< SERVICE INFORMATION >

LIGHTING AND TURN SIGNAL SWITCH

LIGHTING AND TURN SIGNAL SWITCH

Removal and InstallationINFOID:0000000005929098

REMOVAL

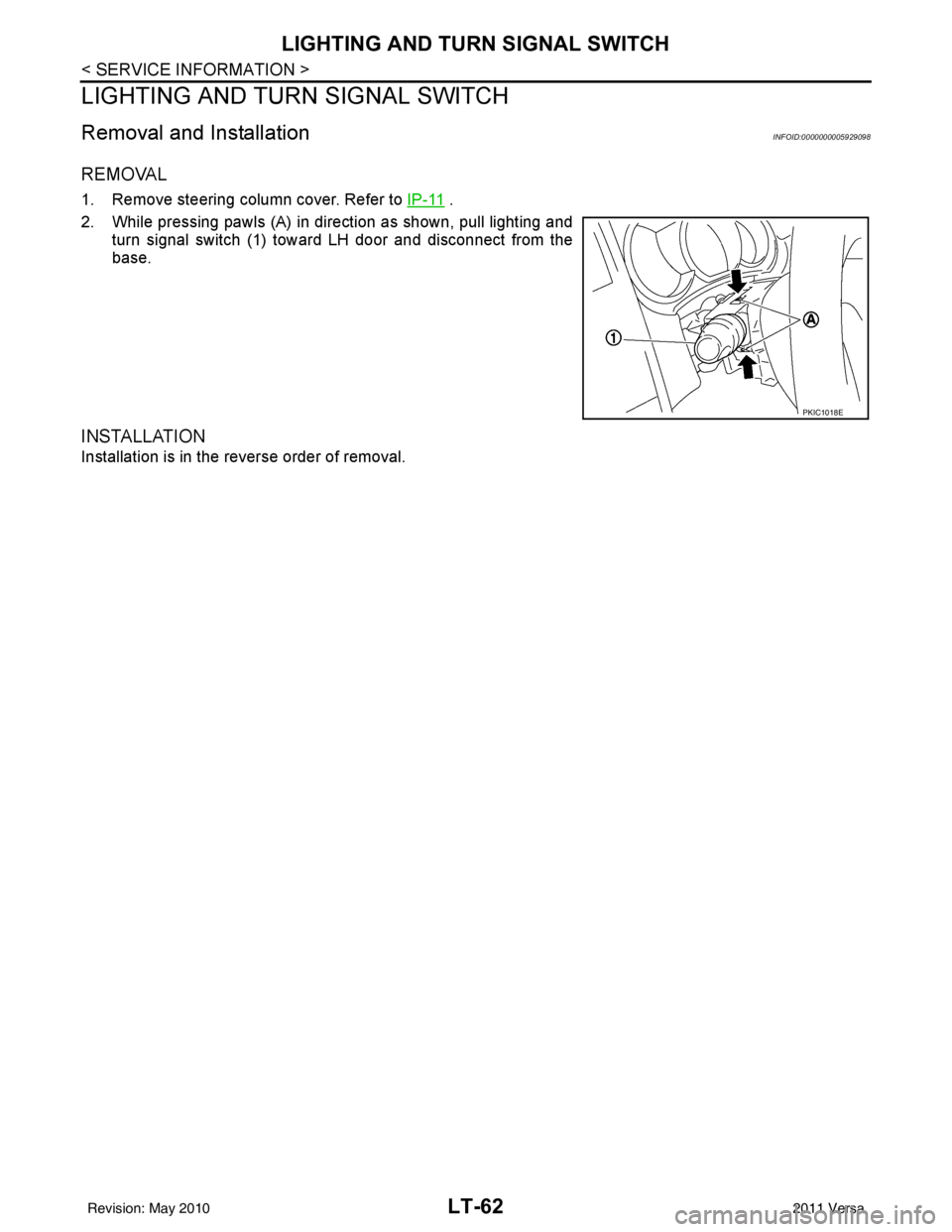

1. Remove steering column cover. Refer to IP-11 .

2. While pressing pawls (A) in direction as shown, pull lighting and turn signal switch (1) toward LH door and disconnect from the

base.

INSTALLATION

Installation is in the reverse order of removal.

PKIC1018E

Revision: May 2010 2011 Versa

Page 3097 of 3787

COMBINATION SWITCHLT-65

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Terminal and Reference Value for BCMINFOID:0000000005929102

Refer to BCS-12, "Terminal and Reference Value for BCM" .

CONSULT-III Function (BCM)INFOID:0000000005929103

Refer to BCS-17, "CONSULT-III Function (BCM)" .

Combination Switch InspectionINFOID:0000000005929104

1.SYSTEM CHECK

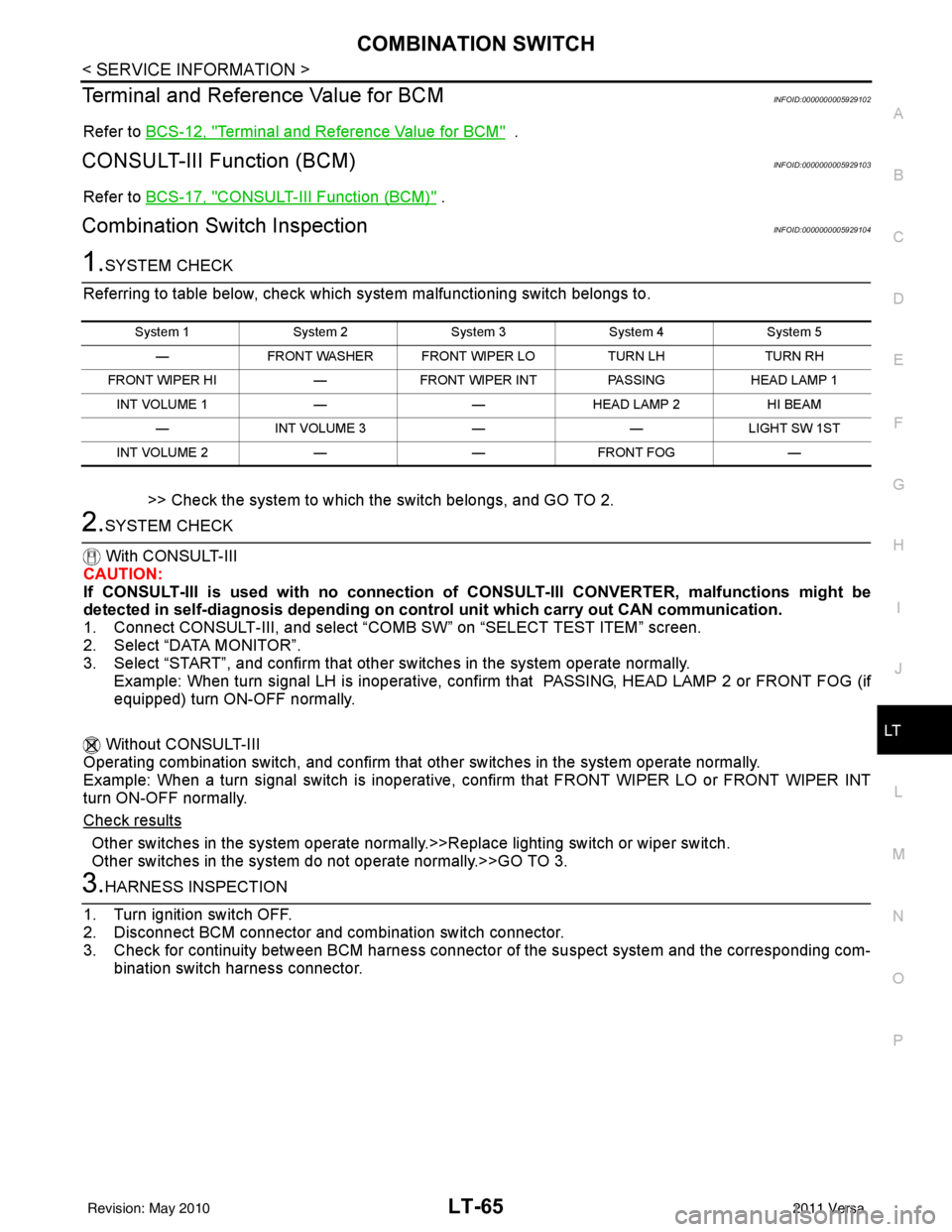

Referring to table below, check which system malfunctioning switch belongs to.

>> Check the system to which the switch belongs, and GO TO 2.

2.SYSTEM CHECK

With CONSULT-III

CAUTION:

If CONSULT-III is used with no connection of CONSULT-III CONVERTER, malfunctions might be

detected in self-diagnosis de pending on control unit which carry out CAN communication.

1. Connect CONSULT-III, and select “C OMB SW” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in the system operate normally.

Example: When turn signal LH is inoperative, confi rm that PASSING, HEAD LAMP 2 or FRONT FOG (if

equipped) turn ON-OFF normally.

Without CONSULT-III

Operating combination switch, and confirm that other switches in the system operate normally.

Example: When a turn signal switch is inoperative, confirm that FRONT WIPER LO or FRONT WIPER INT

turn ON-OFF normally.

Check results

Other switches in the system operate normall y.>>Replace lighting switch or wiper switch.

Other switches in the system do not operate normally.>>GO TO 3.

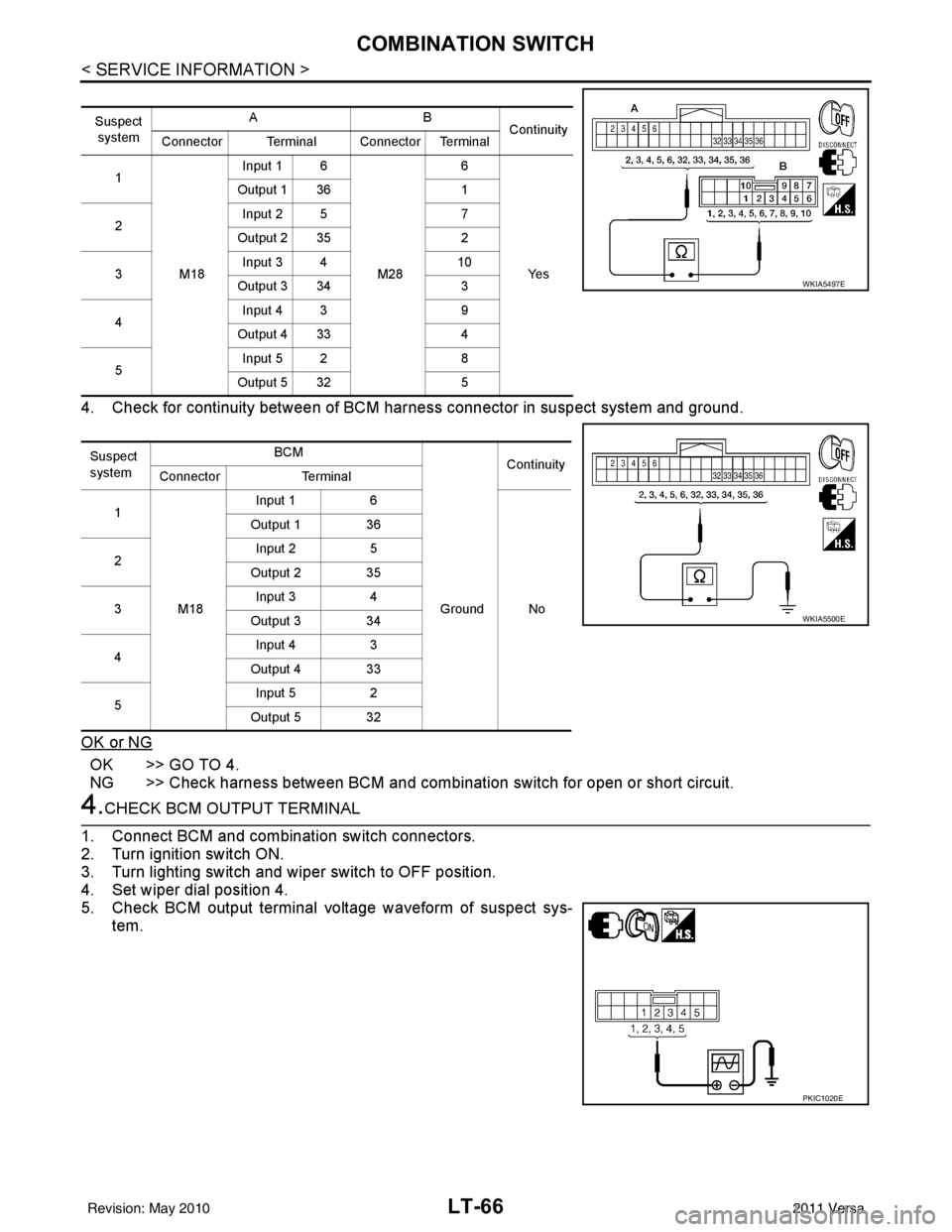

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM connector and combination switch connector.

3. Check for continuity between BCM harness connecto r of the suspect system and the corresponding com-

bination switch harness connector.

System 1 System 2System 3System 4System 5

— FRONT WASHER FRONT WIPER LO TURN LHTURN RH

FRONT WIPER HI —FRONT WIPER INT PASSINGHEAD LAMP 1

INT VOLUME 1 ——HEAD LAMP 2 HI BEAM

— INT VOLUME 3 ——LIGHT SW 1ST

INT VOLUME 2 ——FRONT FOG —

Revision: May 2010 2011 Versa

Page 3098 of 3787

LT-66

< SERVICE INFORMATION >

COMBINATION SWITCH

4. Check for continuity between of BCM harness connector in suspect system and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

4.CHECK BCM OUTPUT TERMINAL

1. Connect BCM and combination switch connectors.

2. Turn ignition switch ON.

3. Turn lighting switch and wiper switch to OFF position.

4. Set wiper dial position 4.

5. Check BCM output terminal voltage waveform of suspect sys- tem.

Suspect

system AB

Continuity

Connector Terminal Connector Terminal

1

M18Input 1 6

M286

Ye s

Output 1 36

1

2 Input 2 5

7

Output 2 35 2

3 Input 3 4

10

Output 3 34 3

4 Input 4 3

9

Output 4 33 4

5 Input 5 2

8

Output 5 32 5

Suspect

system BCM

Continuity

Connector Terminal

1

M18 Input 1

6

Ground No

Output 1 36

2 Input 2

5

Output 2 35

3 Input 3

4

Output 3 34

4 Input 4

3

Output 4 33

5 Input 5

2

Output 5 32

WKIA5497E

WKIA5500E

PKIC1020E

Revision: May 2010 2011 Versa

Page 3099 of 3787

COMBINATION SWITCHLT-67

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

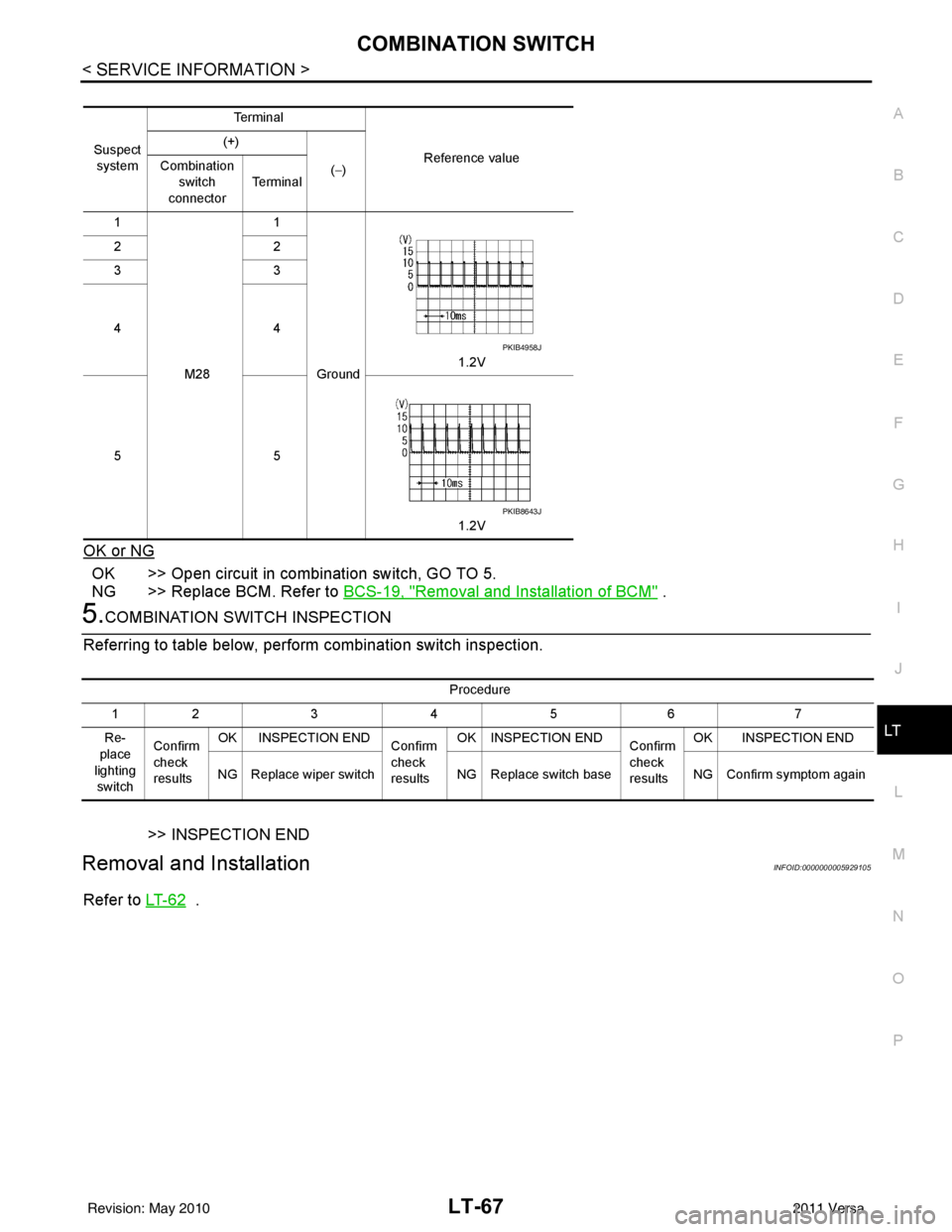

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM" .

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationINFOID:0000000005929105

Refer to LT- 6 2 .

Suspect

system Te r m i n a l

Reference value

(+)

(−)

Combination

switch

connector Te r m i n a l

1

M28 1

Ground 1.2V

22

33

44

55

1.2V

PKIB4958J

PKIB8643J

Procedure

12 3 4 5 6 7

Re-

place

lighting switch Confirm

check

results

OK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NG Replace wiper switch NG Replace switch baseNG Confirm symptom again

Revision: May 2010 2011 Versa

Page 3106 of 3787

LT-74

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

PARKING, LICENSE PLATE AND TAIL LAMPS

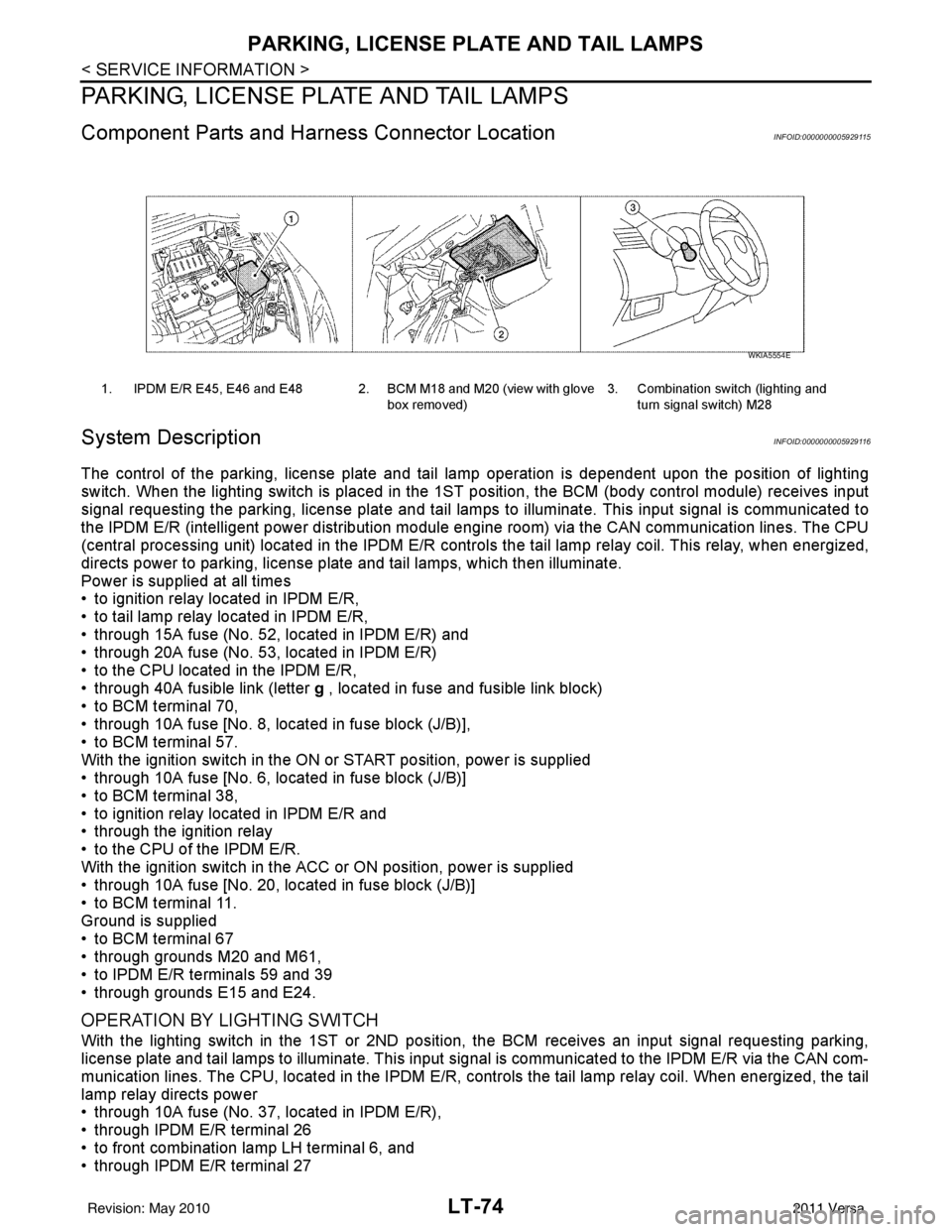

Component Parts and Harness Connector LocationINFOID:0000000005929115

System DescriptionINFOID:0000000005929116

The control of the parking, license plate and tail lamp operation is dependent upon the position of lighting

switch. When the lighting switch is placed in the 1ST position, the BCM (body cont rol module) receives input

signal requesting the parking, license plate and tail lamps to illuminate. This input signal is communicated to

the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines. The CPU

(central processing unit) located in the IPDM E/R contro ls the tail lamp relay coil. This relay, when energized,

directs power to parking, license plate and tail lamps, which then illuminate.

Power is supplied at all times

• to ignition relay located in IPDM E/R,

• to tail lamp relay located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to the CPU located in the IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)],

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• to ignition relay located in IPDM E/R and

• through the ignition relay

• to the CPU of the IPDM E/R.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M20 and M61,

• to IPDM E/R terminals 59 and 39

• through grounds E15 and E24.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position, the BCM receives an input signal requesting parking,

license plate and tail lamps to illuminate. This input signal is communicated to the IPDM E/R via the CAN com-

munication lines. The CPU, located in the IPDM E/R, controls the tail lamp relay coil. When energized, the tail

lamp relay directs power

• through 10A fuse (No. 37, located in IPDM E/R),

• through IPDM E/R terminal 26

• to front combination lamp LH terminal 6, and

• through IPDM E/R terminal 27

1. IPDM E/R E45, E46 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting and

turn signal switch) M28

WKIA5554E

Revision: May 2010 2011 Versa

Page 3107 of 3787

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-75

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

• to front combination lamp RH terminal 6,

• through IPDM E/R terminal 28

• to rear combination lamp LH terminal 4 and

• to license plate lamp LH and RH terminal 1,

• through IPDM E/R terminal 29

• to rear combination lamp RH terminal 4.

Ground is supplied

• to front combination lamp LH and RH terminal 7

• through grounds E15 and E24,

• to rear combination lamp LH terminal 1 and

• to license plate lamp LH and RH terminal 2

• through grounds B7 and B19, and

• to rear combination lamp RH terminal 1

• through grounds B117, B132 (all models) and D402 (with hatchback).

With power and ground supplied, parking, license plate and tail lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting and turn signal switch) is in the 1ST (or 2ND) position and the ignition

switch is turned from ON or ACC to OFF, t he battery saver control feature is activated.

Under this condition, the parking, license and tail lamps remain illumi nated for 5 minutes, then the parking,

license plate and tail lamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-III.

CAN Communication System DescriptionINFOID:0000000005929117

Refer to LAN-7, "System Description" .

Revision: May 2010 2011 Versa

Page 3113 of 3787

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-81

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

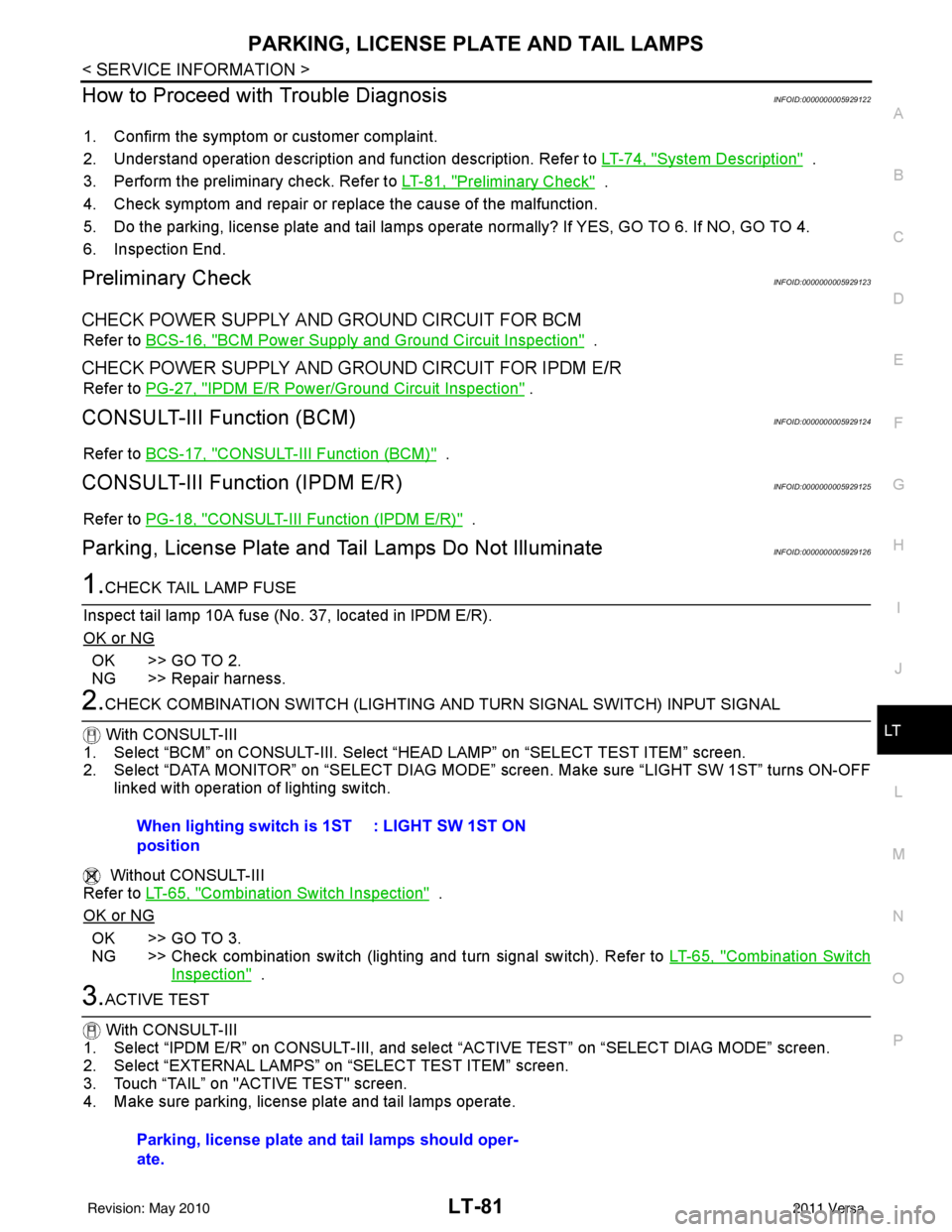

How to Proceed with Trouble DiagnosisINFOID:0000000005929122

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-74, "

System Description" .

3. Perform the preliminary check. Refer to LT-81, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of the malfunction.

5. Do the parking, license plate and tail lamps operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000005929123

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-16, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-27, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-III Function (BCM)INFOID:0000000005929124

Refer to BCS-17, "CONSULT-III Function (BCM)" .

CONSULT-III Function (IPDM E/R)INFOID:0000000005929125

Refer to PG-18, "CONSULT-III Function (IPDM E/R)" .

Parking, License Plate and Tail Lamps Do Not IlluminateINFOID:0000000005929126

1.CHECK TAIL LAMP FUSE

Inspect tail lamp 10A fuse (No. 37, located in IPDM E/R).

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen. Make sure “LIGHT SW 1ST” turns ON-OFF linked with operation of lighting switch.

Without CONSULT-III

Refer to LT-65, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Check combination switch (lighting and turn signal switch). Refer to LT-65, "

Combination Switch

Inspection" .

3.ACTIVE TEST

With CONSULT-III

1. Select “IPDM E/R” on CONSUL T-III, and select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “TAIL” on "ACTIVE TEST" screen.

4. Make sure parking, license plate and tail lamps operate. When lighting switch is 1ST

position

: LIGHT SW 1ST ON

Parking, license plate and tail lamps should oper-

ate.

Revision: May 2010

2011 Versa

Page 3114 of 3787

LT-82

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

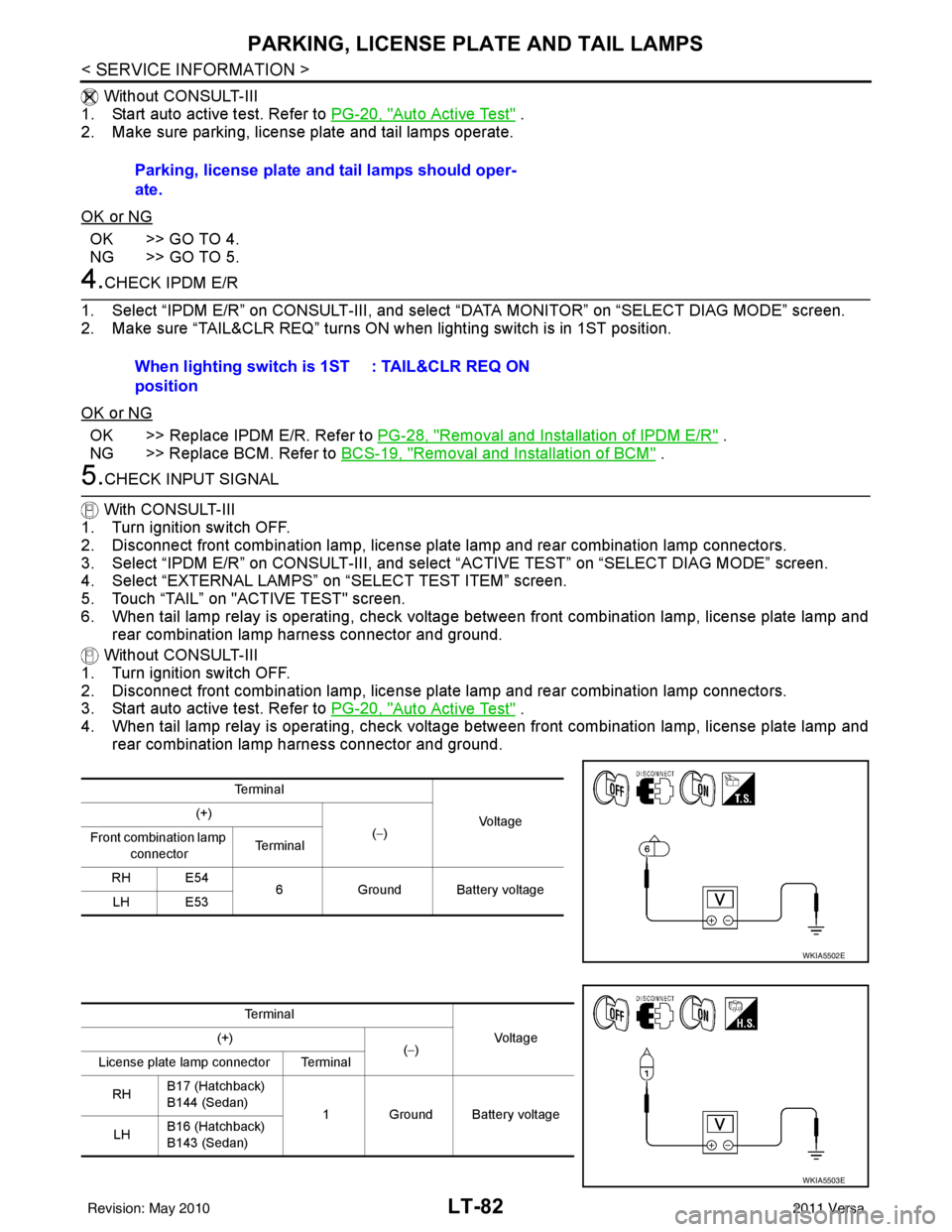

Without CONSULT-III

1. Start auto active test. Refer to PG-20, "

Auto Active Test" .

2. Make sure parking, license plate and tail lamps operate.

OK or NG

OK >> GO TO 4.

NG >> GO TO 5.

4.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-III, and select “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Make sure “TAIL&CLR REQ” turns ON when lighting switch is in 1ST position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM" .

5.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect front combination lamp, license plate lamp and rear combination lamp connectors.

3. Select “IPDM E/R” on CONSULT-III, and sele ct “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “TAIL” on "ACTIVE TEST" screen.

6. When tail lamp relay is operating, check voltage between front combination lamp, license plate lamp and rear combination lamp harness connector and ground.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect front combination lamp, license plate lamp and rear combination lamp connectors.

3. Start auto active test. Refer to PG-20, "

Auto Active Test" .

4. When tail lamp relay is operating, check voltage between front combination lamp, license plate lamp and rear combination lamp harness connector and ground.Parking, license plate and tail lamps should oper-

ate.

When lighting switch is 1ST

position

: TAIL&CLR REQ ON

Te r m i n a l

Voltag e

(+)

(−)

Front combination lamp

connector Te r m i n a l

RH E54 6Ground Battery voltage

LH E53

WKIA5502E

Te r m i n a l

Vo l ta g e

(+)

(−)

License plate lamp connector Terminal

RH B17 (Hatchback)

B144 (Sedan)

1 Ground Battery voltage

LH B16 (Hatchback)

B143 (Sedan)

WKIA5503E

Revision: May 2010

2011 Versa

Page 3116 of 3787

LT-84

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

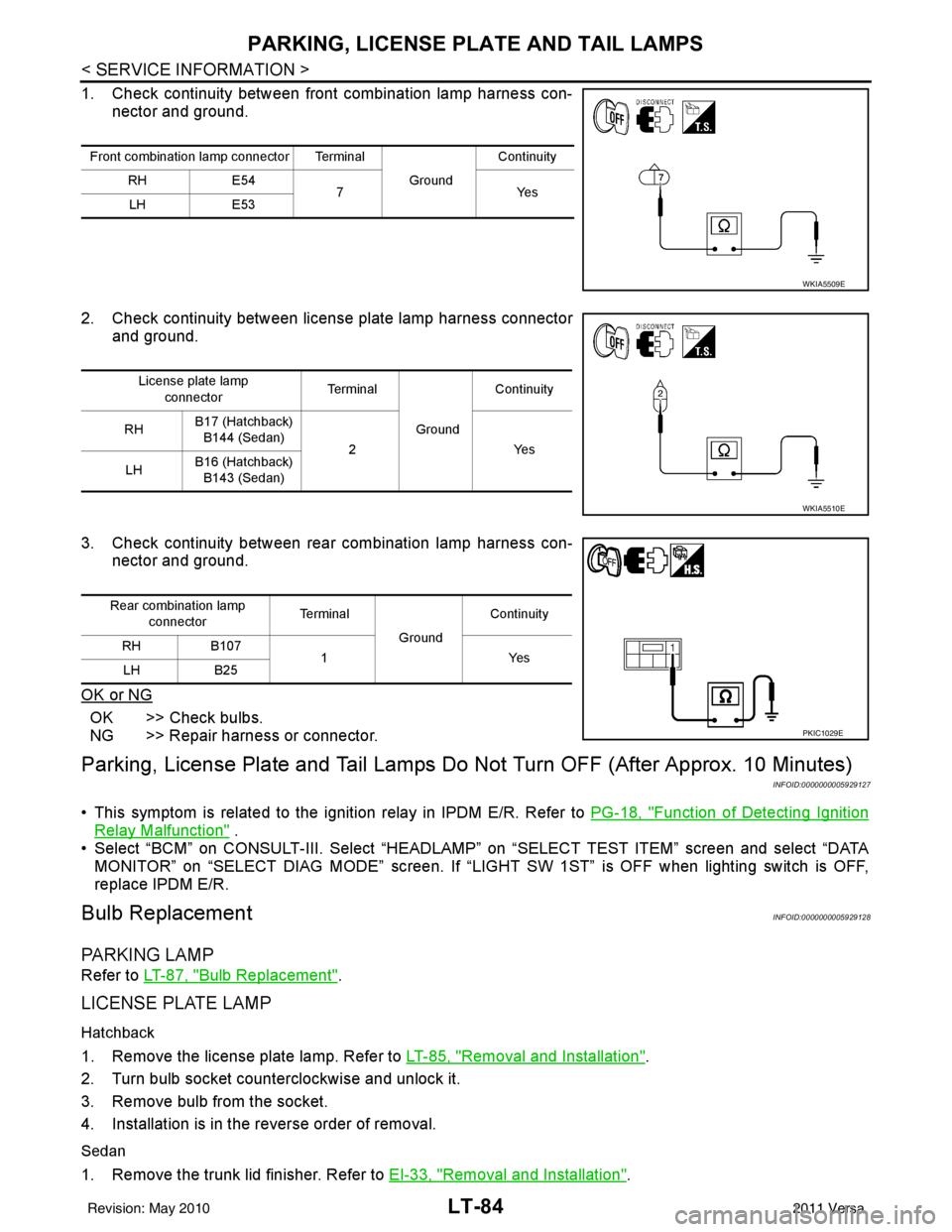

1. Check continuity between front combination lamp harness con-nector and ground.

2. Check continuity between license plate lamp harness connector and ground.

3. Check continuity between rear combination lamp harness con- nector and ground.

OK or NG

OK >> Check bulbs.

NG >> Repair harness or connector.

Parking, License Plate and Tail Lamps Do Not Turn OFF (After Approx. 10 Minutes)

INFOID:0000000005929127

• This symptom is related to the ignition relay in IPDM E/R. Refer to PG-18, "Function of Detecting Ignition

Relay Malfunction" .

• Select “BCM” on CONSULT-III. Select “HEADLAMP” on “SELECT TEST ITEM” screen and select “DATA

MONITOR” on “SELECT DIAG MODE” sc reen. If “LIGHT SW 1ST” is OFF when lighting switch is OFF,

replace IPDM E/R.

Bulb ReplacementINFOID:0000000005929128

PA R K I N G L A M P

Refer to LT-87, "Bulb Replacement".

LICENSE PLATE LAMP

Hatchback

1. Remove the license plate lamp. Refer to LT-85, "Removal and Installation".

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from the socket.

4. Installation is in the reverse order of removal.

Sedan

1. Remove the trunk lid finisher. Refer to EI-33, "Removal and Installation".

Front combination lamp connector Terminal

GroundContinuity

RH E54

7Y es

LH E53

WKIA5509E

License plate lamp

connector Te r m i n a l

GroundContinuity

RH B17 (Hatchback)

B144 (Sedan) 2 Yes

LH B16 (Hatchback)

B143 (Sedan)

WKIA5510E

Rear combination lamp connector Te r m i n a l

GroundContinuity

RH B107

1Y es

LH B25

PKIC1029E

Revision: May 2010 2011 Versa

Page 3141 of 3787

ILLUMINATIONLT-109

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

ILLUMINATION

System DescriptionINFOID:0000000005929150

The control of the illumination lamps operation is dependent upon the position of the lighting switch. When the

lighting switch is placed in the 1ST or 2ND position, the BCM (body control module) receives input signal

requesting the illumination lamps to illuminate. This input signal is communicated to IPDM E/R (intelligent

power distribution module engine room) across CAN communication lines. CPU (central processing unit)

located in the IPDM E/R controls the tail lamp relay coil . This relay, when energized, directs power to the illu-

mination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in IPDM E/R,

• to tail lamp relay, located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70, and

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in IPDM E/R, and

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61

• to IPDM E/R terminals 39 and 59, and

• through grounds E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND positi on, BCM receives input signal requesting the illumination

lamps to illuminate. This input signal is communicat ed to IPDM E/R across CAN communication lines. CPU

located in the IPDM E/R controls the tail lamp relay coil, which, when energized, directs power

• through 10A fuse (No. 37, located in IPDM E/R)

• through IPDM E/R terminal 29

• to illumination control switch terminal 1

• to VDC OFF switch terminal 3 (with VDC)

• to audio unit terminal 9

• to front air control terminal 5

• to A/T shift selector terminal 3 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

• to hazard switch terminal 3

• to combination meter terminal 12

• to door mirror remote control switch terminal 16

• to combination switch (spiral cable) terminal 26 (with steering wheel audio control switches)

• to steering wheel audio control switches through combinat ion switch (spiral cable) terminal 18 (with steering

wheel audio control switches).

Ground is supplied

• to VDC OFF switch terminal 4 (with VDC)

• to illumination control switch terminal 3, and

• through grounds M57 and M61.

The illumination control switch controls illuminat ion intensity by varying the ground to the following

• through illumination control switch terminal 2

• to audio unit terminal 8

• to front air control terminal 6

• to A/T shift selector terminal 4 (with 4-speed A/T)

• to CVT shift selector terminal 3 (with CVT)

Revision: May 2010 2011 Versa