suspension NISSAN TIIDA 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3562 of 3787

SHOCK ABSORBERRSU-9

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SHOCK ABSORBER

Removal and InstallationINFOID:0000000005931087

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly and rear suspension beam. Refer to BRC-

33 .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove shock absorber mask from trunk side fini sher using a flat-bladed screwdriver. Refer to EI-56

.

CAUTION:

Wrap the tip of a screwdriver with cl oth to avoid damaging components.

4. Set jack under rear suspension beam.

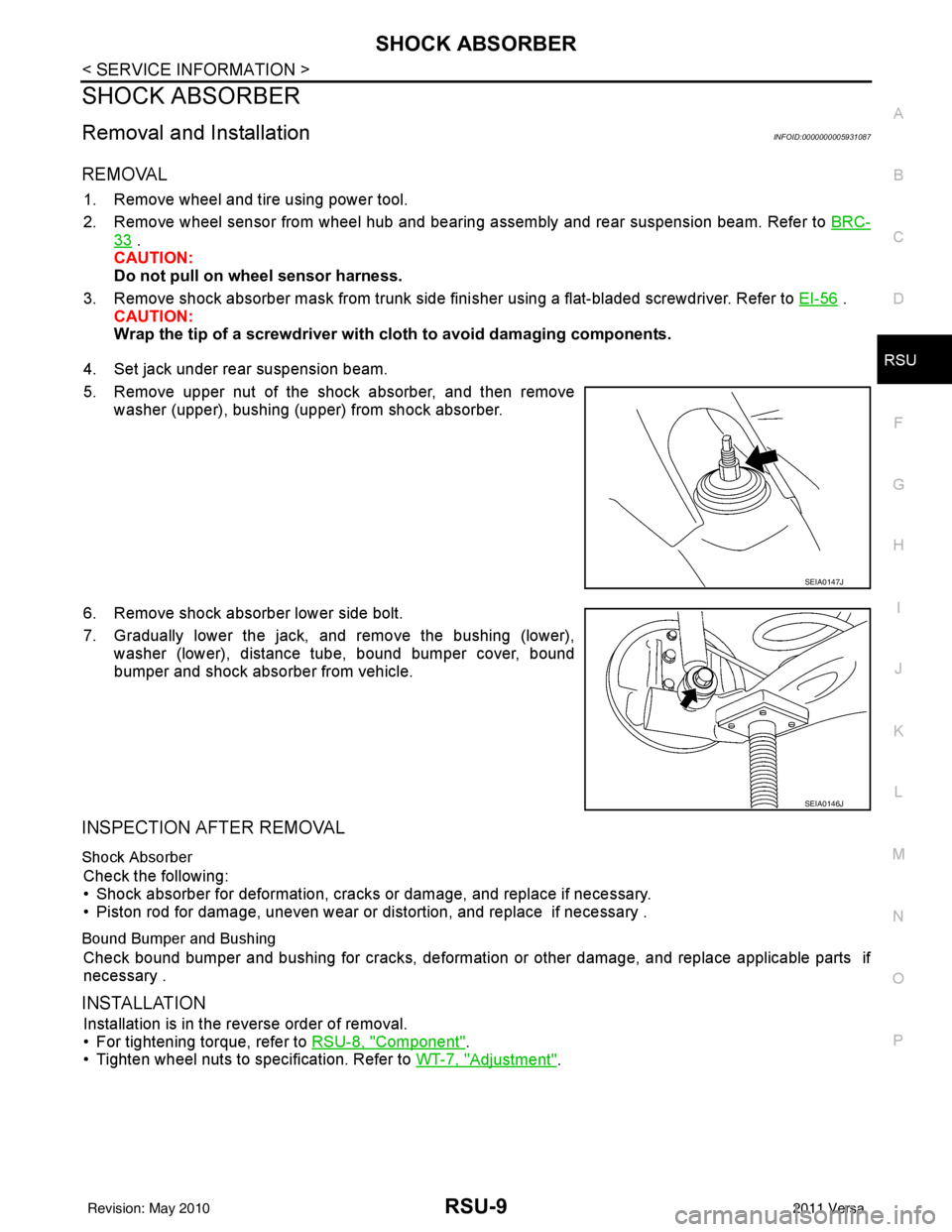

5. Remove upper nut of the shock absorber, and then remove washer (upper), bushing (upper) from shock absorber.

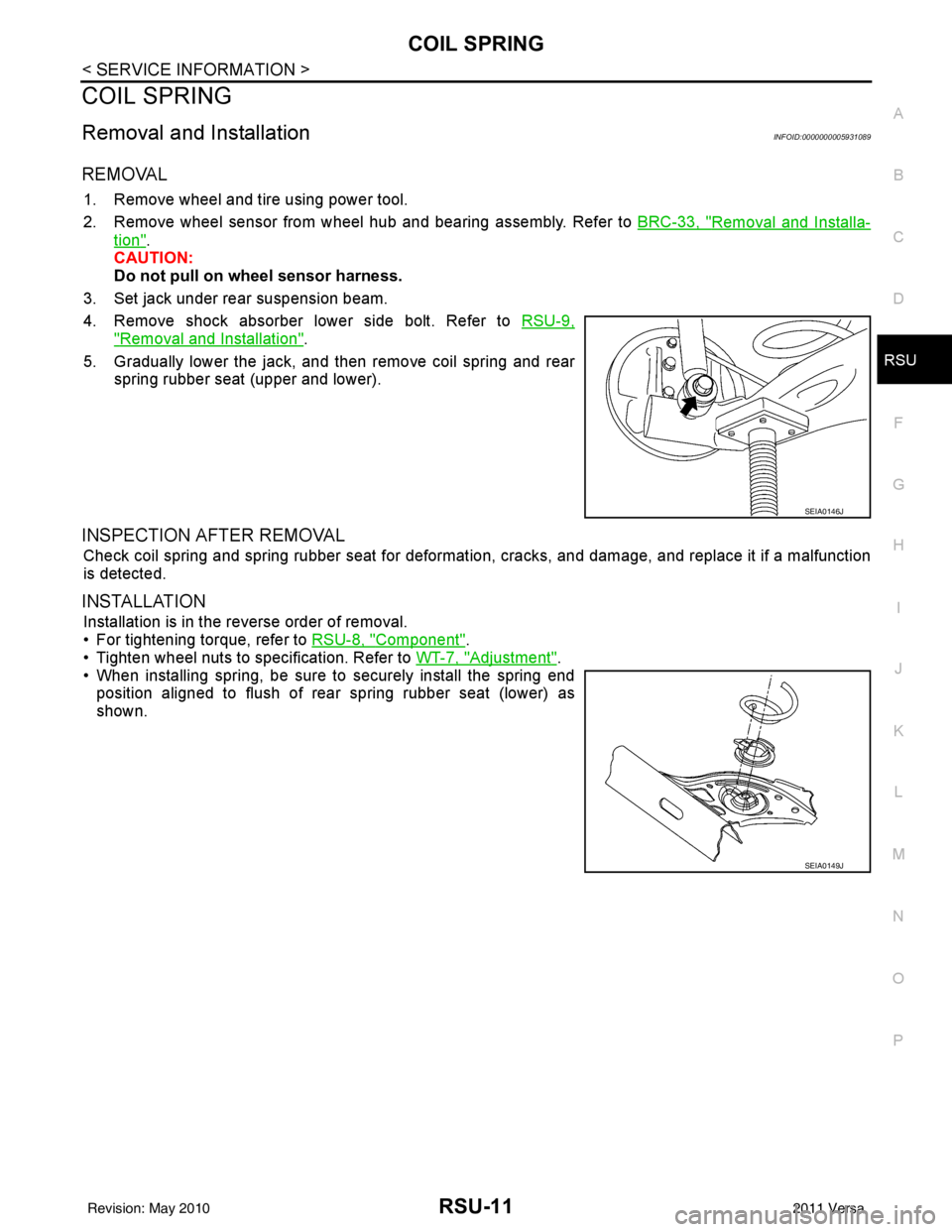

6. Remove shock absorber lower side bolt.

7. Gradually lower the jack, and remove the bushing (lower), washer (lower), distance tube, bound bumper cover, bound

bumper and shock absorber from vehicle.

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following:

• Shock absorber for deformation, cracks or damage, and replace if necessary.

• Piston rod for damage, uneven wear or distortion, and replace if necessary .

Bound Bumper and Bushing

Check bound bumper and bushing for cracks, deformation or other damage, and replace applicable parts if

necessary .

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

SEIA0147J

SEIA0146J

Revision: May 2010 2011 Versa

Page 3564 of 3787

COIL SPRINGRSU-11

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

COIL SPRING

Removal and InstallationINFOID:0000000005931089

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-33, "

Removal and Installa-

tion".

CAUTION:

Do not pull on wheel sensor harness.

3. Set jack under rear suspension beam.

4. Remove shock absorber lower side bolt. Refer to RSU-9,

"Removal and Installation".

5. Gradually lower the jack, and then remove coil spring and rear spring rubber seat (upper and lower).

INSPECTION AFTER REMOVAL

Check coil spring and spring rubber seat for deformation, cracks, and damage, and replace it if a malfunction

is detected.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• When installing spring, be sure to securely install the spring end position aligned to flush of rear spring rubber seat (lower) as

shown.

SEIA0146J

SEIA0149J

Revision: May 2010 2011 Versa

Page 3565 of 3787

RSU-12

< SERVICE INFORMATION >

REAR SUSPENSION BEAM

REAR SUSPENSION BEAM

Removal and InstallationINFOID:0000000005931090

REMOVAL

1. Remove wheel and tire using power tool.

2. Separate parking brake rear cable from rear drum brake and rear suspension beam. Refer to PB-5, "

On-

Vehicle Service".

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-33, "

Removal and Installation".

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, "

Rear Brake Tube and Hose".

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-6, "

On-Vehicle Inspection and Service".

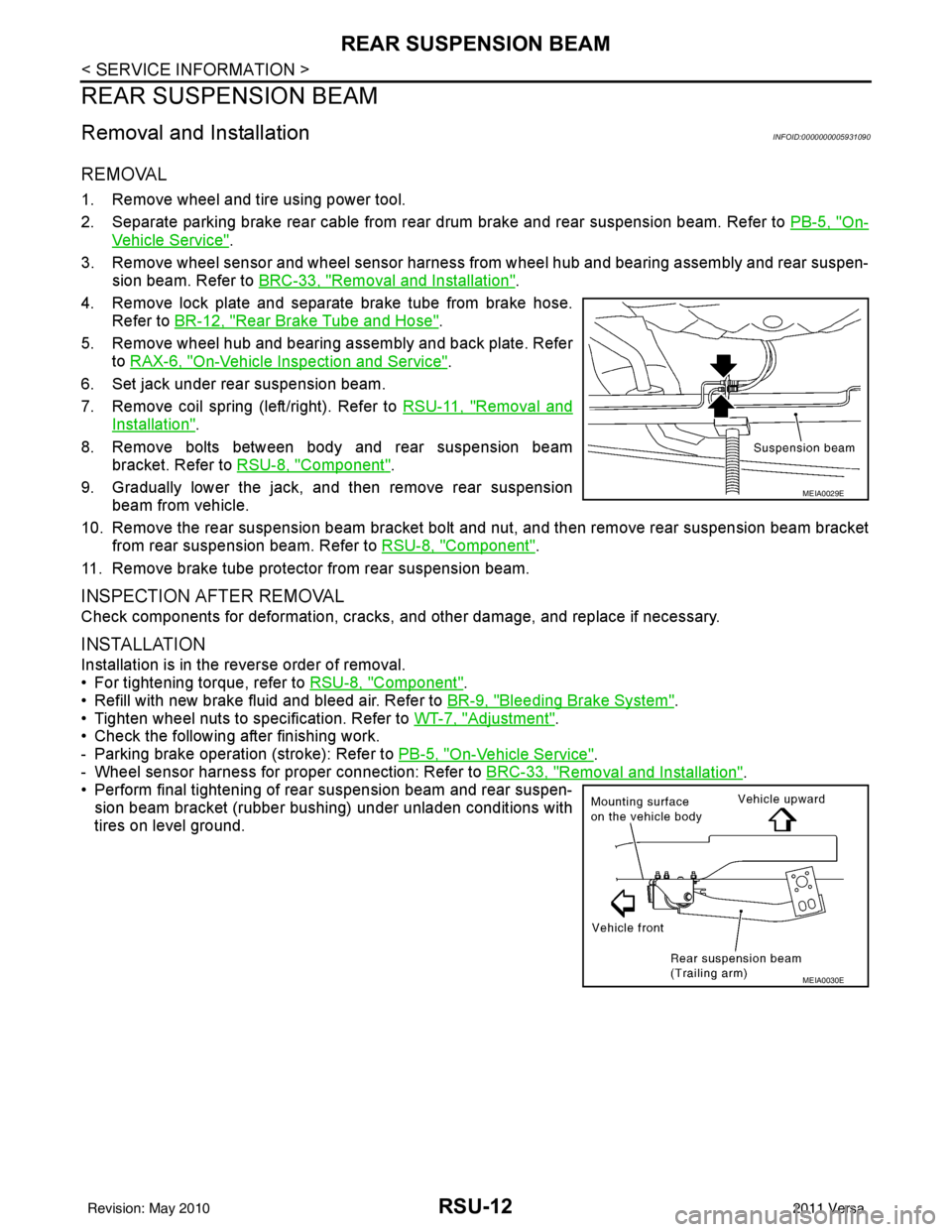

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, "

Removal and

Installation".

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, "

Component".

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, "

Component".

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, "

On-Vehicle Service".

- Wheel sensor harness for proper connection: Refer to BRC-33, "

Removal and Installation".

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground.

MEIA0029E

MEIA0030E

Revision: May 2010 2011 Versa

Page 3718 of 3787

![NISSAN TIIDA 2011 Service Service Manual PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab NISSAN TIIDA 2011 Service Service Manual PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cab](/img/5/57396/w960_57396-3717.png)

PRECAUTIONSSTC-31

< PRECAUTION > [EPS]

C

D

E

F

H I

J

K L

M A

B

STC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service Notice or Precaution for EPS SystemINFOID:0000000005931271

CAUTION:

Check or confirm the following item wh en performing the trouble diagnosis.

• Check any possible causes by interviewing the symptom and it’s condition from the customer if any

malfunction, such as EPS warn ing lamp turns ON, occurs.

• Check if air pressure and size of tires are proper, the specified part is used for the steering wheel,

and control unit is genuine part.

• Check if the connection of steer ing column assembly and steering gear assembly is proper (there is

not looseness of mounting bolts, damage of rods, boots or sealants, and leakage of grease, etc).

• Check if the wheel alignment is adjusted properly.

• Check if there is any damage or modification to su spension or body resulting in increased weight or

altered ground clearance.

• Check if installation conditions of each link and suspension are proper.

• Check if the battery voltage is proper

• Check connection conditions of each connector are proper.

• Before connecting or disconnect ing the EPS control unit har-

ness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Because battery voltage is applied to

EPS control unit even if igniti on switch is turned “OFF”.

• When connecting or disconnect ing pin connectors into or

from EPS control unit, take care not to damage pin terminals

(bend or break).

When connecting pin connectors, make sure that there are no

bends or breaks on EPS control unit pin terminal.

• Before replacing EPS control unit, perform EPS control unit input/output signal inspectio n and make sure whether EPS

control unit functions properly or not. Refer to STC-20, "

Ref-

erence Value".

SEF289H

SEF291H

SDIA1848E

Revision: May 2010 2011 Versa

Page 3719 of 3787

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

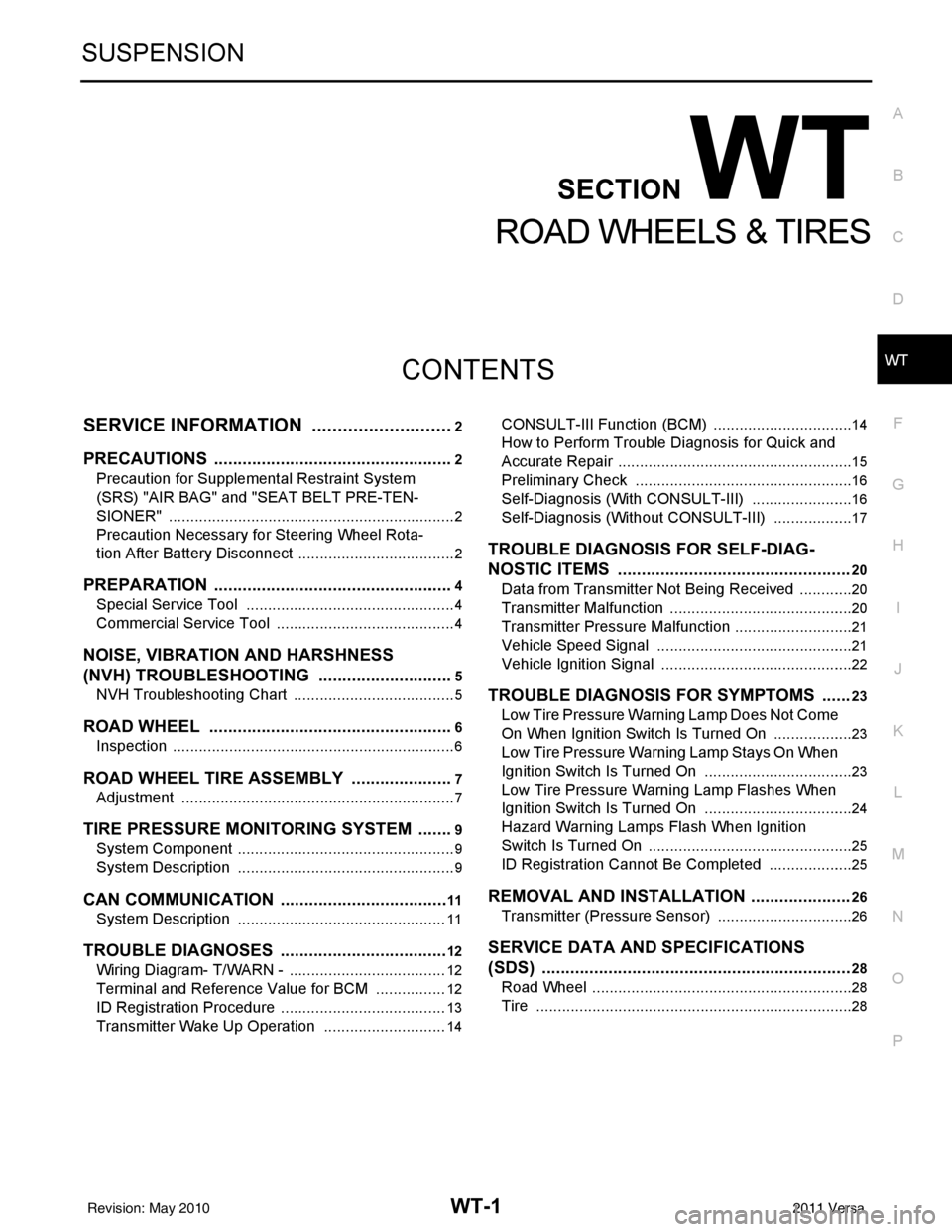

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

ROAD WHEEL ....................................................6

Inspection ............................................................ ......6

ROAD WHEEL TIRE ASSEMBLY ......................7

Adjustment .......................................................... ......7

TIRE PRESSURE MONITORING SYSTEM ........9

System Component ............................................. ......9

System Description ...................................................9

CAN COMMUNICATION ....................................11

System Description ............................................. ....11

TROUBLE DIAGNOSES ....................................12

Wiring Diagram- T/WARN - .....................................12

Terminal and Reference Value for BCM .................12

ID Registration Procedure .......................................13

Transmitter Wake Up Operation .............................14

CONSULT-III Function (BCM) .................................14

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

15

Preliminary Check ...................................................16

Self-Diagnosis (With CONSULT-III) ........................16

Self-Diagnosis (Without CONSULT-III) ...................17

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

20

Data from Transmitter Not Being Received .............20

Transmitter Malfunction ...........................................20

Transmitter Pressure Malfunction ............................21

Vehicle Speed Signal .......................................... ....21

Vehicle Ignition Signal .............................................22

TROUBLE DIAGNOSIS FOR SYMPTOMS ......23

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

23

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ............................... ....

23

Low Tire Pressure Warning Lamp Flashes When

Ignition Switch Is Turned On ...................................

24

Hazard Warning Lamps Flash When Ignition

Switch Is Turned On ................................................

25

ID Registration Cannot Be Completed ....................25

REMOVAL AND INSTALLATION .....................26

Transmitter (Pressure Sens or) ................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

28

Road Wheel ......................................................... ....28

Tire ..........................................................................28

Revision: May 2010 2011 Versa

Page 3723 of 3787

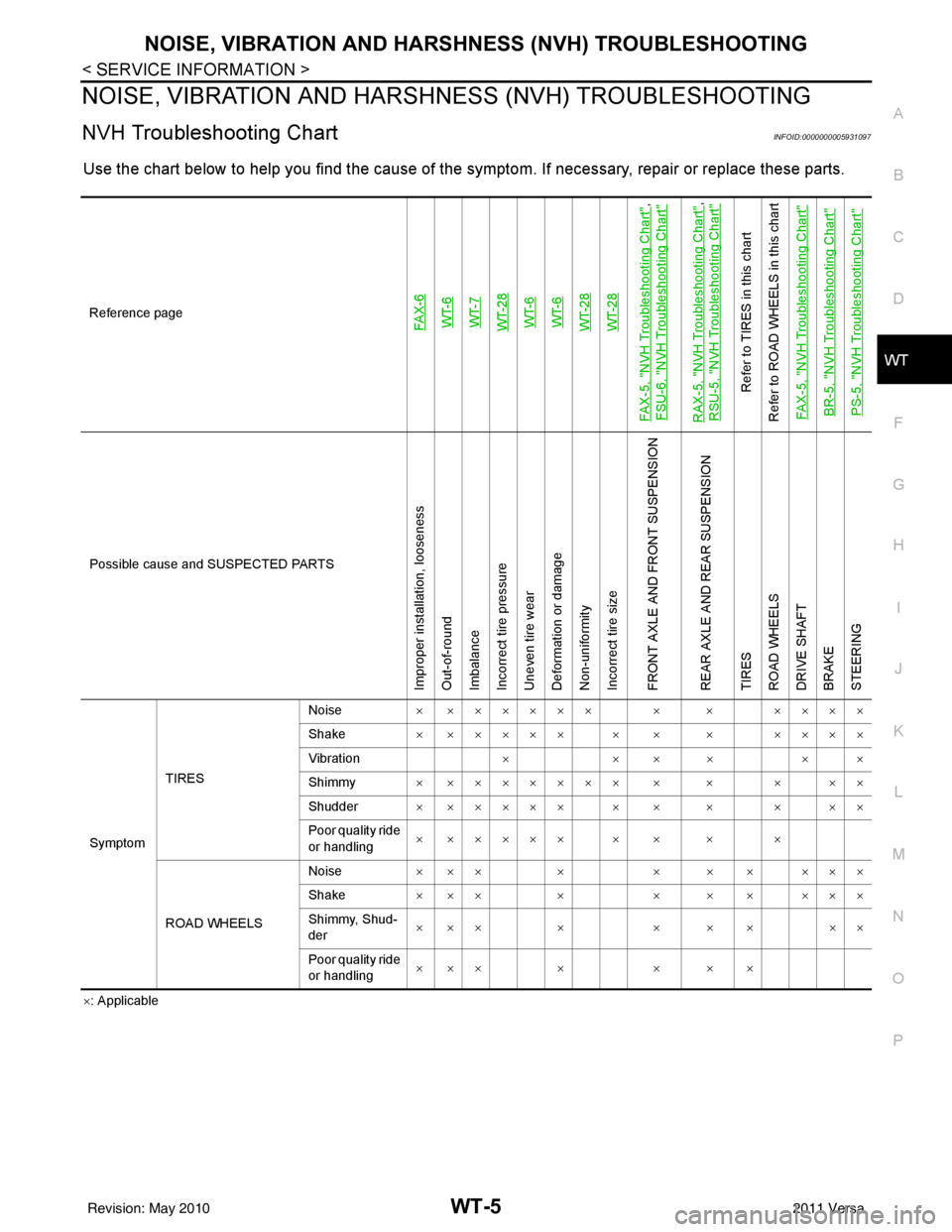

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005931097

Use the chart below to help you find t he cause of the symptom. If necessary, repair or replace these parts.

×: Applicable

Reference page

FAX-6WT-6

WT-7

WT-28WT-6

WT-6

WT-28WT-28

FAX-5, "

NVH Troubleshooting Chart

",

FSU-6, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",

RSU-5, "

NVH Troubleshooting Chart

"

Refer to TIRES in this chart

Refer to ROAD WHEELS in this chart

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRES Noise

× ×××××× × × ××××

Shake × ××××× × × × ××××

Vibration ××××××

Shimmy × ××××××× × × × ××

Shudder × ××××× × × × × ××

Poor quality ride

or handling × ××××× × × × ×

ROAD WHEELS Noise

× ×× × × × × ×××

Shake × ×× × × × × ×××

Shimmy, Shud-

der ××× × × × × ××

Poor quality ride

or handling ××× × × × ×

Revision: May 2010

2011 Versa