engine overheat NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 26 of 3787

PRECAUTIONSAT-9

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• Gaskets, seals and O-rings should be replaced any time the A/T is disassembled.

• It is very important to perform func tional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and seals, or hold bearings and washers in pl ace during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-

18, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-17, "

Changing A/T Fluid", AT-17, "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000005928067

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to CO-16, "

Removal and Installation" (HR16DE engine models), CO-

40, "Removal and Installation" (MR18DE engine models).

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engi ne coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in flui d filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The e xception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-82, "

Diagnosis Procedure without CONSULT-III" for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo- ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-39, "

OBD-II Diagnostic Trouble Code

(DTC)" to complete the repair and avoid unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected us ing ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

- Transmission range switch

- A/T 1GR, 2GR, 3GR, or 4GR function

Revision: May 2010 2011 Versa

Page 92 of 3787

TROUBLE DIAGNOSISAT-75

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

TCM Terminal and Reference ValueINFOID:0000000005928104

TCM HARNESS CONNECTOR TERMINAL LAYOUT

Terminals and Reference Values for TCM

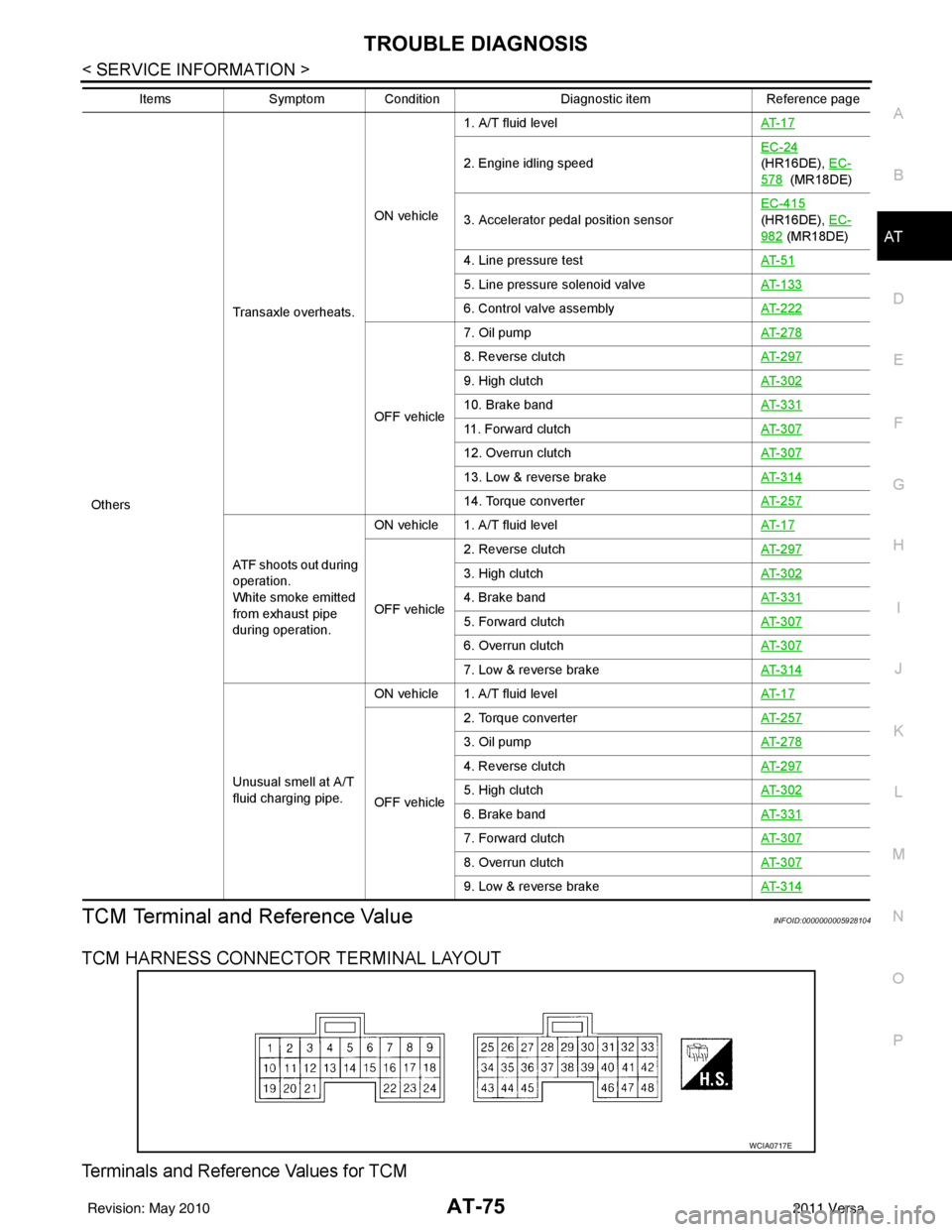

Others Transaxle overheats.

ON vehicle

1. A/T fluid level

AT- 1 7

2. Engine idling speedEC-24

(HR16DE), EC-

578 (MR18DE)

3. Accelerator pedal position sensor EC-415

(HR16DE), EC-

982 (MR18DE)

4. Line pressure test AT- 5 1

5. Line pressure solenoid valveAT- 1 3 3

6. Control valve assemblyAT- 2 2 2

OFF vehicle7. Oil pump

AT- 2 7 8

8. Reverse clutchAT- 2 9 7

9. High clutchAT- 3 0 2

10. Brake bandAT- 3 3 1

11. Forward clutchAT- 3 0 7

12. Overrun clutchAT- 3 0 7

13. Low & reverse brakeAT- 3 1 4

14. Torque converterAT- 2 5 7

ATF shoots out during

operation.

White smoke emitted

from exhaust pipe

during operation.ON vehicle 1. A/T fluid level

AT- 1 7

OFF vehicle2. Reverse clutch

AT- 2 9 7

3. High clutchAT- 3 0 2

4. Brake bandAT- 3 3 1

5. Forward clutchAT- 3 0 7

6. Overrun clutchAT- 3 0 7

7. Low & reverse brakeAT- 3 1 4

Unusual smell at A/T

fluid charging pipe.ON vehicle 1. A/T fluid level

AT- 1 7

OFF vehicle2. Torque converter

AT- 2 5 7

3. Oil pumpAT- 2 7 8

4. Reverse clutchAT- 2 9 7

5. High clutchAT- 3 0 2

6. Brake bandAT- 3 3 1

7. Forward clutchAT- 3 0 7

8. Overrun clutchAT- 3 0 7

9. Low & reverse brakeAT- 3 1 4

ItemsSymptom Condition Diagnostic itemReference page

WCIA0717E

Revision: May 2010 2011 Versa

Page 1001 of 3787

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYMPTOM DIAGNOSIS ...............................7

OVERHEATING CAUSE ANALYSIS ............. .....7

Troubleshooting Chart ...............................................7

FUNCTION DIAGNOSIS .. .............................9

DESCRIPTION ............................................... .....9

Engine Cooling System ....................................... ......9

Engine Cooling System Schematic .........................10

ON-VEHICLE MAINTENANCE ....................11

ENGINE COOLANT ....................................... ....11

Inspection ............................................................ ....11

Changing Engine Coolant .......................................11

RADIATOR .........................................................14

Checking Radiator Cap ....................................... ....14

Checking Radiator ...................................................14

ON-VEHICLE REPAIR .................................16

RADIATOR ..................................................... ....16

Component .......................................................... ....16

Removal and Installation .........................................16

COOLING FAN ..................................................18

Component (Models with A/C) ............................. ....18

Component (Models without A/C) ............................18

Removal and Installation .........................................19

Disassembly and Assembly .....................................19

WATER PUMP ..................................................20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................21

THERMOSTAT ..................................................22

Exploded View .........................................................22

Removal and Installation .........................................22

Inspection ................................................................23

WATER OUTLET ..............................................24

Exploded View .........................................................24

Removal and Installation .........................................24

Inspection ................................................................25

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

26

Periodical Maintenance Specification .................. ....26

Radiator ...................................................................26

Thermostat ..............................................................26

MR18DE

SERVICE INFORMATION .. .........................

27

PRECAUTIONS .................................................27

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

27

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

27

Precaution for Liquid Gasket ...................................28

PREPARATION .................................................30

Revision: May 2010 2011 Versa

Page 1002 of 3787

CO-2

Special Service Tool ...............................................30

Commercial Service Tool .......................................30

OVERHEATING CAUSE ANALYSIS ................32

Troubleshooting Chart ......................................... ...32

COOLING SYSTEM ...........................................34

Cooling Circuit ..................................................... ...34

ENGINE COOLANT ...........................................36

Inspection ............................................................ ...36

Changing Engine Coolant .......................................36

RADIATOR ........................................................39

Checking Radiator Cap ....................................... ...39

Checking Radiator ..................................................39

Component .............................................................40

Removal and Installation ........................................40

Inspection ...............................................................41

COOLING FAN ..................................................43

Component (Models with A/C) ................................43

Component (Models without A/C) ...........................43

Removal and Installation .........................................44

Disassembly and Assembly ................................. ...44

WATER PUMP ...................................................45

Component .......................................................... ...45

Removal and Installation .........................................45

THERMOSTAT ............................................... ...47

Component .......................................................... ...47

Removal and Installation .........................................47

Inspection ............................................................. ...48

WATER OUTLET AND WATER CONTROL

VALVE ...............................................................

50

Component .......................................................... ...50

Removal and Installation .........................................51

Inspection ............................................................. ...53

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

55

Standard and Limit ............................................... ...55

Revision: May 2010 2011 Versa

Page 1007 of 3787

![NISSAN TIIDA 2011 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

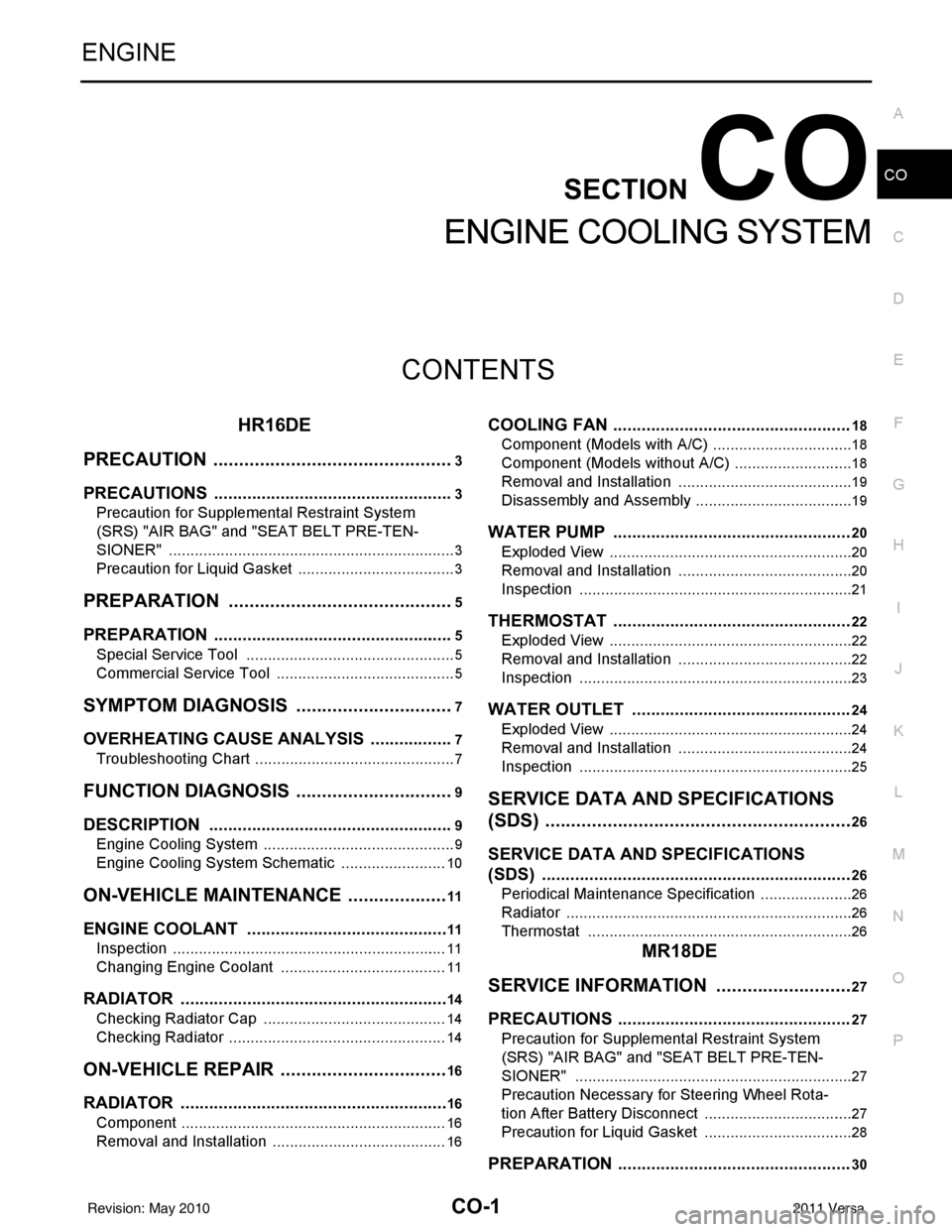

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930774

Symptom

Check it NISSAN TIIDA 2011 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930774

Symptom

Check it](/img/5/57396/w960_57396-1006.png)

OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930774

Symptom

Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed

—

Damaged fins Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud —Radiator shroud —

Improper engine coolant

mixture ratio —

Engine coolant viscosity —

Poor engine coolant quality — —

Insufficient engine coolant Engine coolant leaks Cooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Reservoir tank cap Loose

Poor sealing

Radiator O-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing systemCylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: May 2010

2011 Versa

Page 1008 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CO-8

< SYMPTOM DIAGNOSIS >[HR16DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function—

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for NISSAN TIIDA 2011 Service Repair Manual CO-8

< SYMPTOM DIAGNOSIS >[HR16DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function—

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for](/img/5/57396/w960_57396-1007.png)

CO-8

< SYMPTOM DIAGNOSIS >[HR16DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function—

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Power train system mal-

function

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper

Installed front bumper fas-

cia cover

—

Blocked radiator grille Mud contamination or paper

clogging

Blocked radiator Blocked air flow

Blocked condenser

Installed large fog lamp

Symptom

Check items

Revision: May 2010 2011 Versa

Page 1032 of 3787

![NISSAN TIIDA 2011 Service Repair Manual CO-32

< SERVICE INFORMATION >[MR18DE]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930804

Symptom

Check items

Cooling sys-

tem parts

malfunction Poor he NISSAN TIIDA 2011 Service Repair Manual CO-32

< SERVICE INFORMATION >[MR18DE]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930804

Symptom

Check items

Cooling sys-

tem parts

malfunction Poor he](/img/5/57396/w960_57396-1031.png)

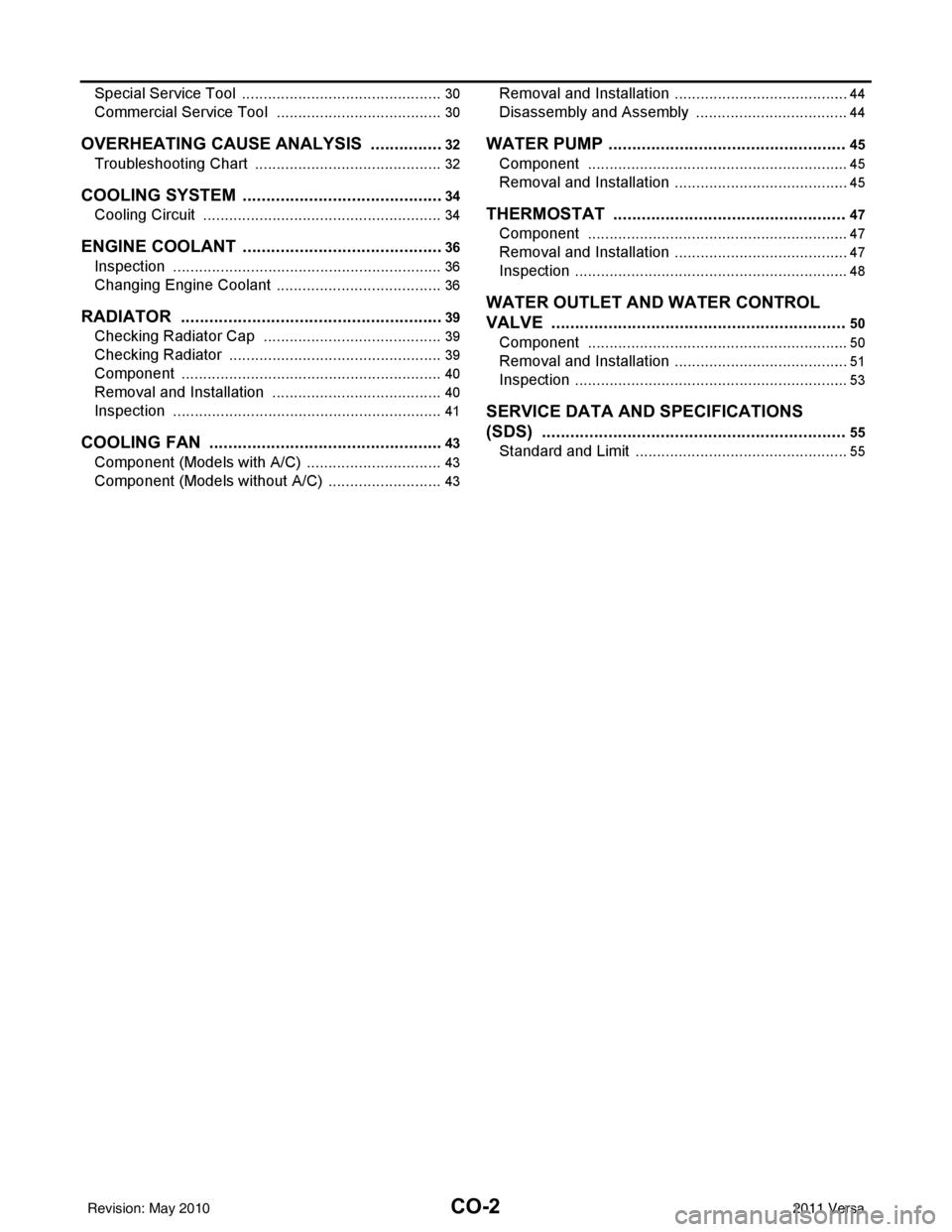

CO-32

< SERVICE INFORMATION >[MR18DE]

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000005930804

Symptom

Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed Thermostat

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — —

Improper engine coolant

mixture ratio —

Engine coolant viscosity —

Poor engine coolant quality — —

Insufficient engine coolant Engine coolant leaksCooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for da

mage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: May 2010

2011 Versa

Page 1033 of 3787

![NISSAN TIIDA 2011 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm und NISSAN TIIDA 2011 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm und](/img/5/57396/w960_57396-1032.png)

OVERHEATING CAUSE ANALYSISCO-33

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Power train system mal-

function

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper

Installed front bumper fas-

cia cover

—

Blocked radiator grille Mud contamination or paper

clogging

Blocked radiator Blocked air flow

Blocked condenser

Installed large fog lamp

Symptom

Check items

Revision: May 2010 2011 Versa

Page 1306 of 3787

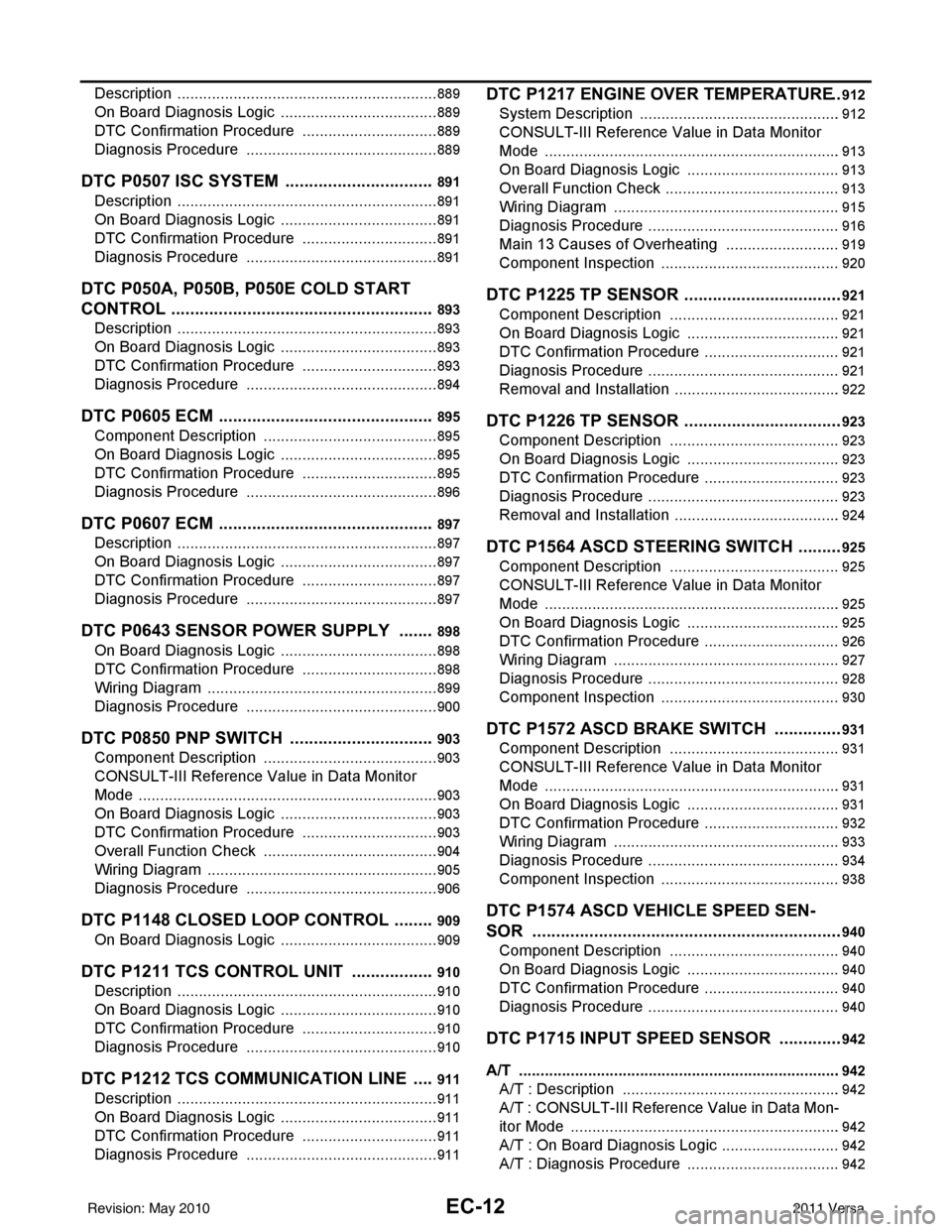

EC-12

Description .............................................................889

On Board Diagnosis Logic .....................................889

DTC Confirmation Procedure ................................889

Diagnosis Procedure .............................................889

DTC P0507 ISC SYSTEM ................................891

Description ........................................................... ..891

On Board Diagnosis Logic .....................................891

DTC Confirmation Procedure ................................891

Diagnosis Procedure .............................................891

DTC P050A, P050B, P050E COLD START

CONTROL ........................................................

893

Description ........................................................... ..893

On Board Diagnosis Logic .....................................893

DTC Confirmation Procedure ................................893

Diagnosis Procedure .............................................894

DTC P0605 ECM ..............................................895

Component Description ....................................... ..895

On Board Diagnosis Logic .....................................895

DTC Confirmation Procedure ................................895

Diagnosis Procedure .............................................896

DTC P0607 ECM ..............................................897

Description ........................................................... ..897

On Board Diagnosis Logic .....................................897

DTC Confirmation Procedure ................................897

Diagnosis Procedure .............................................897

DTC P0643 SENSOR POWER SUPPLY ........898

On Board Diagnosis Logic ................................... ..898

DTC Confirmation Procedure ................................898

Wiring Diagram ......................................................899

Diagnosis Procedure .............................................900

DTC P0850 PNP SWITCH ...............................903

Component Description ....................................... ..903

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

903

On Board Diagnosis Logic .....................................903

DTC Confirmation Procedure ................................903

Overall Function Check .........................................904

Wiring Diagram ......................................................905

Diagnosis Procedure .............................................906

DTC P1148 CLOSED LOOP CONTROL .........909

On Board Diagnosis Logic ................................... ..909

DTC P1211 TCS CONTROL UNIT ..................910

Description ........................................................... ..910

On Board Diagnosis Logic .....................................910

DTC Confirmation Procedure ................................910

Diagnosis Procedure .............................................910

DTC P1212 TCS COMMUNICATION LINE .....911

Description ........................................................... ..911

On Board Diagnosis Logic .....................................911

DTC Confirmation Procedure ................................911

Diagnosis Procedure .............................................911

DTC P1217 ENGINE OVER TEMPERATURE ..912

System Description .............................................. .912

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

913

On Board Diagnosis Logic ....................................913

Overall Function Check .........................................913

Wiring Diagram .....................................................915

Diagnosis Procedure .............................................916

Main 13 Causes of Overheating ...........................919

Component Inspection ..........................................920

DTC P1225 TP SENSOR ..................................921

Component Description ....................................... .921

On Board Diagnosis Logic ....................................921

DTC Confirmation Procedure ................................921

Diagnosis Procedure .............................................921

Removal and Installation .......................................922

DTC P1226 TP SENSOR ................................ ..923

Component Description ....................................... .923

On Board Diagnosis Logic ....................................923

DTC Confirmation Procedure ................................923

Diagnosis Procedure .............................................923

Removal and Installation .......................................924

DTC P1564 ASCD STEERING SWITCH ........ ..925

Component Description ....................................... .925

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

925

On Board Diagnosis Logic ....................................925

DTC Confirmation Procedure ................................926

Wiring Diagram .....................................................927

Diagnosis Procedure .............................................928

Component Inspection ..........................................930

DTC P1572 ASCD BRAKE SWITCH ...............931

Component Description ....................................... .931

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

931

On Board Diagnosis Logic ....................................931

DTC Confirmation Procedure ................................932

Wiring Diagram .....................................................933

Diagnosis Procedure .............................................934

Component Inspection ..........................................938

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

940

Component Description ....................................... .940

On Board Diagnosis Logic ....................................940

DTC Confirmation Procedure ................................940

Diagnosis Procedure .............................................940

DTC P1715 INPUT SPEED SENSOR ..............942

A/T .......................................................................... .942

A/T : Description ...................................................942

A/T : CONSULT-III Reference Value in Data Mon-

itor Mode ...............................................................

942

A/T : On Board Diagnosis Logic ............................942

A/T : Diagnosis Procedure ....................................942

Revision: May 2010 2011 Versa

Page 1406 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-112

< FUNCTION DIAGNOSIS >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

*: Leaving cooling fan OFF with CONSULT-III whil

e engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STAT NISSAN TIIDA 2011 Service Repair Manual EC-112

< FUNCTION DIAGNOSIS >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

*: Leaving cooling fan OFF with CONSULT-III whil

e engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STAT](/img/5/57396/w960_57396-1405.png)

EC-112

< FUNCTION DIAGNOSIS >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

*: Leaving cooling fan OFF with CONSULT-III whil

e engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

• For items whose SRT codes are set, “CMPLT” is displayed on the CONSULT-III screen; for items whose

SRT codes are not set, “INCMP” is displayed.

• “SRT STATUS” provides the presence or absence of permanent DTCs stored in ECM memory.

PERMANENT DTC STATUS Mode

How to display permanent DTC status

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

5. Select “PERMANENT DTC ST ATUS” in “DTC & SRT CONFIRMATION” mode with CONSULT-III.

NOTE:

Permanent DTCs stored in ECM memory are displayed on the CONSULT-III screen to show if a driving

pattern required for erasing permanent DTCs is complete (CMPLT) or incomplete (INCMP).

CAUTION:

Since the “PERMANENT DTC STATUS” screen displ ays the previous trip information, repeat the

following twice to update the in formation: “Ignition switch OFF” , “Wait for more than 10 seconds”

and “Ignition switch ON”.

NOTE:

This mode is not used in regions that permanent DTCs are not regulated by law.

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

PERMANENT DTC WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to comp lete the driving pattern that is required for erasing

permanent DTC.

NOTE:

This mode is not used in regions that permanent DTCs are not regulated by law.

VENT CONTROL/V• Ignition switch: ON (Engine

stopped)

• Turn solenoid valve “ON” and “OFF” using the CONSULT-III

and listen to operating sound. Solenoid valve makes an operating

sound.

• Harness and connectors

• Solenoid valve

V/T ASSIGN ANGLE • Engine: Return to the original

trouble condition

• Change intake valve timing us- ing CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

• Harness and connectors

• Intake valve timing control sole-

noid valve

TEST ITEM

CONDITION JUDGMENT CHECK ITEM (REMEDY)

JSBIA0062GB

Revision: May 2010 2011 Versa