system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1301 of 3787

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Description ..........................................................

..

492

PRECAUTION ............................................493

PRECAUTIONS .............................................. ..493

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

493

Precaution for Procedure without Cowl Top Cover ..493

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

493

General Precautions .............................................494

PREPARATION .........................................497

PREPARATION .............................................. ..497

Special Service Tools .......................................... ..497

Commercial Service Tools ....................................497

ON-VEHICLE MAINTENANCE ..................499

FUEL PRESSURE .......................................... ..499

Inspection ............................................................ ..499

EVAP LEAK CHECK ........................................501

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

503

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

503

Idle Speed ........................................................... ..503

Ignition Timing .......................................................503

Calculated Load Value ..........................................503

Mass Air Flow Sensor ...........................................503

MR18DE

SERVICE INFORMATION .. .......................

504

INDEX FOR DTC ............................................ ..504

U0101-U1001 ...................................................... ..504

P0011-P0075 ........................................................504

P0101-P0128 ........................................................504

P0130-P0183 ........................................................505

P0222-P0420 ........................................................505

P0441-P0463 ........................................................506

P0500-P0643 ........................................................506

P0705-P0734 ........................................................507

P0740-P0840 ........................................................507

P0850-P1574 ........................................................508

P1610-P1615 ........................................................508

P1715-P1805 ........................................................508

P2100-P2A00 ........................................................509

PRECAUTIONS ................................................510

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

510

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

510

Precaution for Procedure without Cowl Top Cover ..511

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ................................................................

511

Precaution .............................................................511

PREPARATION ...............................................515

Special Service Tool ..............................................515

Commercial Service Tool ......................................515

ENGINE CONTROL SYSTEM ........................517

Schematic ............................................................ ..517

Multiport Fuel Injection (MFI) System ....................517

Electronic Ignition (EI) System ..............................520

Fuel Cut Control (at No Load and High Engine

Speed) ...................................................................

520

AIR CONDITIONING CUT CONTROL ............522

Input/Output Signal Chart ......................................522

System Description ................................................522

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

523

System Description ................................................523

Component Description .........................................524

CAN COMMUNICATION .................................525

System Description ................................................525

EVAPORATIVE EMISSION SYSTEM .............526

Description .............................................................526

Component Inspection ...........................................528

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Revision: May 2010 2011 Versa

Page 1304 of 3787

EC-10

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

741

On Board Diagnosis Logic .....................................741

DTC Confirmation Procedure ................................741

Overall Function Check .........................................743

Wiring Diagram ......................................................744

Diagnosis Procedure .............................................745

Component Inspection ...........................................747

Removal and Installation .......................................749

DTC P014C, P014D A/F SENSOR 1 ...............750

Component Description ....................................... ..750

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

750

On Board Diagnosis Logic .....................................750

DTC Confirmation Procedure ................................750

Wiring Diagram ......................................................753

Diagnosis Procedure .............................................754

Removal and Installation .......................................757

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION .......................................................

758

On Board Diagnosis Logic ................................... ..758

DTC Confirmation Procedure ................................758

Wiring Diagram ......................................................760

Diagnosis Procedure .............................................761

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION .......................................................

764

On Board Diagnosis Logic ................................... ..764

DTC Confirmation Procedure ................................764

Wiring Diagram ......................................................766

Diagnosis Procedure .............................................767

DTC P0181 FTT SENSOR ...............................770

Component Description ....................................... ..770

On Board Diagnosis Logic .....................................770

DTC Confirmation Procedure ................................770

Wiring Diagram ......................................................771

Diagnosis Procedure .............................................771

Component Inspection ...........................................773

Removal and Installation .......................................773

DTC P0182, P0183 FTT SENSOR ..................774

Component Description ....................................... ..774

On Board Diagnosis Logic .....................................774

DTC Confirmation Procedure ................................774

Wiring Diagram ......................................................775

Diagnosis Procedure .............................................775

Component Inspection ...........................................777

Removal and Installation .......................................777

DTC P0222, P0223 TP SENSOR ....................778

Component Description ....................................... ..778

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

778

On Board Diagnosis Logic .....................................778

DTC Confirmation Procedure ................................778

Wiring Diagram ......................................................779

Diagnosis Procedure .............................................780

Component Inspection ......................................... .782

Removal and Installation .......................................782

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MISFIRE ...... ..

783

On Board Diagnosis Logic ................................... .783

DTC Confirmation Procedure ................................783

Diagnosis Procedure .............................................784

DTC P0327, P0328 KS .....................................789

Component Description ....................................... .789

On Board Diagnosis Logic ....................................789

DTC Confirmation Procedure ................................789

Wiring Diagram .....................................................790

Diagnosis Procedure .............................................791

Component Inspection ..........................................792

Removal and Installation .......................................792

DTC P0335 CKP SENSOR (POS) .................. ..793

Component Description ....................................... .793

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

793

On Board Diagnosis Logic ....................................793

DTC Confirmation Procedure ................................793

Wiring Diagram .....................................................794

Diagnosis Procedure .............................................795

Component Inspection ..........................................798

Removal and Installation .......................................798

DTC P0340 CMP SENSOR (PHASE) ............ ..799

Component Description ....................................... .799

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

799

On Board Diagnosis Logic ....................................799

DTC Confirmation Procedure ................................799

Wiring Diagram .....................................................800

Diagnosis Procedure .............................................801

Component Inspection ..........................................803

Removal and Installation .......................................804

DTC P0420 THREE WAY CATALYST FUNC-

TION ................................................................ ..

805

On Board Diagnosis Logic ................................... .805

DTC Confirmation Procedure ................................805

Overall Function Check .........................................805

Diagnosis Procedure .............................................806

DTC P0441 EVAP CONTROL SYSTEM ..........810

System Description .............................................. .810

On Board Diagnosis Logic ....................................810

DTC Confirmation Procedure ................................810

Overall Function Check .........................................811

Diagnosis Procedure .............................................811

Component Inspection ..........................................814

DTC P0442 EVAP CONTROL SYSTEM ..........815

On Board Diagnosis Logic ................................... .815

DTC Confirmation Procedure ................................816

Diagnosis Procedure .............................................816

Component Inspection ..........................................821

Revision: May 2010 2011 Versa

Page 1305 of 3787

EC-11

C

DE

F

G H

I

J

K L

M

EC A

N

O P

DTC P0443 EVAP CANISTER PURGE VOL-

UME CONTROL SOLENOID VALVE ............ ..

822

Description .......................................................... ..822

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

822

On Board Diagnosis Logic ....................................823

DTC Confirmation Procedure ................................823

Wiring Diagram .....................................................825

Diagnosis Procedure .............................................826

Component Inspection ..........................................829

Removal and Installation .......................................829

DTC P0444, P0445 EVAP CANISTER PURGE

VOLUME CONTROL SOLENOID VALVE ..... ..

830

Description .......................................................... ..830

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

830

On Board Diagnosis Logic ....................................831

DTC Confirmation Procedure ................................831

Wiring Diagram .....................................................832

Diagnosis Procedure .............................................833

Component Inspection ..........................................834

Removal and Installation .......................................835

DTC P0447 EVAP CANISTER VENT CON-

TROL VALVE ...................................................

836

Component Description ....................................... ..836

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

836

On Board Diagnosis Logic ....................................836

DTC Confirmation Procedure ................................836

Wiring Diagram .....................................................837

Diagnosis Procedure .............................................838

Component Inspection ..........................................840

DTC P0448 EVAP CANISTER VENT CON-

TROL VALVE ...................................................

842

Component Description .........................................842

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

842

On Board Diagnosis Logic ....................................842

DTC Confirmation Procedure ................................842

Wiring Diagram .....................................................844

Diagnosis Procedure .............................................845

Component Inspection ..........................................846

DTC P0451 EVAP CONTROL SYSTEM

PRESSURE SENSOR .................................... ..

848

Component Description ....................................... ..848

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

848

On Board Diagnosis Logic ....................................848

DTC Confirmation Procedure ................................848

Diagnosis Procedure .............................................849

Component Inspection ..........................................850

DTC P0452 EVAP CONTROL SYSTEM

PRESSURE SENSOR .................................... ..

851

Component Description ....................................... ..851

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

851

On Board Diagnosis Logic .....................................851

DTC Confirmation Procedure ................................851

Wiring Diagram ......................................................853

Diagnosis Procedure .............................................854

Component Inspection ...........................................857

DTC P0453 EVAP CONTROL SYSTEM

PRESSURE SENSOR .....................................

858

Component Description .........................................858

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

858

On Board Diagnosis Logic .....................................858

DTC Confirmation Procedure ................................859

Wiring Diagram ......................................................860

Diagnosis Procedure .............................................861

Component Inspection ...........................................865

DTC P0455 EVAP CONTROL SYSTEM .........866

On Board Diagnosis Logic .....................................866

DTC Confirmation Procedure ................................866

Diagnosis Procedure .............................................867

Component Inspection ...........................................872

DTC P0456 EVAP CONTROL SYSTEM .........873

On Board Diagnosis Logic .....................................873

DTC Confirmation Procedure ................................874

Overall Function Check .........................................874

Diagnosis Procedure .............................................875

Component Inspection ...........................................880

DTC P0460 FUEL LEVEL SENSOR ...............881

Component Description .........................................881

On Board Diagnosis Logic .....................................881

DTC Confirmation Procedure ................................881

Diagnosis Procedure .............................................881

Removal and Installation .......................................882

DTC P0461 FUEL LEVEL SENSOR ...............883

Component Description .........................................883

On Board Diagnosis Logic .....................................883

Overall Function Check .........................................883

Diagnosis Procedure .............................................884

Removal and Installation .......................................884

DTC P0462, P0463 FUEL LEVEL SENSOR ..885

Component Description .........................................885

On Board Diagnosis Logic .....................................885

DTC Confirmation Procedure ................................885

Diagnosis Procedure .............................................885

Removal and Installation .......................................886

DTC P0500 VSS ..............................................887

Description .............................................................887

On Board Diagnosis Logic .....................................887

DTC Confirmation Procedure ................................887

Overall Function Check .........................................888

Diagnosis Procedure .............................................888

DTC P0506 ISC SYSTEM ...............................889

Revision: May 2010 2011 Versa

Page 1306 of 3787

EC-12

Description .............................................................889

On Board Diagnosis Logic .....................................889

DTC Confirmation Procedure ................................889

Diagnosis Procedure .............................................889

DTC P0507 ISC SYSTEM ................................891

Description ........................................................... ..891

On Board Diagnosis Logic .....................................891

DTC Confirmation Procedure ................................891

Diagnosis Procedure .............................................891

DTC P050A, P050B, P050E COLD START

CONTROL ........................................................

893

Description ........................................................... ..893

On Board Diagnosis Logic .....................................893

DTC Confirmation Procedure ................................893

Diagnosis Procedure .............................................894

DTC P0605 ECM ..............................................895

Component Description ....................................... ..895

On Board Diagnosis Logic .....................................895

DTC Confirmation Procedure ................................895

Diagnosis Procedure .............................................896

DTC P0607 ECM ..............................................897

Description ........................................................... ..897

On Board Diagnosis Logic .....................................897

DTC Confirmation Procedure ................................897

Diagnosis Procedure .............................................897

DTC P0643 SENSOR POWER SUPPLY ........898

On Board Diagnosis Logic ................................... ..898

DTC Confirmation Procedure ................................898

Wiring Diagram ......................................................899

Diagnosis Procedure .............................................900

DTC P0850 PNP SWITCH ...............................903

Component Description ....................................... ..903

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

903

On Board Diagnosis Logic .....................................903

DTC Confirmation Procedure ................................903

Overall Function Check .........................................904

Wiring Diagram ......................................................905

Diagnosis Procedure .............................................906

DTC P1148 CLOSED LOOP CONTROL .........909

On Board Diagnosis Logic ................................... ..909

DTC P1211 TCS CONTROL UNIT ..................910

Description ........................................................... ..910

On Board Diagnosis Logic .....................................910

DTC Confirmation Procedure ................................910

Diagnosis Procedure .............................................910

DTC P1212 TCS COMMUNICATION LINE .....911

Description ........................................................... ..911

On Board Diagnosis Logic .....................................911

DTC Confirmation Procedure ................................911

Diagnosis Procedure .............................................911

DTC P1217 ENGINE OVER TEMPERATURE ..912

System Description .............................................. .912

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

913

On Board Diagnosis Logic ....................................913

Overall Function Check .........................................913

Wiring Diagram .....................................................915

Diagnosis Procedure .............................................916

Main 13 Causes of Overheating ...........................919

Component Inspection ..........................................920

DTC P1225 TP SENSOR ..................................921

Component Description ....................................... .921

On Board Diagnosis Logic ....................................921

DTC Confirmation Procedure ................................921

Diagnosis Procedure .............................................921

Removal and Installation .......................................922

DTC P1226 TP SENSOR ................................ ..923

Component Description ....................................... .923

On Board Diagnosis Logic ....................................923

DTC Confirmation Procedure ................................923

Diagnosis Procedure .............................................923

Removal and Installation .......................................924

DTC P1564 ASCD STEERING SWITCH ........ ..925

Component Description ....................................... .925

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

925

On Board Diagnosis Logic ....................................925

DTC Confirmation Procedure ................................926

Wiring Diagram .....................................................927

Diagnosis Procedure .............................................928

Component Inspection ..........................................930

DTC P1572 ASCD BRAKE SWITCH ...............931

Component Description ....................................... .931

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... .

931

On Board Diagnosis Logic ....................................931

DTC Confirmation Procedure ................................932

Wiring Diagram .....................................................933

Diagnosis Procedure .............................................934

Component Inspection ..........................................938

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

940

Component Description ....................................... .940

On Board Diagnosis Logic ....................................940

DTC Confirmation Procedure ................................940

Diagnosis Procedure .............................................940

DTC P1715 INPUT SPEED SENSOR ..............942

A/T .......................................................................... .942

A/T : Description ...................................................942

A/T : CONSULT-III Reference Value in Data Mon-

itor Mode ...............................................................

942

A/T : On Board Diagnosis Logic ............................942

A/T : Diagnosis Procedure ....................................942

Revision: May 2010 2011 Versa

Page 1311 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS AND REPAIR WORK FLOWEC-17

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

YES >> GO TO 10.

NO >> Check Intermittent Incident according to

EC-122, "

Diagnosis Procedure".

6.PER NISSAN TIIDA 2011 Service Repair Manual DIAGNOSIS AND REPAIR WORK FLOWEC-17

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

YES >> GO TO 10.

NO >> Check Intermittent Incident according to

EC-122, "

Diagnosis Procedure".

6.PER](/img/5/57396/w960_57396-1310.png)

DIAGNOSIS AND REPAIR WORK FLOWEC-17

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

YES >> GO TO 10.

NO >> Check Intermittent Incident according to

EC-122, "

Diagnosis Procedure".

6.PERFORM BASIC INSPECTION

Perform EC-20, "

BASIC INSPECTION : Special Repair Requirement".

Do you have CONSULT-III?

YES >> GO TO 7.

NO >> GO TO 9.

7.PERFORM SPEC IN DATA MONITOR MODE

With CONSULT-III

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL” and “A/F ALPHA-B1” are within the SP value using

“SPEC” of “DATA MONITOR” mode with CONSULT-III. Refer to EC-114, "

Component Function Check".

Are they within the SP value?

YES >> GO TO 9.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-115, "

Diagnosis Procedure".

Is malfunctioning part detected?

YES >> GO TO 11.

NO >> GO TO 9.

9.DETECT MALFUNCTIONING SY STEM BY SYMPTOM TABLE

Detect malfunctioning system according to EC-488, "

Symptom Table" based on the confirmed symptom in

step 4, and determine the trouble diagnosis or der based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

NOTE:

The Diagnosis Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnosis Procedure. For details, refer to “Circuit Inspection” in GI-

25, "How to Perform Efficient Diagnosis for an Electrical Incident".

Is malfunctioning part detected?

YES >> GO TO 11.

NO >> Monitor input data from related sensors or c heck the voltage of related ECM terminals using CON-

SULT-III. Refer to EC-464, "

Reference Value".

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it.

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC CO NFIRMATION PROCEDURE or Component Function

Check again, and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

Is DTC detected and does symptom remain?

YES-1 >> DTC is detected: GO TO 10.

YES-2 >> Symptom remains: GO TO 6.

Revision: May 2010 2011 Versa

Page 1315 of 3787

![NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for abou](/img/5/57396/w960_57396-1314.png)

INSPECTION AND ADJUSTMENTEC-21

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to EC-24, "

IDLE SPEED : Special Repair

Requirement". For specification, refer to EC-503, "Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-25, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

ment".

>> GO TO 5.

5.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Perform EC-25, "

THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-26, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. For procedure, refer to EC-24, "

IDLE SPEED : Special Repair Requirement".

For specification, refer to EC-503, "

Idle Speed".

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-272, "

DTC Logic".

• Check crankshaft position sensor (POS) and circuit. Refer to EC-267, "

DTC Logic".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace. Then GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is rare.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to BL-247, "

ECM Re-communicating Function".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

PBIA8513J

Revision: May 2010 2011 Versa

Page 1317 of 3787

![NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-23

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. NISSAN TIIDA 2011 Service Repair Manual INSPECTION AND ADJUSTMENTEC-23

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit.](/img/5/57396/w960_57396-1316.png)

INSPECTION AND ADJUSTMENTEC-23

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-272, "

DTC Logic".

• Check crankshaft position sensor (POS) and circuit. Refer to EC-267, "

DTC Logic".

Is the inspection result normal?

YES >> GO TO 18.

NO >> Repair or replace. Then GO TO 4.

18.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is rare.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to EC-23, "

ADDITIONAL SERVICE WHEN REPLACING CO NTROL UNIT : Special Repair Requirement".

>> GO TO 4.

19.INSPECTION END

If ECM is replaced during this BASIC INSPECTION procedure, perform EC-23, "

ADDITIONAL SERVICE

WHEN REPLACING CONTROL UNIT : Special Repair Requirement".

>> INSPECTION END

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000005929747

When replacing ECM, this procedure must be performed.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000005929748

1.PERFORM INITIALIZATION OF NATS SYSTEM AND REGISTRATION OF ALL NATS IGNITION KEY IDS

Refer to BL-247, "

ECM Re-communicating Function".

>> GO TO 2.

2.PERFORM VIN REGISTRATION

Refer to EC-25, "

VIN REGISTRATION : Special Repair Requirement".

>> GO TO 3.

3.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

Refer to EC-25, "

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Requirement".

>> GO TO 4.

4.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Refer to EC-25, "

THROTTLE VALVE CLOSED POSITION L EARNING : Special Repair Requirement".

>> GO TO 5.

5.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-26, "

IDLE AIR VOLUME LEARNING : Special Repair Requirement".

>> END

Revision: May 2010 2011 Versa

Page 1320 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO NISSAN TIIDA 2011 Service Repair Manual EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO](/img/5/57396/w960_57396-1319.png)

EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING

: Special Repair RequirementINFOID:0000000005929760

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (A/T), Neutral (M/T)

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- A/T models

• With CONSULT-III: Drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “TRANSMISSION”

system indicates less than 0.9 V.

• Without CONSULT-III: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

Revision: May 2010 2011 Versa

Page 1323 of 3787

![NISSAN TIIDA 2011 Service Repair Manual HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in NISSAN TIIDA 2011 Service Repair Manual HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in](/img/5/57396/w960_57396-1322.png)

HOW TO SET SRT CODEEC-29

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO SET SRT CODE

DescriptionINFOID:0000000006314657

OUTLINE

In order to set all SRTs, the self-diagnoses as in

the “SRT ITEM” table must have been performed at least

once. Each diagnosis may require actual driving for a long period of time under various conditions.

SRT ITEM

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

• *1: Though displayed on the CONSULT-III screen, “HO2S HTR” is not SRT item.

• *2: If completion of several SRTs is required, per form driving patterns (DTC confirmation procedure), one by

one based on the priority for models with CONSULT-III.

SRT SERVICE PROCEDURE

If a vehicle has failed the state emissions inspection due to one or more SRT items indicating “INCMP”, review

the flowchart diagnostic sequence, referring to the following flowchart.

SRT item*1

(CONSULT-III indication) Performance

Priority*2Required self-diagnostic items to set the SRT to “CMPLT” Corresponding

DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 P0133

Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139

EGR/VVT SYSTEM 3 Intake value timing control function P0011

Revision: May 2010 2011 Versa

Page 1334 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa NISSAN TIIDA 2011 Service Repair Manual EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa](/img/5/57396/w960_57396-1333.png)

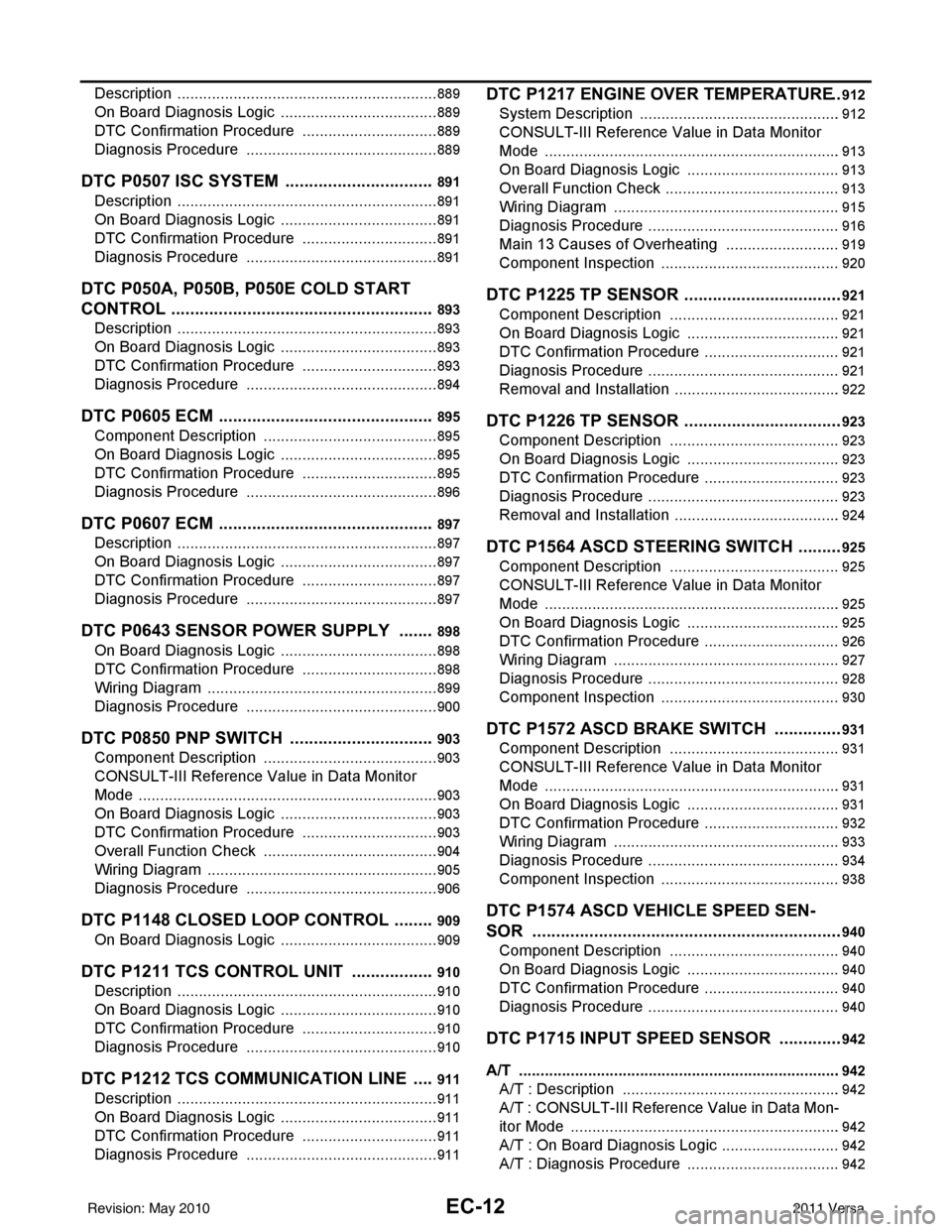

EC-40

< FUNCTION DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM

FUNCTION DIAGNOSIS

ENGINE CONTROL SYSTEM

System DiagramINFOID:0000000005929763

JMBIA2191GB

Revision: May 2010

2011 Versa