engine NISSAN TIIDA 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 97 of 3787

AT-80

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1: Refer to AT- 4 1 , "Malfunction Indicator Lamp (MIL)" .

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

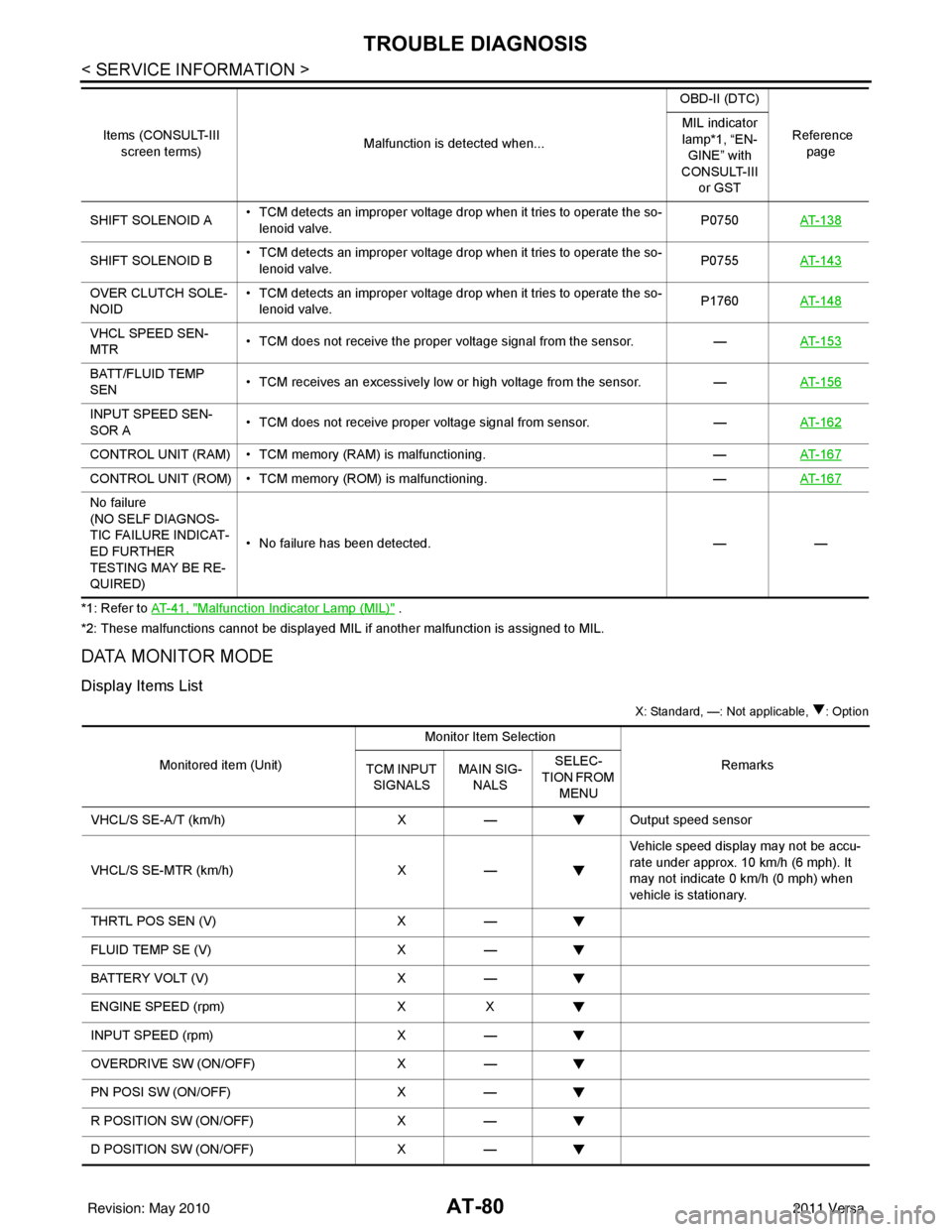

SHIFT SOLENOID A • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0750

AT- 1 3 8

SHIFT SOLENOID B • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0755

AT- 1 4 3

OVER CLUTCH SOLE-

NOID • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P1760

AT- 1 4 8

VHCL SPEED SEN-

MTR • TCM does not receive the proper voltage signal from the sensor.

—AT- 1 5 3

BATT/FLUID TEMP

SEN • TCM receives an excessively low or high voltage from the sensor.

—AT- 1 5 6

INPUT SPEED SEN-

SOR A • TCM does not receive proper voltage signal from sensor.

—AT- 1 6 2

CONTROL UNIT (RAM) • TCM memory (RAM) is malfunctioning. —AT- 1 6 7

CONTROL UNIT (ROM) • TCM memory (ROM) is malfunctioning. —AT- 1 6 7

No failure

(NO SELF DIAGNOS-

TIC FAILURE INDICAT-

ED FURTHER

TESTING MAY BE RE-

QUIRED) • No failure has been detected.

——

Items (CONSULT-III

screen terms) Malfunction is detected when... OBD-II (DTC)

Reference page

MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III or GST

Monitored item (Unit) Monitor Item Selection

Remarks

TCM INPUT

SIGNALS MAIN SIG-

NALS SELEC-

TION FROM MENU

VHCL/S SE-A/T (km/h) X— Output speed sensor

VHCL/S SE-MTR (km/h) X— Vehicle speed display may not be accu-

rate under approx. 10 km/h (6 mph). It

may not indicate 0 km/h (0 mph) when

vehicle is stationary.

THRTL POS SEN (V) X—

FLUID TEMP SE (V) X—

BATTERY VOLT (V) X—

ENGINE SPEED (rpm) XX

INPUT SPEED (rpm) X—

OVERDRIVE SW (ON/OFF) X—

PN POSI SW (ON/OFF) X—

R POSITION SW (ON/OFF) X—

D POSITION SW (ON/OFF) X—

Revision: May 2010 2011 Versa

Page 98 of 3787

TROUBLE DIAGNOSISAT-81

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

CAN DIAGNOSTIC SUPPORT MONITOR MODE

Refer to LAN-14, "CAN Diagnostic Support Monitor".

DTC & SRT CONFIRMATION

Display Items List

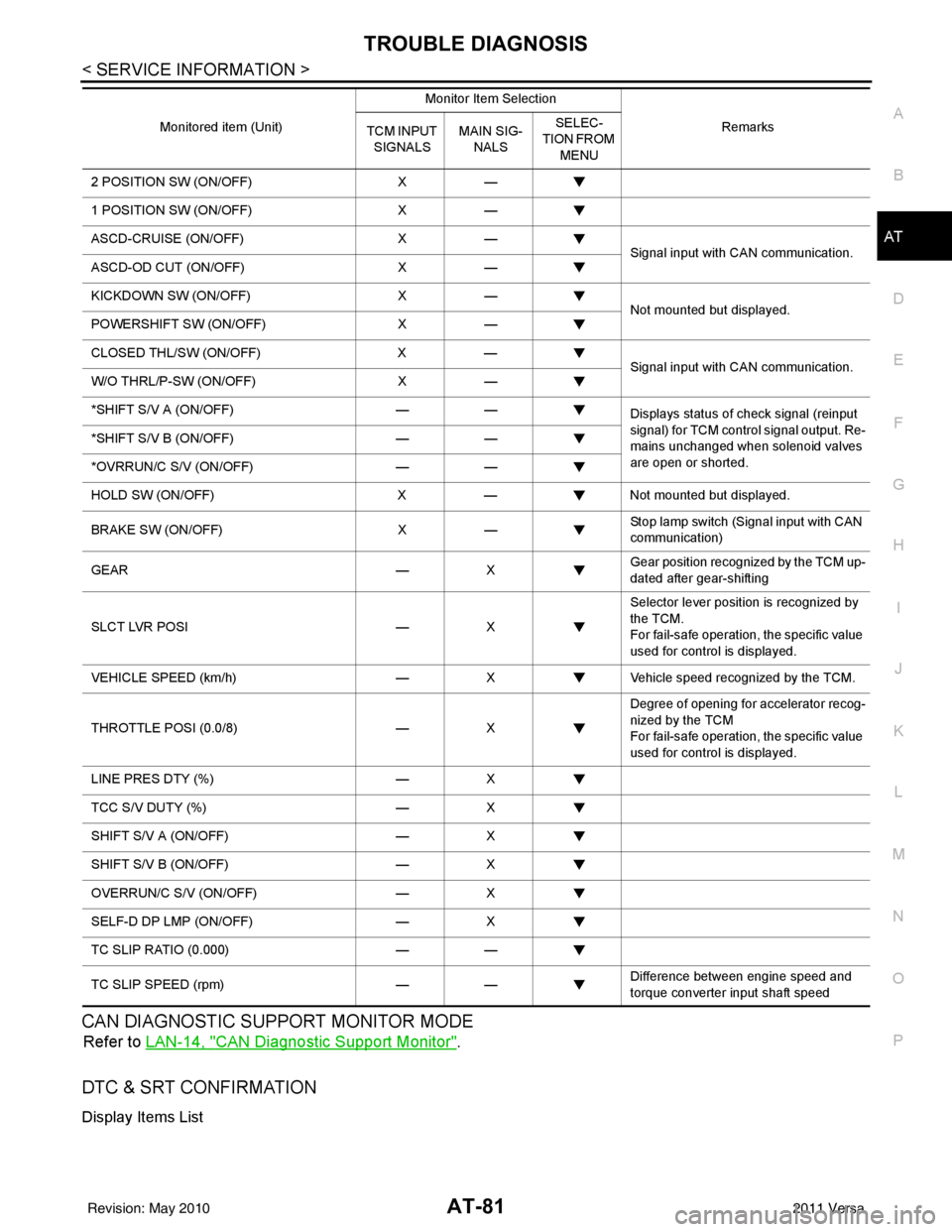

2 POSITION SW (ON/OFF) X—

1 POSITION SW (ON/OFF) X—

ASCD-CRUISE (ON/OFF) X—

Signal input with CAN communication.

ASCD-OD CUT (ON/OFF) X—

KICKDOWN SW (ON/OFF) X—

Not mounted but displayed.

POWERSHIFT SW (ON/OFF) X—

CLOSED THL/SW (ON/OFF) X—

Signal input with CAN communication.

W/O THRL/P-SW (ON/OFF) X—

*SHIFT S/V A (ON/OFF) ——

Displays status of check signal (reinput

signal) for TCM control signal output. Re-

mains unchanged when solenoid valves

are open or shorted.

*SHIFT S/V B (ON/OFF)

——

*OVRRUN/C S/V (ON/OFF) ——

HOLD SW (ON/OFF) X— Not mounted but displayed.

BRAKE SW (ON/OFF) X— Stop lamp switch (Signal input with CAN

communication)

GEAR —X Gear position recognized by the TCM up-

dated after gear-shifting

SLCT LVR POSI —X Selector lever position is recognized by

the TCM.

For fail-safe operation, the specific value

used for control is displayed.

VEHICLE SPEED (km/h) —X Vehicle speed reco gnized by the TCM.

THROTTLE POSI (0.0/8) —X Degree of opening for accelerator recog-

nized by the TCM

For fail-safe operation, the specific value

used for control is displayed.

LINE PRES DTY (%) —X

TCC S/V DUTY (%) —X

SHIFT S/V A (ON/OFF) —X

SHIFT S/V B (ON/OFF) —X

OVERRUN/C S/V (ON/OFF) —X

SELF-D DP LMP (ON/OFF) —X

TC SLIP RATIO (0.000) ——

TC SLIP SPEED (rpm) —— Difference between engine speed and

torque converter input shaft speed

Monitored item (Unit)

Monitor Item Selection

Remarks

TCM INPUT

SIGNALS MAIN SIG-

NALS SELEC-

TION FROM

MENU

Revision: May 2010 2011 Versa

Page 100 of 3787

TROUBLE DIAGNOSISAT-83

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

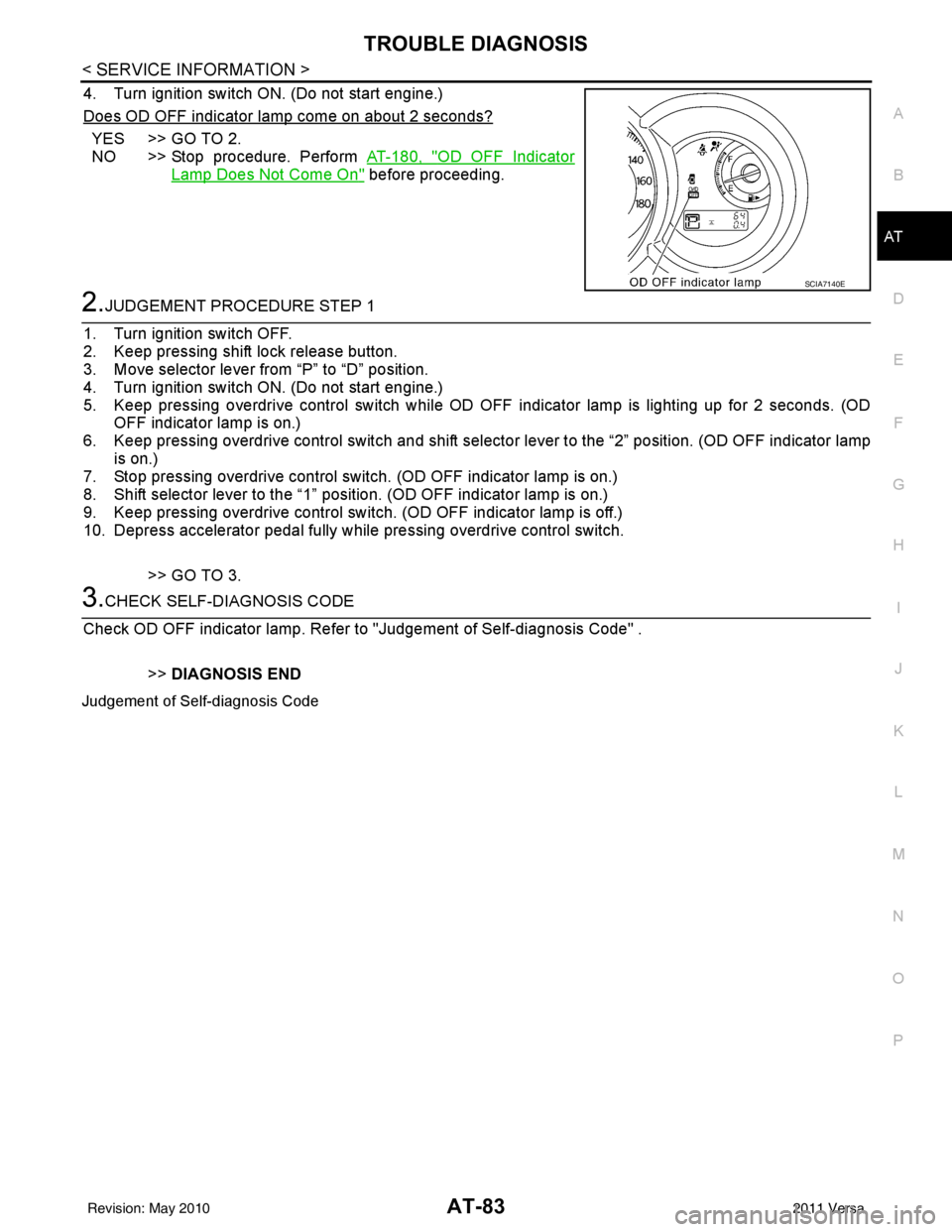

4. Turn ignition switch ON. (Do not start engine.)

Does OD OFF indicator lamp come on about 2 seconds?

YES >> GO TO 2.

NO >> Stop procedure. Perform AT-180, "

OD OFF Indicator

Lamp Does Not Come On" before proceeding.

2.JUDGEMENT PROCEDURE STEP 1

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Turn ignition switch ON. (Do not start engine.)

5. Keep pressing overdrive control switch while OD OFF indicator lamp is lighting up for 2 seconds. (OD OFF indicator lamp is on.)

6. Keep pressing overdrive control swit ch and shift selector lever to the “2” position. (OD OFF indicator lamp

is on.)

7. Stop pressing overdrive control switch. (OD OFF indicator lamp is on.)

8. Shift selector lever to the “1” position. (OD OFF indicator lamp is on.)

9. Keep pressing overdrive control switch . (OD OFF indicator lamp is off.)

10. Depress accelerator pedal fully while pressing overdrive control switch.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check OD OFF indicator lamp. Refer to "Judgement of Self-diagnosis Code" .

>>DIAGNOSIS END

Judgement of Self-diagnosis Code

SCIA7140E

Revision: May 2010 2011 Versa

Page 102 of 3787

TROUBLE DIAGNOSISAT-85

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

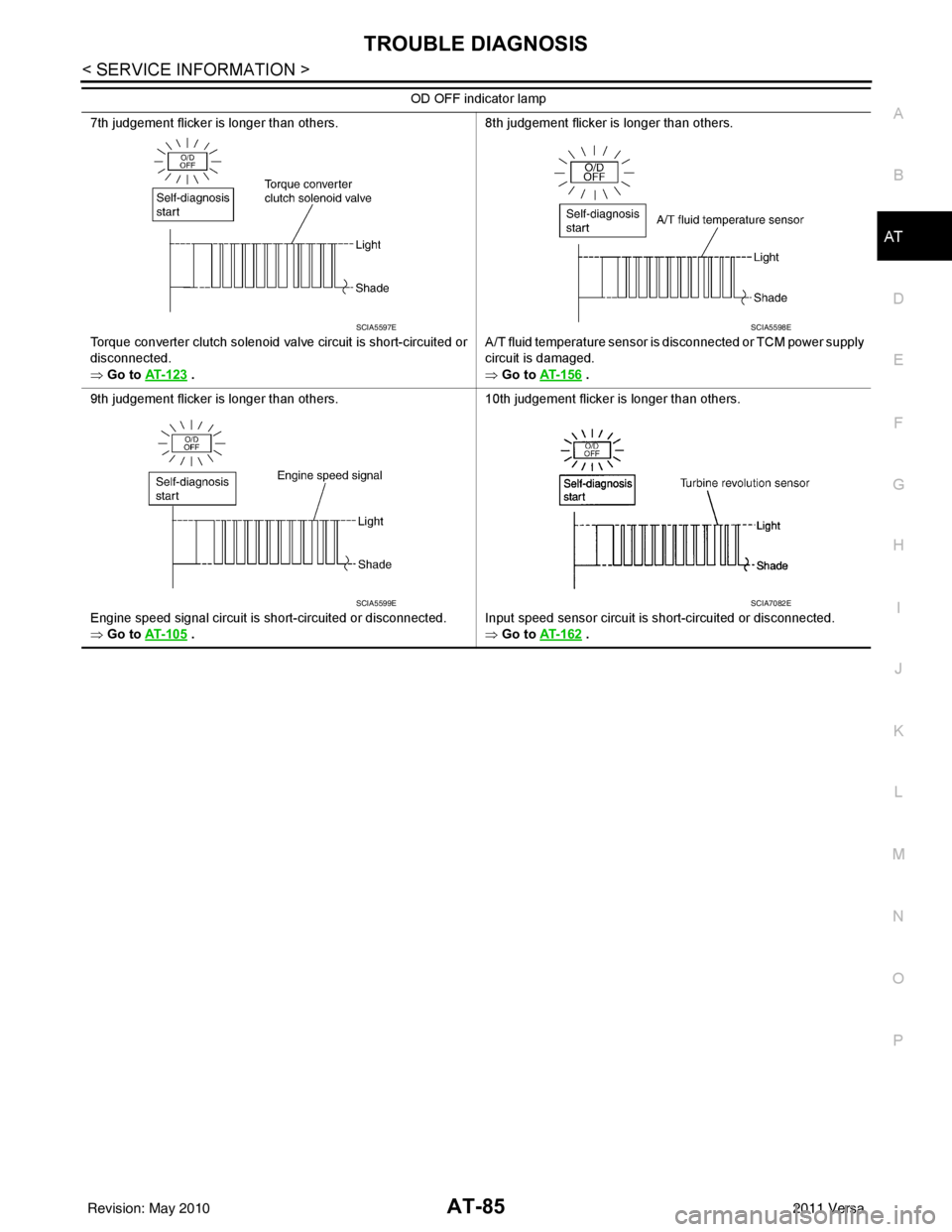

7th judgement flicker is longer than others.

Torque converter clutch solenoid valve circuit is short-circuited or

disconnected.

⇒ Go to AT- 1 2 3

. 8th judgement flicker is longer than others.

A/T fluid temperature sensor is disconnected or TCM power supply

circuit is damaged.

⇒ Go to

AT- 1 5 6 .

9th judgement flicker is longer than others.

Engine speed signal circuit is short-circuited or disconnected.

⇒ Go to AT- 1 0 5

. 10th judgement flicker is longer than others.

Input speed sensor circuit is short-circuited or disconnected.

⇒ Go to

AT- 1 6 2 .

OD OFF indicator lamp

SCIA5597ESCIA5598E

SCIA5599ESCIA7082E

Revision: May 2010

2011 Versa

Page 104 of 3787

U1000 CAN COMM CIRCUITAT-87

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000005928107

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communica tion speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L li ne) allowing a high rate of information transmission

with less wiring. Each control unit transmits/recei ves data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000005928108

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “U1000 CAN COMM CIRCUIT” wit h CONSULT-III or 12th judgement flicker without

CONSULT-III is detected when TCM cannot communicate to other control units.

Possible CauseINFOID:0000000005928109

Harness or connector

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928110

CAUTION:

If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Wait at least 6 seconds or start engine and wait for at least 6 seconds.

5. If DTC is detected, go to AT-89, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Wait at least 6 seconds or start engine and wait at least 6 seconds.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III".

4. If DTC is detected, go to AT-89, "

Diagnosis Procedure".

Revision: May 2010 2011 Versa

Page 106 of 3787

U1000 CAN COMM CIRCUITAT-89

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Diagnosis ProcedureINFOID:0000000005928112

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-III1. Turn ignition switch ON and start engine.

2. Select “SELF-DIAG RESULTS” mode for “TRANSMISSION” with CONSULT-III.

Is any malfunction of the

“U1000 CAN COMM CIRCUIT” indicated?

YES >> Print out CONSULT-III screen, Go to LAN section. Refer to LAN-26, "CAN System Specification

Chart".

NO >> INSPECTION END

Revision: May 2010 2011 Versa

Page 107 of 3787

AT-90

< SERVICE INFORMATION >

P0705 TRANSMISSION RANGE SWITCH A

P0705 TRANSMISSION RANGE SWITCH A

DescriptionINFOID:0000000005928113

• The transmission range switch detects the selector lever position and sends a signal to the TCM.

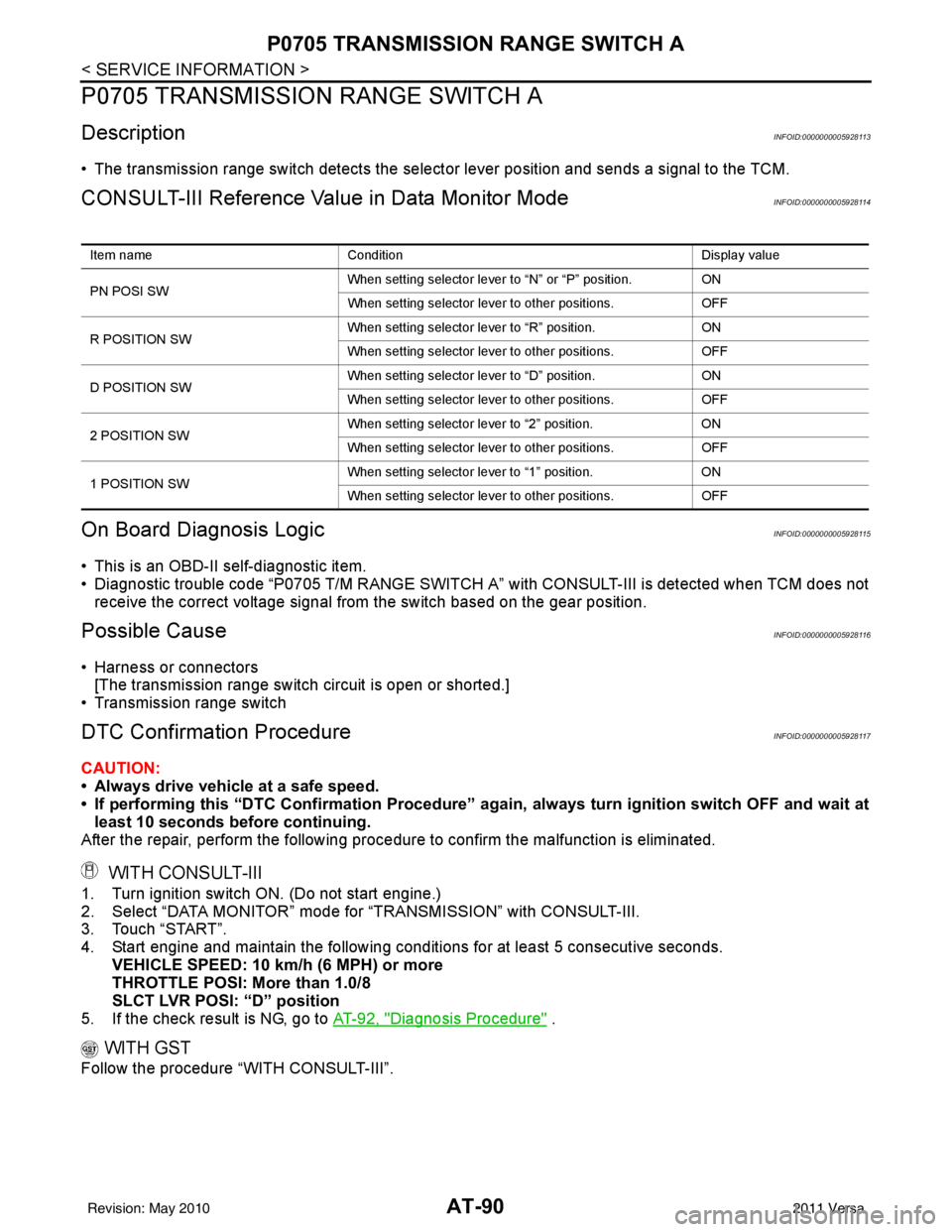

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928114

On Board Diagnosis LogicINFOID:0000000005928115

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 T/M RANGE SWITCH A” with CONSULT-III is detected when TCM does not

receive the correct voltage signal from the switch based on the gear position.

Possible CauseINFOID:0000000005928116

• Harness or connectors [The transmission range switch circuit is open or shorted.]

• Transmission range switch

DTC Confirmation ProcedureINFOID:0000000005928117

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-92, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position.

ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position.

ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position.

ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position.

ON

When setting selector lever to other positions. OFF

Revision: May 2010 2011 Versa

Page 109 of 3787

AT-92

< SERVICE INFORMATION >

P0705 TRANSMISSION RANGE SWITCH A

Diagnosis Procedure

INFOID:0000000005928119

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

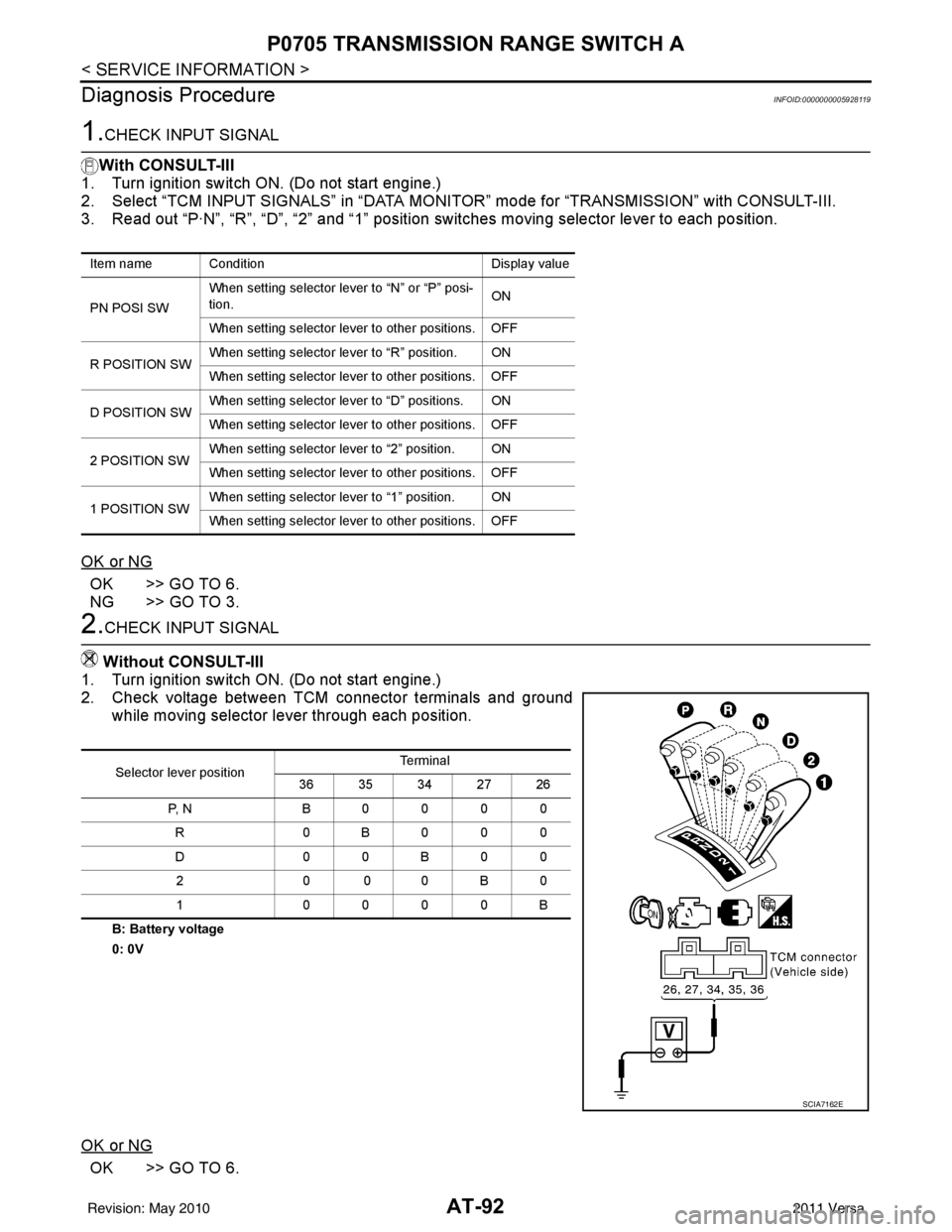

2.CHECK INPUT SIGNAL

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position.

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 6.

Item name Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Selector lever position Te r m i n a l

36 35 34 27 26

P, N B0000 R 0B000

D0 0B 00

20 00B 0

1 0000B

SCIA7162E

Revision: May 2010 2011 Versa

Page 112 of 3787

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR AAT-95

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0710 TRANSMISSION FLUI D TEMPERATURE SENSOR A

DescriptionINFOID:0000000005928121

The A/T fluid temperature sensor detects the A/ T fluid temperature and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928122

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928123

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0710 FLUID TEMP SENSOR A” with CONSULT-III is detected when TCM

receives an excessively low or high voltage from the sensor.

Possible CauseINFOID:0000000005928124

• Harness or connector

(The sensor circuit is open or shorted.)

• A/T fluid temperature sensor

DTC Confirmation ProcedureINFOID:0000000005928125

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine and maintain the following conditions for at least 10 minutes (Total). (It is not necessary to maintain continuously.)

ENGINE SPEED: 450 rpm or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

4. If the check result is NG, go to AT-96, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Item nameCondition Display value (Approx.)

FLUID TEMP SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

Revision: May 2010 2011 Versa

Page 114 of 3787

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR AAT-97

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

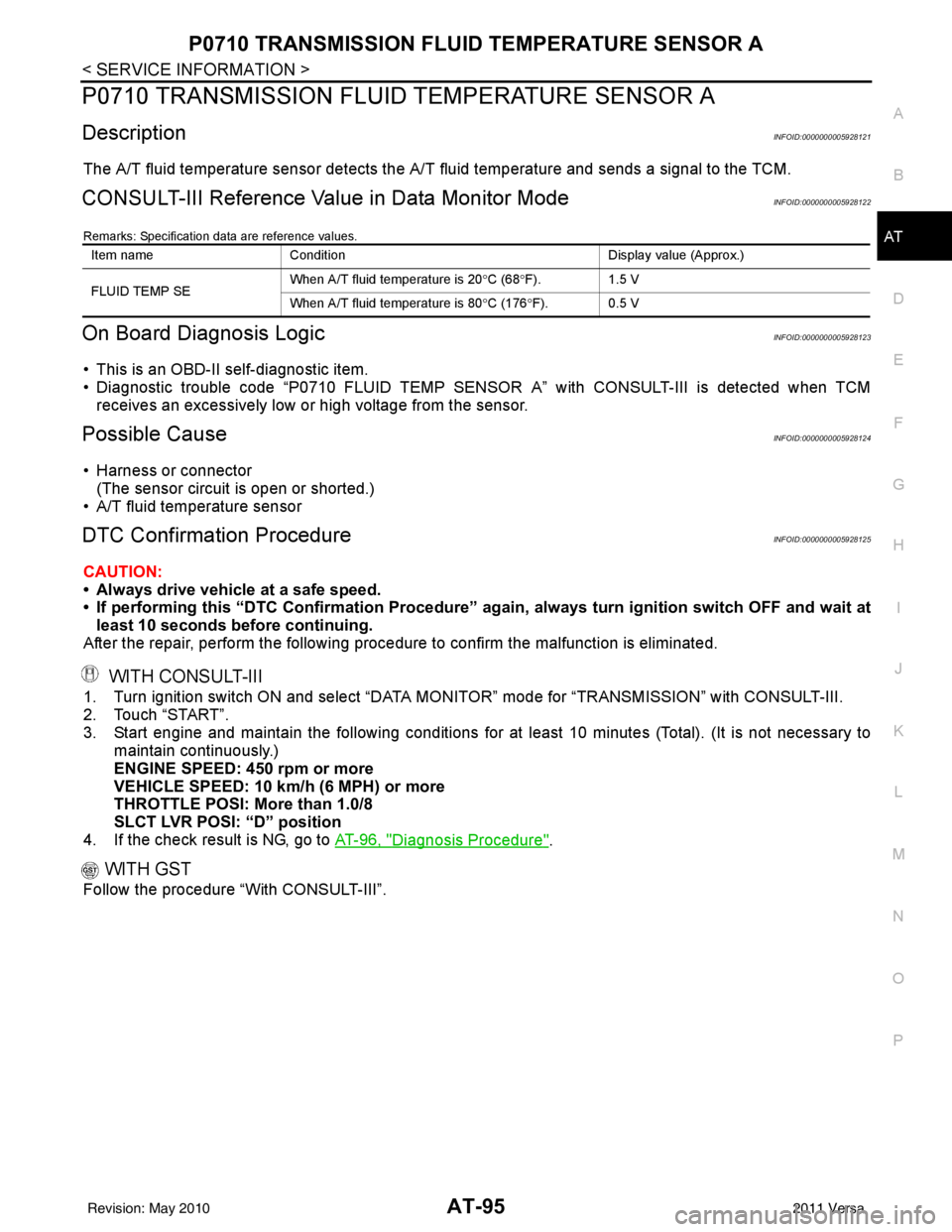

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “FLUID TEMP SE”.

Without CONSULT-III

1. Start engine.

2. Check voltage TCM connector terminals while warming up A/T.

OK or NG

OK >> GO TO 7.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING ITEMS

Check the following.

• Harness for short or open between TCM, ECM and terminal cord assembly

• Ground circuit for ECM, Refer to EC-123

(HR16DE), EC-633 (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

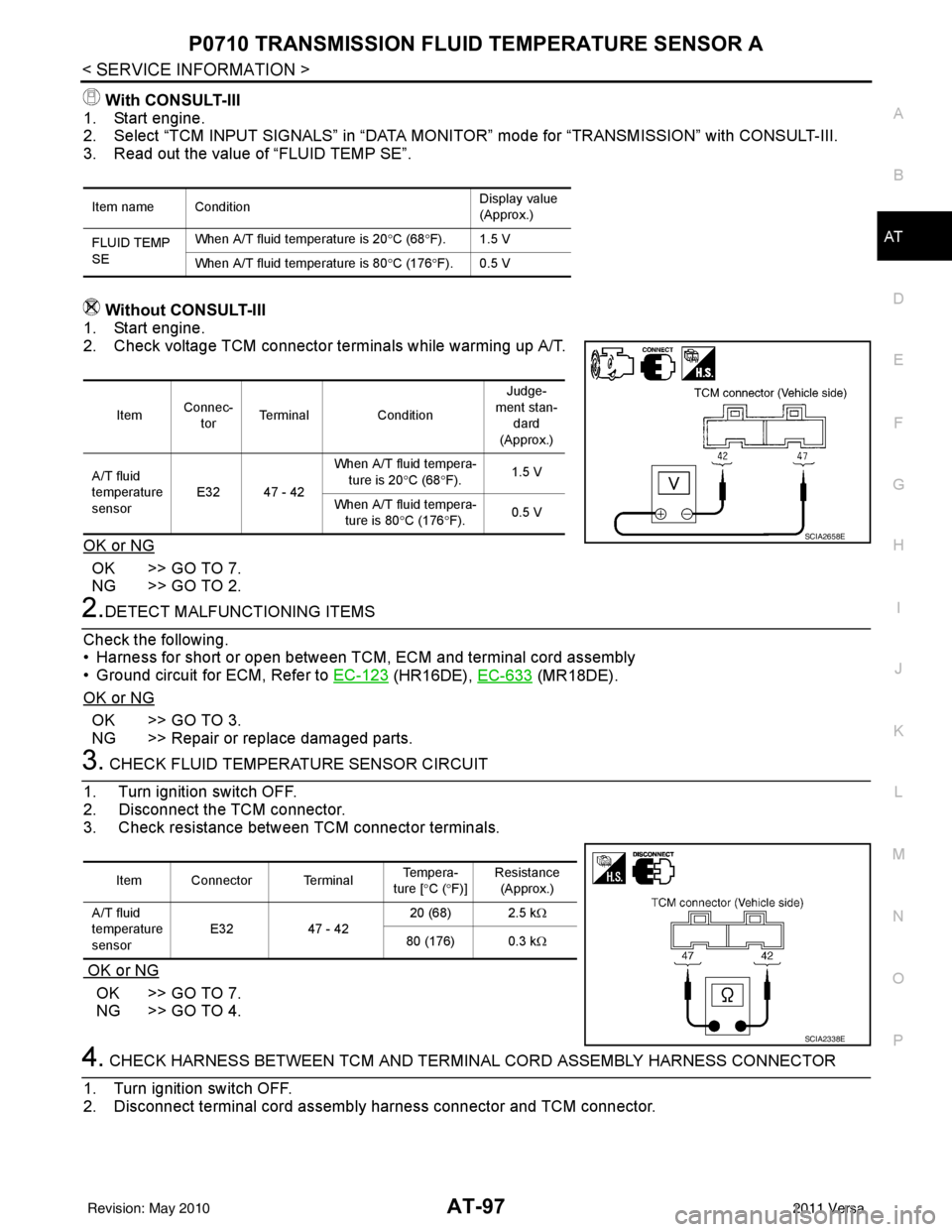

3. CHECK FLUID TEMPERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between TCM connector terminals.

OK or NG

OK >> GO TO 7.

NG >> GO TO 4.

4. CHECK HARNESS BETWEEN TCM AND TERMINAL CORD ASSEMBLY HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect terminal cord assemb ly harness connector and TCM connector.

Item name Condition Display value

(Approx.)

FLUID TEMP

SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

Item Connec-

tor Terminal

Condition Judge-

ment stan- dard

(Approx.)

A/T fluid

temperature

sensor E32 47 - 42 When A/T fluid tempera-

ture is 20 °C (68 °F). 1.5 V

When A/T fluid tempera- ture is 80 °C (176 °F). 0.5 V

SCIA2658E

Item Connector Terminal Te m p e r a -

ture [ °C ( °F)] Resistance

(Approx.)

A/T fluid

temperature

sensor E32

47 - 42 20 (68) 2.5 k

Ω

80 (176) 0.3 k Ω

SCIA2338E

Revision: May 2010 2011 Versa